Ellipse head lining manufacturing process

An elliptical head and manufacturing process technology, applied in the field of elliptical head lining manufacturing technology, can solve the problems of slow construction progress, insufficient assembly accuracy, and long delivery cycle, so as to speed up the construction schedule, reduce labor costs, and achieve assembly high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0057] A manufacturing process for an elliptical head lining, characterized in that it comprises the following steps:

[0058] S1. Making the inner pot lid 1:

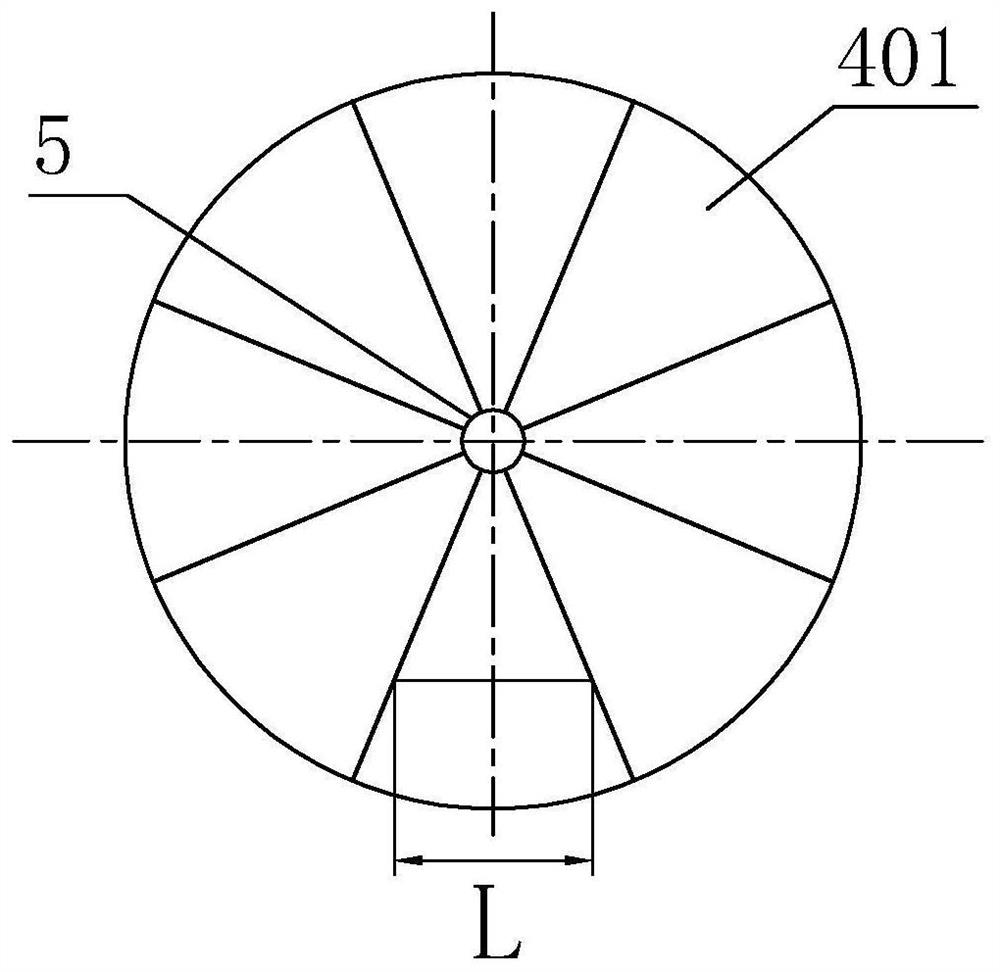

[0059] S11. Divide the inner surface of the head 41 into N equal divisions to obtain N equal division areas 401;

