Method and system for integral lifting of asymmetric inner ring truss and cable dome

A technology of overall lifting and ring truss, applied to roofs, building components, buildings, etc., can solve problems such as uneven distribution of gravity, collision of lifting frames, hidden safety hazards, etc., to increase safety and reliability, speed up construction schedule, and improve efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

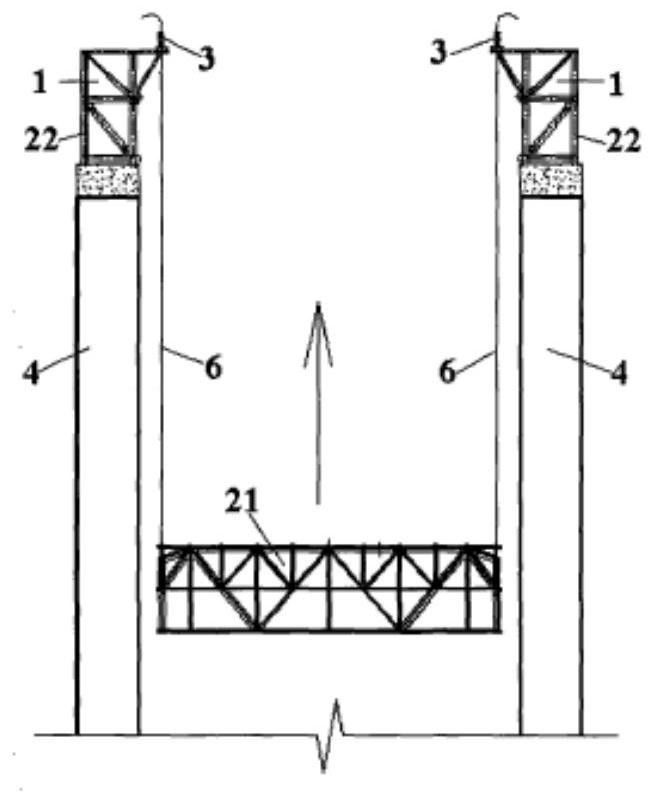

[0085] As a preferred embodiment of the overall lifting system of the asymmetric inner ring truss and cable dome of the present invention, it also includes:

[0086] The horizontal tie is fixed on the first connecting frame 51 at the top of the plurality of lifting frames 50; and

[0087] After the inner ring truss 40 is lifted to a height above the middle, the horizontal tie is fixed to the second connecting frame 52 in the middle of the plurality of lifting frames 50 .

[0088] As a preferred embodiment of the integrated lifting system of the asymmetric inner ring truss and cable dome of the present invention, it also includes a plurality of splayed braces 41 fixed to the inner ring truss 40 and corresponding to the lifting frame 50 .

[0089] As a preferred embodiment of the overall hoisting system of the asymmetric inner ring truss and cable dome of the present invention, it also includes multiple anti-wind cables 80 fixed on the opposite sides of the top of the correspond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com