Construction method of flexible arch bridge with rigid beams

A construction method and beam flexibility technology, applied in the construction field of rigid beam flexible arch bridges, can solve the problems of increasing the burden of arch ribs and beams, increasing the project cost, and the lifting height of cranes, etc., so as to improve the integrity and stability, reduce the Small construction cost and the effect of improving economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

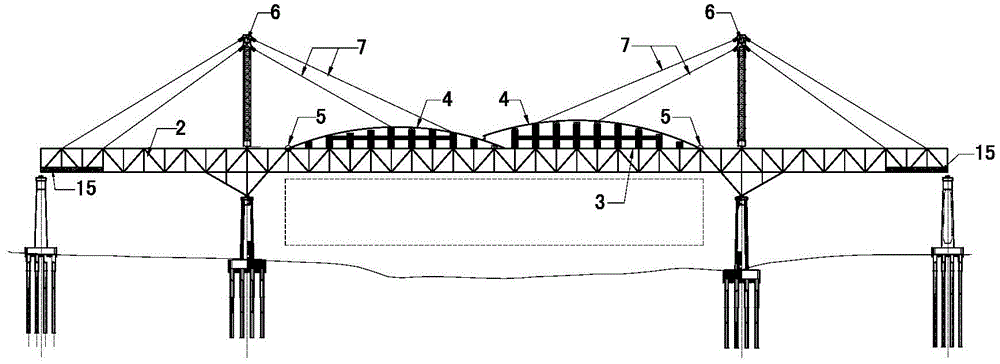

[0020] Below take two main pier, both sides pier as example to describe the present invention in detail with reference to accompanying drawing, Figure 1-Figure 6 Two bridge piers in the middle are main piers, and two bridge piers outside are side piers; Construction steps of the present invention:

[0021] 1) The middle steel truss girder 1 between the two main piers, the side steel truss girder 2 between the main pier and the side piers, the steel box arch 4 and the flexible suspender 8 are divided into individual components in the factory and fabricated in sections;

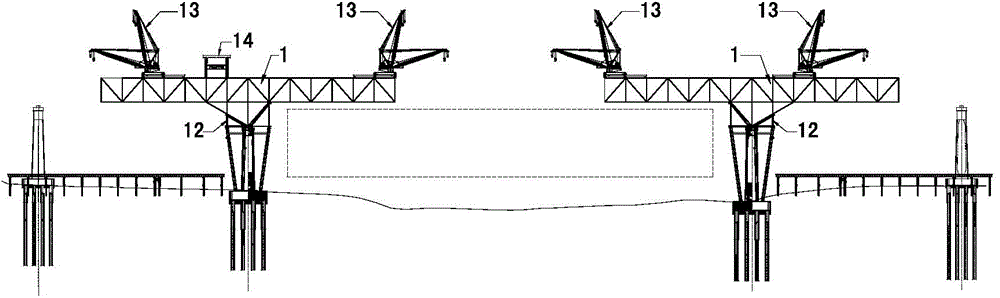

[0022] 2) Set up the pier side bracket 12 on the top of the main pier, use the floating crane to assemble the medium steel truss girders 1 between the four sections on the pier side bracket, install a 70t full-slewing girder crane 13 on the medium steel truss girder, lift rack 14 (see figure 1 );

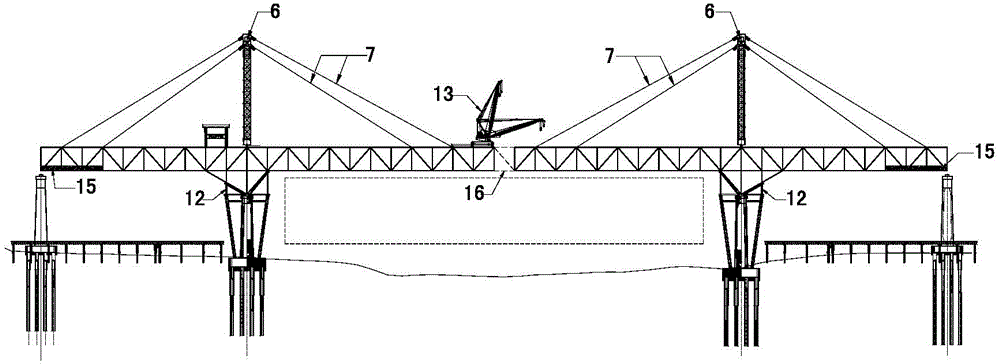

[0023] 3) Assemble the sling tower 6 on the medium steel truss girder 1, continue to assemble the side steel t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com