Patents

Literature

31results about How to "Speed up the schedule" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method, device and equipment for calculating construction progress and readable storage medium

PendingCN112561487AShorten the timeSave energyImage enhancementImage analysisConstruction engineeringStructural engineering

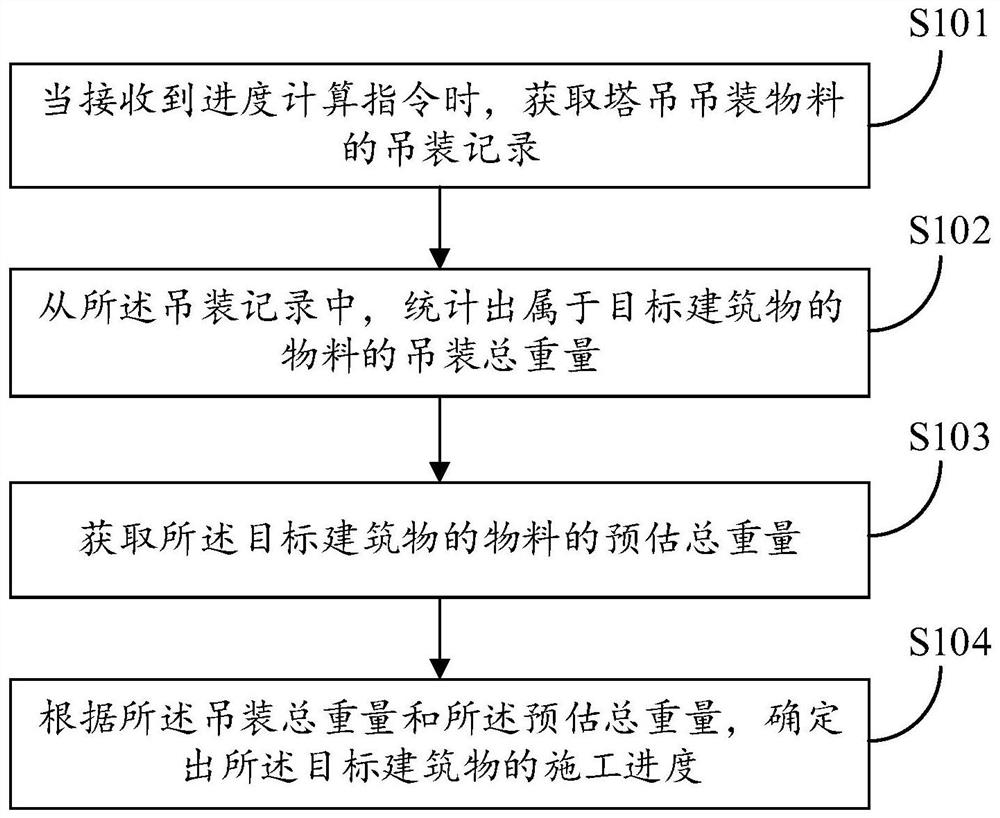

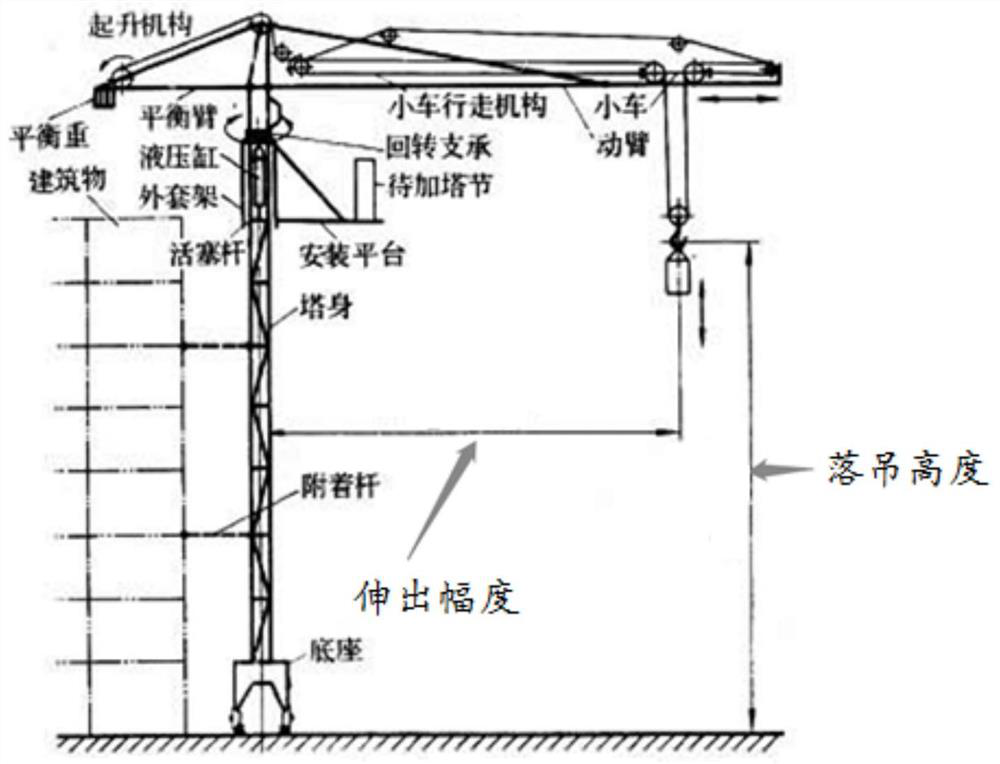

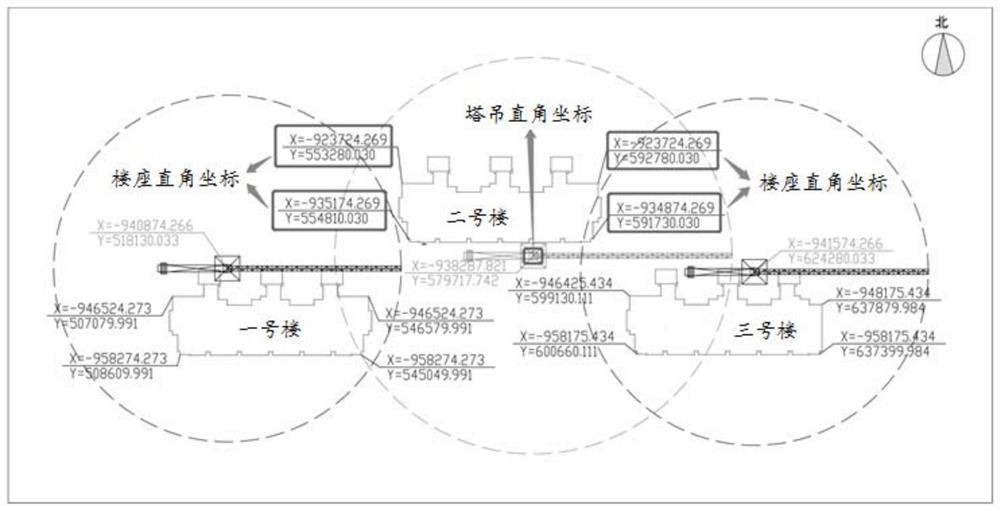

The invention discloses a construction progress calculation method, device and equipment and a readable storage medium. The method comprises the steps: obtaining a hoisting record of a tower crane hoisting material when a progress calculation instruction is received; counting the total hoisting weight of the material belonging to the target building from the hoisting record; obtaining the estimated total weight of the material of the target building; determining the construction progress of the target building according to the total hoisting weight and the estimated total weight; the method can accurately calculate the on-site progress information of the construction stage of the building main body structure.

Owner:GLODON CO LTD

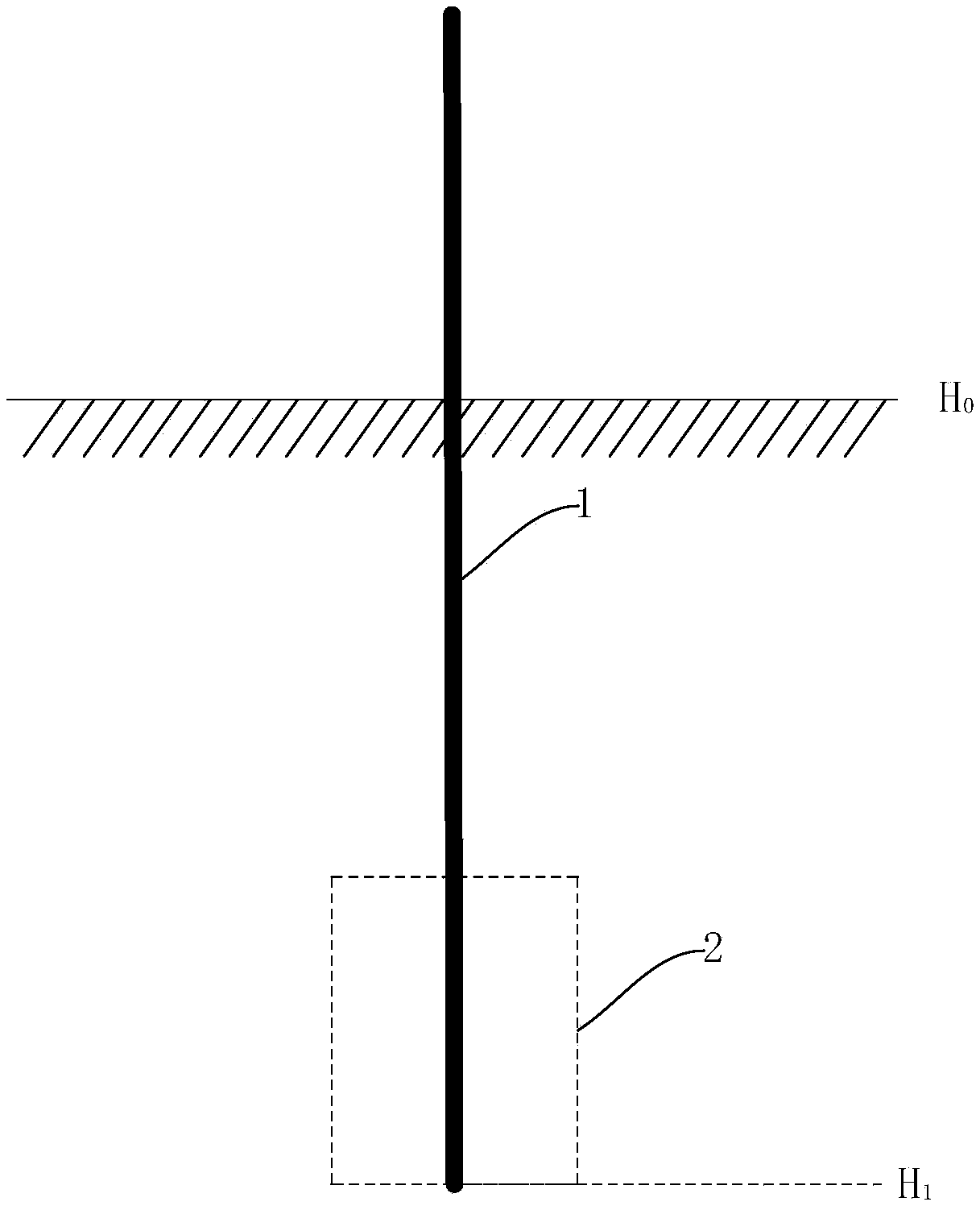

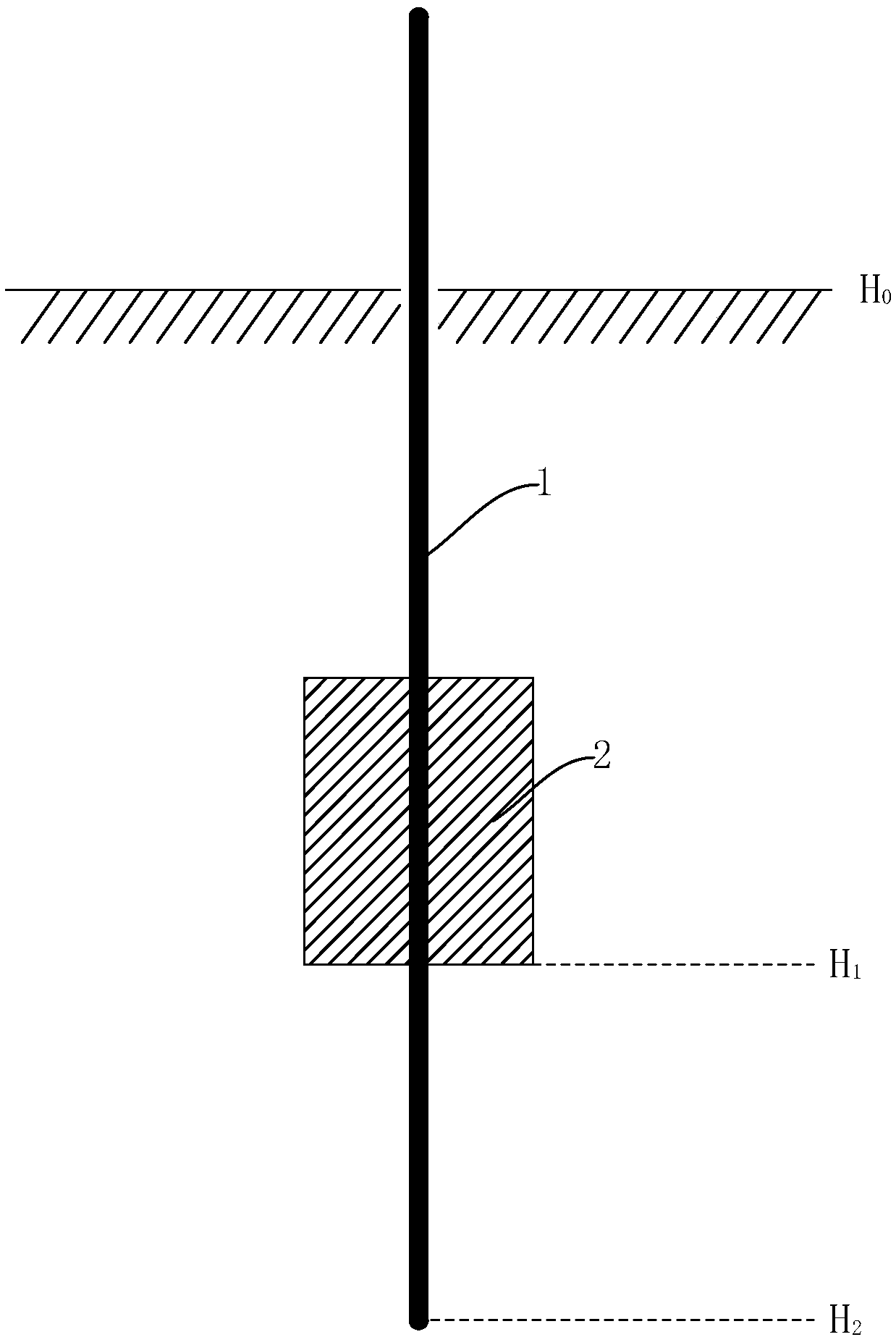

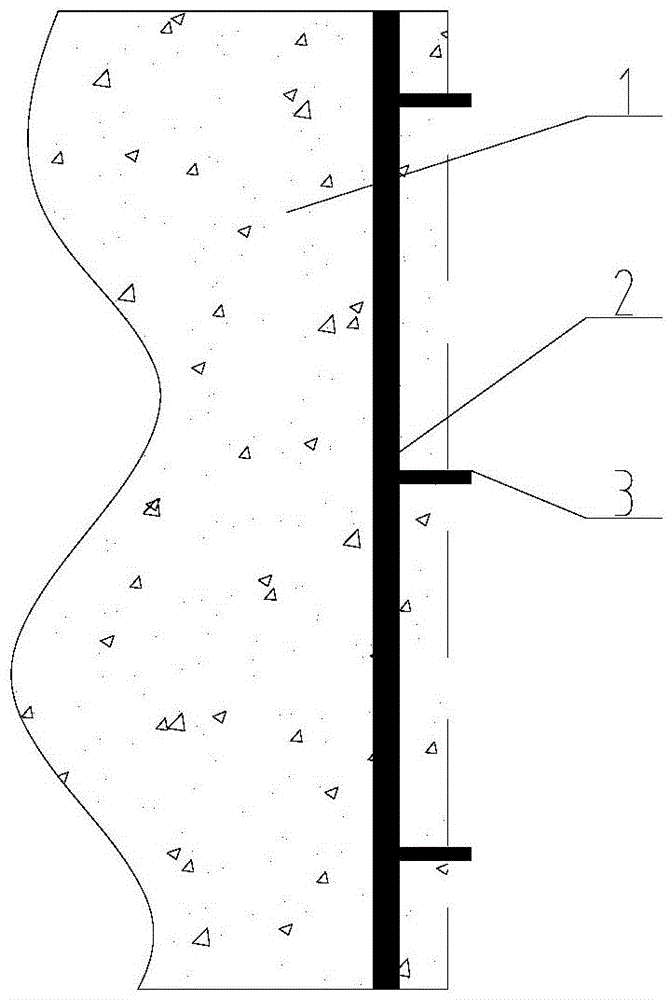

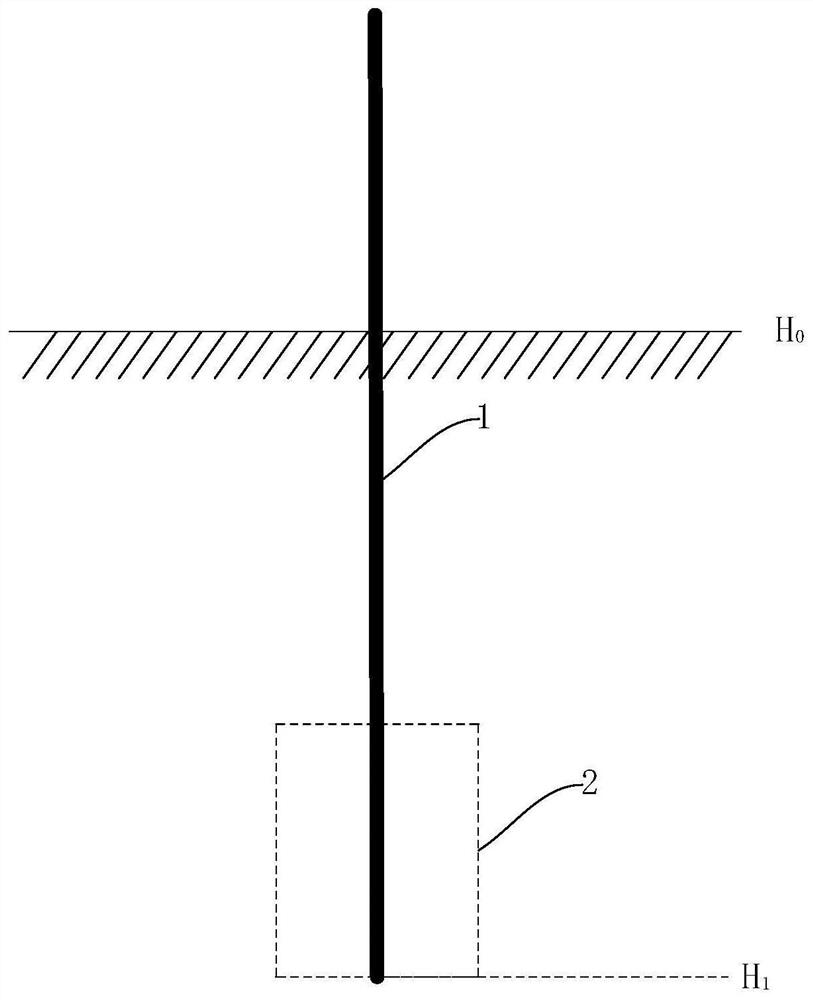

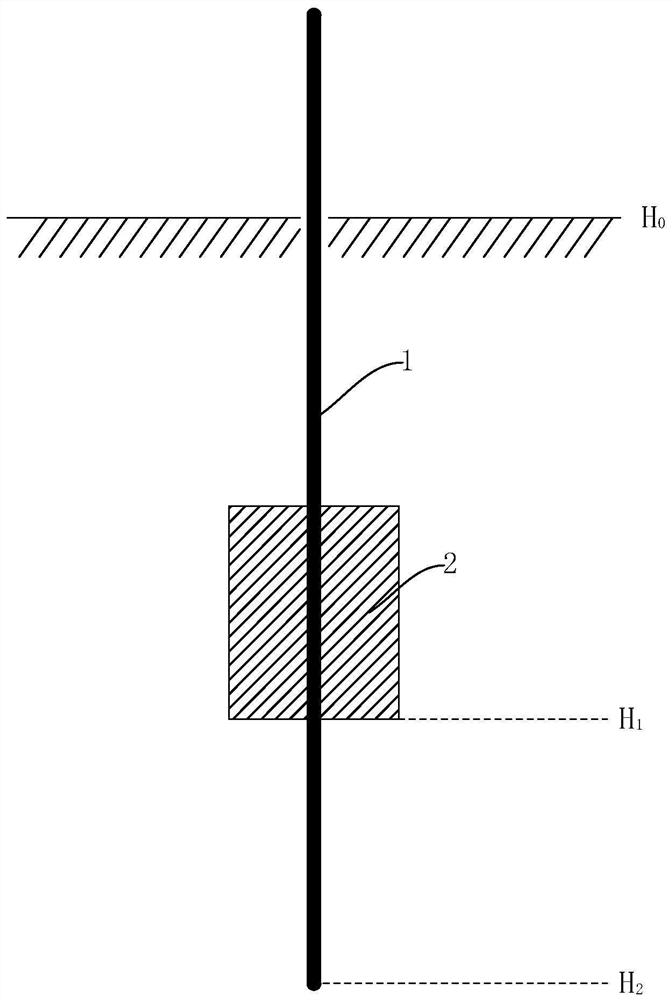

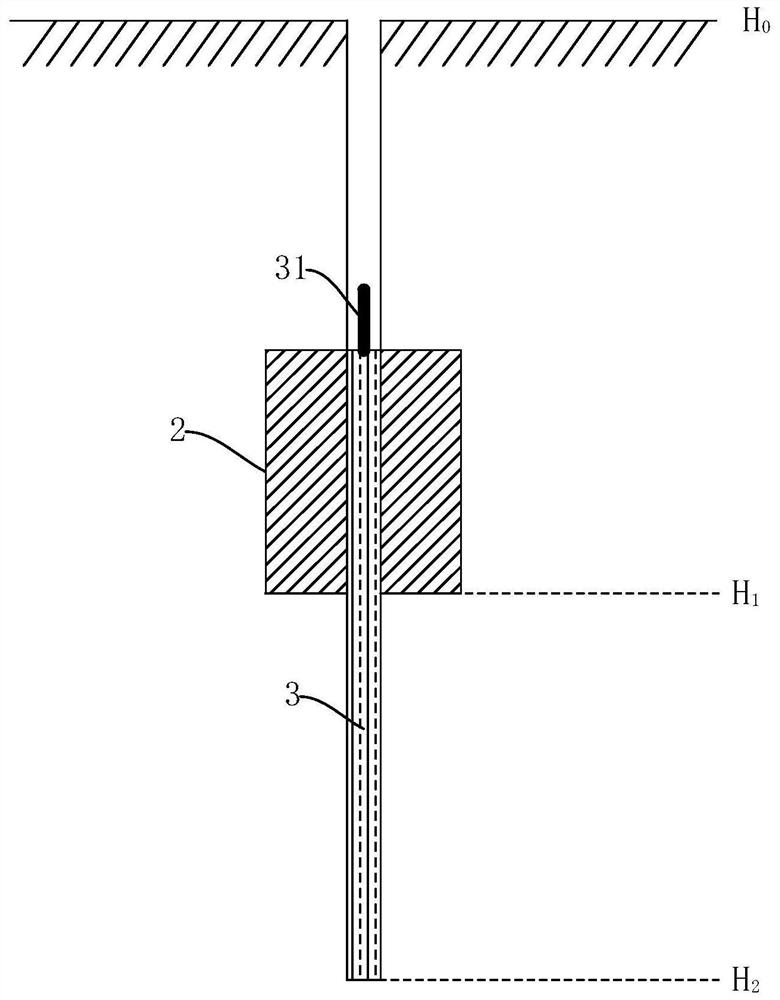

Anti-floating anchor rod construction method

ActiveCN109183857ASynchronous maintenanceSpeed up the scheduleProtective foundationEngineeringHigh pressure

The invention discloses an anti-floating anchor rod construction method. According to the anti-floating anchor rod construction method, an anchor rod is constructed before a foundation pit is excavated, a reinforcing part is formed in the soil body surrounding the upper part of the anchor rod through high-pressure rotary spraying, and it is guaranteed that the anchor rod does not deflect when thefoundation pit is excavated. In addition, beforehand construction of the anti-floating anchor rod can be synchronized with the construction of a pile foundation and the maintenance, no extra construction period is occupied, and thus the construction period progress can be accelerated; the anti-floating anchor rod can be constructed before the foundation pit is excavated, so that the problem that the working plane after excavation is not beneficial to mechanical construction due to the fact that the soil at the bottom of the foundation pit is poor is solved; and the high-pressure rotary spraying method is adopted by the construction method, partial cement soil below the designed excavation bottom plane is reinforced, so that the stability of the anchor rod itself and the stability of the whole foundation pit, especially the soft soil foundation pit, are enhanced.

