Manufacturing method of high-strength galvanized steel sheet

A galvanized steel sheet, high-strength technology, applied in cells, electrolytic components, electrolytic processes, etc., can solve the problems of difficult synthesis of combined galvanized steel sheets, environmental pollution by heavy metal pollutants, etc., to avoid heavy metal poisoning, low steel content, and high strength. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

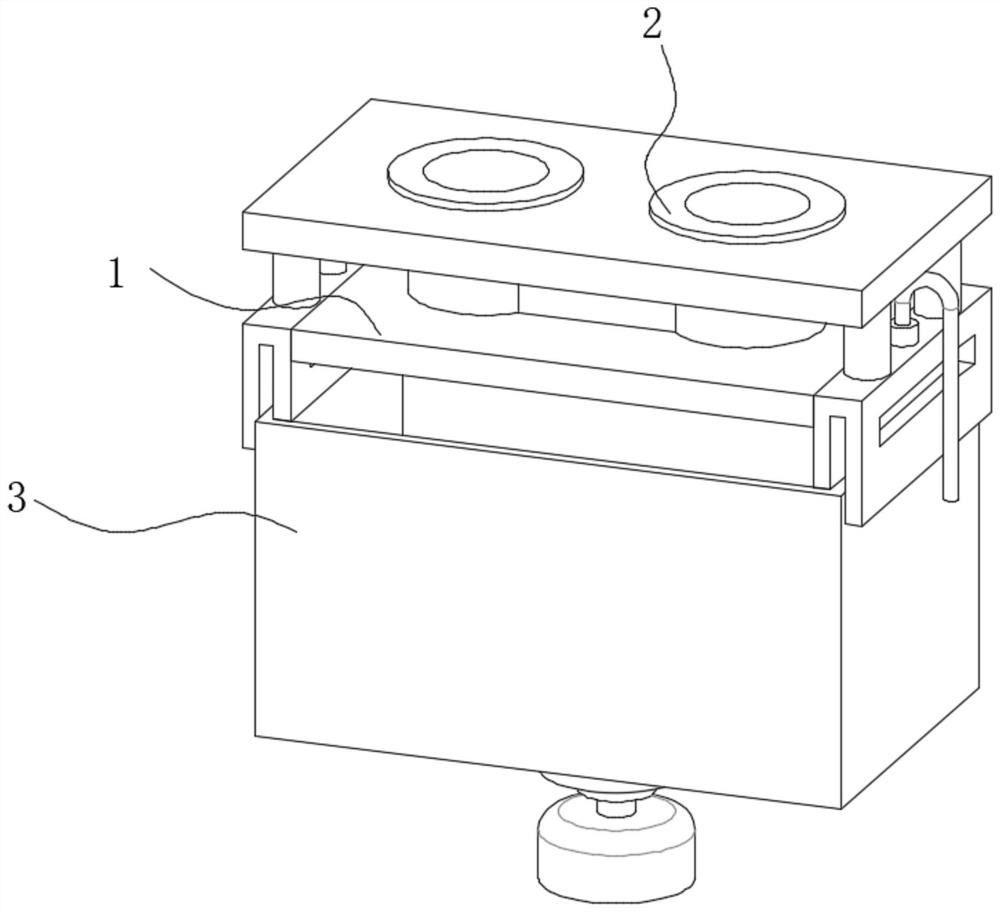

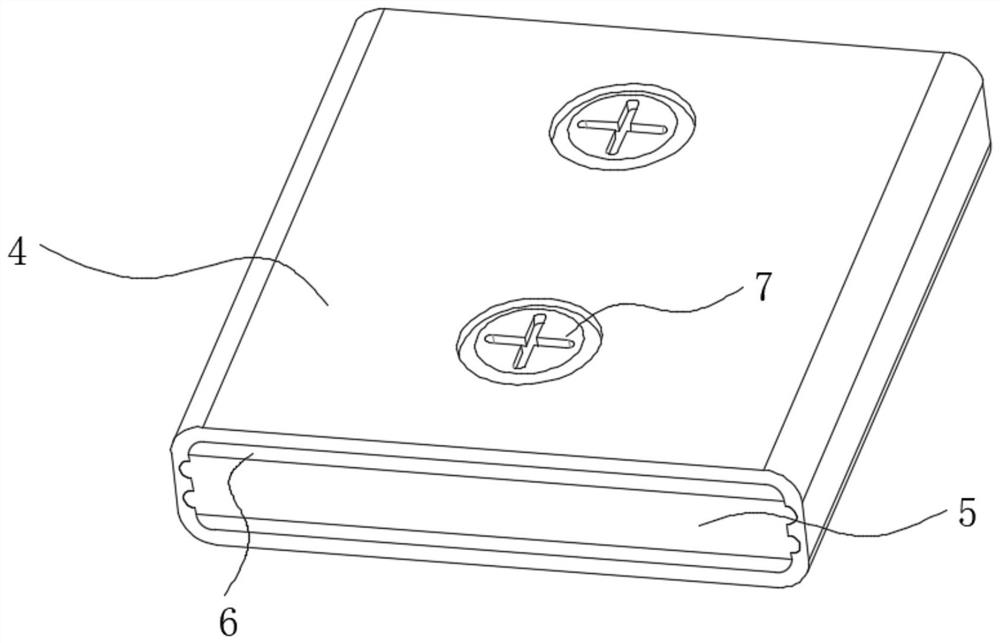

[0032] use Figure 1-Figure 7 A method for producing a high-strength galvanized steel sheet according to an embodiment of the present invention will be described below.

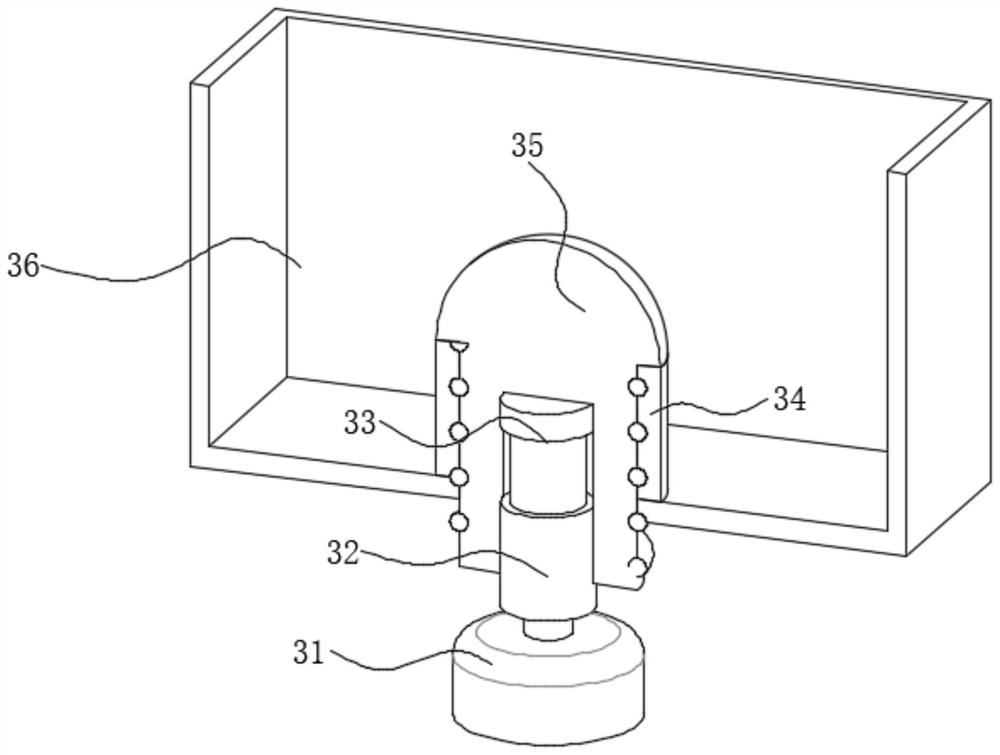

[0033] like Figure 1-Figure 7 As shown, a high-strength galvanized steel sheet manufacturing device according to the present invention includes a galvanizing device 3, and adjustment devices 1 are slidably connected to the left and right sides of the upper part of the outer surface of the galvanizing device 3, and the lower part of the inner wall of the adjustment device 1 is provided with There are pressure devices 2.

[0034] The galvanizing device 3 includes an electrolytic cell 36, the middle part of the lower part of the inner wall of the electrolytic cell 36 is provided with a through-turn opening, the lower part of the inner wall of the electrolytic cell 36 is fixedly connected with a vertical guide shell 34 through the through-turn opening, and the inner wall of the vertical guide shell 34 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com