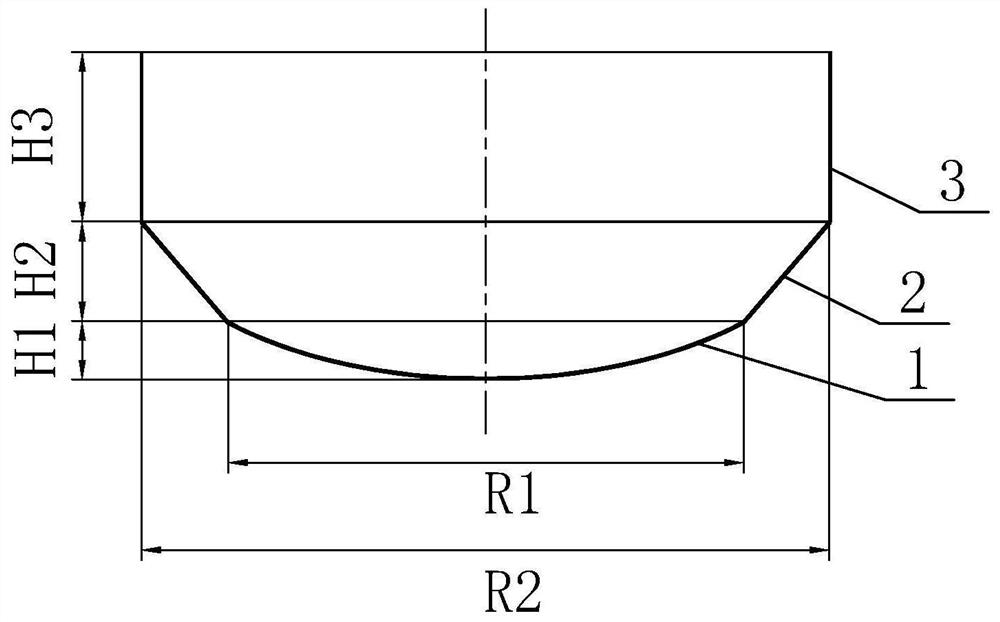

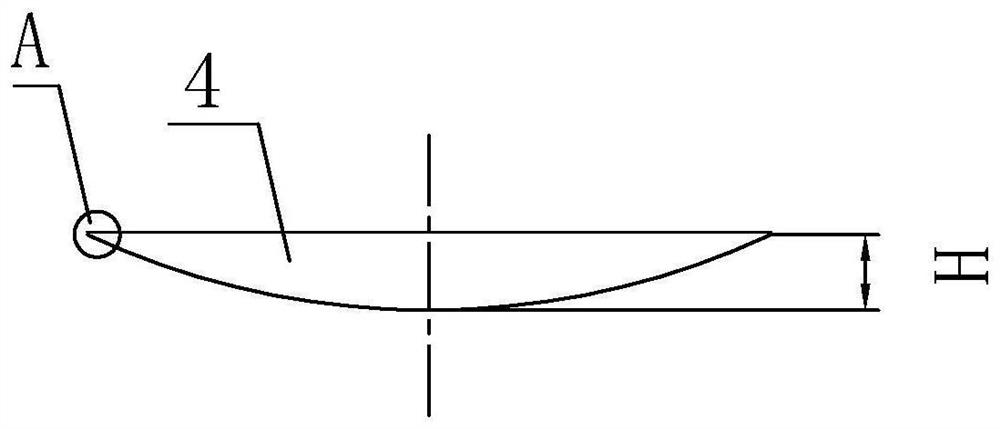

[0060] S12. Spot weld a round steel rod 5 equal to the height H1 of the inner surface of the inner surface of the head, and place the center point of the round steel rod on the head according to the size of the opening diameter R1 of the inner pot lid. Draw the outer trajectory line of the lined pot cover on the inner surface, which is the edge line where the lined pot cover overlaps with the inner surface of the head, and remove the round steel rod;

[0061] S13. Measure the radian size and width L of the equally divided area 401:

[0062] S131. In the radial direction, every 1 / 16 of the opening diameter R1 of the lining pot lid is actually measured to measure the radian size of the equally divided area...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com