Owner:浙江坤德创新岩土工程有限公司

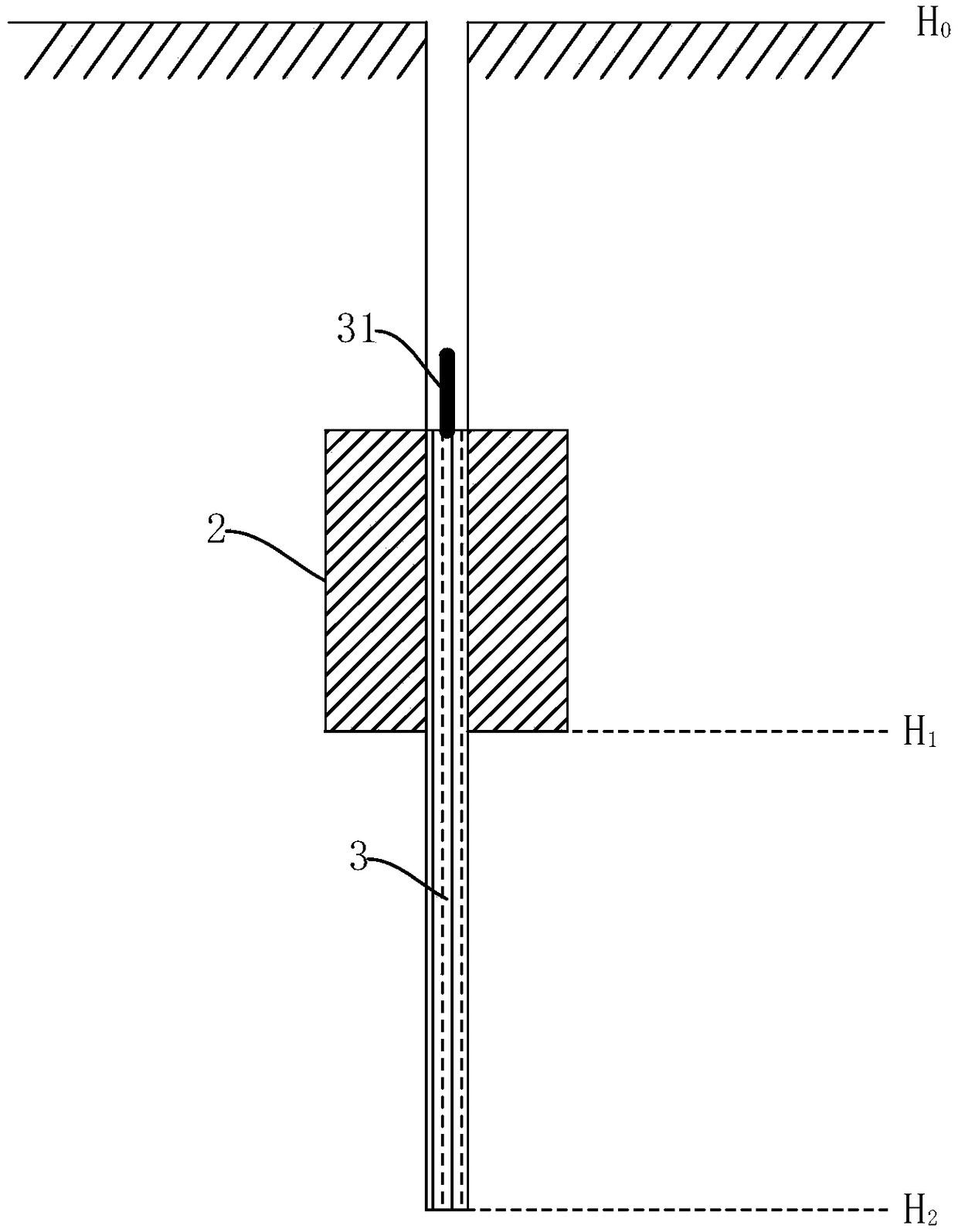

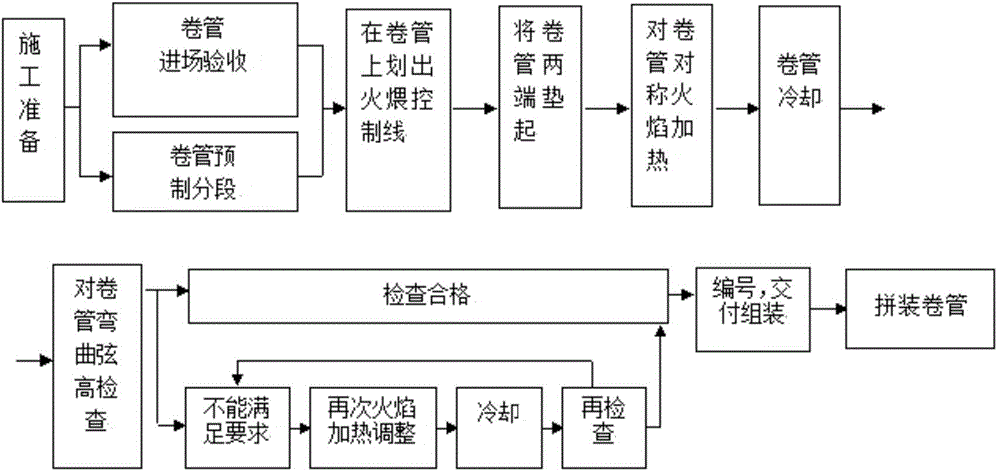

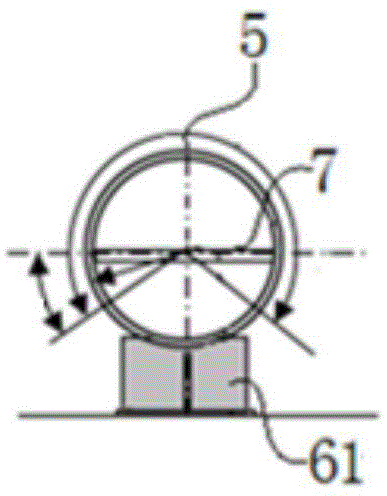

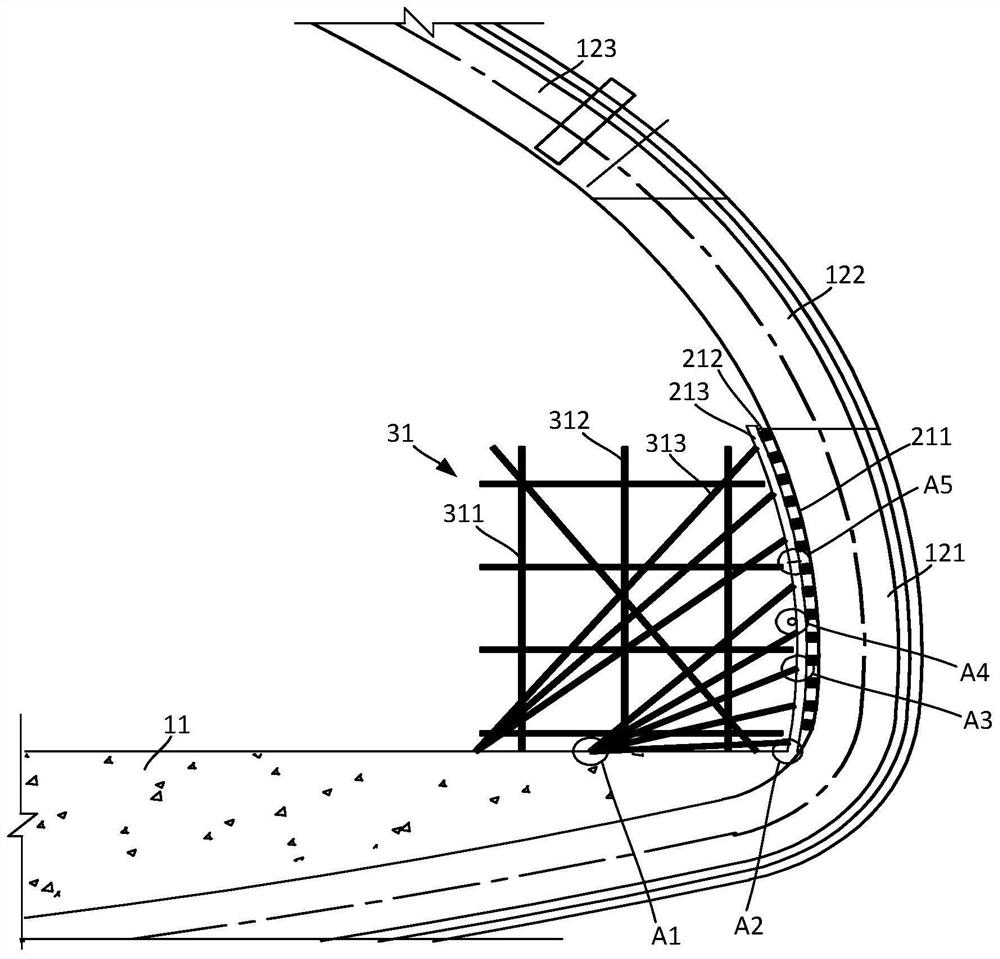

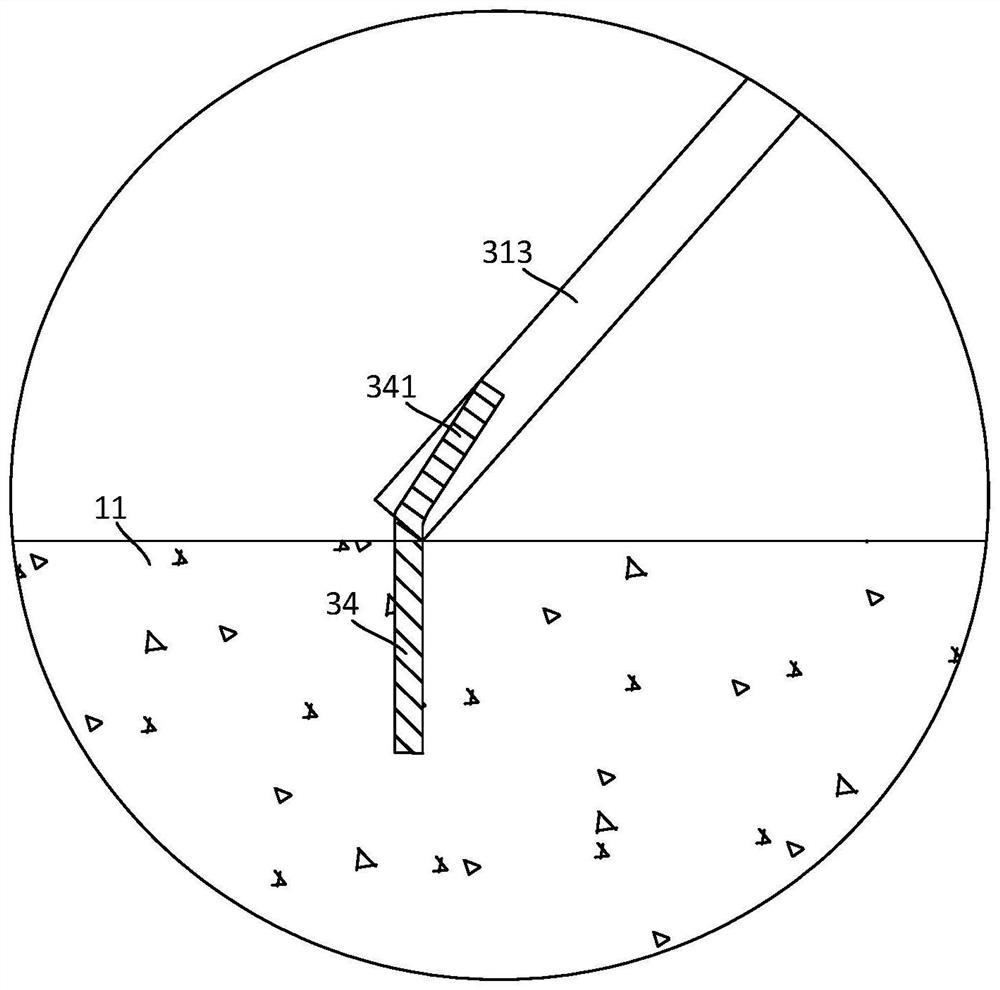

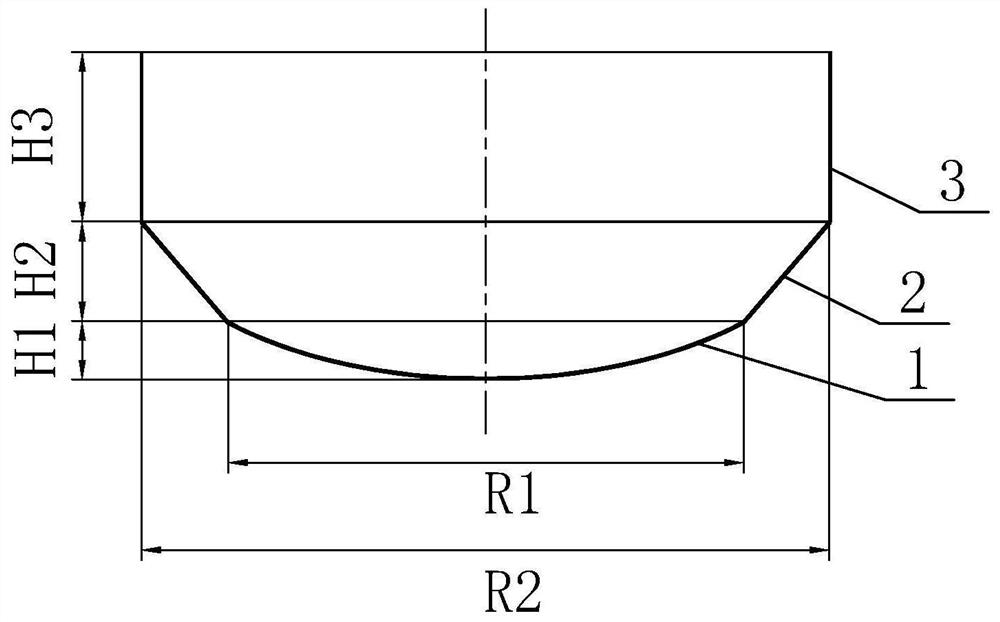

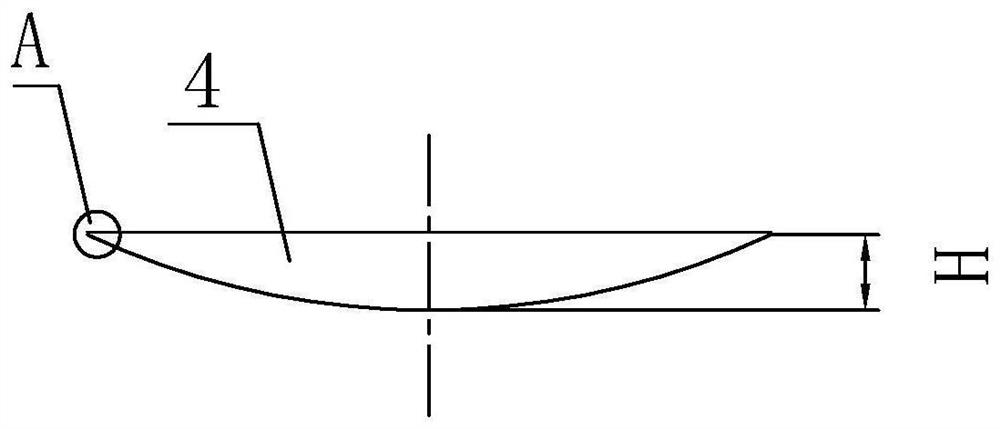

Method for manufacturing large bent steel members on basis of fire bending

ActiveCN104138942AAchieve the purpose of simmeringSimplify construction proceduresMetal working apparatusEngineeringPipe support

The invention discloses a method for manufacturing large bent steel members on the basis of fire bending and belongs to the technical field of pipeline machining. The method comprises the step of construction preparation, wherein quality detection and algorithm quantification are carried out on reel pipes; the step of reel pipe marking, wherein the reel pipes are supported by a reel pipe supporting device, and heating areas are marked on the reel pipes; the step of fire bending, the heating areas marked well are bent along the zigzag path, and the time duration for bending is decided according to colors generated when the reel pipes are heated; the step of cooling detection, wherein after the reel pipes are cooled, whether the distance between the lower bottoms of the bent reel pipes and the upper end of a detection board is within 3 mm or not is detected, and the reel pipes are qualified if the distance is within 3 mm; the step of secondary processing, wherein when deviation between the actual reel pipe bending chord height H1 and the theoretical reel pipe bending chord height H is large, adjustment is carried out through a gas welding baking handle; the step of reel pipe splicing, wherein the reel pipes reaching the bending standard are welded through a structural steel platform. The method solves the problem that a large instrument is needed when the large bent steel members are manufactured, and no external force needs to be applied.

Owner:CHINA NAT CHEM ENG THIRD CONSTR

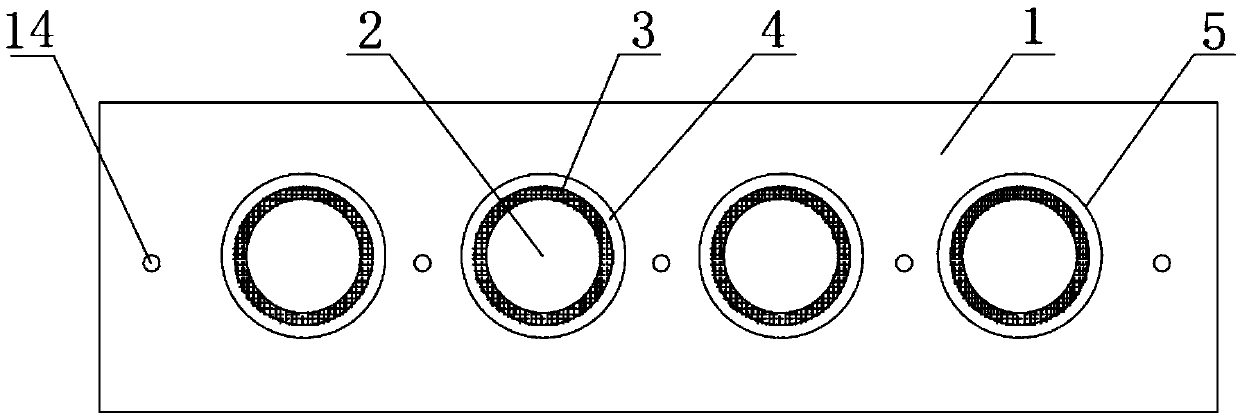

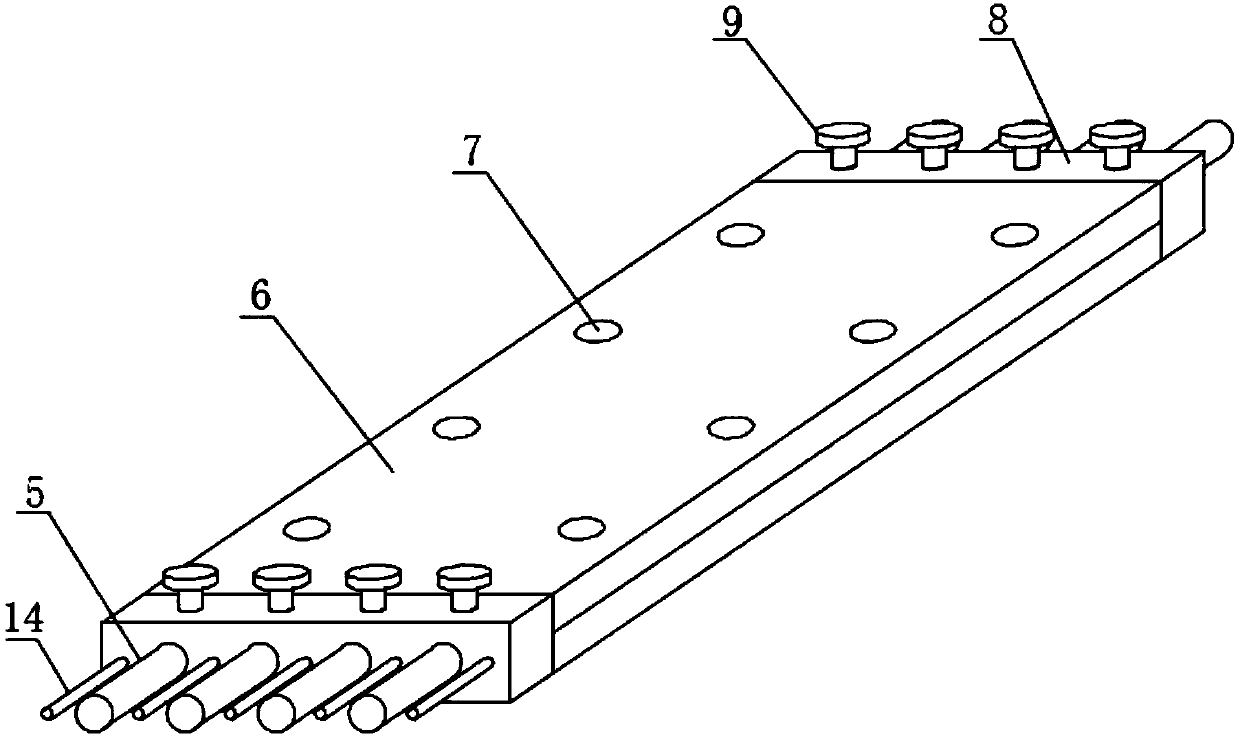

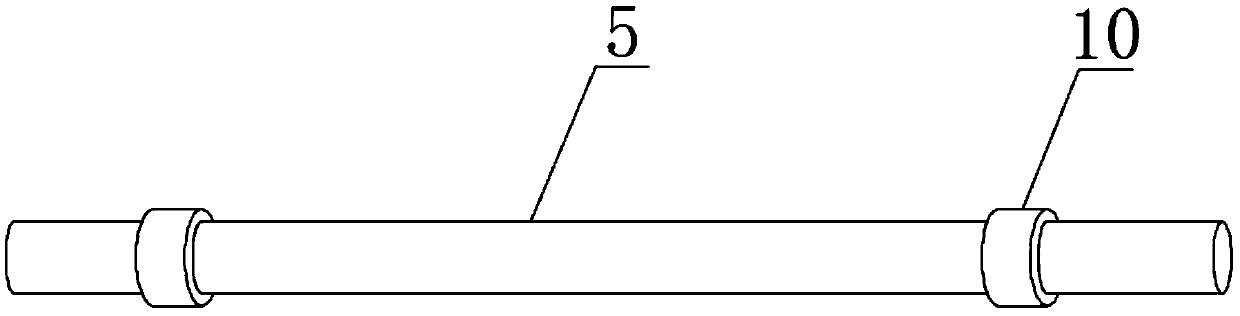

Wire harness used for integrated wallboard, injection molding device and production method

InactiveCN107696394ARapid productionThe production method produces fastInsulated cablesManufacturing wire harnessesInjection mouldingInjection molding machine

The invention discloses a wire harness used for an integrated wallboard, an injection molding device and a production method. The longitudinal section of a wire harness outer cladding layer is square,and a plurality of wire cores are arranged inside the outer cladding layer in the width direction of the outer cladding layer; in the injection molding device used for production of the wire harness,an injection molding cavity is formed in a mold, and the two ends of the mold are connected into two clamping mechanisms in an inserted mode and are clamped; injection molding holes are formed in themold, and an injection molding pump communicates with a storage and the injection molding cavity; the two ends of the mold are coaxially provided with first left limiting holes and first right limiting holes communicating with the injection molding cavity, and the multiple first left limiting holes and the multiple first right limiting holes are formed in the width direction of the mold; and a plurality of wire core clamping holes which are coaxial with the first left limiting holes or the first right limiting holes are formed in the clamping mechanisms, and the method for producing the wireharness through the injection molding device comprises the steps of cutting, positioning, pouring and finishing. The wire harness produced through the production method by using the injection moldingdevice is specially used in the integrated wallboard.

