Fabricated formwork-removal-free prefabricated floor bottom plate structure

A formwork-free and assembled technology, which is applied in the direction of floors, building components, building structures, etc., can solve the problem of increased consumption of steel bars and concrete materials, low enthusiasm for the application of prefabricated floor slabs, inconvenient transportation, hoisting, and assembly, etc. problems, to achieve the effect of reducing construction support costs, speeding up project progress, and reducing the workload of steel bar binding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

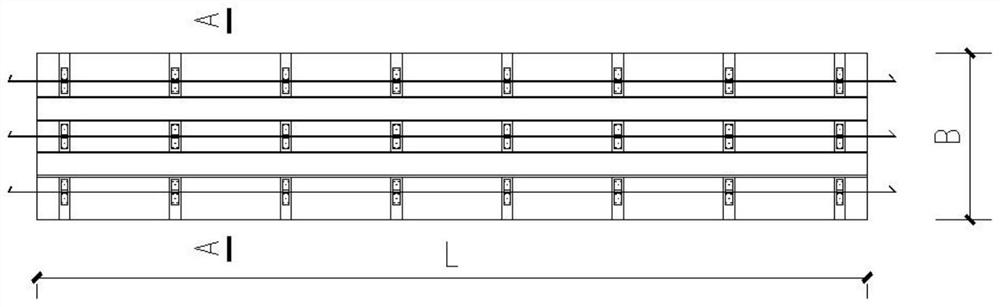

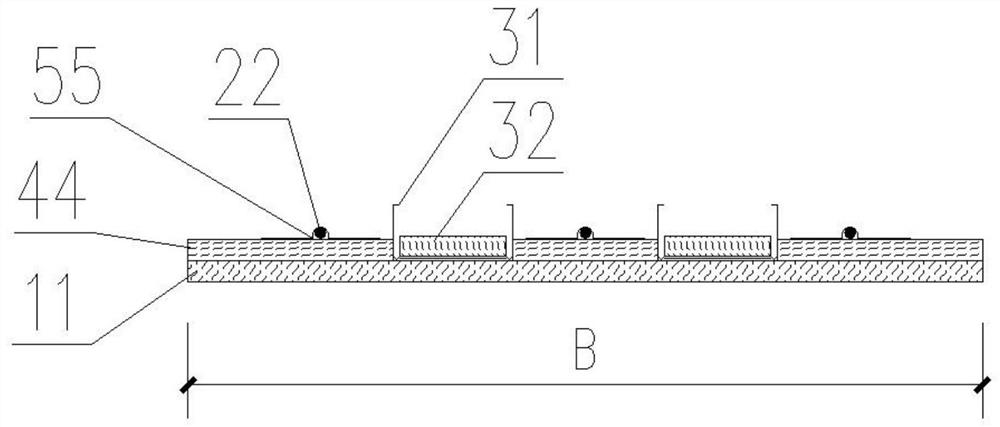

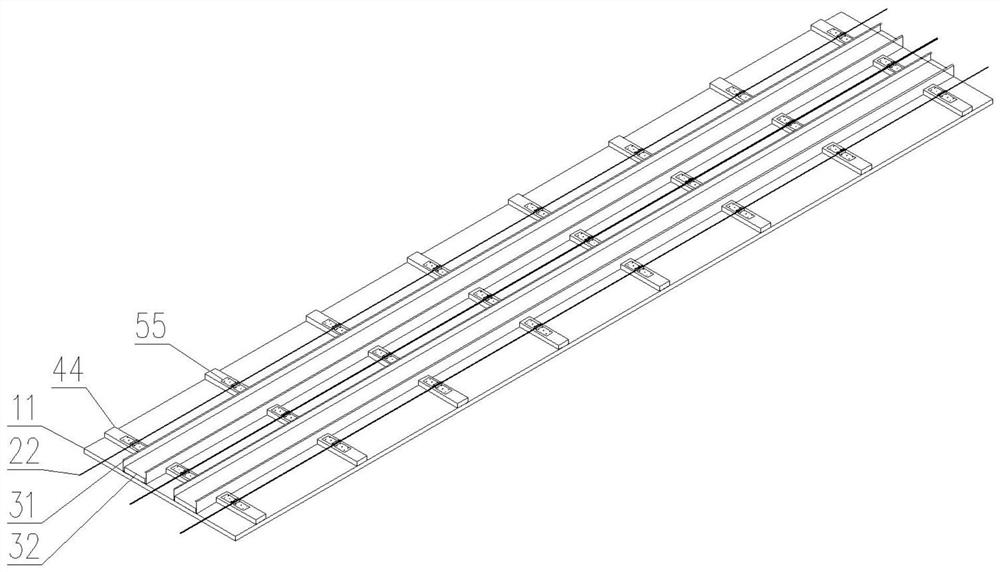

[0027] The components of the present invention include a formwork-free prefabricated bottom plate 11 , longitudinal reinforcing bars 22 , C-shaped light steel 31 , longitudinal stiffening ribs 32 , transverse stiffening ribs 44 and galvanized iron sheet lifting rings 55 .

[0028] The present invention will be described in further detail below with reference to the accompanying drawings.

[0029] 1. Use two prefabricated base plates produced by Magnesium Construction Technology (Chongqing) Co., Ltd. that meet the requirements of Class A fire protection, one large board with the size of 3000×1200×16mm, and the other large board with the size of 3000×1200×15mm .

[0030] 2. Cut the 16mm thick board into two pieces from the middle, the size is 3000×600×16mm, one is used as the prefabricated bottom plate 11, and the other is cut into two slats with the size of 3000×80×16mm, as longitudinal reinforcement Rib 32.

[0031] 3. Cut the 15mm thick plate into several pieces with dimens...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com