Large-span railway desk type concrete arch bridge structure

A large-span, concrete technology, applied in the field of bridge construction, can solve the problems of poor coordination between the upper structure of the arch and the main arch ring, many columns on the arch, and limited lateral stiffness, so as to reduce the construction difficulty and construction risk, reduce the project cost, Reasonable effect of structural stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with drawings and embodiments.

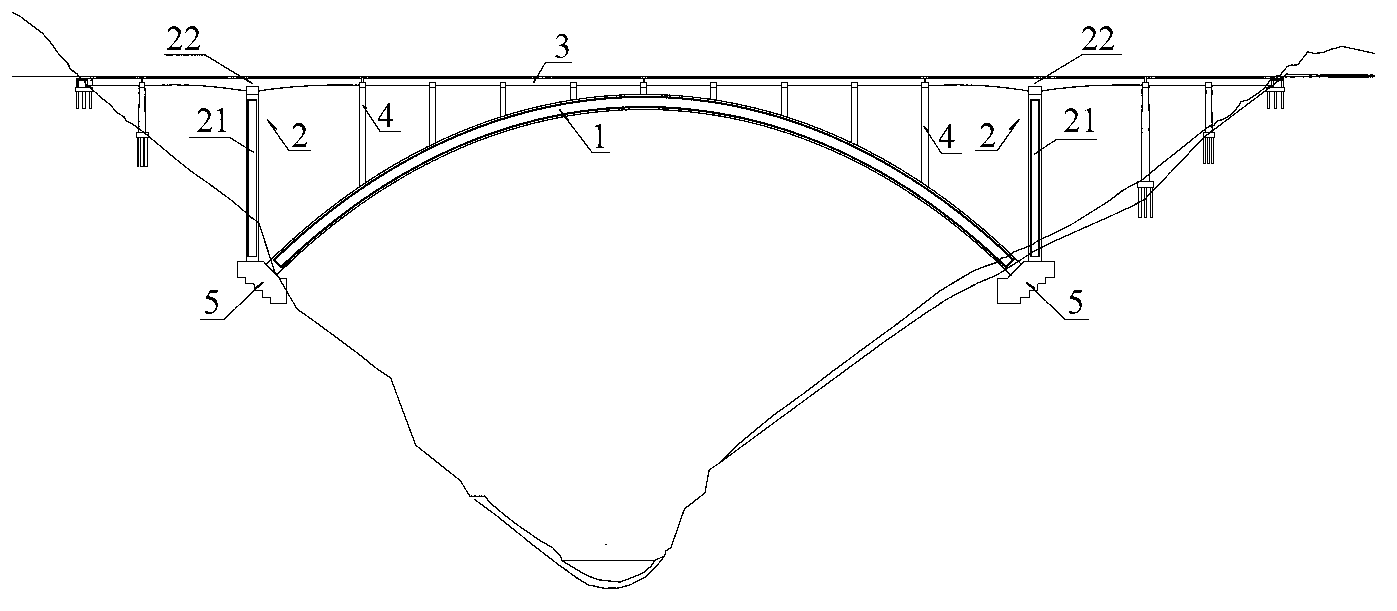

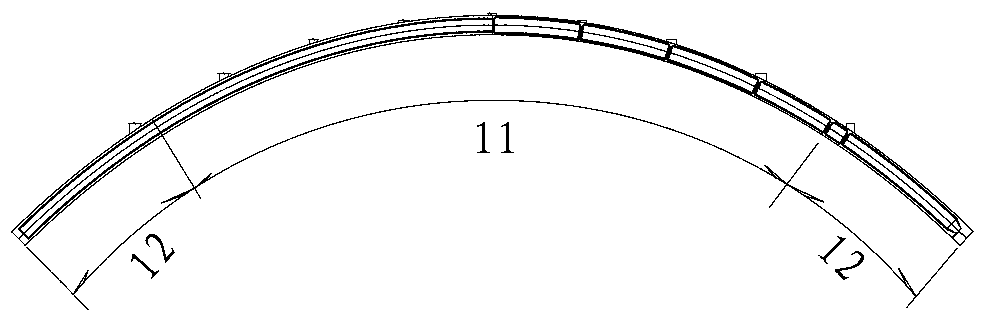

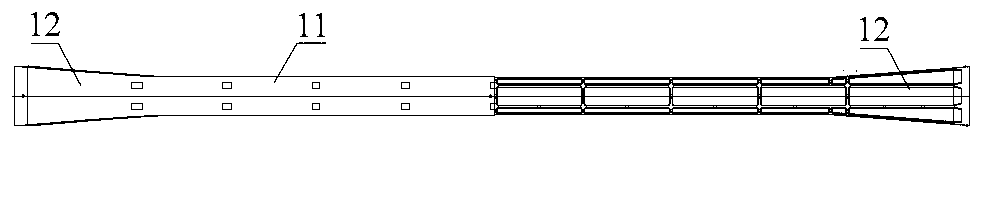

[0019] refer to figure 1 , the structure of the large-span railway overhead concrete arch bridge of the present invention includes a main arch ring 1, a junction pier 21, an arch upper beam 3, an arch upper column 4 and an abutment foundation 5, and the junction piers 21 and the arches on both sides of the main arch ring 1 The feet are supported on the abutment foundation 5, and the arch beam 3 is supported on the main arch ring 1 through the arch column 4. refer to Figure 1 to Figure 4 , the main arch ring 1 is a single-box multi-chamber cross-section box-shaped plate arch of equal height. , increasing the lateral stiffness of the main arch ring, thus forming a new type of top-supporting box-shaped plate arch shape.

[0020] Figure 4 with Figure 5 A typical structure of the main arch 1 is shown, that is, the main arch 1 is a single-box three-chamber cross-secti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com