Owner:WUHU INST OF TECH

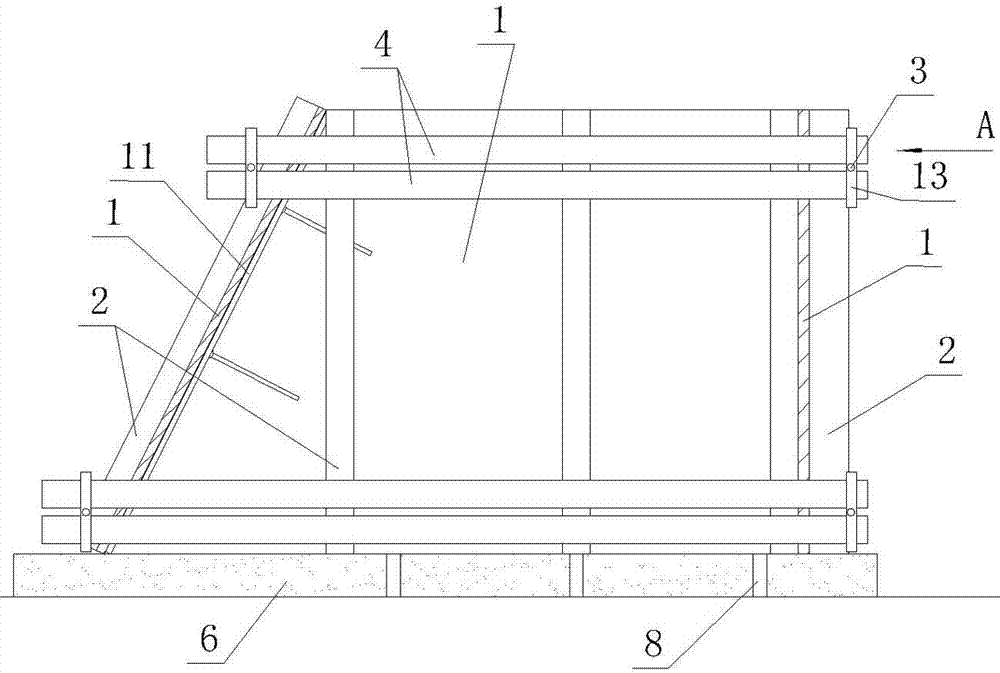

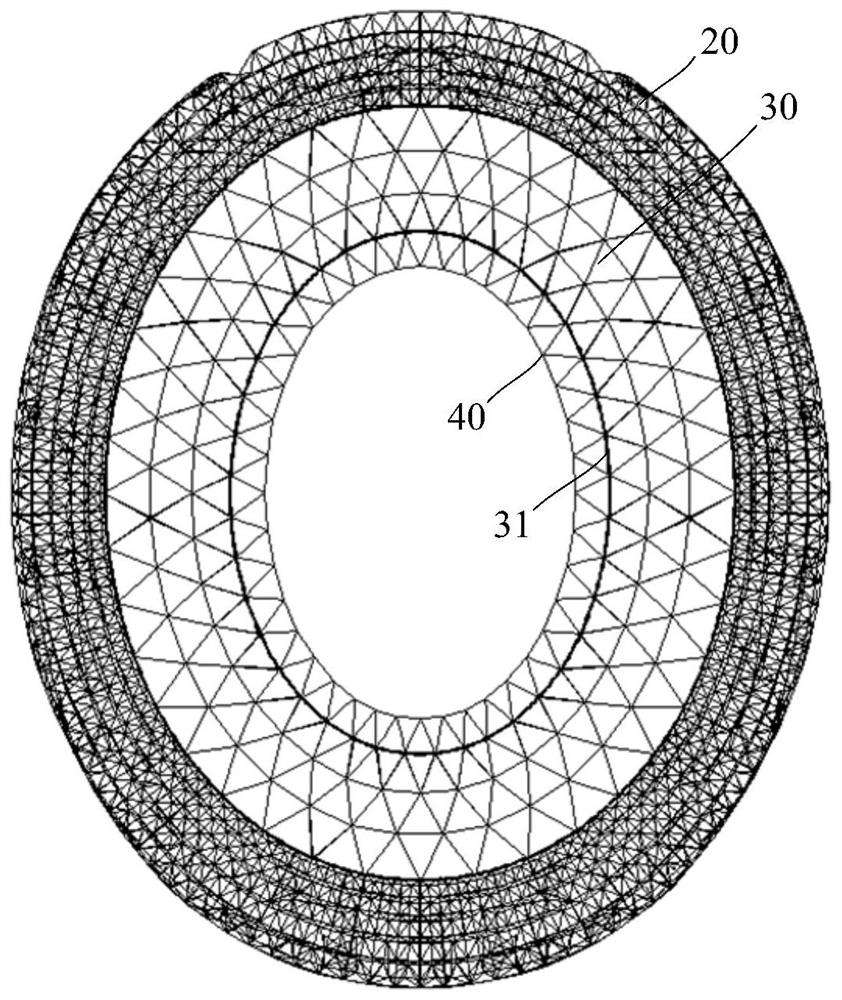

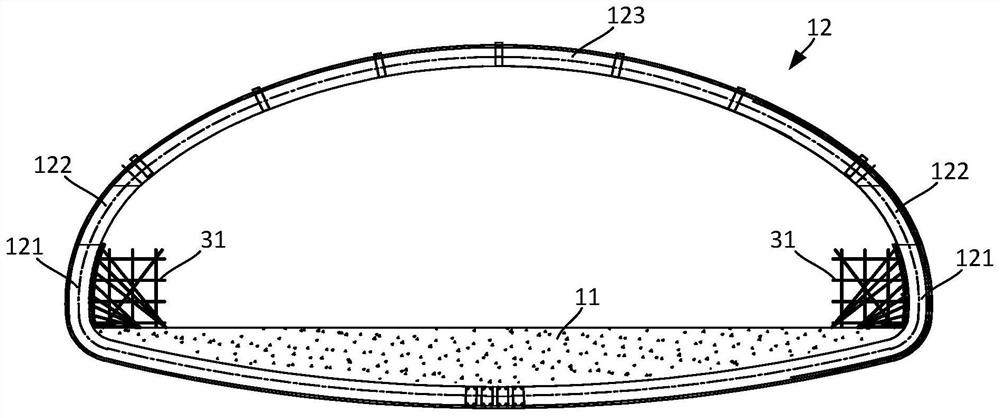

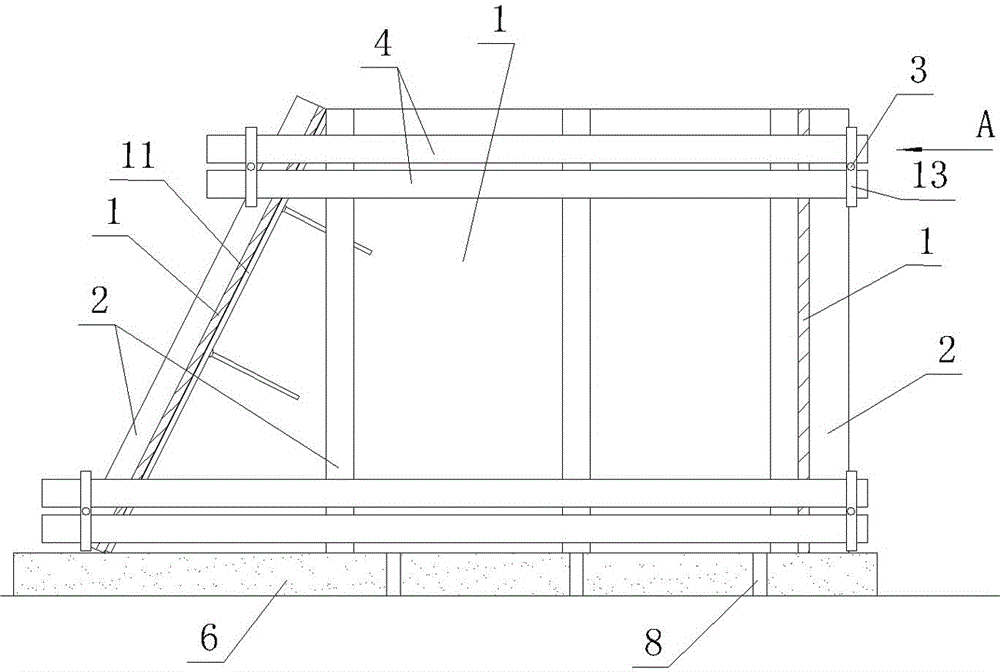

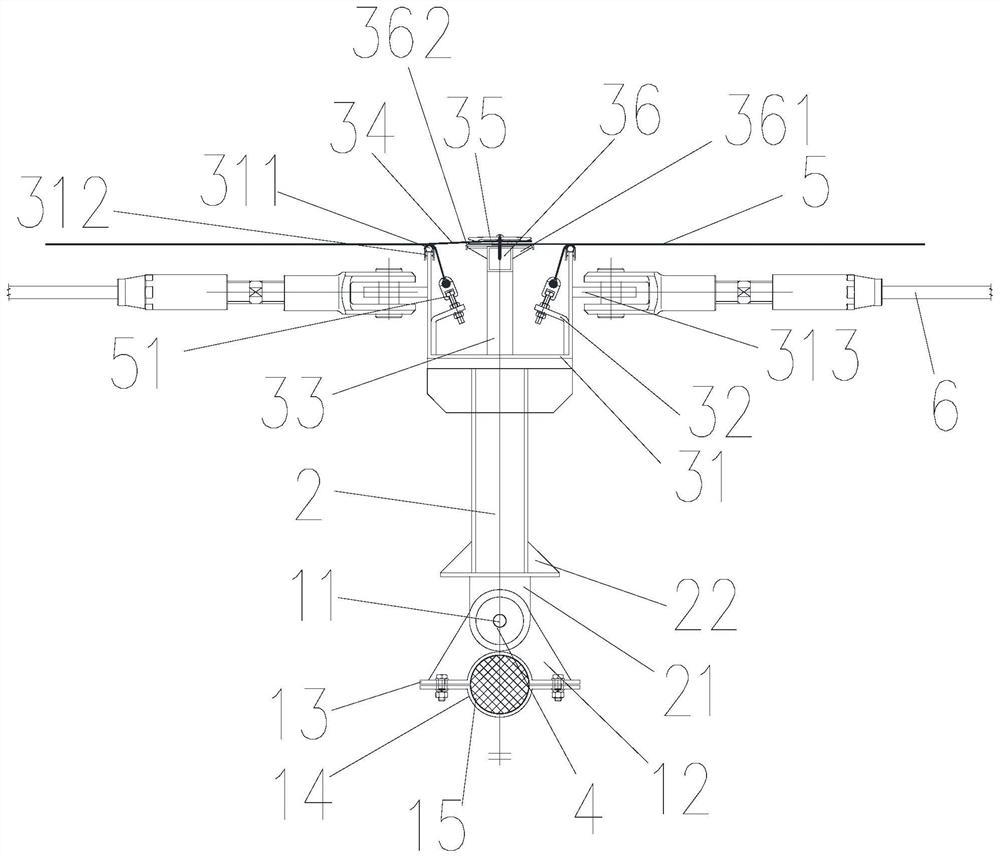

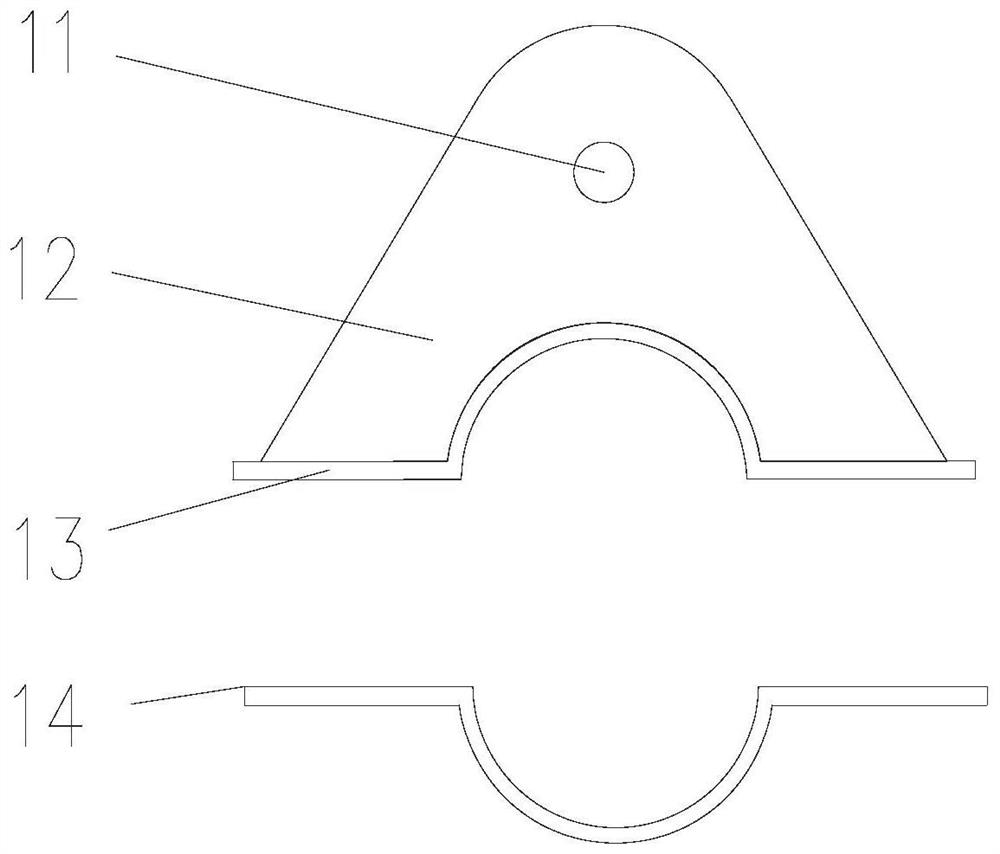

Unlocking-prevention cable and film connecting structure of large-opening cable dome structure and construction method

ActiveCN111794432AAvoid unlocking effectsImprove securityBuilding roofsBuilding material handlingClassical mechanicsCable net

The invention discloses an unlocking-prevention cable and film connecting structure of a large-opening cable dome structure and a construction method. The structure comprises a torsion connecting assembly, a supporting column (2) and a gutter assembly. The gutter assembly is mounted at the top of the supporting column (2). One end of a film structure (5) is mounted in the gutter assembly in a sealed manner. One end of the torsion connecting assembly is fixedly mounted on a main cable, and a rotating part (11) is arranged at the other end of the torsion connecting assembly. The cable dome maincable (4), the bottom of the supporting column (2) and the other end of the torsion connecting assembly are rotationally connected through the rotating part (11) so that the film structure mounted onthe supporting column (2) and the main cable can relatively rotate. According to the unlocking-prevention cable and film connecting structure, a main cable net of the cable dome structure is used as amain force bearing component of the film structure, the unlocking risk is avoided through a rotational hinged joint, it can be ensued that the cable dome structure and an ETFE film structure meet structure safety and the building use function at the same time, and it is ensured that an overall cable dome structure building is attractive.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

