Iron casting polishing device

A technology for cast iron castings and grinding wheels, which is used in grinding drive devices, grinding/polishing safety devices, grinding machines, etc., can solve the problems of poor grinding quality, low grinding efficiency, damage to cast iron castings, etc. Efficiency and quality, improving the effect of effective buffering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

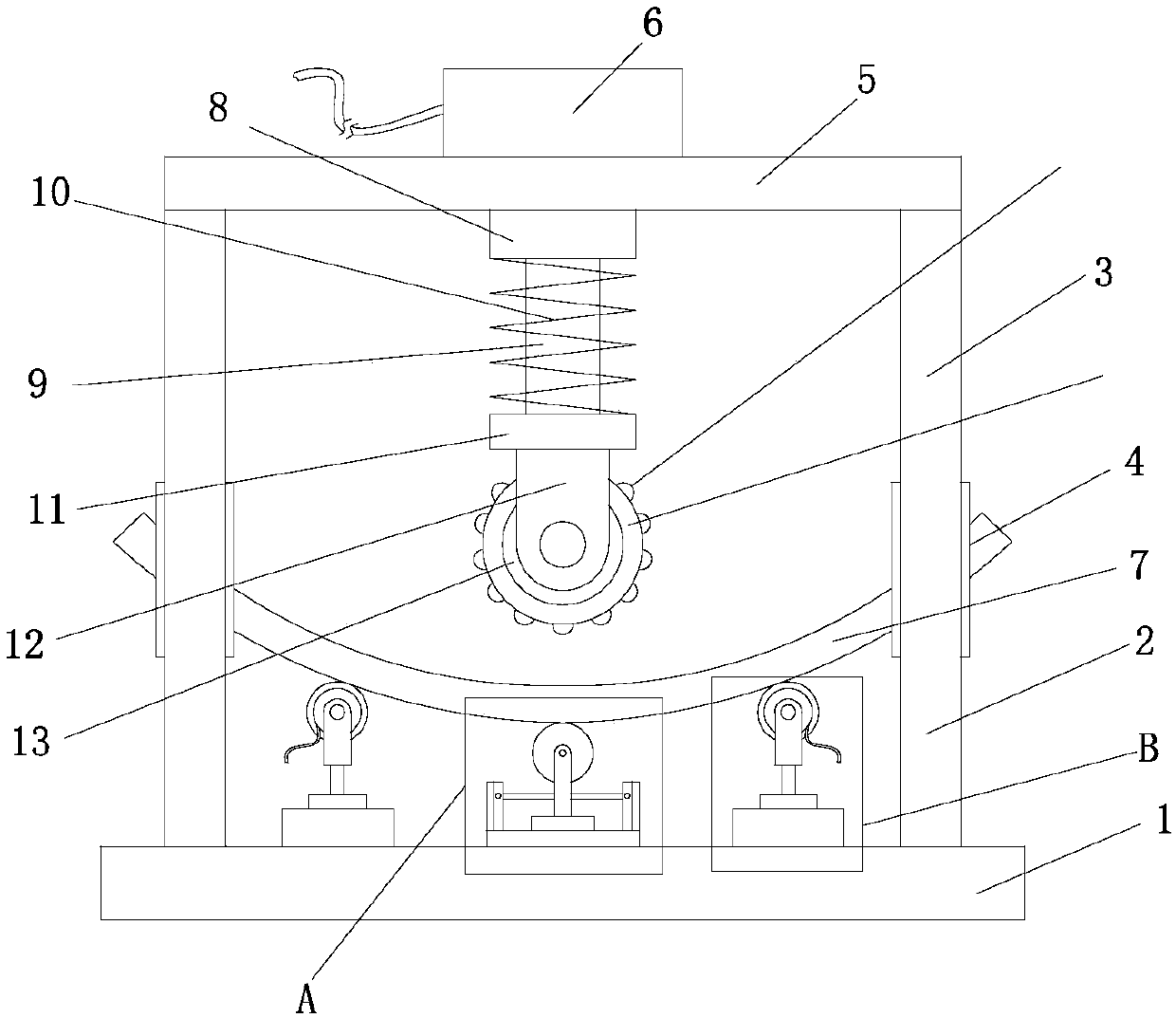

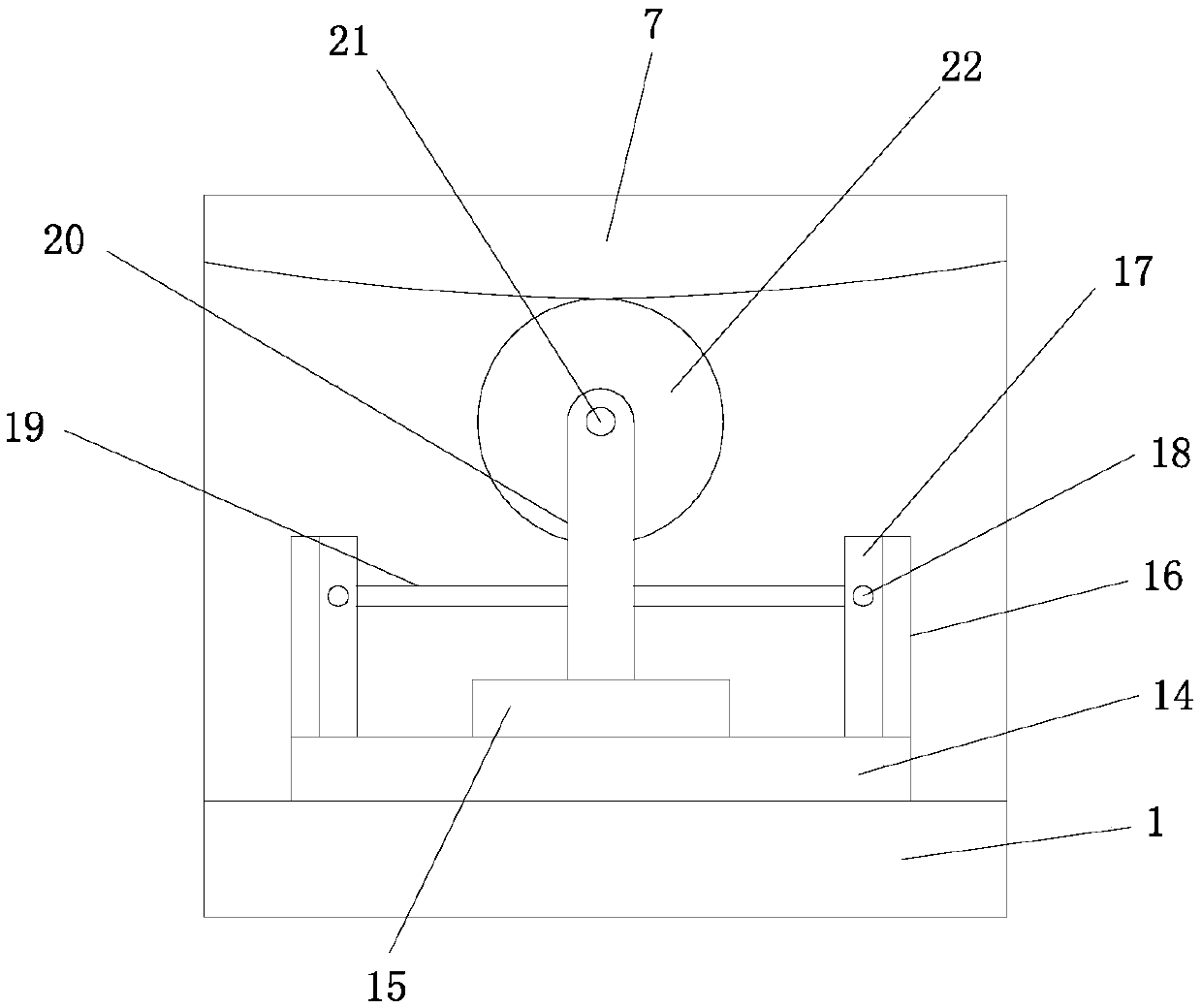

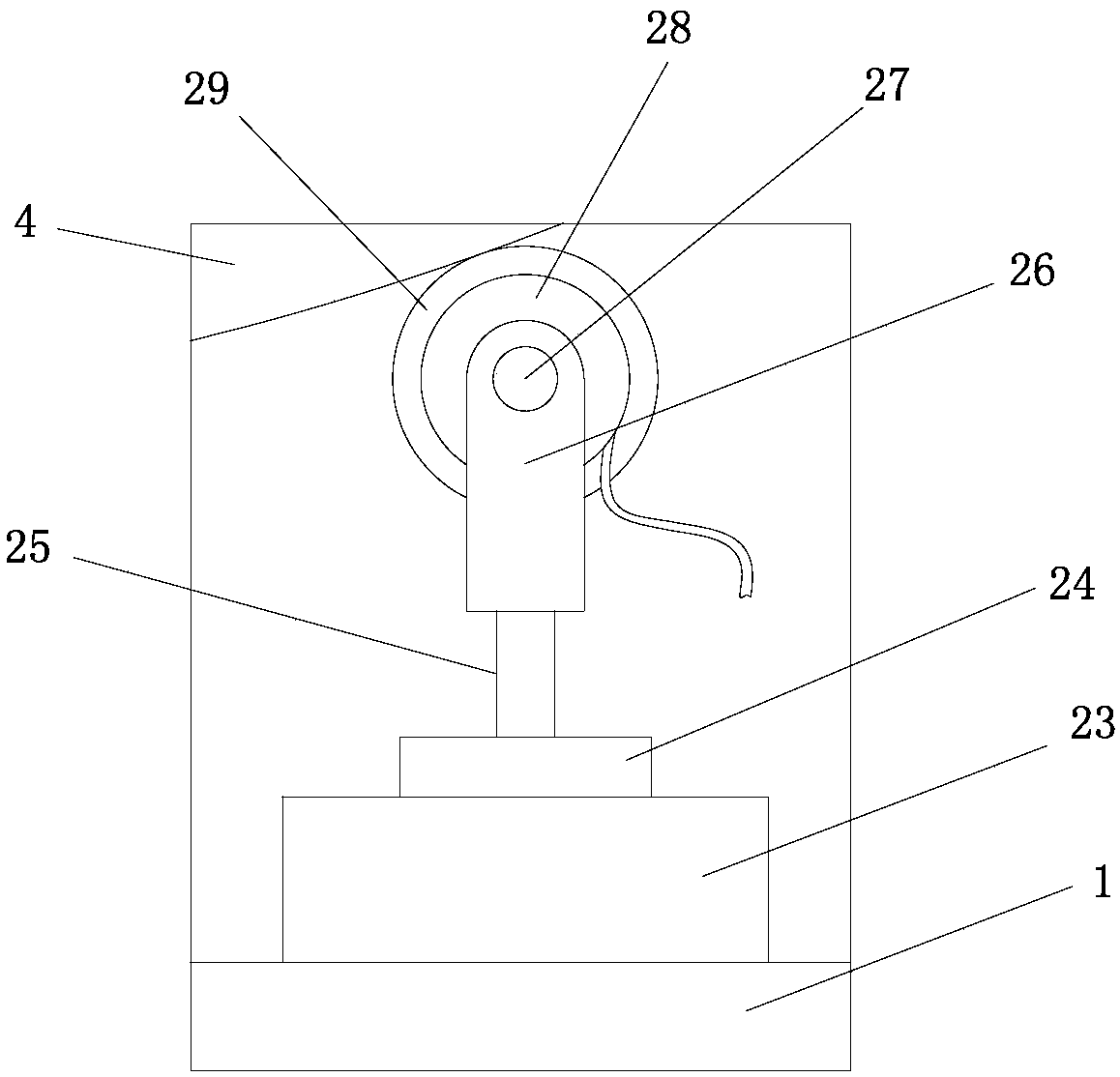

[0025] Such as Figure 1-3 As shown, the present invention provides a casting grinding device, which includes a lower base 1 and an upper base 4, the lower base 1 and the upper base 4 are connected by a first mounting plate 2, and the upper base 4 is close to the lower base 1 A grinding wheel 13 is installed on one side of the upper base 4, and a hydraulic pump 5 is also installed on the upper end of the upper base 4. A first piston 7 is installed on the side of the upper base 4 close to the lower base 1, and the first piston 7 is far away from the upper base. A first piston shaft 8 is installed on one side of the base 4, and a limiting plate 10 is installed on the side of the first piston shaft 8 far away from the first piston 7, and a first installation shaft 11 is installed on the limiting plate 10. A first motor 12 is installed on the first installation shaft 11, the grinding wheel 13 is installed on the first motor 12, a passage 3 is provided on the first installation pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com