One-truss steel bar floor support plate with disassembly-free bottom form

A technology of reinforced floor deck and truss, which is applied to floors, building components, buildings, etc., can solve problems such as large steel content, high cost, and influence on application and promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

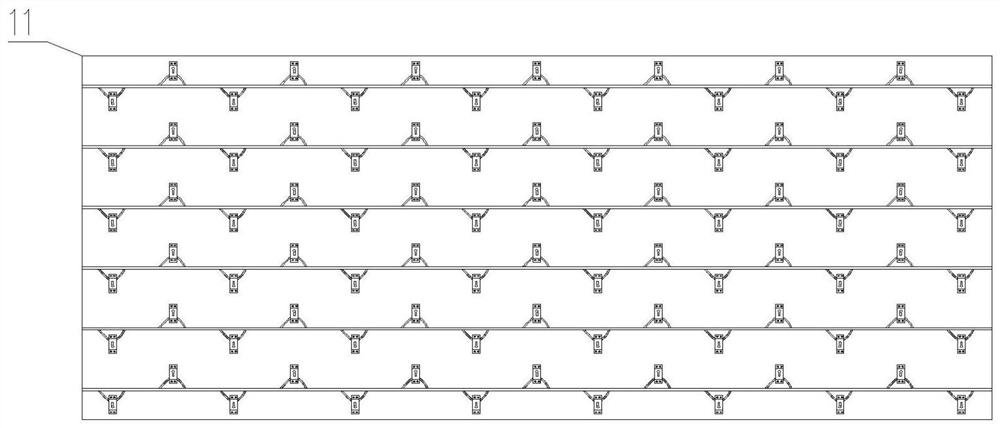

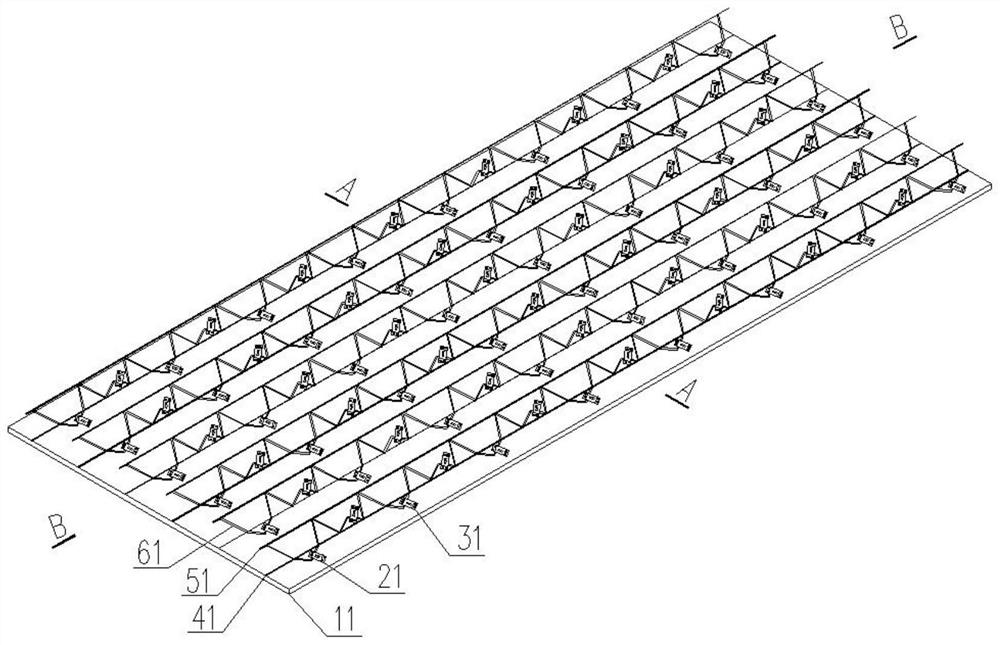

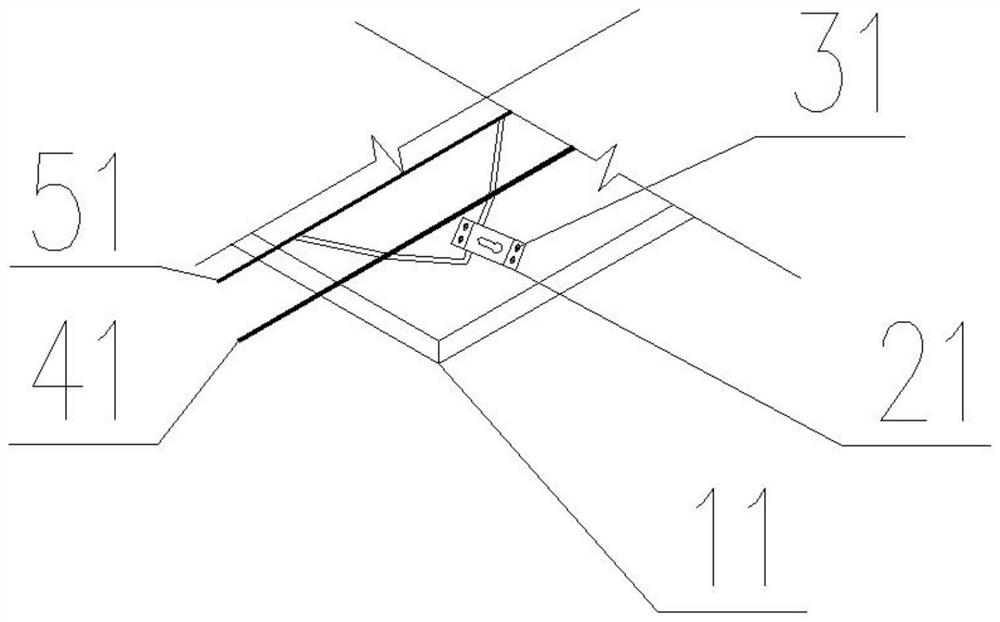

[0034] The member of the present invention consists of a non-demolition-free bottom formwork 11, a few-shaped profile connector 21, self-tapping screws 31, a lower chord longitudinal reinforcement 41 in a truss reinforcement structure, an upper chord longitudinal reinforcement 51, and a web bar wave-shaped reinforcement 61 with bent feet. .

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0036] 1. Use a piece of fiber cement board produced by Magnesium Construction Technology (Chongqing) Co., Ltd. that meets the requirements of Class A fire protection as the bottom-free formwork, with a size of 3000×1200×12mm.

[0037] 2. Use a 12mm-thick board as the non-demolition-free bottom template 11, and roughen the board surface to form a concave-convex surface to enhance the bonding force with the concrete.

[0038] 3. Produce and manufacture several character profile connectors 21 with professional equipment, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com