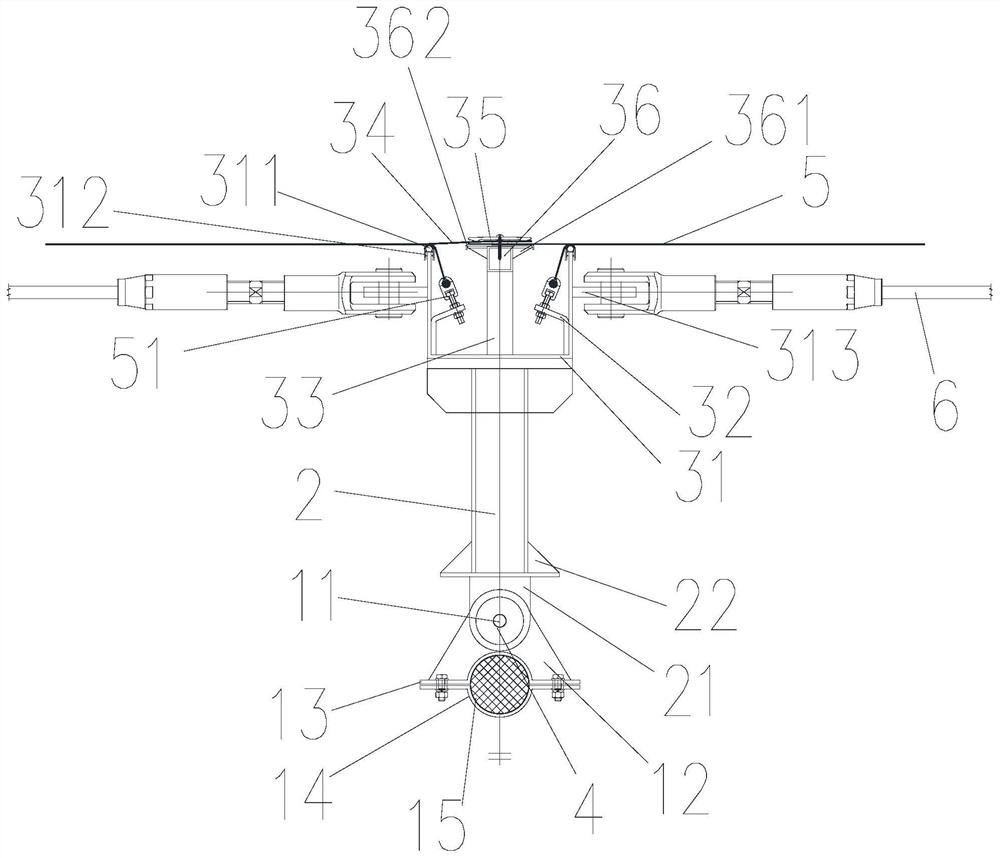

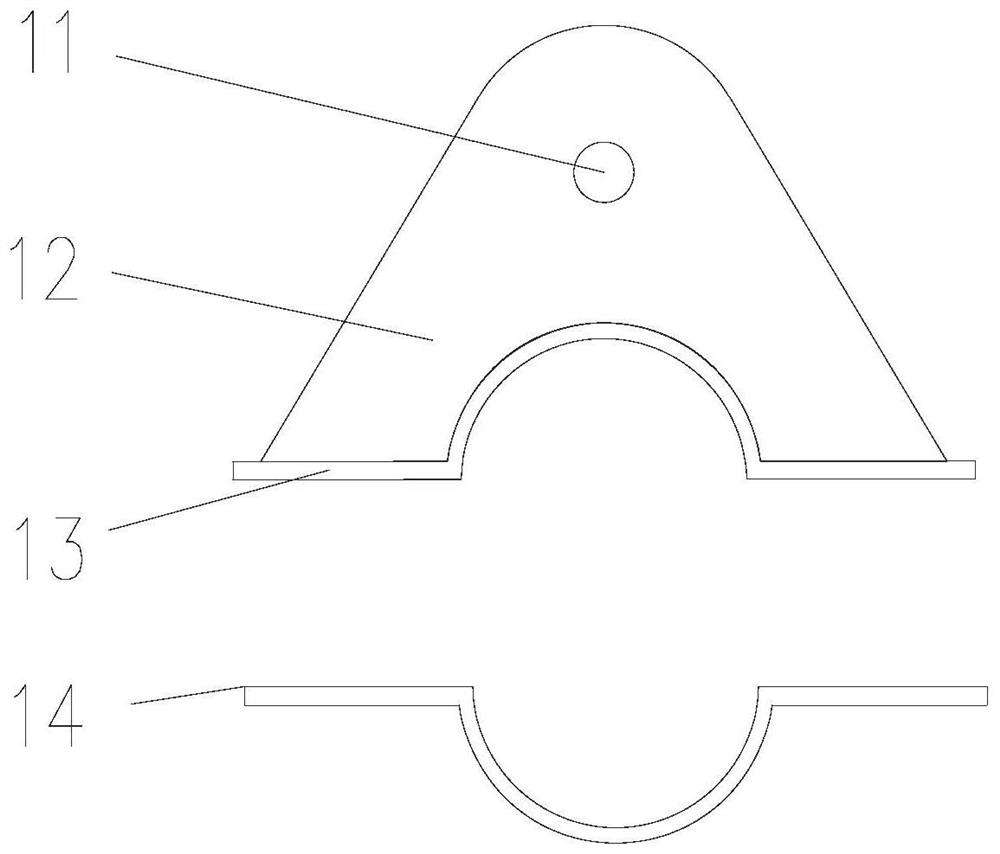

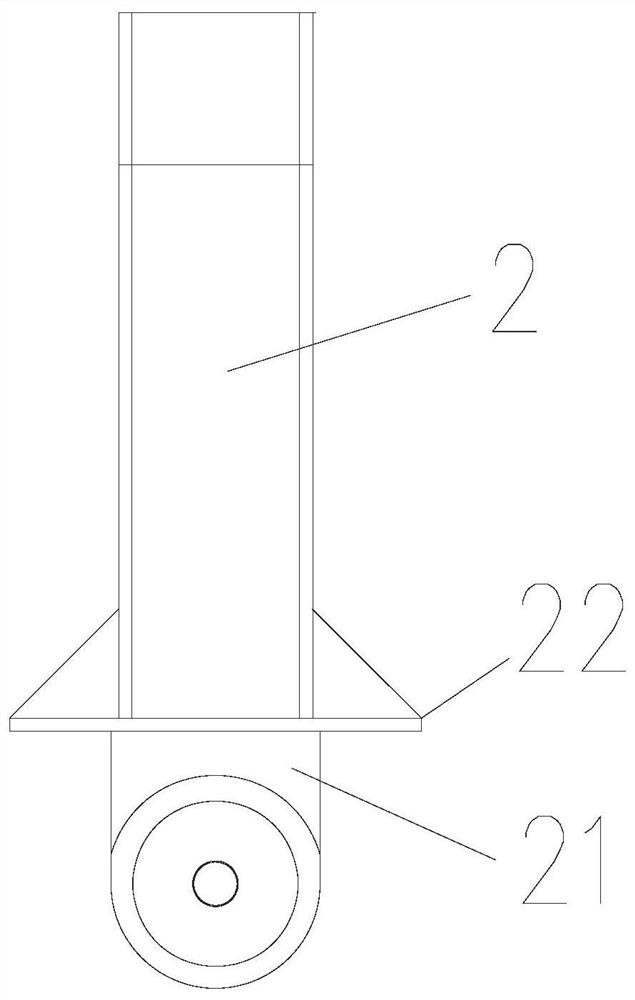

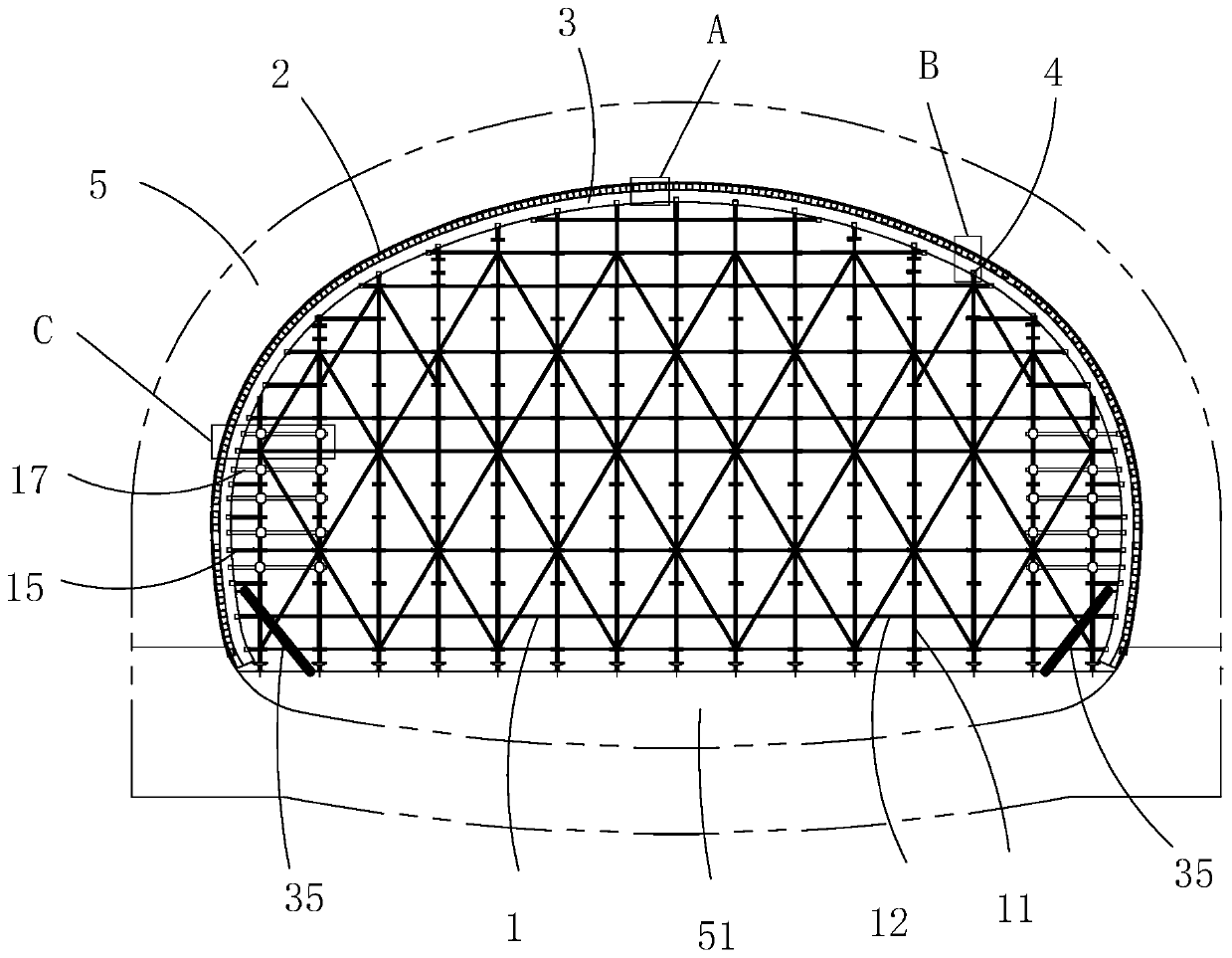

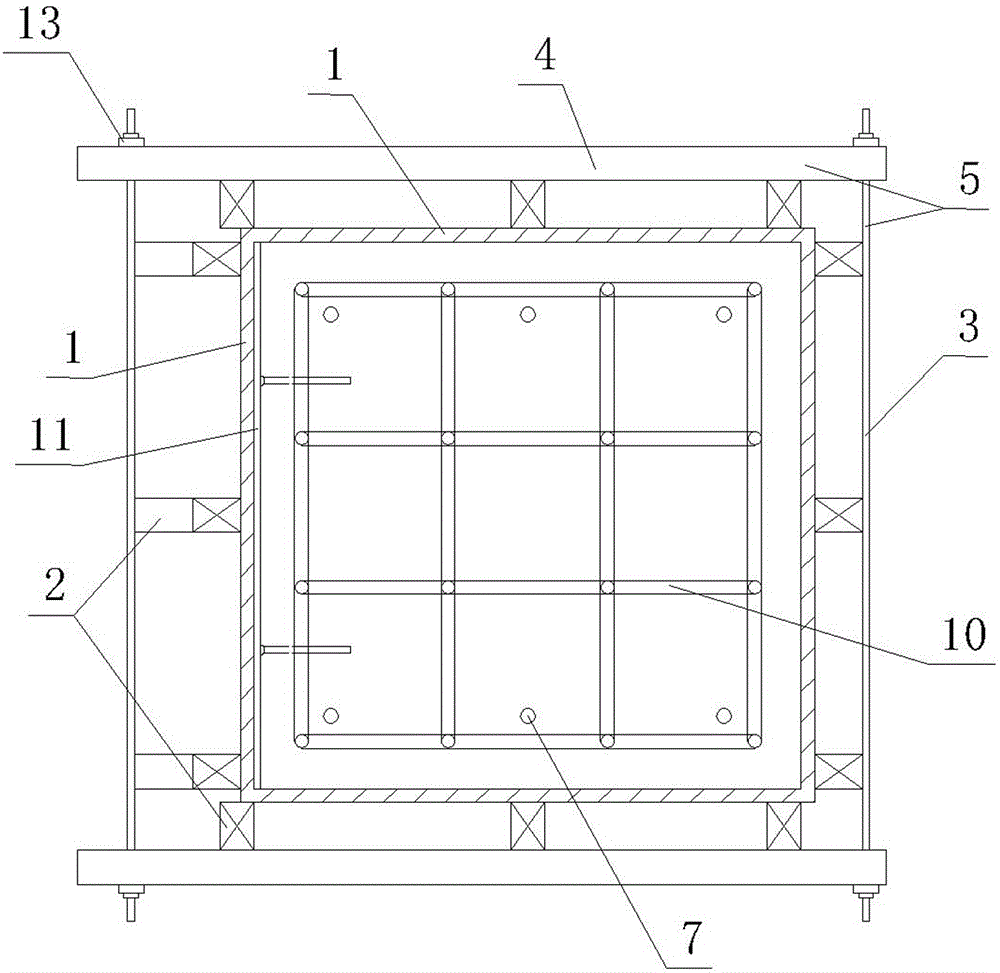

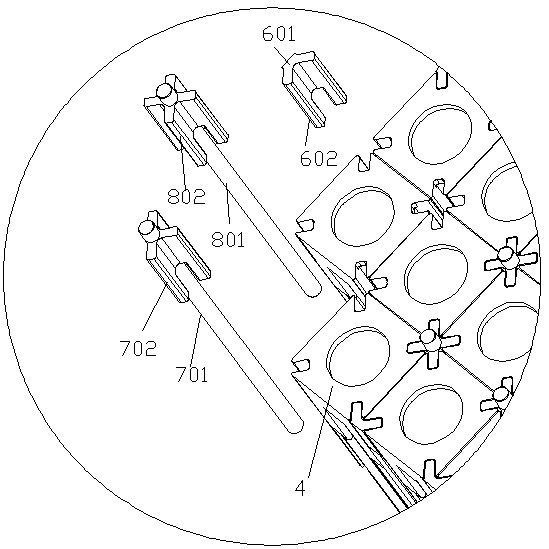

Disc buckling support system and construction system used for open-cut tunnel

PendingCN111520160ASpeed up the scheduleImprove economyArtificial islandsUnderground chambersSupporting systemClassical mechanics

The invention relates to the technical field of tunnel engineering, in particular to a disc buckling support system and a construction system used for an open-cut tunnel. The disc buckling support system comprises a disc buckling support, wherein the outer side of the disc buckling support is in supporting connection with a supporting truss, the outer side of the supporting truss is in supportingconnection with an arched formwork, and the shape of the arched formwork is adaptive to the shape of the inner wall of the tunnel. According to the disc buckling support system used for the open-cut tunnel, through a principle that the disc buckling support can be split into a plurality of small parts, a combination of the disc buckling support, the supporting truss and the arched formwork is usedfor replacing an inner mold trolley, when the disc buckling support is installed or disassembled, other construction plate blocks are not affected, so that multiple points can be simultaneously operated ahead of the trolley, a plan of days for construction is greatly quickened, and the disc buckling support system exhibits good economic efficiency and is easy in turnover.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD +1

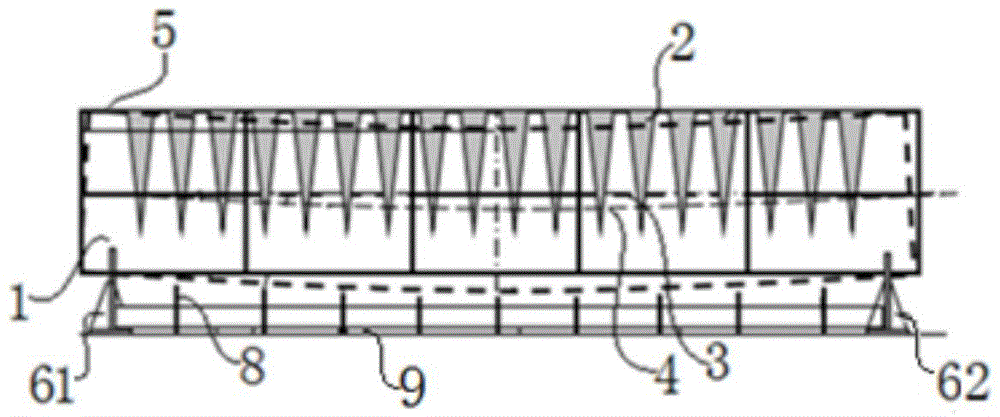

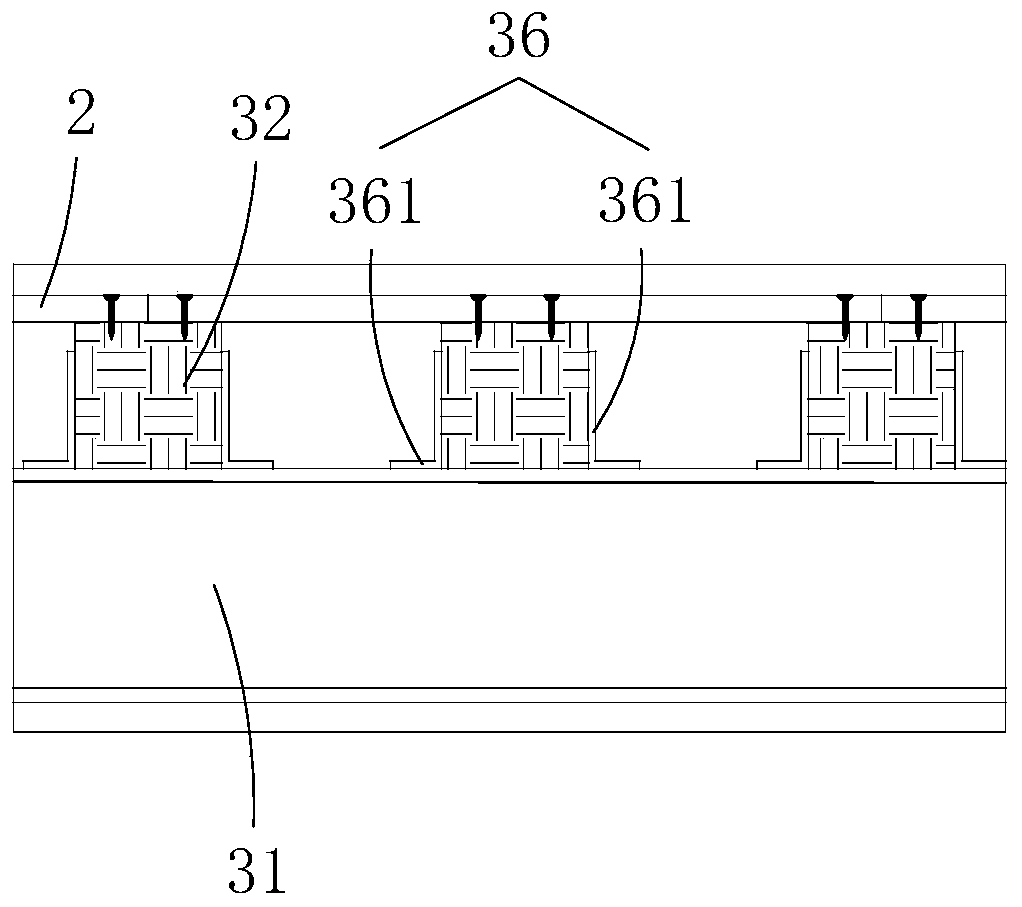

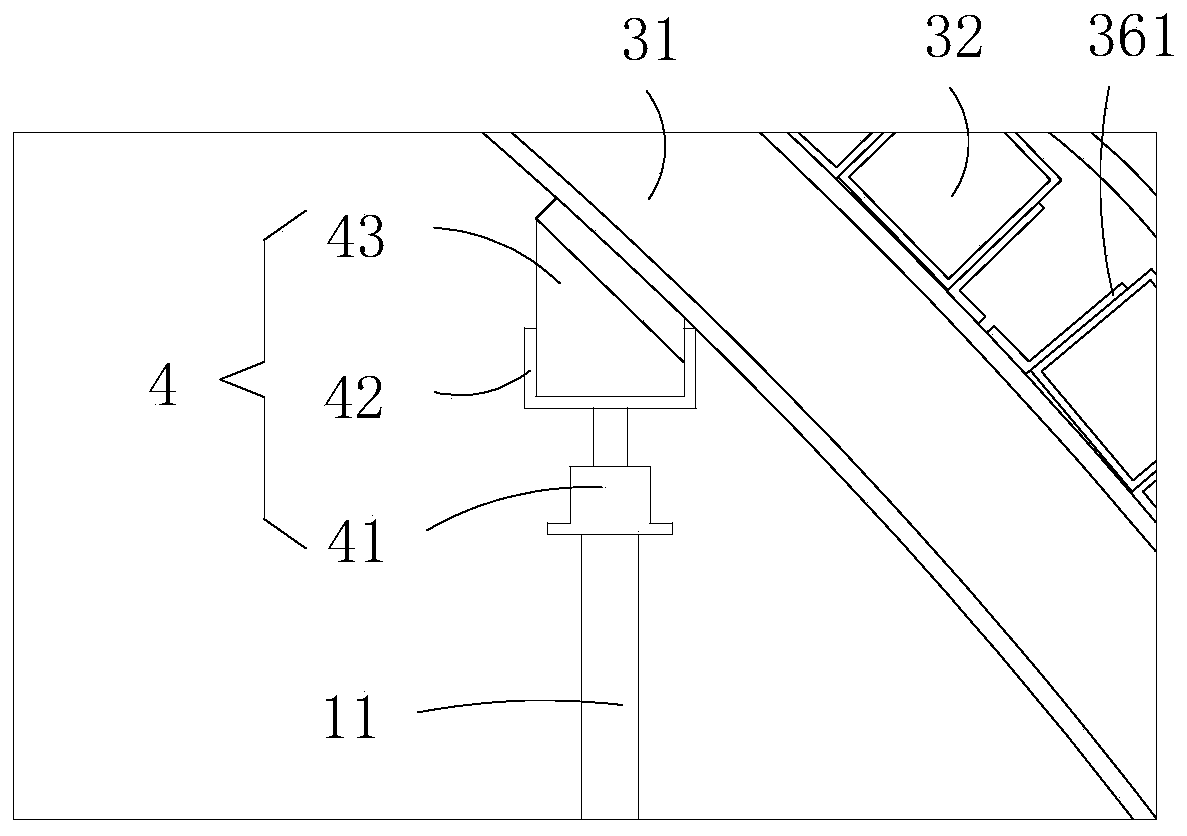

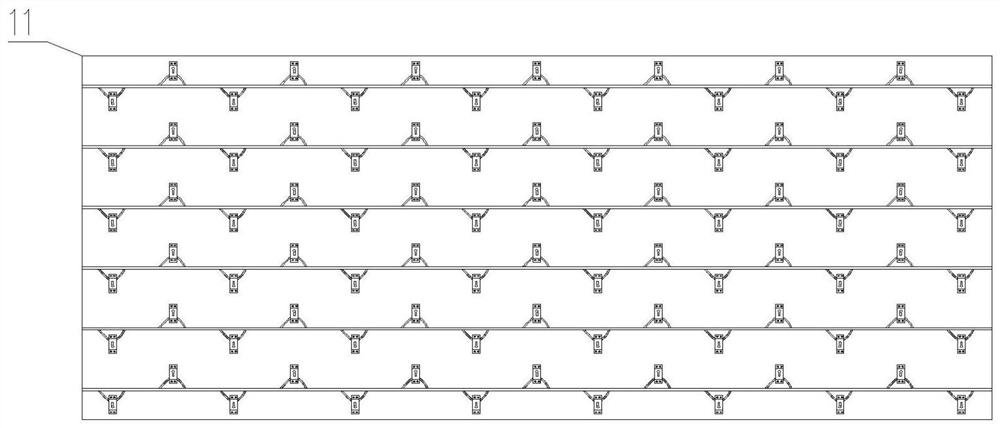

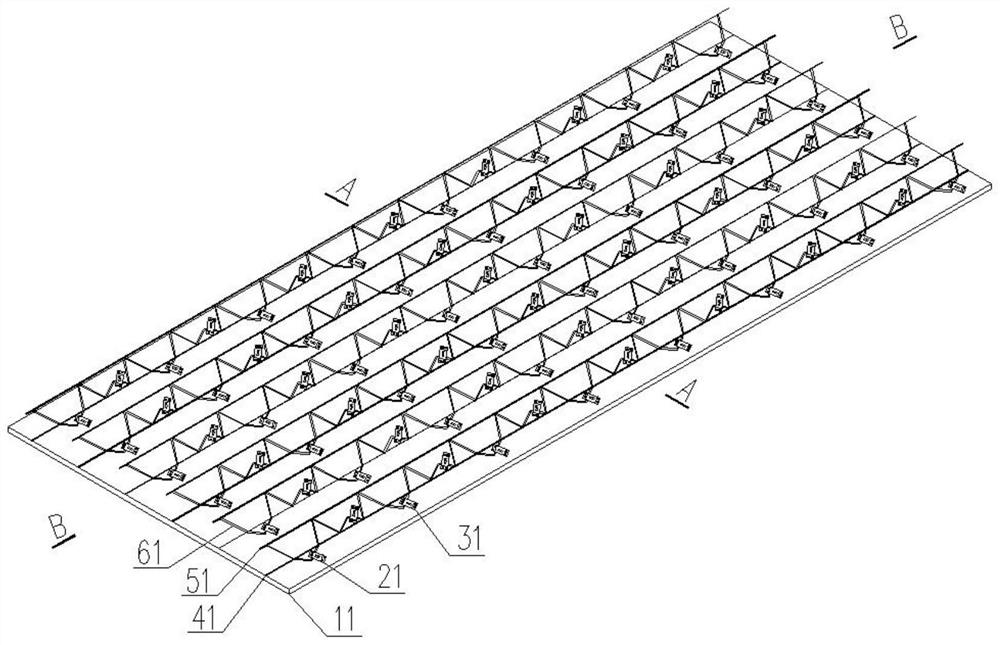

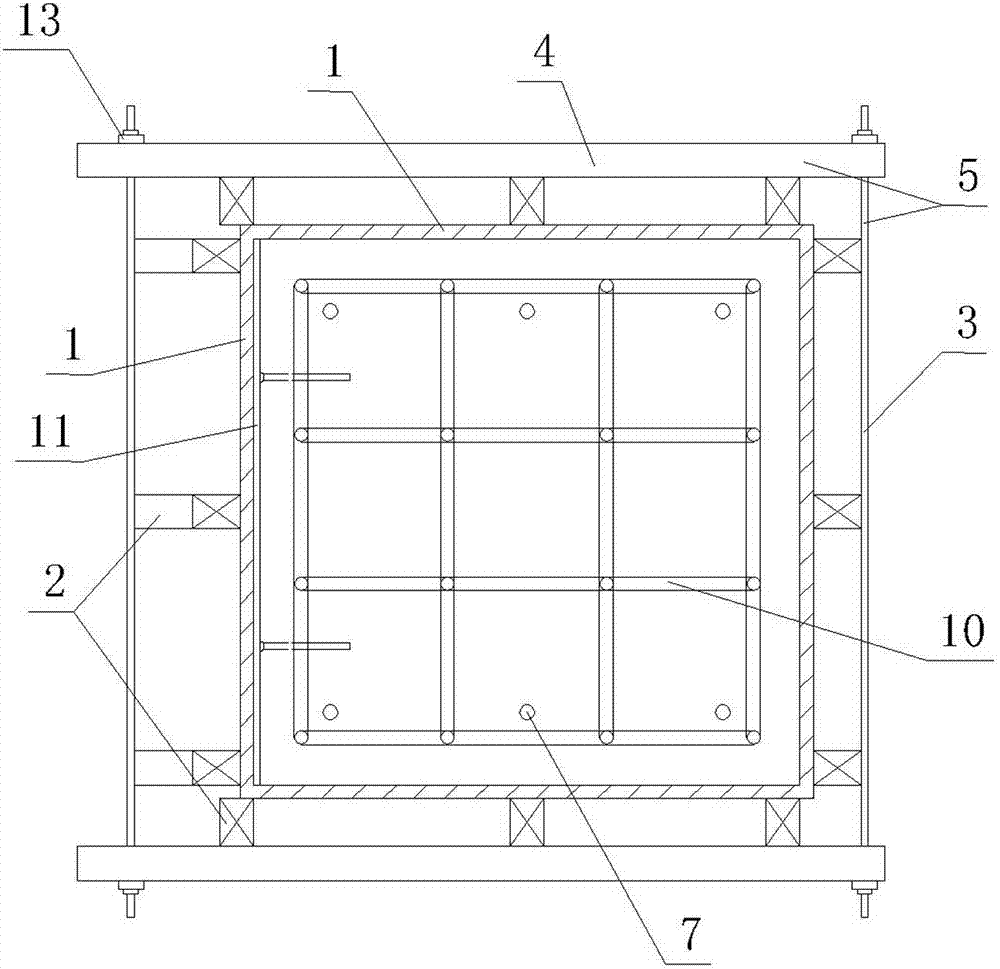

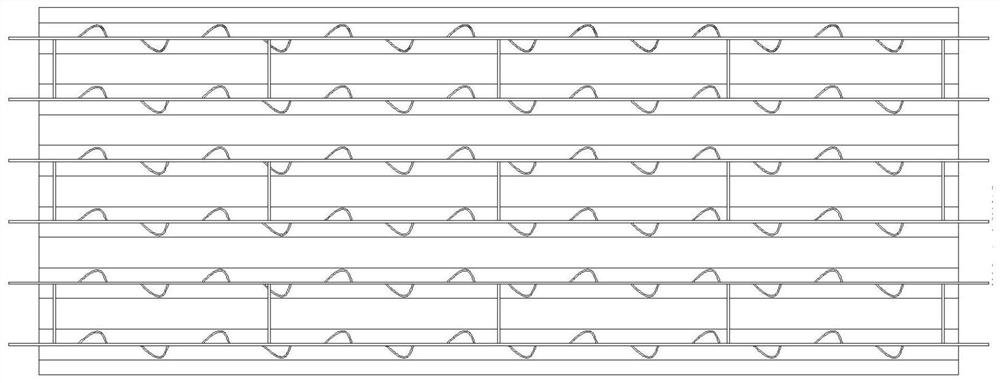

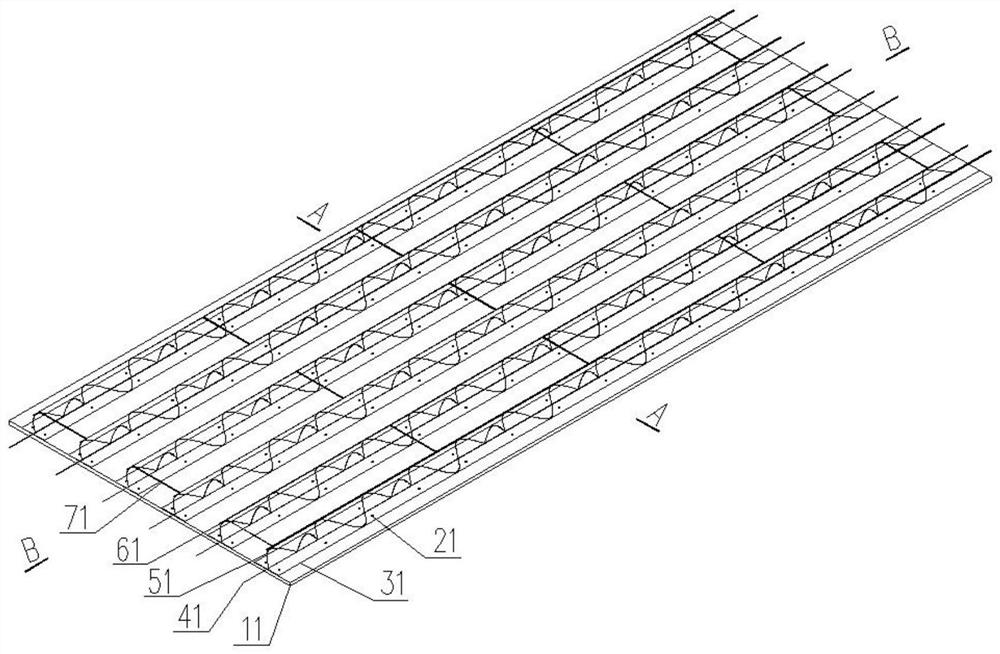

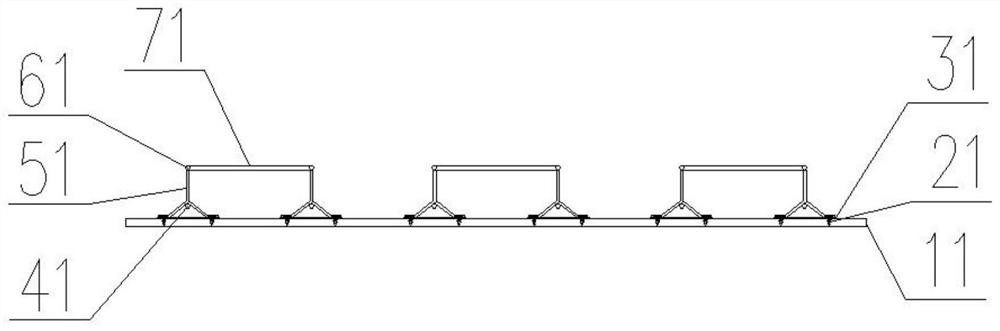

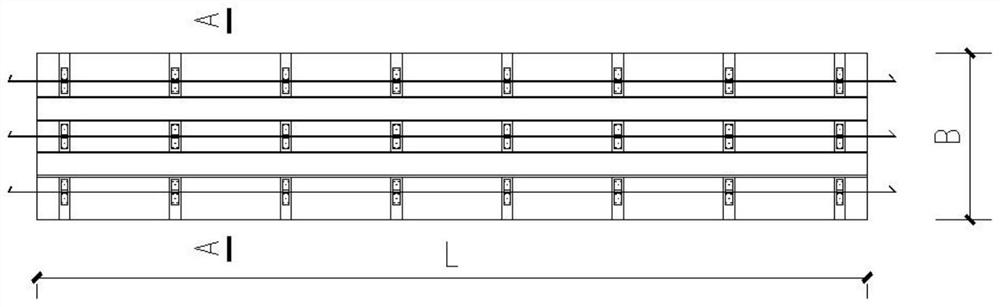

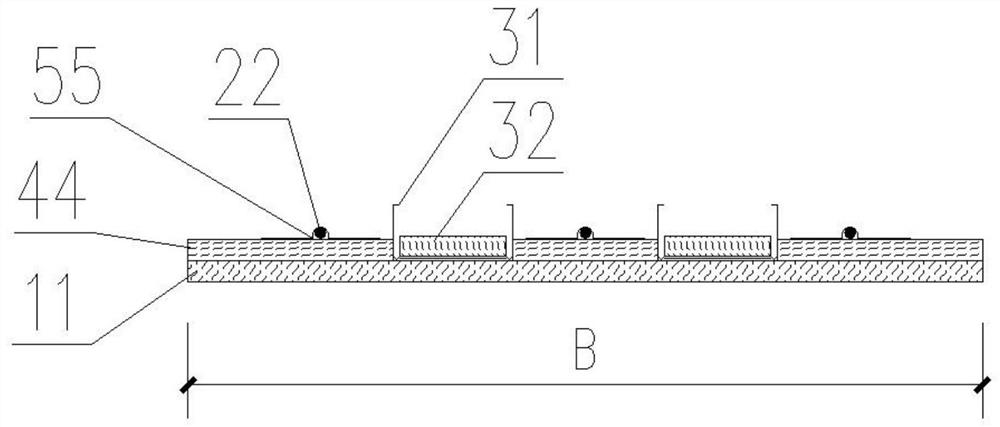

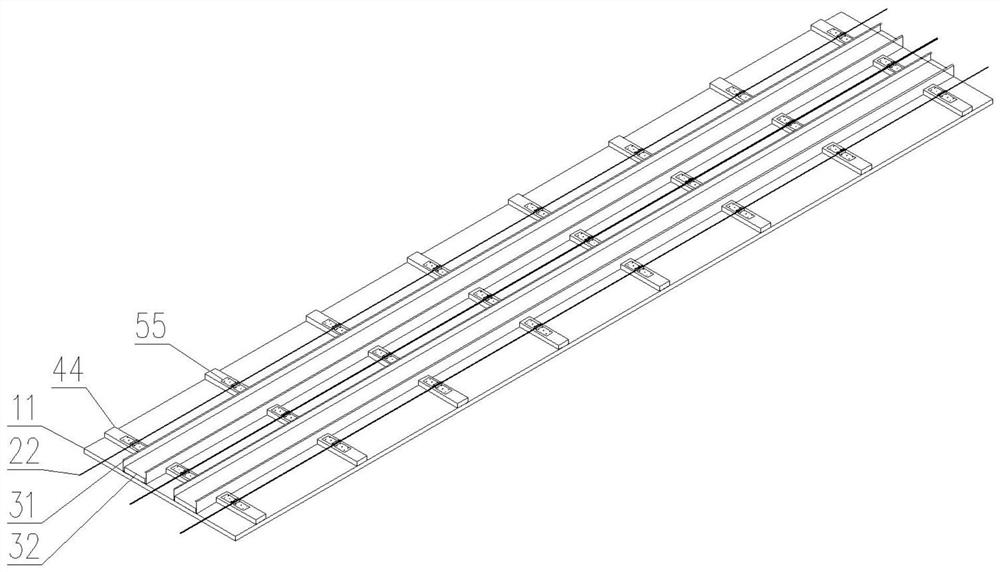

One-truss steel bar floor support plate with disassembly-free bottom form

PendingCN113374141ALow steel contentReduce the workload of demolitionFloorsRebarMechanical engineering

The invention discloses a one-truss steel bar floor support plate with a disassembly-free bottom form. The one-truss steel bar floor support plate is characterized by being formed by combining the disassembly-free bottom form, capital-omega-shaped material connecting pieces, self-tapping screws, lower chord longitudinal steel bars in a one-truss steel bar structure, upper chord longitudinal steel bars and web member wave-shaped steel bars with bent feet. According to the one-truss steel bar floor support plate with the disassembly-free bottom form, the longitudinally-arranged steel bars are single steel bar trusses, compared with triangular steel bar trusses in a steel bar truss floor support plate with a metal bottom form, due to the fact that the number of the lower chord longitudinal steel bars and the number of the web member steel bars used in each truss are both one smaller than the number of the steel bars used in the steel bar truss floor support plate with the metal bottom form, the steel content is greatly reduced, the steel content is closest to that of a traditional cast-in-place slab system, and the bottom of the disassembly-free bottom form can be directly subjected to puttying decoration; and according to the one-truss steel bar floor support plate with the disassembly-free bottom form, the cost is saved for a construction side, the fast turnover target is achieved, the workload of deepening design is saved for a design side, the construction progress is accelerated for the construction side, the construction quality is better controlled, and the productivity is completely released for a component producer, so that all project participants obtain respective benefits.

