A method for improving the ribbon structure of flexspline raw material

A band structure and raw material technology, applied in heating/cooling equipment, furnaces, heat treatment equipment, etc., can solve the problem of high processing cost and achieve the effect of low price, low cost and accelerated time schedule

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

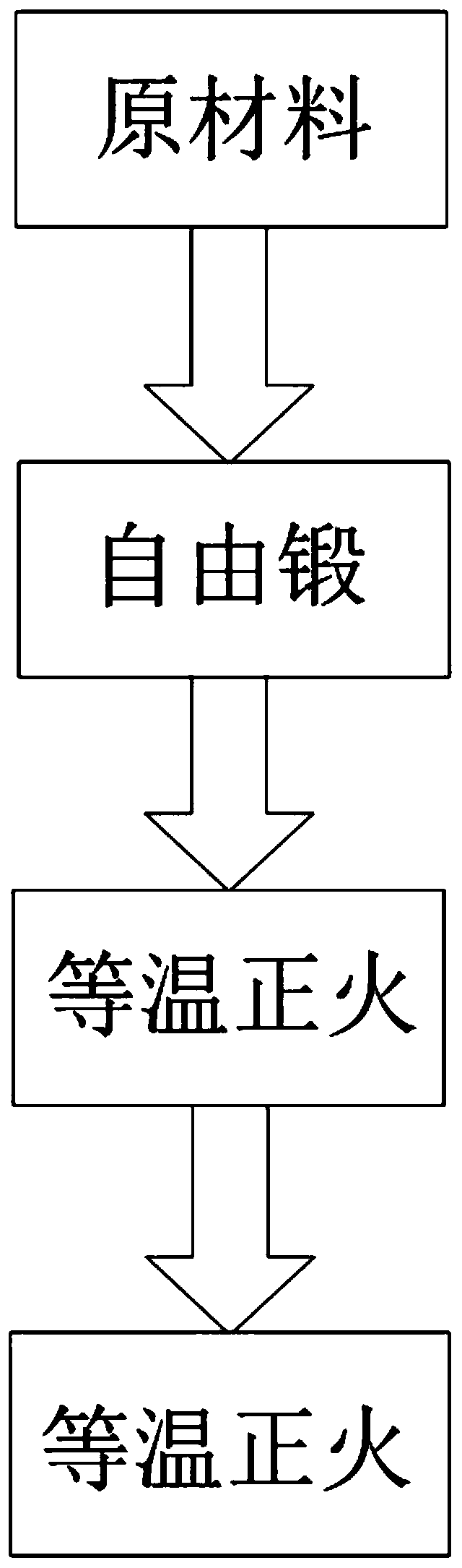

Method used

Image

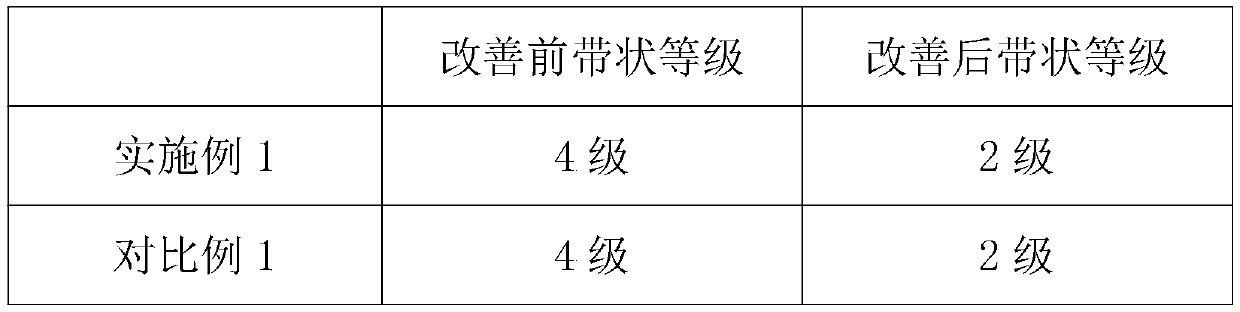

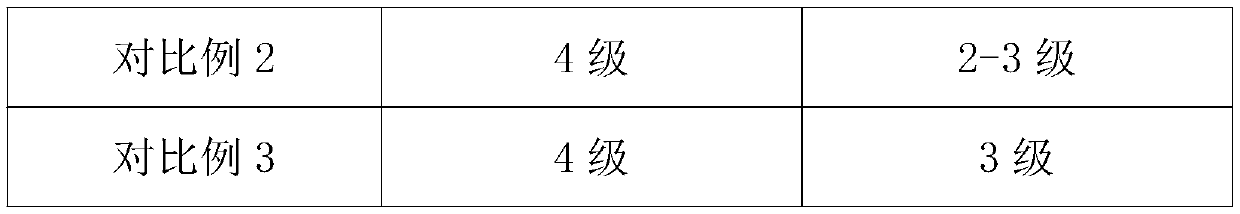

Examples

Embodiment 1

[0051] In this embodiment, a method for improving the banded structure of the flexspline raw material comprises the following steps:

[0052] Step 1, free forging the material with severe band structure in the flexspline raw material, including the following steps:

[0053] a. Screen out the materials with serious band structure from the flexspline raw materials;

[0054] b. The screened materials are heated for initial forging, and the temperature for initial forging heating is 1050°C;

[0055] c. Put the heated material for initial forging into a flat anvil or mandrel for free forging. The forging ratio of free forging is 2.0. After free forging is completed, it will be heated for final forging, and the temperature for final forging heating is 1000°C;

[0056] Step 2, carry out isothermal normalizing once to the material after completing step 1, including the following steps:

[0057] d. Put the material after step 1 into the heating furnace for the first heating and then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com