Modular steel bar truss floor support plate

A technology for steel trusses and floor decks, applied in the field of prefabricated buildings, can solve the problems of putty decoration and cost increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

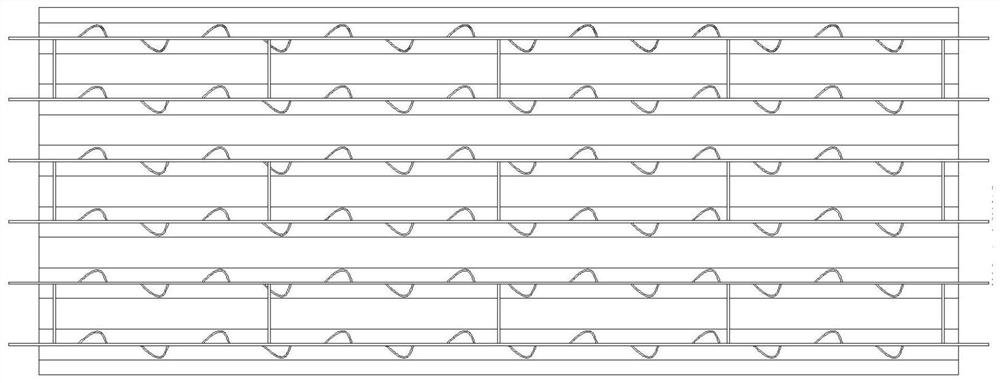

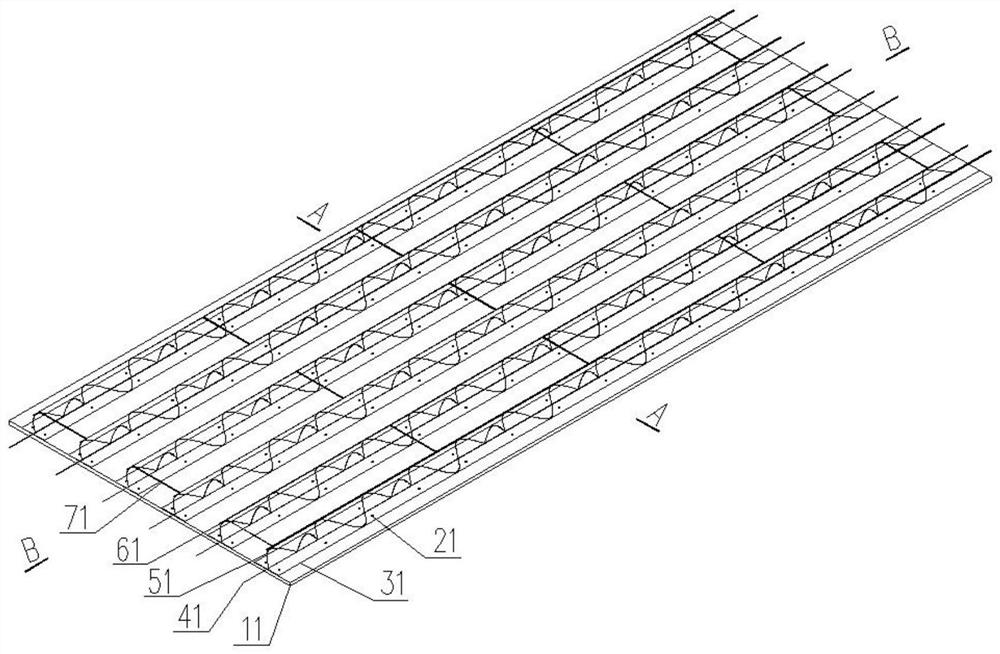

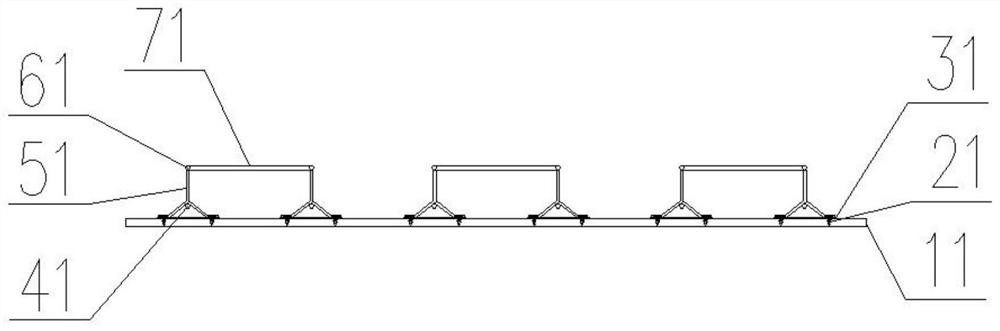

[0029] The component of the present invention consists of prefabricated bottom plate 11, self-tapping nails or rivets 21, galvanized thin steel plate 31, lower chord longitudinal reinforcement 41, web bar wave-shaped reinforcement 51, upper chord longitudinal reinforcement 61, and upper chord transverse short reinforcement 71.

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0031] 1. Use a fiber cement board produced by Magnesium Construction Technology (Chongqing) Co., Ltd. that meets Class A fire protection requirements as the prefabricated bottom board 11, a large board with a size of 3000×1200×10mm.

[0032] 2. Make the in-line steel bar truss: use automated equipment to spot-weld the peaks of an upper chord longitudinal steel bar 61 and a web bar wave-shaped bar 51, and the lower bending point of the lower chord longitudinal bar 41 and the web bar wave-shaped bar 51 Welding is connected into a strai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com