Owner:广西装配式建筑科技有限公司

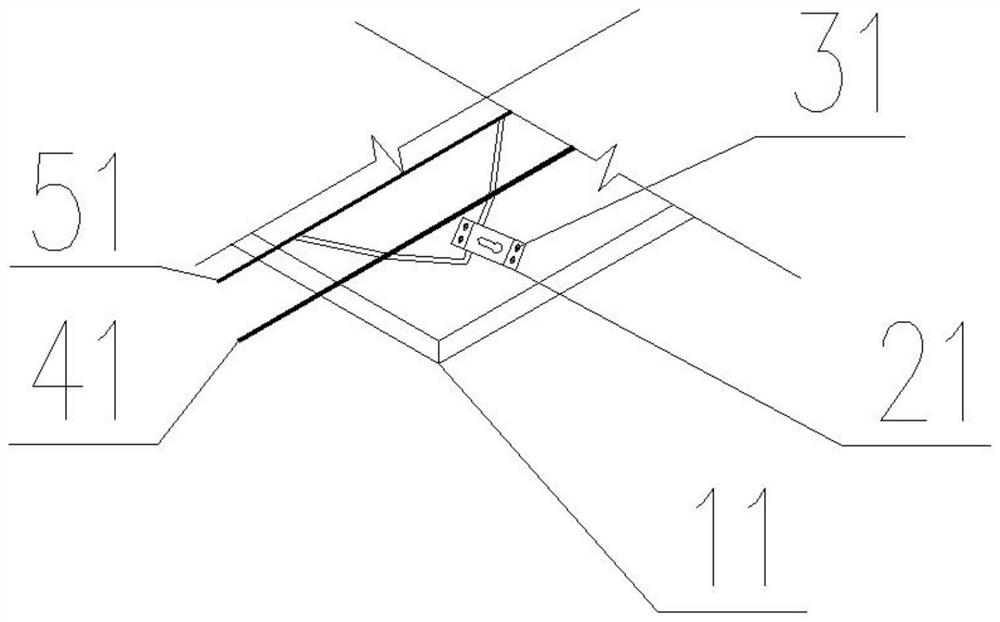

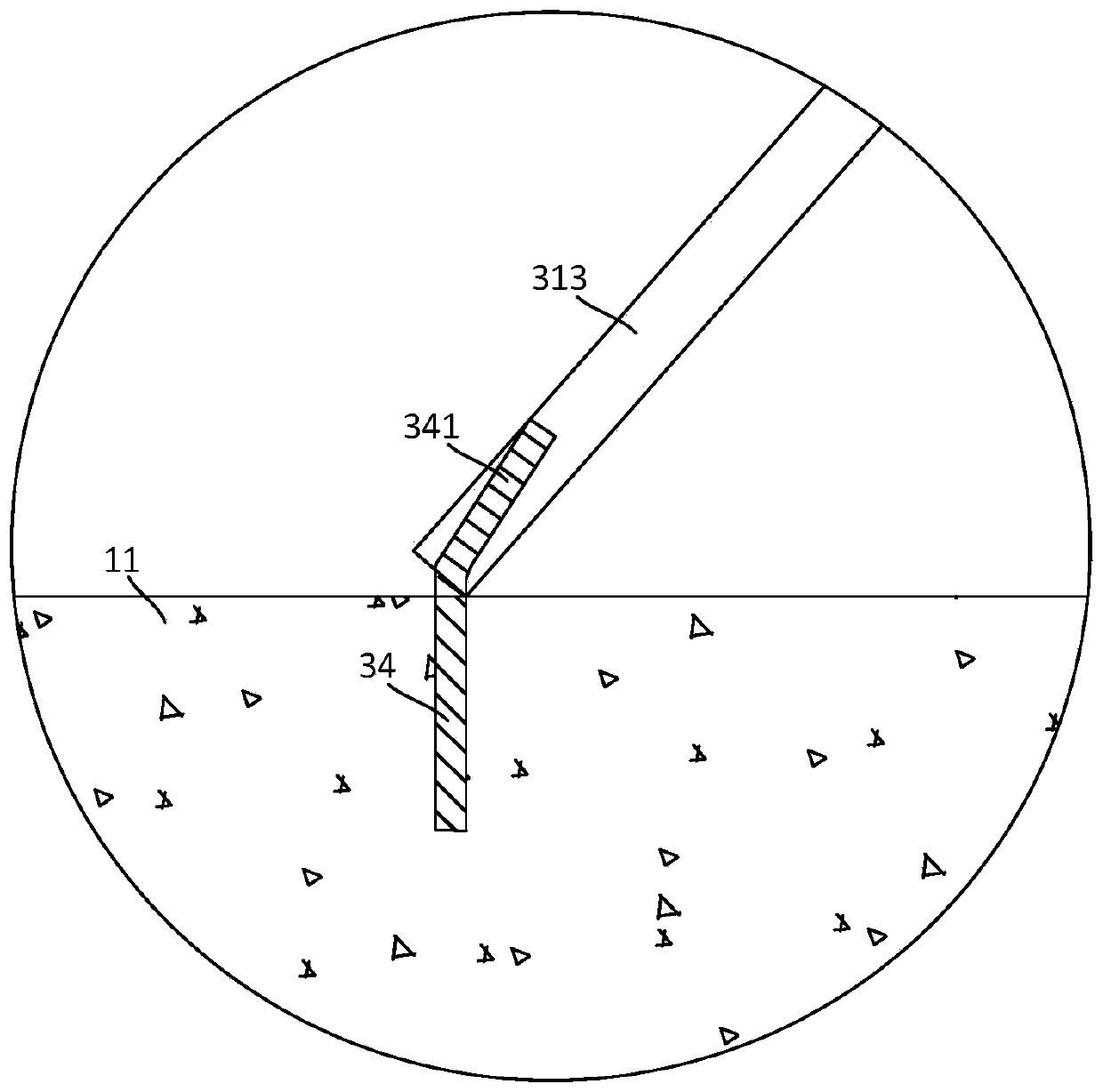

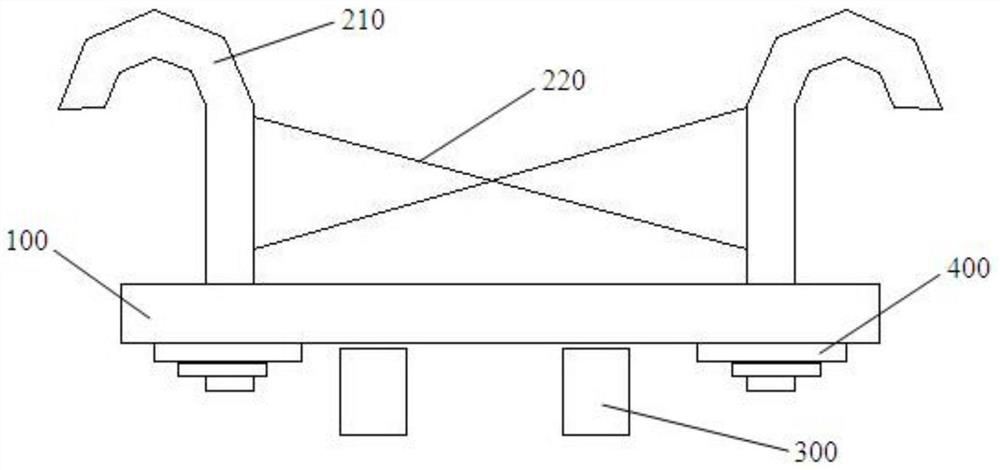

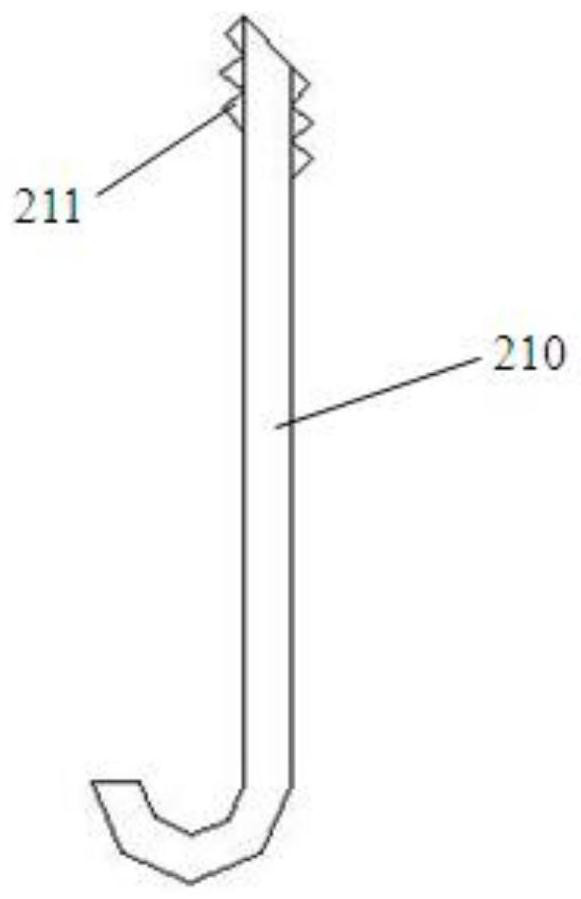

Bracket at lower end of inclined inner support of supporting structure of foundation pit, manufacturing tool and construction method

InactiveCN103572762ALow costOmit the steps of on-site constructionExcavationsEngineeringBuilding construction

Owner:ZHEJIANG WANHUA CONSTR

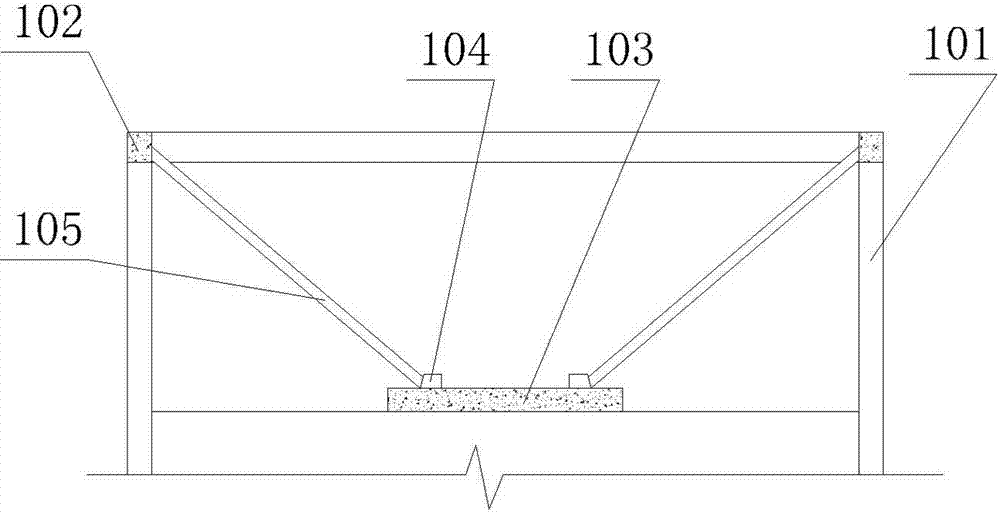

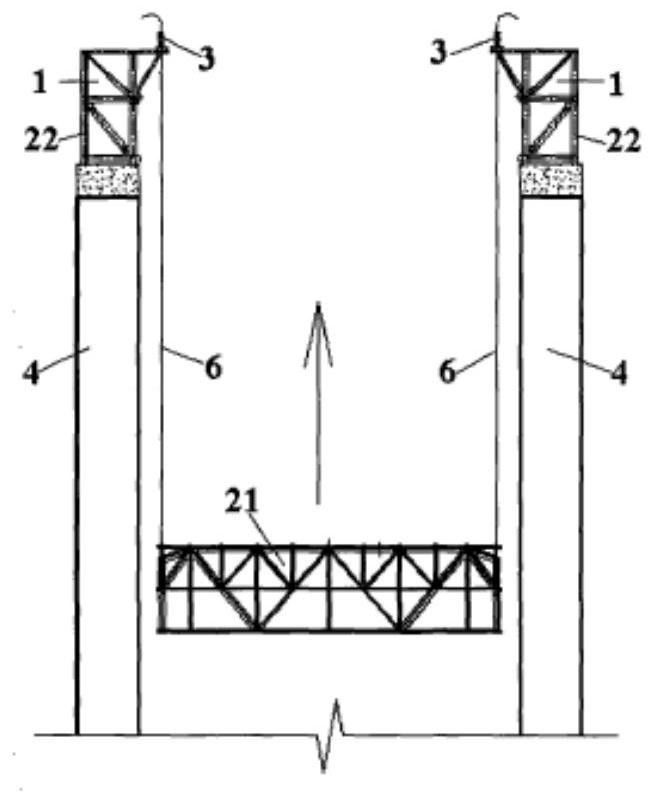

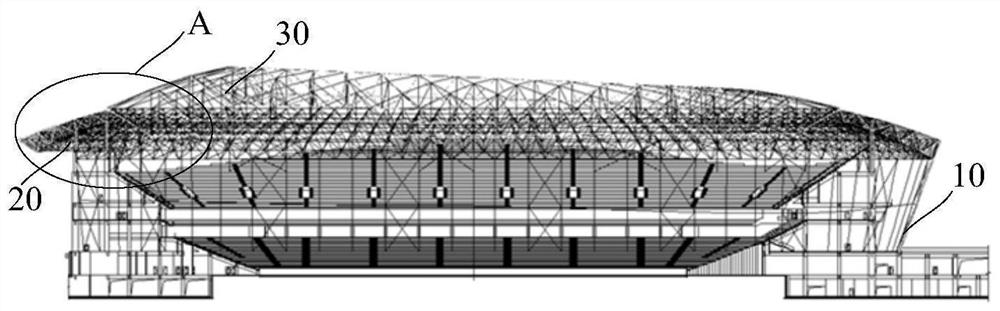

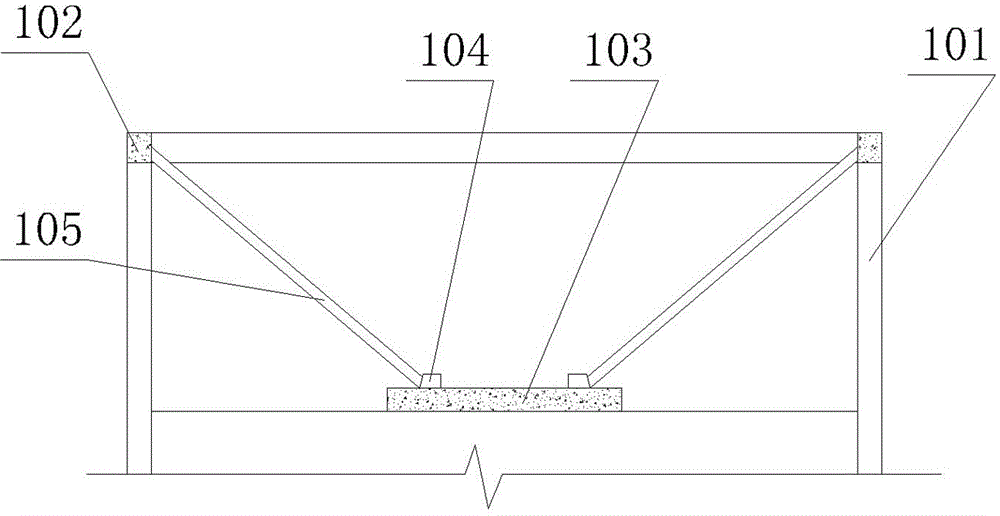

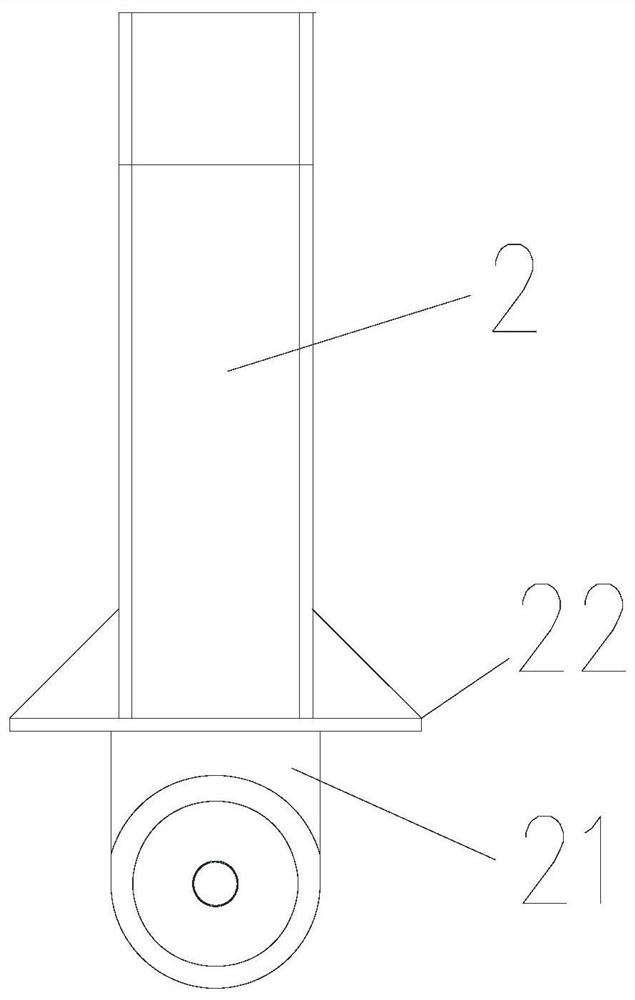

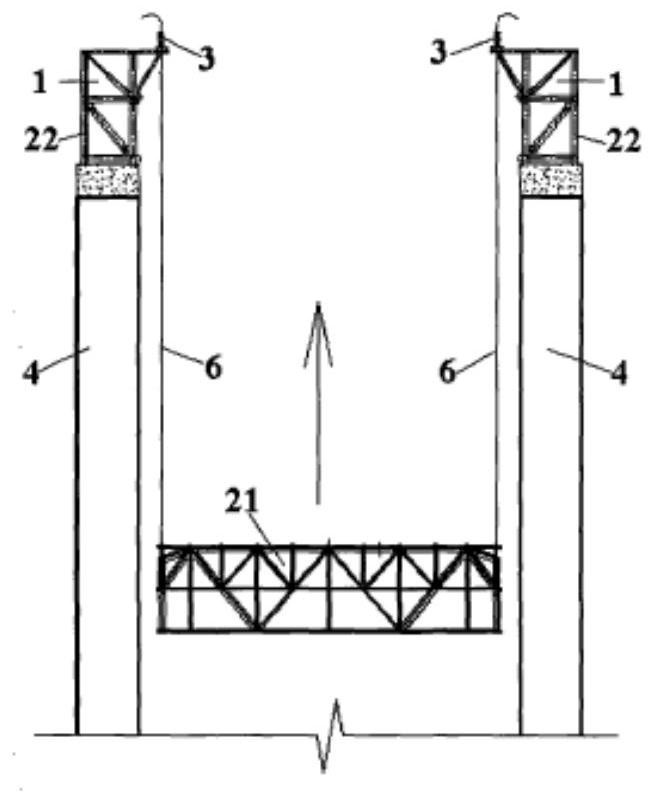

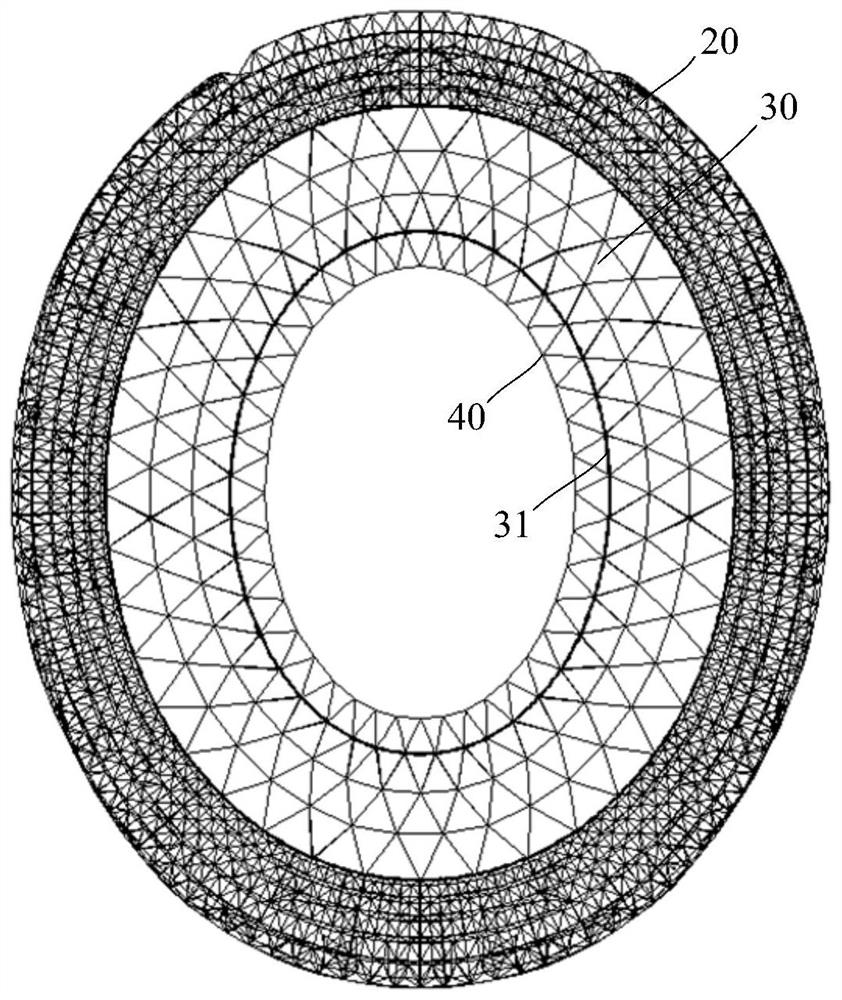

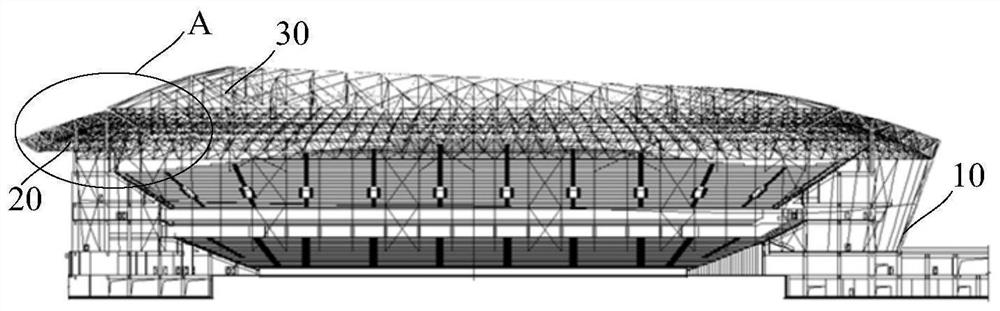

Method and system for integral lifting of asymmetric inner ring truss and cable dome

