Construction Method of Secondary Lining Structure of Long-span and Ultra-thick Tunnel

A construction method and large-span technology, applied in the direction of tunnel lining, tunnel, shaft lining, etc., can solve problems such as unstable support, high construction risk, and difficult construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be further described below with reference to the accompanying drawings and specific examples.

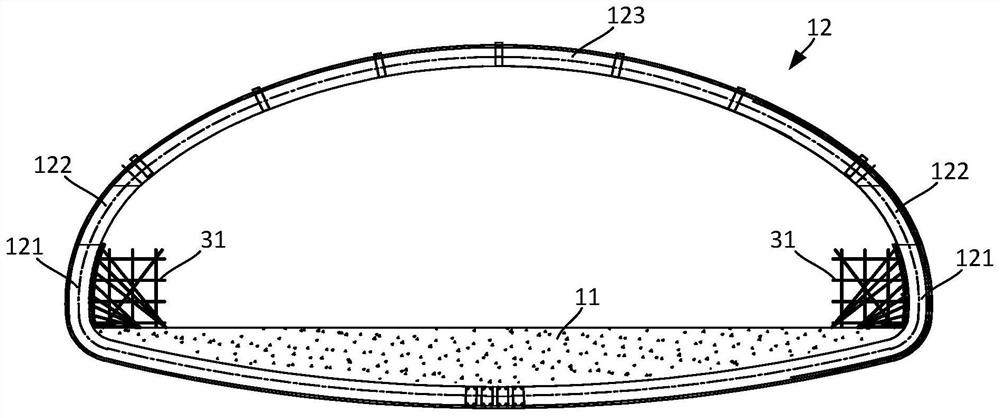

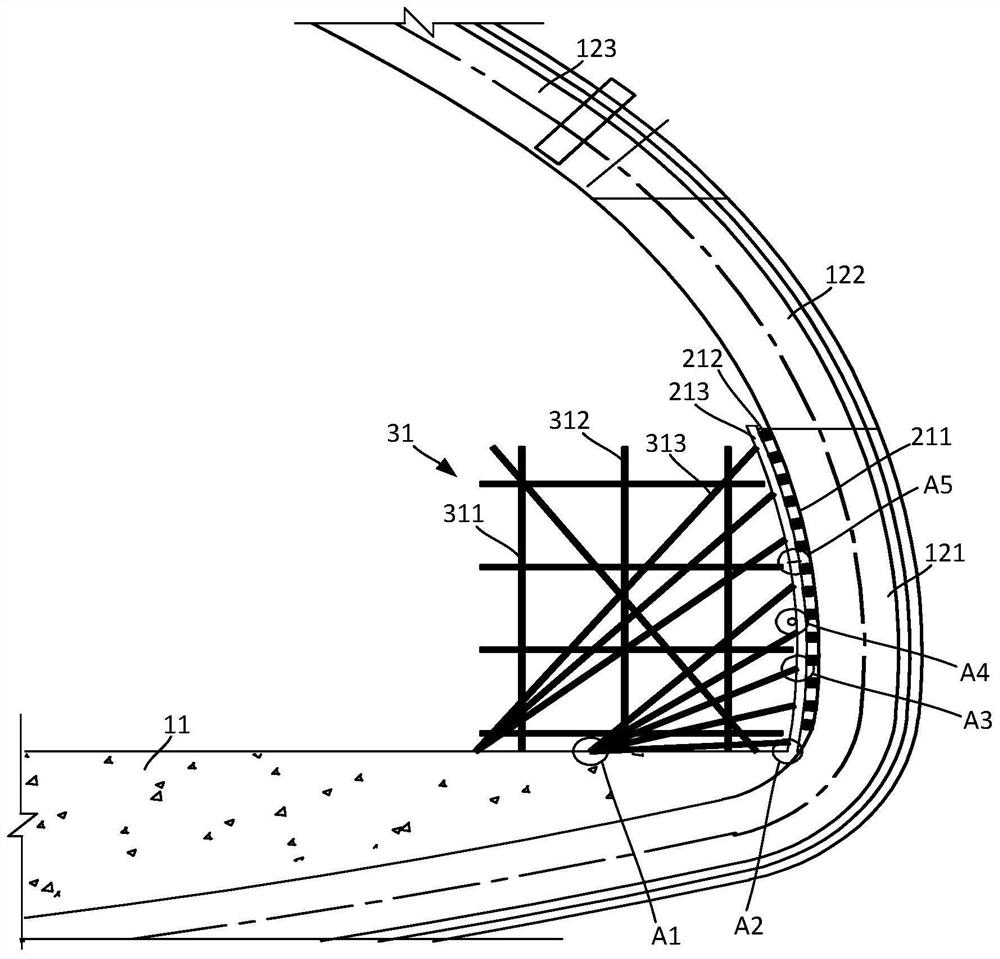

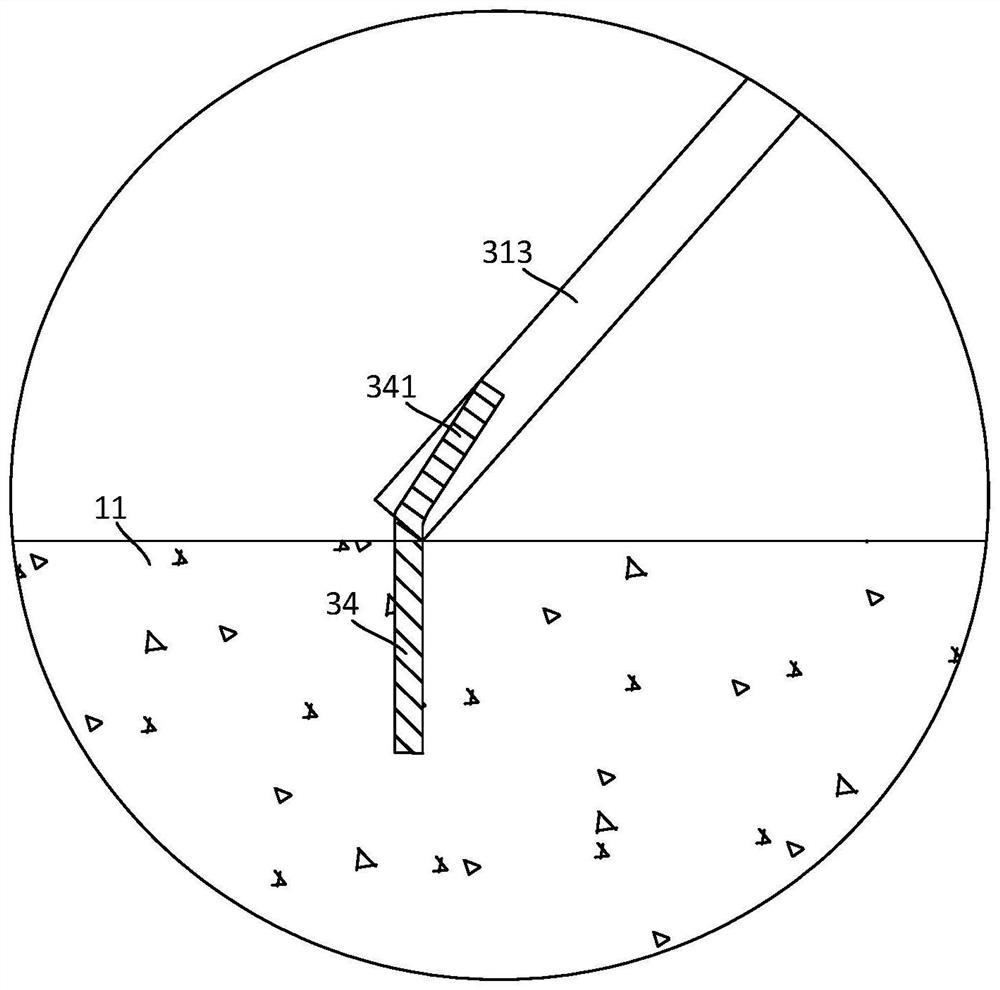

[0061] See figure 1 The present invention provides a construction method of a large-thick tunnel bining structure, which is suitable for construction of a large cave chamber two in-line structure that cannot be employed. The large span refers to the span greater than equal to 32m, super The thickness means that the thickness is greater than or equal to 5m. The main purpose of the present invention is to improve the safety during the construction process to ensure the safety of construction safety, which can complete the difficulty of high-span ultra-thick bilaying construction. The present invention overcomes the problem of large construction difficulty in the tunnel large cave, high-risk, and has also abandoned a bulky big steel tube support mode, strengthened the surveillance of the framework process, solved the 32M large span 5m Temporary support of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com