ActiveCN111719757AControl rotationControl offsetBuilding roofsBuilding material handlingClassical mechanicsStructural engineering

The invention relates to a method and system for integral lifting of an asymmetric inner ring truss and a cable dome. The method comprises the steps that the inner ring truss and the cable dome are formed by assembling, and the cable dome is connected with the inner ring truss; a plurality of lifting frames are arranged at intervals along the position where the inner ring truss is to be installedand fixed to the ground, and the lifting frames are connected with each other; a plurality of lifting devices are fixed to the top parts of the corresponding lifting frames, and the lifting devices are connected with the inner ring truss correspondingly; a plurality of traction devices are fixed to the top parts of the corresponding lifting frames, and the traction devices are connected with the cable dome correspondingly; the lifting devices are used to lift the inner ring truss up horizontally, the traction devices are used for stretching the cable dome during the process of lifting the inner ring truss, and radial traction of the cable dome is carried out through the traction devices, so that the horizontal force is applied to the inner ring truss through the cable dome to control the horizontal displacement of the inner ring truss; and lifting of the inner ring truss and stretching of the cable dome are carried out alternately until the inner ring truss reaches the design elevation.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

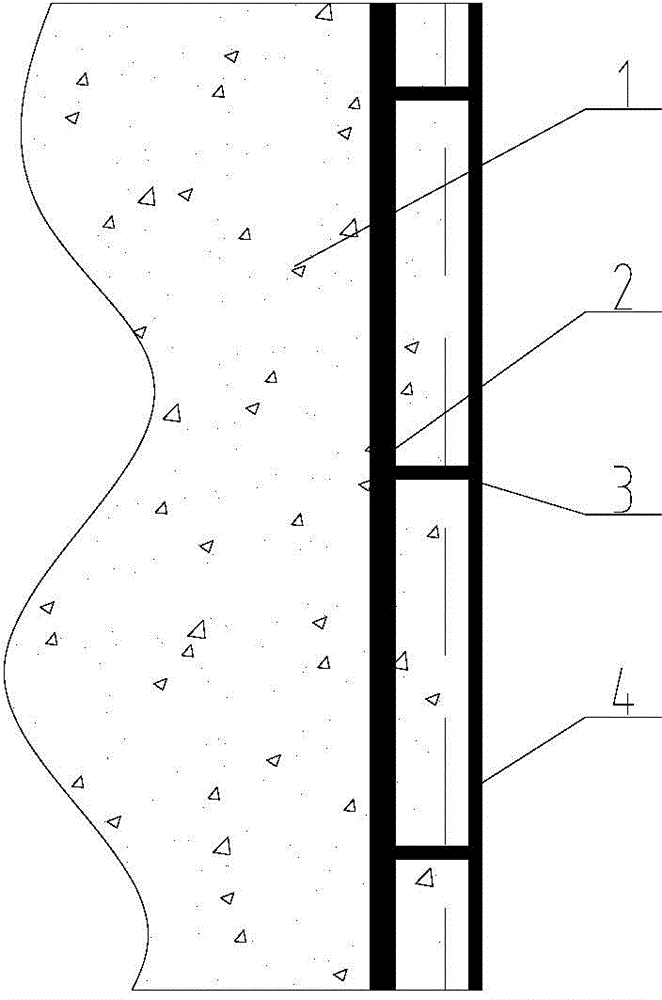

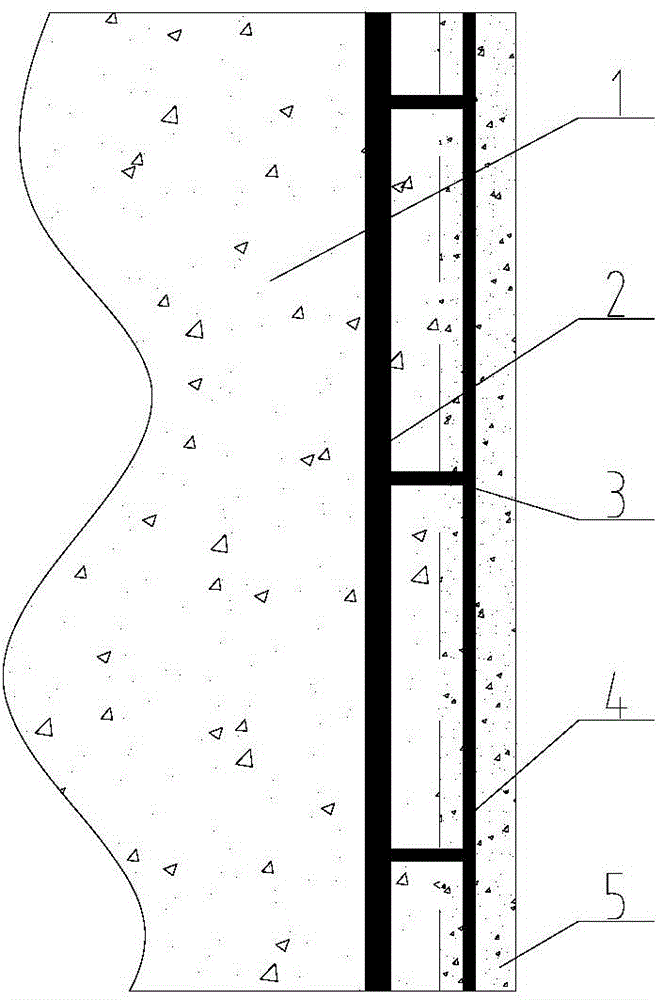

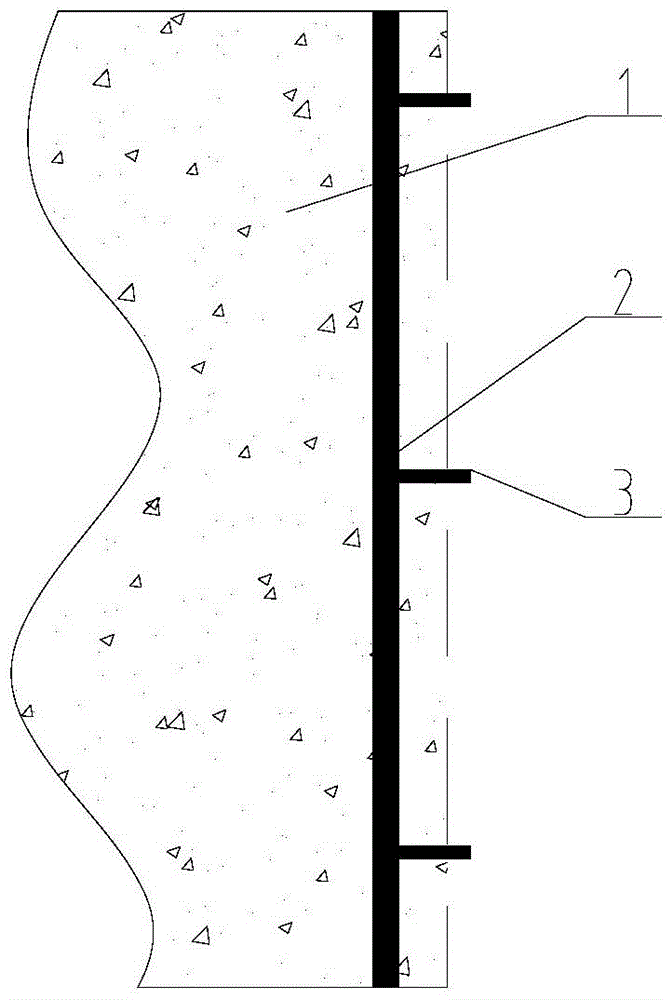

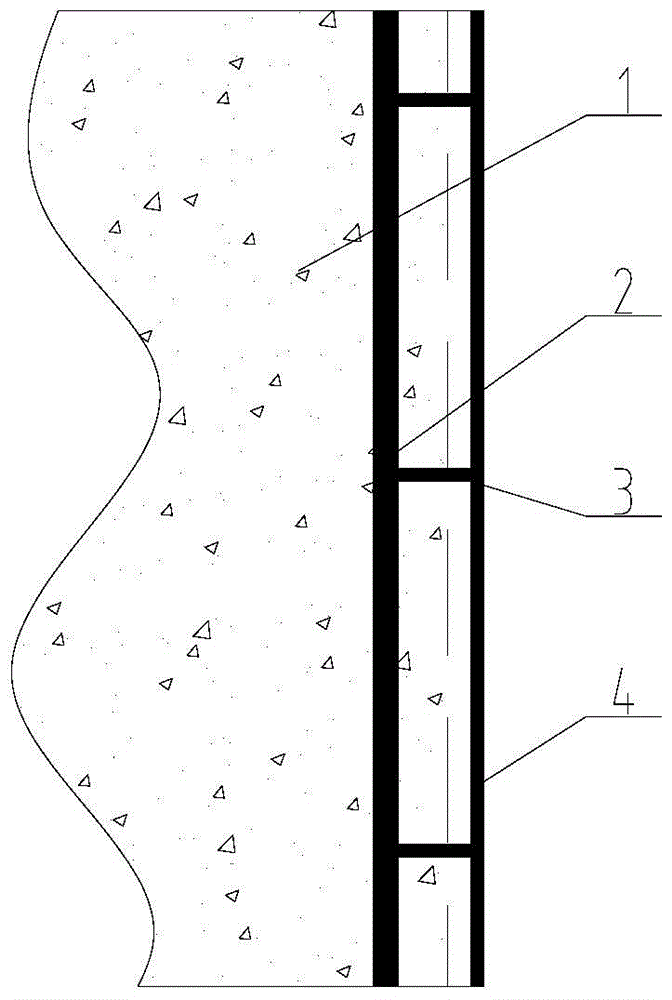

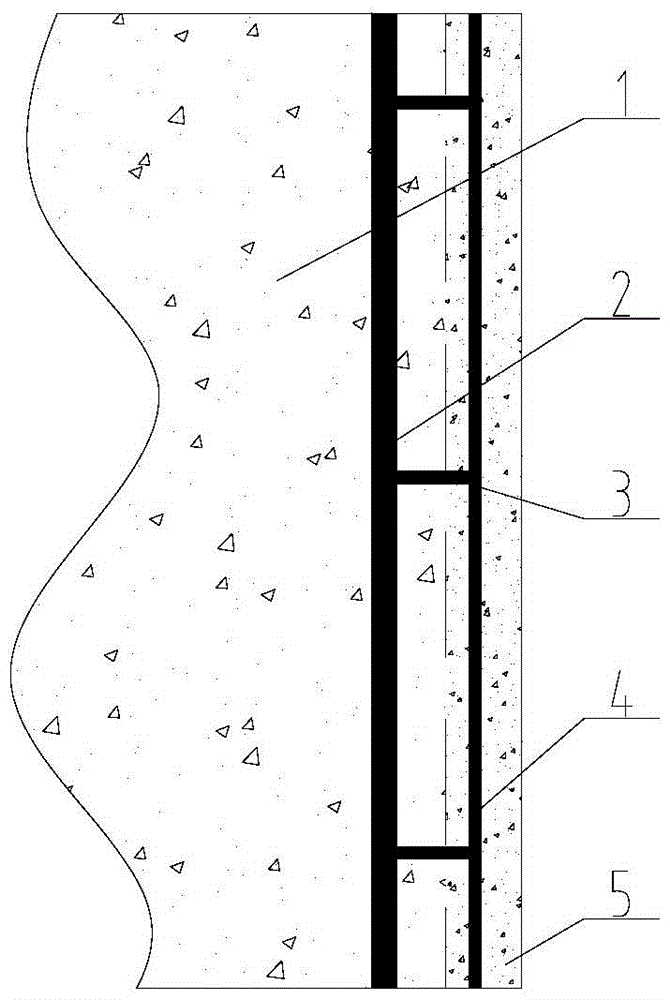

Multi-layer functional corrosion-resistant concrete structure and connecting method thereof

InactiveCN104818883ASatisfy the requirements of anti-corrosion damageIncreased durabilityArtificial islandsTowersSurface layerRebar

The invention provides multi-layer functional corrosion-resistant concrete. The multi-layer functional corrosion-resistant concrete comprises a core concrete structure, a core steel structure, connectors with steel sleeves, welded steel fabric and a surface layer concrete structure. The core steel structure is arranged inside the core concrete structure, the welded steel fabric is arranged inside the surface layer concrete structure, and the core steel structure is connected with the welded steel fabric through the connectors with the steel sleeves. The invention further relates to a mechanical connecting method of the multi-layer functional corrosion-resistant concrete. The core steel structure and the welded steel fabric structure on the surface layer are connected through the connectors, the steel sleeves and deformed steel bars. According to the invention, the requirement for the service strength of marine facilities can be met, the high corrosion resistance is achieved, and therefore oceanic building concrete can have the longer service life. The multi-layer functional corrosion-resistant concrete and the mechanical connecting method of the multi-layer functional corrosion-resistant concrete have the advantages of being high in practicability and functionality.

Owner:盐城市同力新型建材有限公司 +1

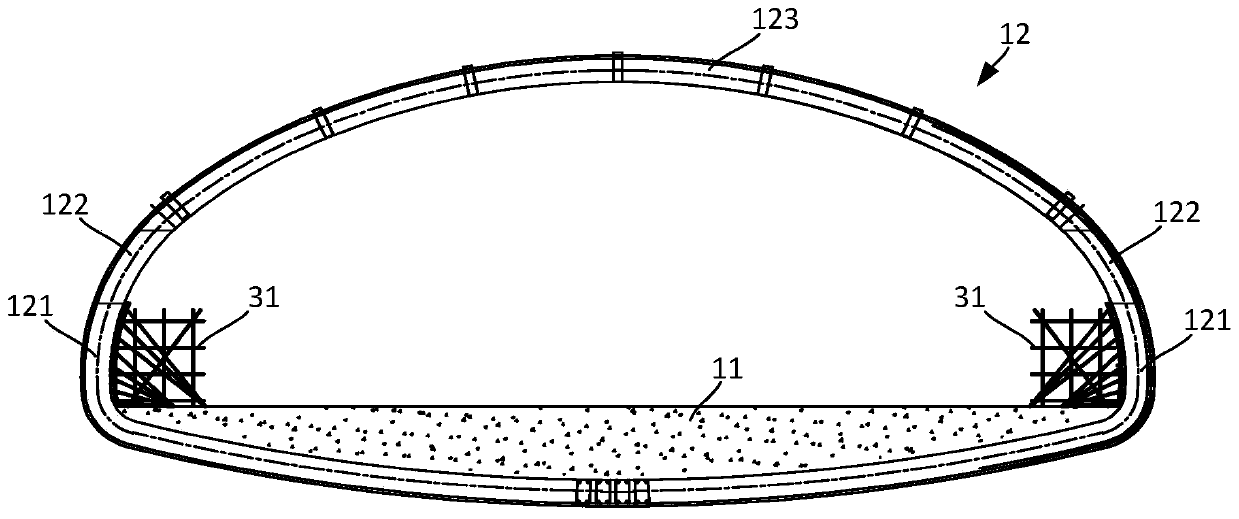

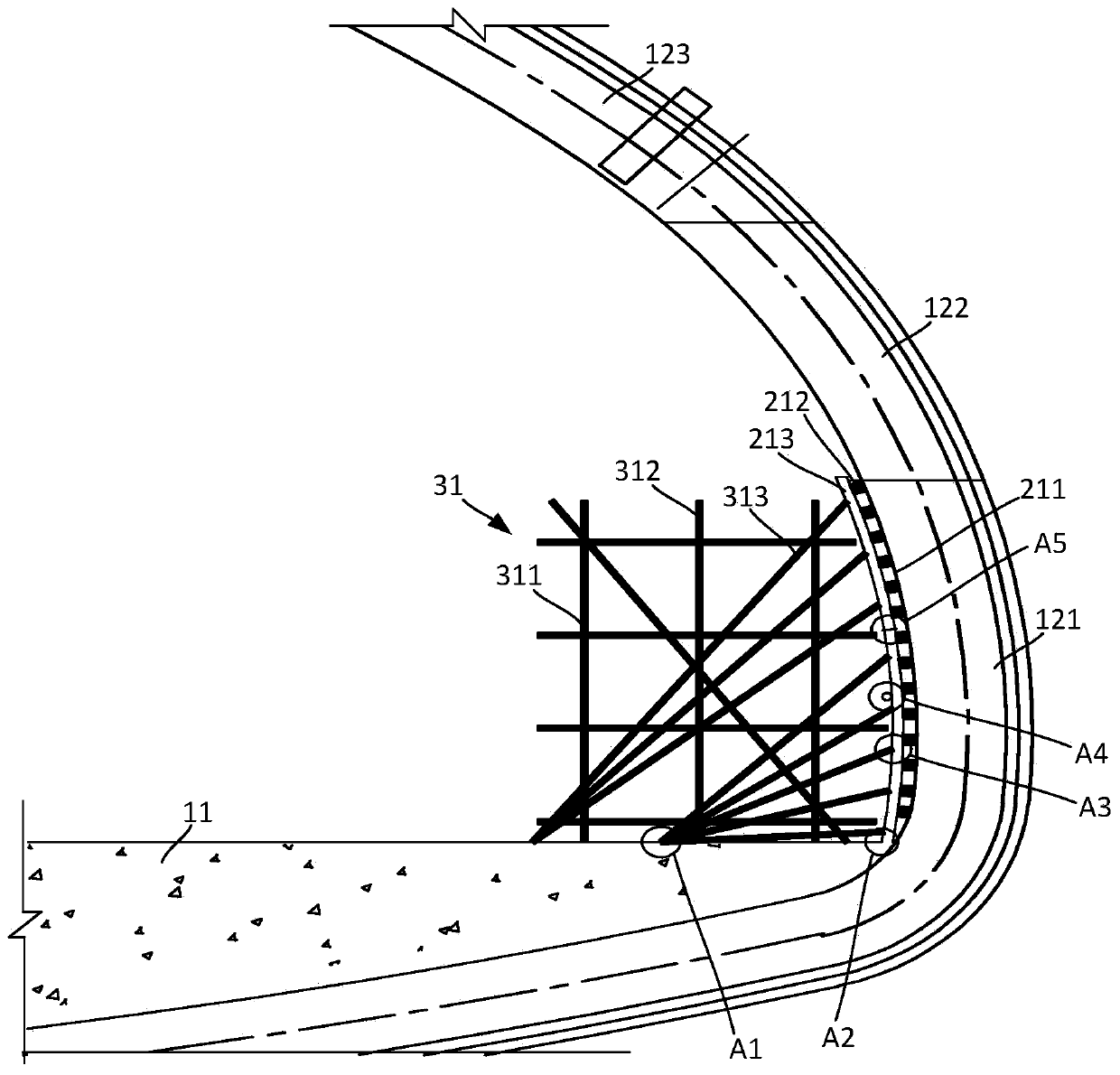

Construction method of long-span and super-thick tunnel second lining structure

ActiveCN109854277ASolve difficultySolve the dangerUnderground chambersTunnel liningSupporting systemLong span

The invention relates to a construction method of a long-span and super-thick tunnel second lining structure. The construction method comprises the following steps that a tunnel second lining structure to be constructed is divided into a first subsection, a second subsection and a third subsection; the first subsection is constructed, a supporting system is arranged on an inverted arch of a tunnelto support first formworks, and pouring is carried out to form a first side wall structure; the second subsection is constructed, the supporting system is heightened to support second formworks, andpouring is carried out to form a second side wall structure connected with the first side wall structure; and the third subsection is constructed, a top bracing system is arranged on the inverted archof the tunnel, the top bracing system is connected with the second side wall structure in a top-bracing mode, third formworks are supported by the top bracing system, and pouring is carried out to form a top arch structure connected with the second side wall structure, so that the construction of the tunnel second lining structure is completed. According to the construction method of the long-span and super-thick tunnel second lining structure, step-by-step flow process and different formwork supporting systems are adopted, the problem of large difficulty and high dangerousness of the whole construction of the large-span and super-thick secondary lining structure is solved, and the construction schedule is speeded up.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

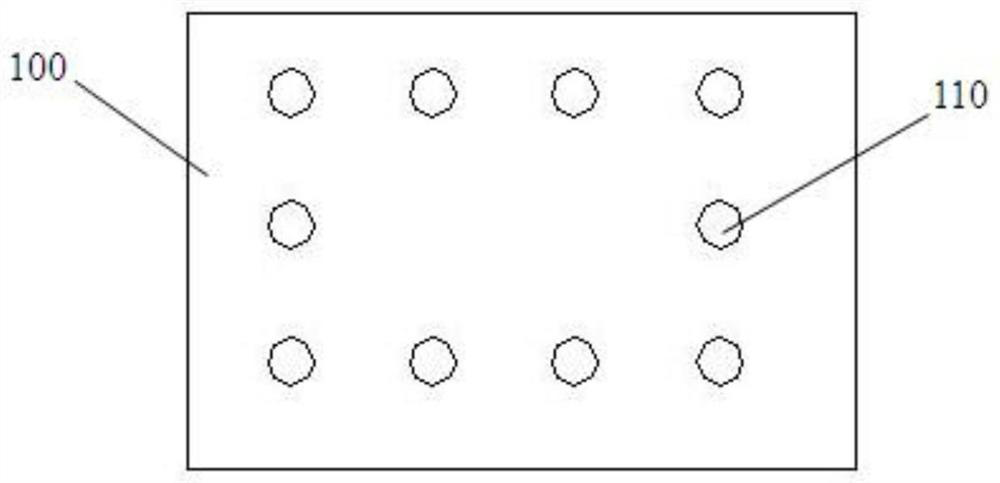

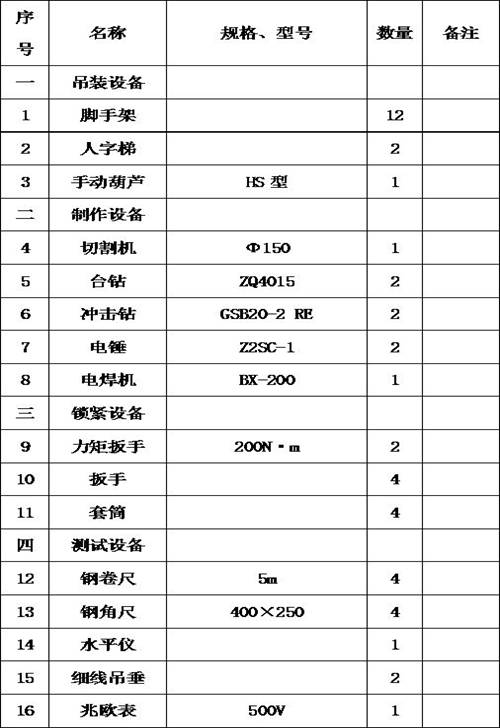

Steel structure foundation embedded bolt structure and construction method thereof

PendingCN111851754AImprove integrityFast constructionBuilding constructionsConstruction engineeringRebar

The invention discloses a steel structure foundation embedded bolt structure and a construction method thereof. The steel structure foundation embedded bolt structure comprises a positioning plate, wherein a plurality of positioning drilling holes allowing embedded parts to penetrate through are formed in the positioning plate; the embedded parts are fixedly connected on the positioning plate; a plurality of connecting steel bars are fixedly connected among the embedded parts; and the embedded parts and the connecting steel bars form an integral embedded part structure. According to the construction method, the construction manufacturing and installation of the steel structure foundation embedded bolt structure are achieved, the whole embedded part structure can be independently manufactured, the integrity is good, the processing can be carried out at any time, the construction speed is high, and the construction method cannot be limited by sites, and cannot be affected by the construction steps and the construction progress on a bearing platform. The embedded bolt structure can be quickly installed after binding with steel bars at the bottom of the bearing platform, the construction period cannot be affected, and the construction period process is favorably accelerated.

Owner:GUANGZHOU HOUSES DEV CONSTR +2

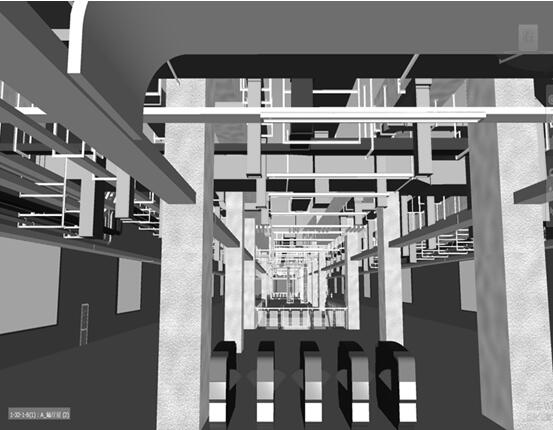

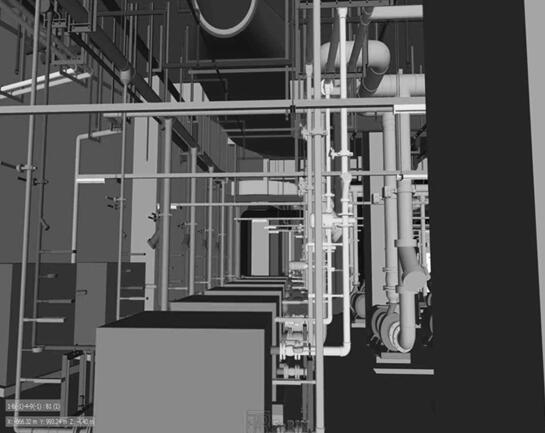

Subway environmental control machine room fabricated electromechanical construction method based on BIM technology

PendingCN112632684ALow costImprove construction qualityGeometric CADBuilding material handlingReworkLaser scanning

The invention discloses a subway environmental control machine room fabricated electromechanical construction method based on a BIM technology. The method comprises the steps of obtaining a BIM model on a 3D laser scanning site, comprehensively optimizing an electromechanical system model, performing die assembly through various professional models, completing basic model optimization and prefabricating a processing part, through a material statistics function of BIM software, generating required processing part materials and processing styles, carrying out prefabrication processing, using a robot to accurately locate parts, and using a BIM lofting robot to carry out traditional operation modes on a plurality of professional projects at the same time on site. According to the invention, the working efficiency of equipment installation and system debugging is greatly improved, the labor cost, the machine tool use cost, the material cost, the management cost and the like are reduced, the budget control capability is greatly improved, the quality is improved, the rework is greatly reduced, the engineering quality is improved, the safety is improved, problems are predicted in advance, dangerous factors are reduced, the working efficiency is greatly improved, and the disassembly and modification workload is reduced.

Owner:南通装配式建筑与智能结构研究院 +1

Modular steel bar truss floor support plate

PendingCN112814243ALow steel contentReduce the workload of demolitionFloorsHeat proofingSheet steelArchitectural engineering

The invention discloses a modular steel bar truss floor support plate. The modular steel bar truss floor support plate is characterized by comprising a prefabricated bottom plate, self-tapping screws or rivets, a galvanized steel sheet, lower chord longitudinal steel bars, upper chord longitudinal steel bars, web member wave-shaped steel bars and upper chord transverse short bars. Steel bars matched with the modular steel bar truss floor support plate are in-line single-truss steel bar trusses, the steel content is less, the bottom is flat, and putty can be directly scraped for decoration. According to the modular steel bar truss floor support plate, the cost is saved for a construction party, the purpose of fast turnover is achieved, the workload of deepening design is saved for a design party, the construction progress is accelerated for the construction party, the construction quality is better controlled, the capacity is completely released for a component production party, and therefore all parties involved in a project can obtain respective benefits.

Owner:广西装配式建筑科技有限公司

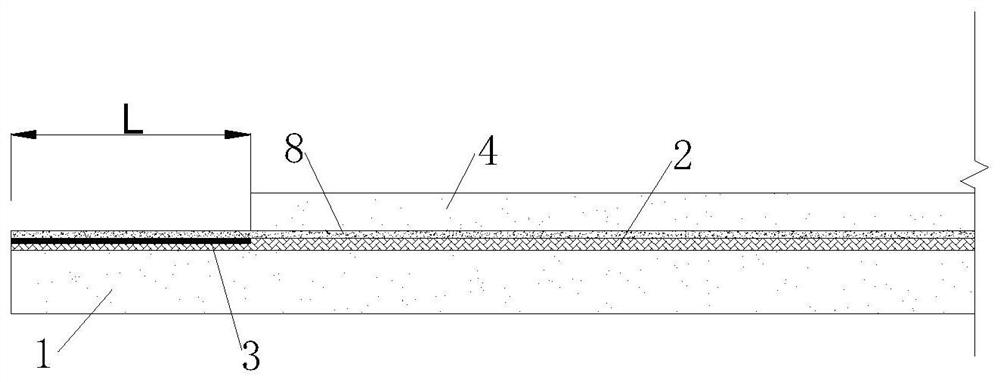

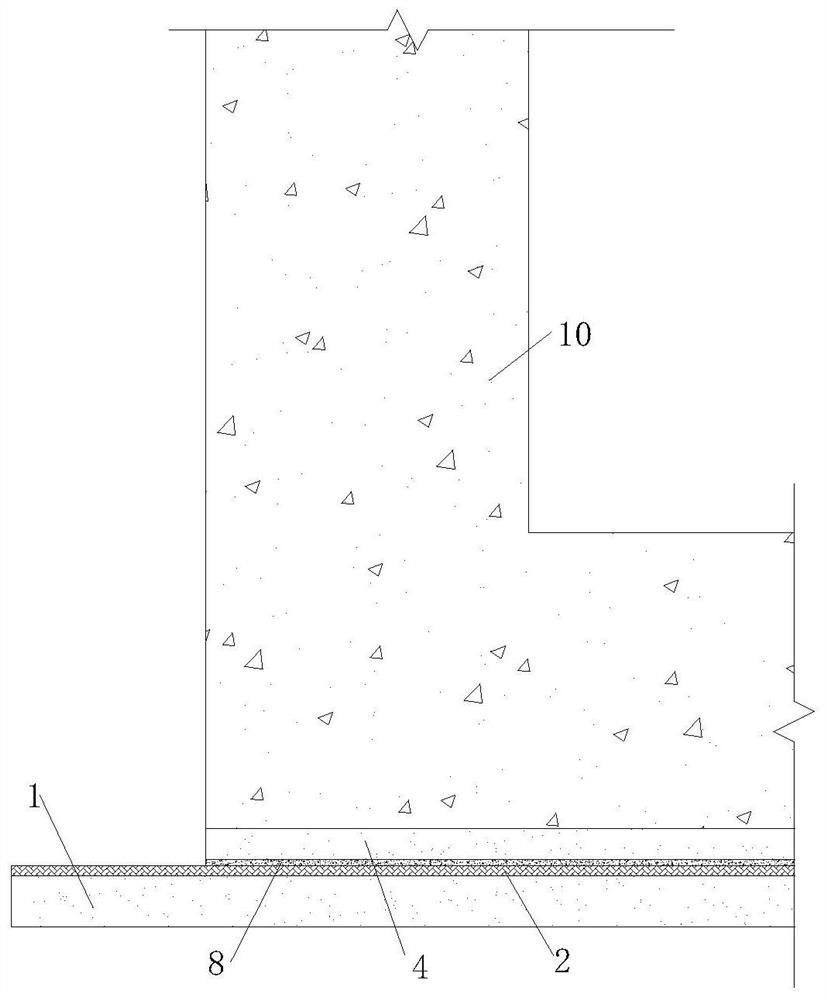

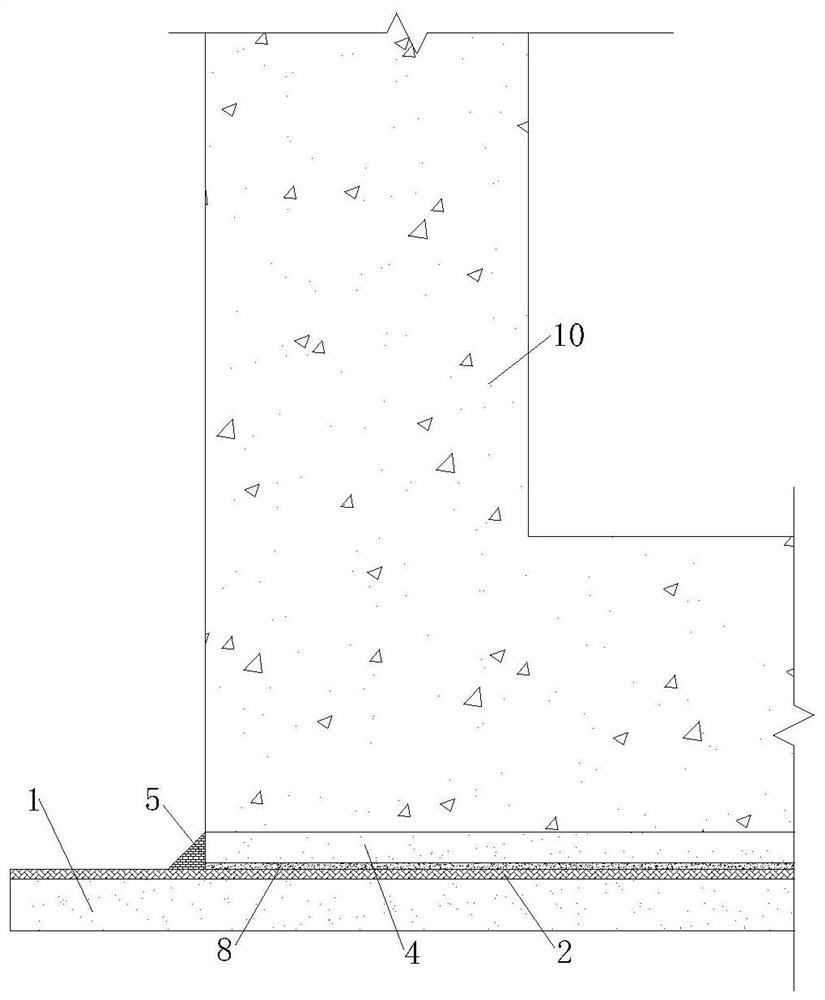

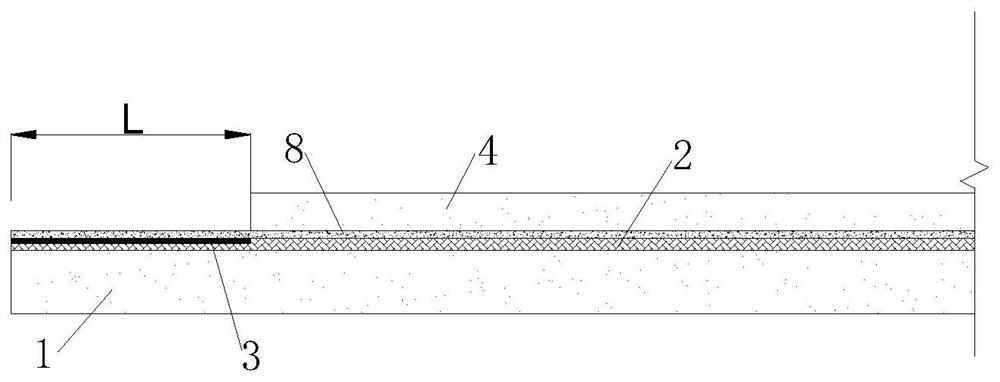

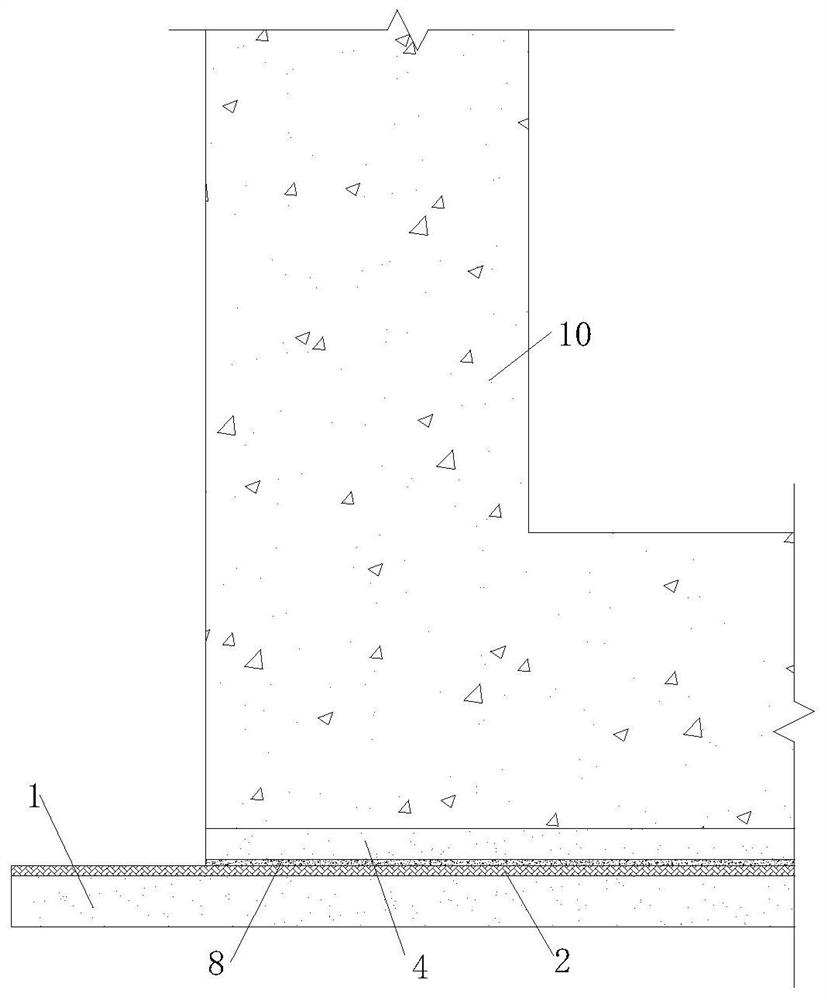

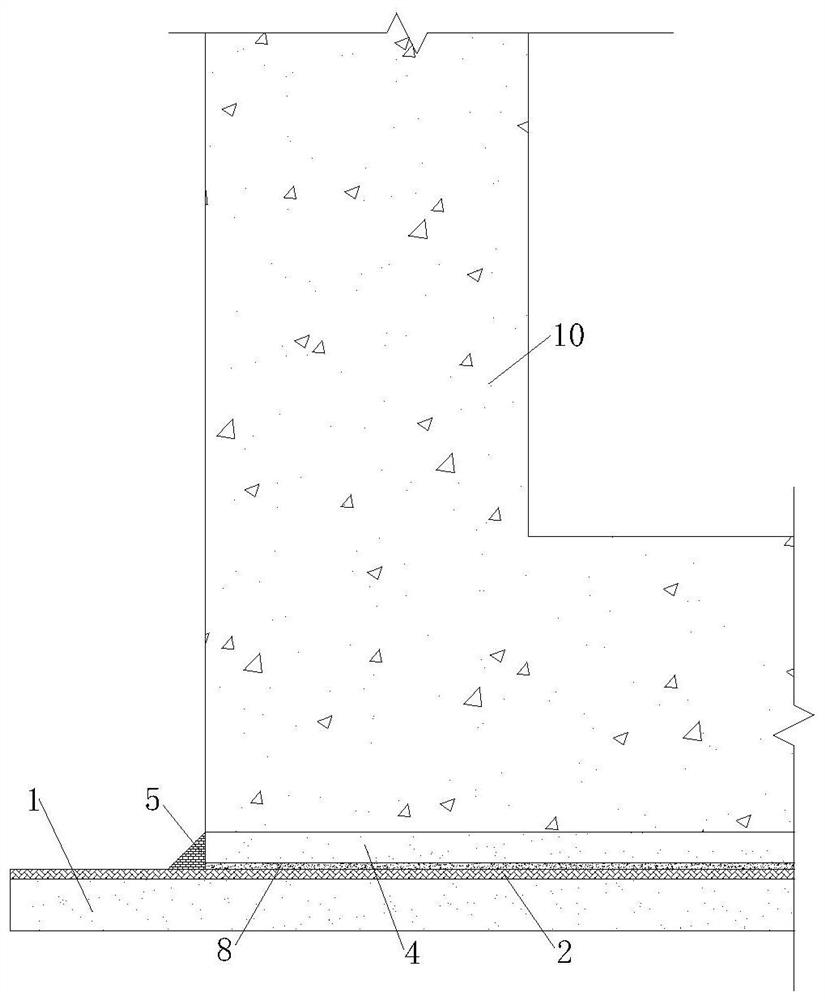

Waterproof construction method for external corner of bottom plate of urban underground comprehensive pipe gallery

ActiveCN113338335AGuaranteed waterproof qualitySimple construction methodArtificial islandsClimate change adaptationArchitectural engineeringLap joint

The invention discloses a waterproof construction method for an external corner of a bottom plate of an urban underground comprehensive pipe gallery. The waterproof construction method comprises the steps that S1, a bottom plate waterproof structure is smeared; S2, a silicone oil paper layer is laid; S3, a mortar isolation layer is smeared; S4, a bottom plate protection layer is poured, and main body construction is conducted; S5, a part of the mortar isolation layer is removed, and the chamfers are flattened; S6, an outer waterproof layer and a waterproof reinforcing layer are smeared; and S7, a waterproof protection layer on the outer side of the bottom plate is poured, and a side wall protection layer is pasted. According to the waterproof construction method, the silicone oil paper layer and the mortar isolation layer are laid between the bottom plate waterproof structure and the bottom plate protection layer, by means of the combined structure of the silicone oil paper layer and the mortar isolation layer, after bottom waterproof construction of the underground comprehensive pipe gallery base layer is completed, in the construction process of a main body structure, the bottom plate waterproof layer at the lap joint part of the bottom plate external corner is protected and is not damaged in the main body construction process, and the waterproof quality of the bottom plate external corner is ensured.

Owner:SINOHYRDO ENG BUREAU 3 CO LTD

A waterproof construction method for the outer corner of the bottom plate of an urban underground comprehensive pipe gallery

ActiveCN113338335BGuaranteed waterproof qualitySimple construction methodArtificial islandsClimate change adaptationArchitectural engineeringLap joint

The invention discloses a waterproof construction method for the outer corner of the bottom plate of an urban underground comprehensive pipe gallery. The method comprises the following steps: first, applying a waterproof structure to the bottom plate; step two, laying a silicone oil paper layer; step three, applying a mortar isolation layer; And carry out the main construction; step 5, remove part of the mortar isolation layer and smooth the chamfer; step 6, apply the outer waterproof layer and waterproof reinforcement layer; step 7, pour the outer waterproof protective layer of the bottom plate and paste the side wall protective layer. In the present invention, a silicone oil paper layer and a mortar isolation layer are laid between the bottom plate waterproof structure and the bottom plate protective layer, and the combined structure of the silicone oil paper layer and the mortar isolation layer is used to complete the bottom waterproof construction of the base of the underground comprehensive pipe gallery. Then, in the construction process of the main structure, the base plate waterproof layer at the lap joint of the base plate's outer corner is protected from damage during the main body construction process, which ensures the waterproof quality of the base plate's outer corner.

Owner:SINOHYRDO ENG BUREAU 3 CO LTD

A kind of anti-floating anchor construction method

ActiveCN109183857BSynchronous maintenanceSpeed up the scheduleProtective foundationArchitectural engineeringSoil cement

Owner:浙江坤德创新岩土工程有限公司

Construction Method of Secondary Lining Structure of Long-span and Ultra-thick Tunnel

ActiveCN109854277BSolve difficultySolve the dangerUnderground chambersTunnel liningSupporting systemArchitectural engineering

The invention relates to a construction method for a large-span and ultra-thick tunnel secondary lining structure, comprising the following steps: dividing the tunnel secondary lining structure to be constructed into a first section, a second section and a third section; In subsections, a support system is set on the invert of the tunnel to support the first formwork, and the first side wall structure is formed by pouring; in the second subsection, the support system is heightened to support the second formwork, and poured to form a structure similar to that of the first side wall. The second side wall structure connected with the side wall structure; in the third construction section, a top bracing system is set on the invert of the tunnel, and the top bracing system is connected with the top bracing of the second side wall structure, and the first side wall structure is supported by the top bracing system. Three formworks were poured to form the top arch structure connected with the second side wall structure, thus completing the construction of the second lining structure of the tunnel. The invention adopts step-by-step flow operation and different formwork support systems, which solves the problems of difficulty and high risk in the overall construction of the large-span and super-thick secondary lining structure, and speeds up the progress of the construction period.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

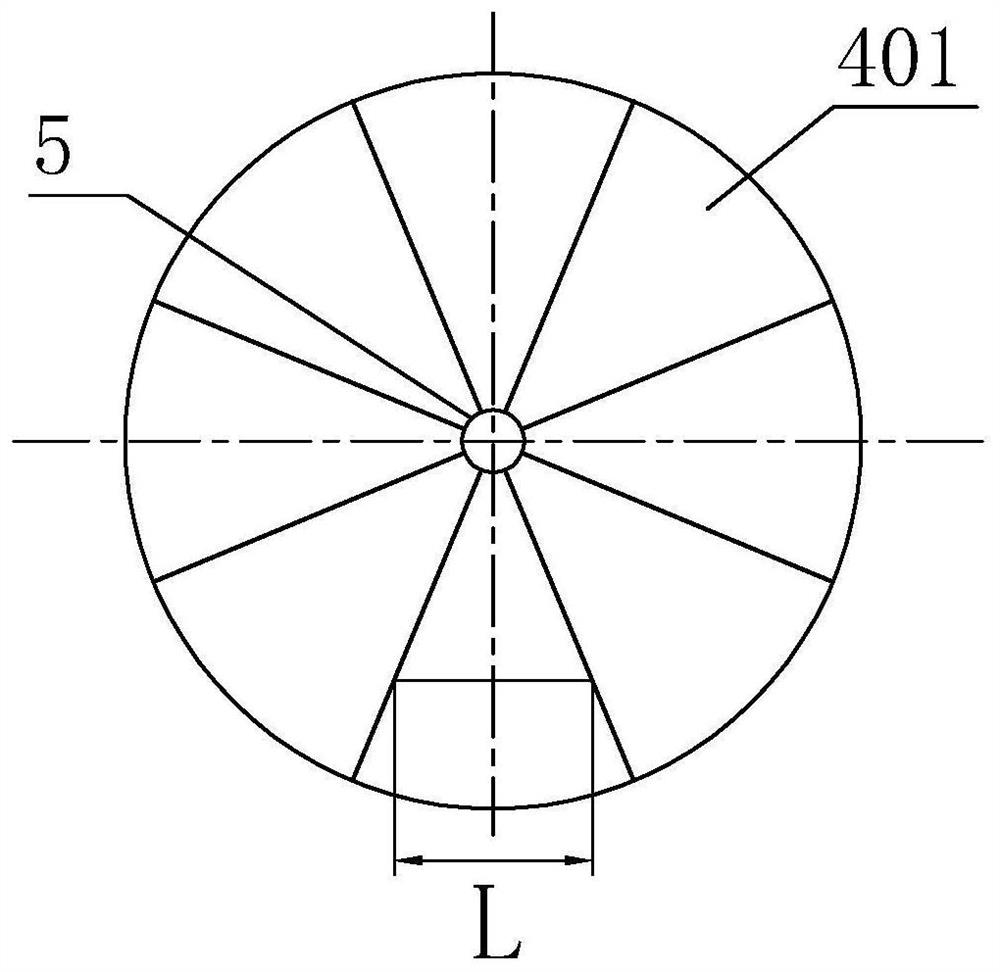

Ellipse head lining manufacturing process

The invention relates to a manufacturing process of an inner liner with an oval seal head, which comprises the following steps: S1, manufacturing an inner liner cover, which includes S11, marking theinner surface of the seal head into N equal parts, S12, drawing an outer edge trace line of the inner liner cover on the inner surface of the seal head, S13, measuring the arc size and the width sideL of the marked dividing area, S14, making one piece of watermelon petal inner liner cover sample, S15, making the remaining N-1 piece of watermelon petals inner liner cover samples, and S16, assemblywelding N pieces equal divided watermelon petal inner liner cover samples; S2, manufacturing an inner liner cone; S3, manufacturing an inner liner cylinder body and S4, assembling an oval seal head inner liner. The manufacturing process of the inner liner with an oval seal head adopts the rolling and forming of the plate bending machine, is not limited by the size of the diameter of the seal head, is convenient to manufacture, accelerates the construction period, saves the cost and has high assembly precision; the inner liner of the oval seal head has an anti-wear effect on a pressure container, and effectively prolongs the service life of the pressure container.

Owner:LIUZHOU ELEVEN METALLURGICAL MACHINERY MFG

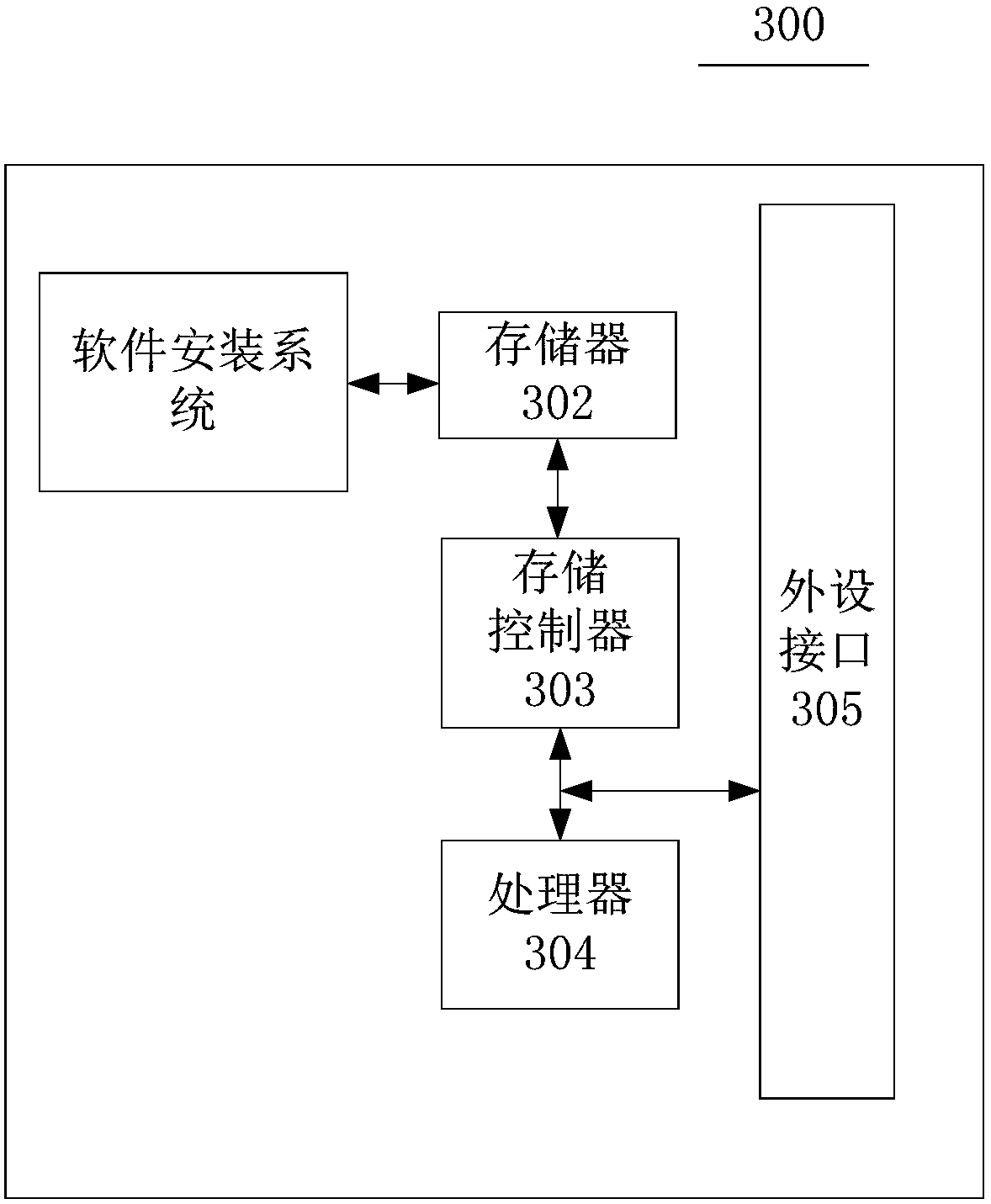

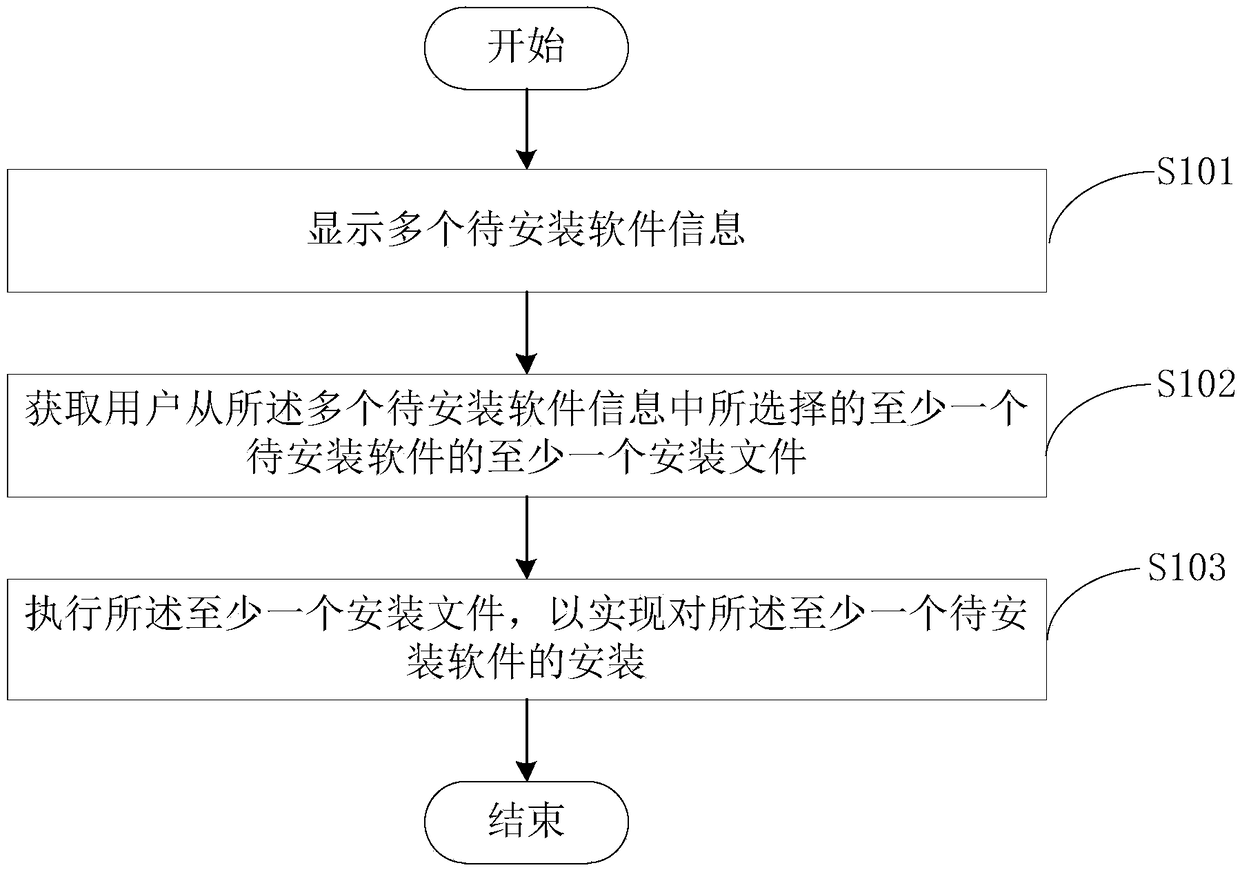

An software installation method and system

InactiveCN109408068AAchieve installationSpeed up the scheduleSoftware deploymentSoftware engineeringSoftware

The embodiment of the invention provides a software installation method and system, belonging to the computer technical field. The method comprises the following steps of: displaying a plurality of software information to be installed; acquiring at least one installation file of at least one software to be installed selected by a user from the plurality of software to be installed information; executing at least one installation file to realize installation of the at least one to-be-installed software. Through displaying a plurality of software information to be installed, the user selects from the plurality of software information to be installed, thereby acquiring at least one installation file of at least one software to be installed selected by the user, and finally the at least one installation file is executed to realize the installation of the at least one software to be installed. Further, at least one software to be installed can be installed at one time by that user, and theuser can install multiple softwares and the time progress of the installation is accelerated.

Underground backfill material suitable for karst regions and preparation method thereof

InactiveCN111574180ASolve the subsidence problemImprove thermal conductivityCeramicwareSoil scienceAdhesive

The invention discloses an underground backfill material suitable for karst regions and a preparation method of the underground backfill material. The underground backfill material comprises the following raw materials in percentage by mass: 80%-90% of a base material, 10%-20% of a water permeable material, 1%-5% of an adhesive and 1%-5% of a retarder, wherein the adhesive is sodium silicate. Thebackfill material mainly solves the problem that underground water is difficult to treat in karst regions, can overcome the problem that a conventional backfill material sinks and can be effectively improved tin heat conduction effect through the water absorption and release effects of external special materials; the selected backfill material in the invention enables shallow low-temperature energy to be effectively utilized and stored; in addition, the backfill material enables an early-stage drilling disposal rate to be greatly reduced, project progress to be accelerated and late-stage maintenance cost to be low, and therefore, the utilization and popularization strength of shallow geothermal energy is improved.

Owner:GUIZHOU UNIV

The construction method of pattern tiling on the roof of the Venerable Master

ActiveCN106948553BAvoid too many situationsFine grid methodRoof covering using slabs/sheetsRoof covering insulationsSocial benefitsBrick

The invention discloses a pattern brick sticking construction method for an accessible roof. The pattern brick sticking construction method for the accessible roof comprises: base layer cleanup, insulating layer laying, slope making layer construction, cement mortar leveling layer construction, waterproof layer construction, protective layer construction, grille screen electronic map drawing, roof field lofting, and face brick laying. Compared with a fixed-point lofting brick-sticking roof of a common total station, the pattern brick sticking construction method for the accessible roof has the advantages that a grille screen method is refined, so a brick sticking worker can cut each brick visibly, the situation of more scraps during cutting is avoided, the brick sticking efficiency is improved, and the brick sticking loss is reduced. The project progress is accelerated while the construction procedure is simplified; meanwhile, construction waste is reduced, environment protection is facilitated, and social benefits are better.

Owner:启东建筑集团有限公司

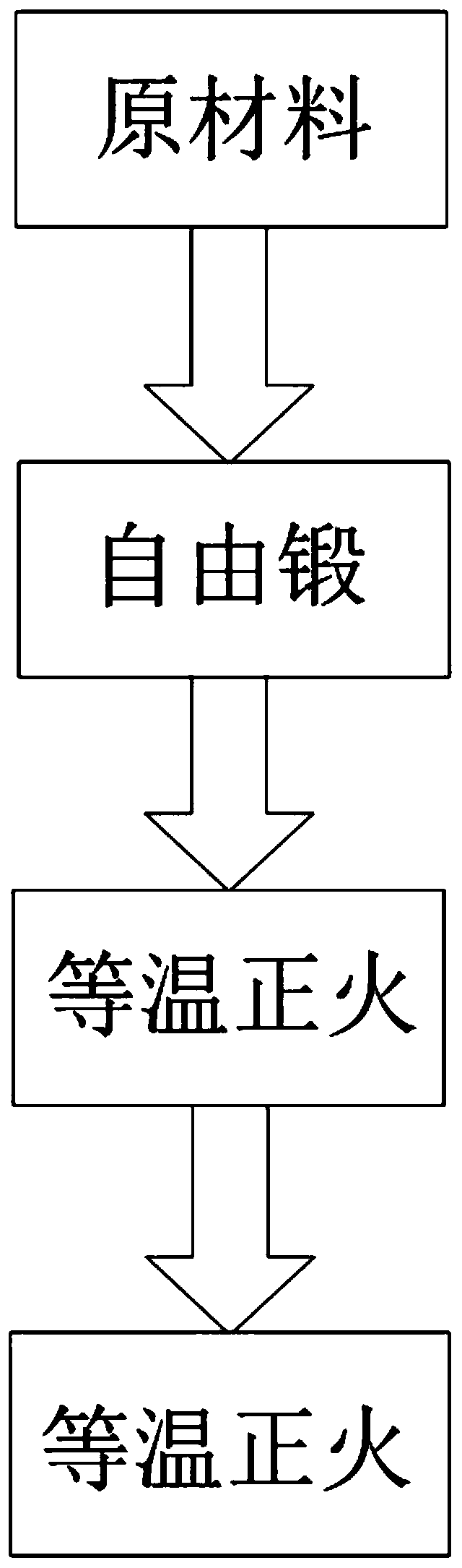

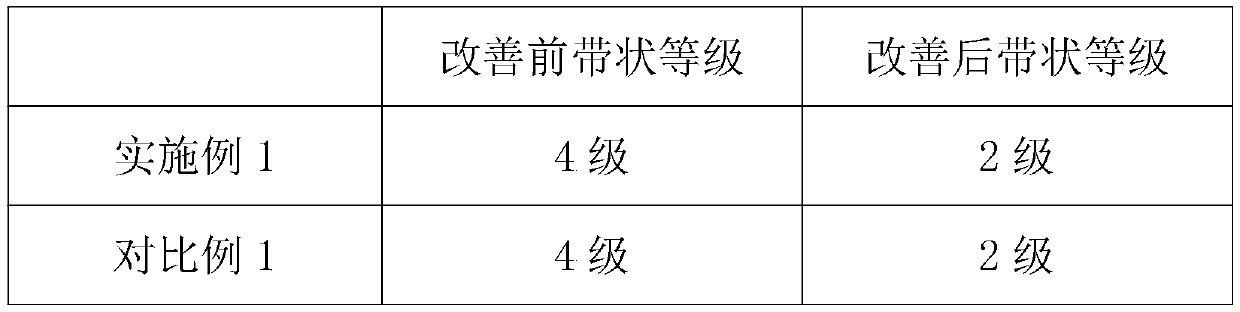

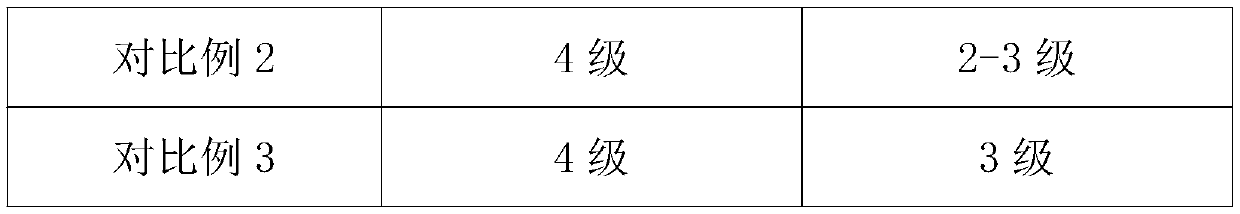

A method for improving the ribbon structure of flexspline raw material

ActiveCN108998643BLow costSpeed up the scheduleFurnace typesHeating/cooling devicesHeat conservationHeating furnace

The invention relates to the field of harmonic reducers and particularly relates to a method for improving banded structures of raw materials of flexible wheels. The method is used for improving materials with severe banded structures in the raw materials of flexible wheels through processes of free forging, primary isothermal normalizing and secondary isothermal normalizing. The method specifically comprises the following steps: a, screening the materials with severe banded structures; b, heating the screened materials; c, freely forging the materials; d, putting the materials into a heatingfurnace, heating for a first time and keeping temperature; e, cooling the furnace to 650 DEG C and keeping the temperature; f, taking the materials out and cooling the materials to normal temperaturein the air; g, putting the materials into the heating furnace and heating for a second time; h, cooling the furnace to 650 DEG C and keeping the temperature; and I, taking the materials out and cooling the materials to normal temperature in the air. Through the method, the banded structures are improved; the time progress is accelerated; the time waste caused by returning materials and replacing goods is avoided; the processes of free forging and isothermal normalizing are low in costs; compared with a process of diffusion annealing, the processing cost is greatly reduced.

Owner:东莞市国森科精密工业有限公司

Fabricated formwork-removal-free prefabricated floor bottom plate structure

PendingCN114809407AReduce construction support costsSpeed up the scheduleFloorsStructural systemRebar

The invention discloses an assembly type formwork-removal-free prefabricated floor bottom plate structure. The structure is formed by combining a formwork-removal-free prefabricated bottom plate, longitudinal steel bars, C-shaped light steel, longitudinal stiffening ribs, transverse stiffening ribs and galvanized iron sheet hanging rings. The structural system is light in weight and very convenient to transport, hoist and assemble; according to the structure, the content of concrete is not increased, the content of steel bars is not increased, the cost is saved for a construction party, the aim of fast period is achieved, the workload of deepening design is saved for a design party, the construction progress is accelerated for the construction party, the construction quality is better controlled, and the productivity is completely released for a component producer; therefore, all parties participating in the project obtain respective benefits.

Owner:广西装配式建筑科技有限公司

Corbel at the lower end of the inclined inner brace of the foundation pit support structure, manufacturing tools and construction method

Owner:ZHEJIANG WANHUA CONSTR

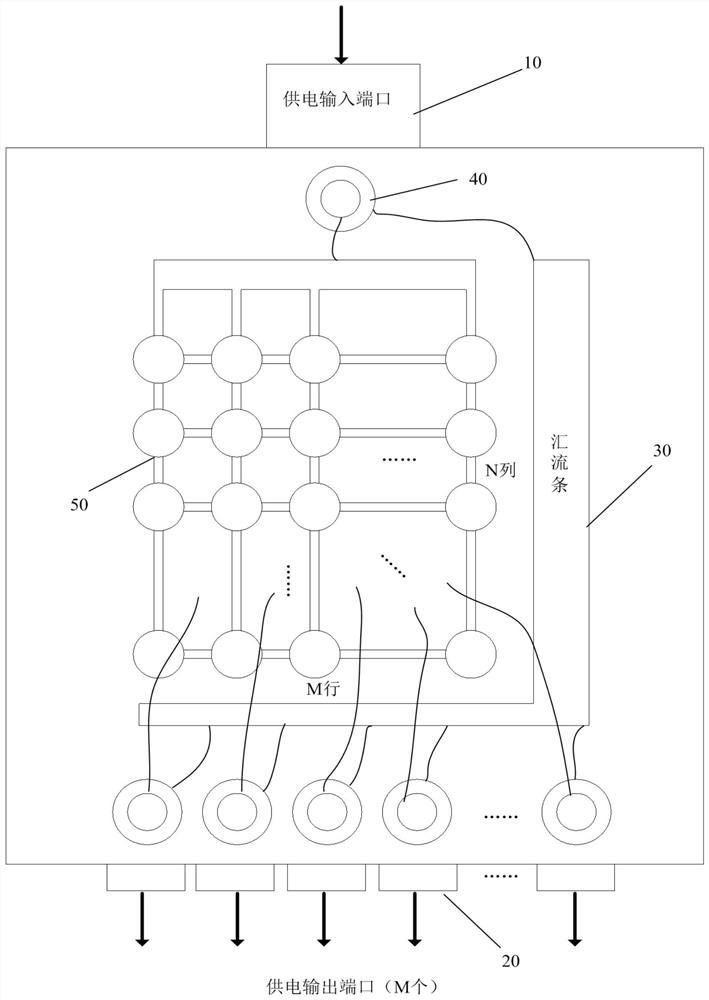

Unmanned aerial vehicle-mounted universal electrical adapter device, task system and unmanned aerial vehicle

PendingCN114759762AReduce the cost of power supply adaptation and modificationAchieve reorganizationAircraft componentsPower conversion systemsControl engineeringUncrewed vehicle

The invention provides an unmanned aerial vehicle-mounted universal electrical adapter device, a task system and an unmanned aerial vehicle, and the device comprises a power supply input port which is connected with an unmanned aerial vehicle power supply system; the power supply output port is connected with the unmanned aerial vehicle load equipment; the power supply input port, the current-carrying controller, the node current unit array, the power supply output port and the bus bar are connected in sequence, the current-carrying controller is arranged between the power supply input port and the node current unit array, and the node current unit array is arranged between the current-carrying controller and the node current unit array. The node current unit array comprises a plurality of node current units which are sequentially arranged in parallel, and the current-carrying controller is used for selecting a set number of node current units from the plurality of node current units according to the electric quantity required by the unmanned aerial vehicle load equipment for connection operation. According to the technical scheme, the technical problems that in the prior art, the safety risk of the whole machine is increased and the cost is increased due to the fact that loading equipment is reloaded on an unmanned aerial vehicle task system are solved.

Owner:HIWING AVIATION GENERAL EQUIP

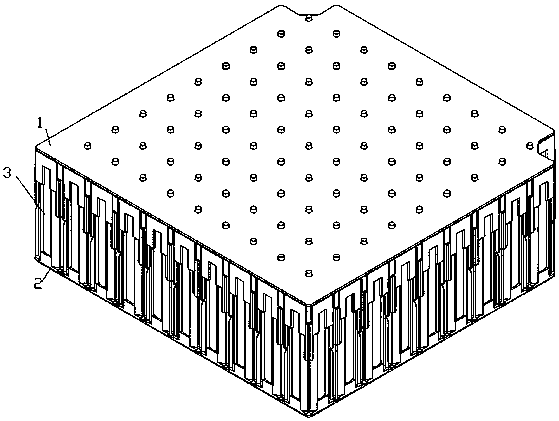

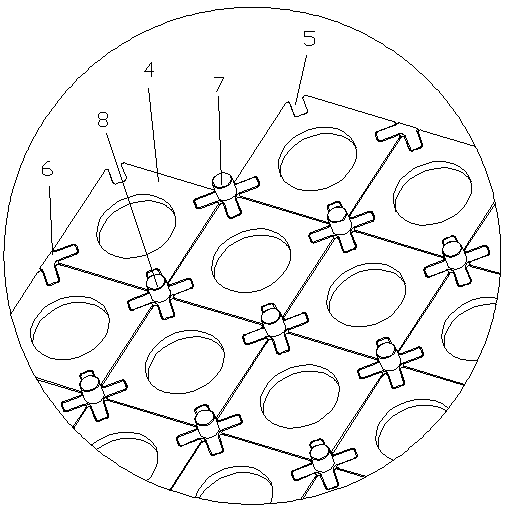

Battery module structure and assembly method

PendingCN111430624ASpeed up the scheduleReduce wasteCell component detailsEngineeringStructural engineering

The invention relates to a battery module structure and an assembly method. The battery module structuredevice comprises an upper cover plate, a lower cover plate and a module., th The module comprises a plurality of single modules which are regularly arranged between an the upper cover plate and a the lower cover plate, each single module comprises a bracket support and a battery cell mounted inthe bracketsupport; the upper and lower end faces of the support abut against the upper cover plate and the lower cover plate respectively. Limiting fixing grooves are formed in the four corners of the upper end face of the support. Every two adjacent single modules located on the outer side edge of the module are connected through a side edge connecting piece. Three adjacent single modules located at the corners of the outer side edges of the module are connected through corner connecting pieces. Four adjacent single modules in the module are connected through an inner connecting piece; according to the design, a. A modular structure is adopted, the composition form of the module, standardized battery monomer blocks and accessories of the standardized battery monomer blocks can be flexibly configured, the design period can be shortened, the project time schedule can be accelerated, the cost can be greatly reduced, the interchangeability of stiff parts between projects can be enhanced,and unnecessary waste of the parts can be reduced.

Owner:福建飞毛腿动力科技有限公司

A multi-layer functional anti-corrosion concrete structure and its connection method

InactiveCN104818883BSatisfy the requirements of anti-corrosion damageIncreased durabilityArtificial islandsTowersSurface layerRebar

The invention provides multi-layer functional corrosion-resistant concrete. The multi-layer functional corrosion-resistant concrete comprises a core concrete structure, a core steel structure, connectors with steel sleeves, welded steel fabric and a surface layer concrete structure. The core steel structure is arranged inside the core concrete structure, the welded steel fabric is arranged inside the surface layer concrete structure, and the core steel structure is connected with the welded steel fabric through the connectors with the steel sleeves. The invention further relates to a mechanical connecting method of the multi-layer functional corrosion-resistant concrete. The core steel structure and the welded steel fabric structure on the surface layer are connected through the connectors, the steel sleeves and deformed steel bars. According to the invention, the requirement for the service strength of marine facilities can be met, the high corrosion resistance is achieved, and therefore oceanic building concrete can have the longer service life. The multi-layer functional corrosion-resistant concrete and the mechanical connecting method of the multi-layer functional corrosion-resistant concrete have the advantages of being high in practicability and functionality.

Owner:盐城市同力新型建材有限公司 +1

Cable-membrane connection structure and construction method for anti-unlocking of large opening cable dome structure

ActiveCN111794432BAvoid unlocking effectsImprove securityBuilding roofsBuilding material handlingClassical mechanicsMechanical engineering

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

Integral Lifting Method and System for Asymmetric Inner Ring Truss and Cable Dome

ActiveCN111719757BControl offsetAvoid collisionBuilding roofsBuilding material handlingStructural engineeringControl theory

The invention relates to a method and system for integral lifting of an asymmetric inner ring truss and a cable dome. The method includes: assembling the inner ring truss and the cable dome, connecting the cable dome and the inner ring truss; The positions to be installed of the trusses are arranged at intervals and fixed on the ground, and multiple lifting frames are connected to each other; multiple lifters are fixed on the top of the corresponding lifting frames, and multiple lifters are connected to the inner ring truss correspondingly; multiple The tractor is fixed on the top of the corresponding lifting frame, and multiple tractors are connected to the cable dome correspondingly; multiple lifters are used to lift the inner ring truss horizontally upwards, and multiple tractors are used to tension the inner ring truss during the process of lifting the inner ring truss The cable dome is radially pulled by the tractor, so that the horizontal force is applied to the inner ring truss through the cable dome to control the horizontal displacement of the inner ring truss; alternately lift the inner ring truss and tension the cable dome until the inner ring truss reaches the design elevation .

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com