High-strength anti-seismic wall, integral cast-in-situ building and construction method thereof

A high-strength, anti-seismic wall technology, applied to buildings, building components, building reinforcements, etc., to achieve good seismic performance, save steel content, and shorten the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

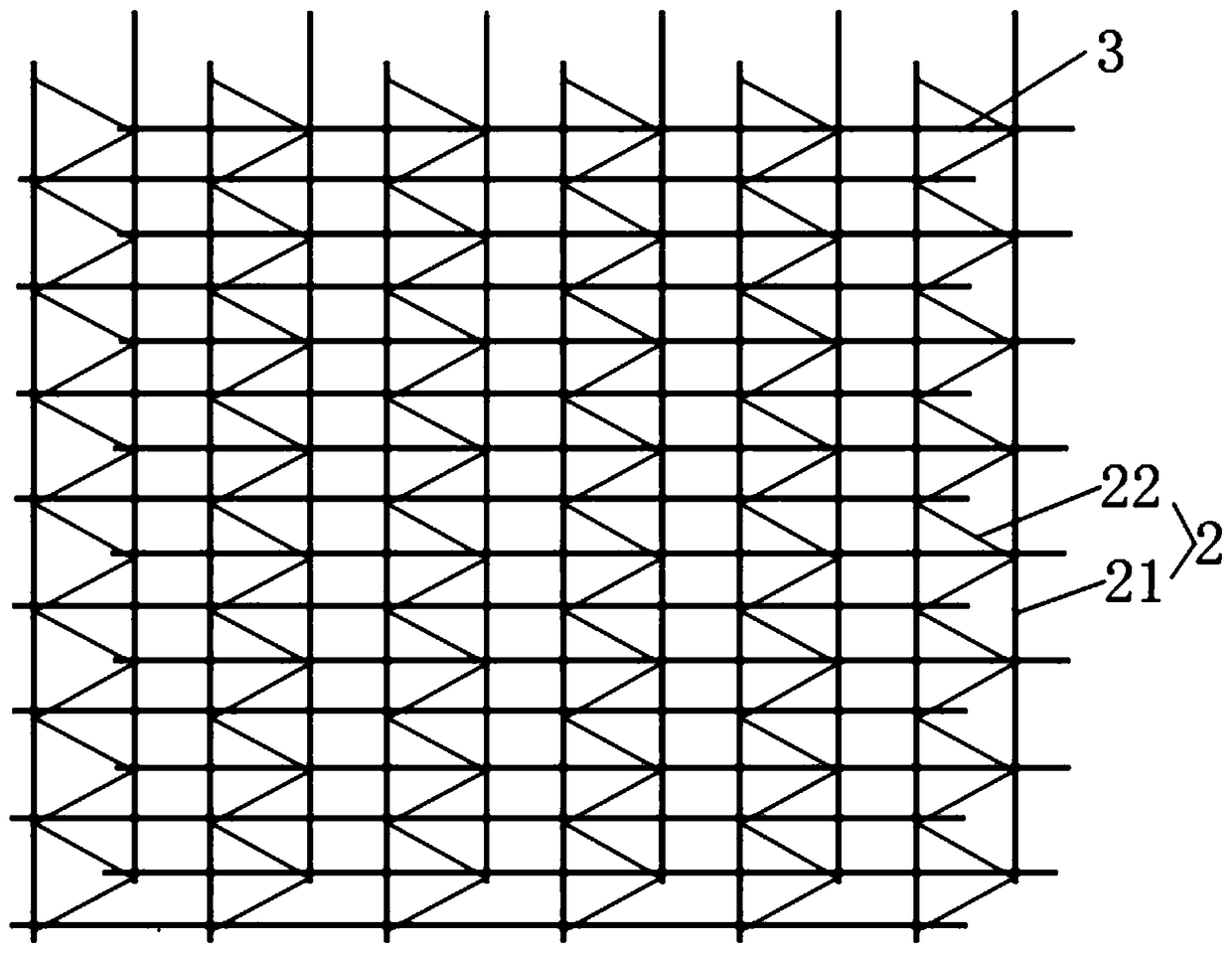

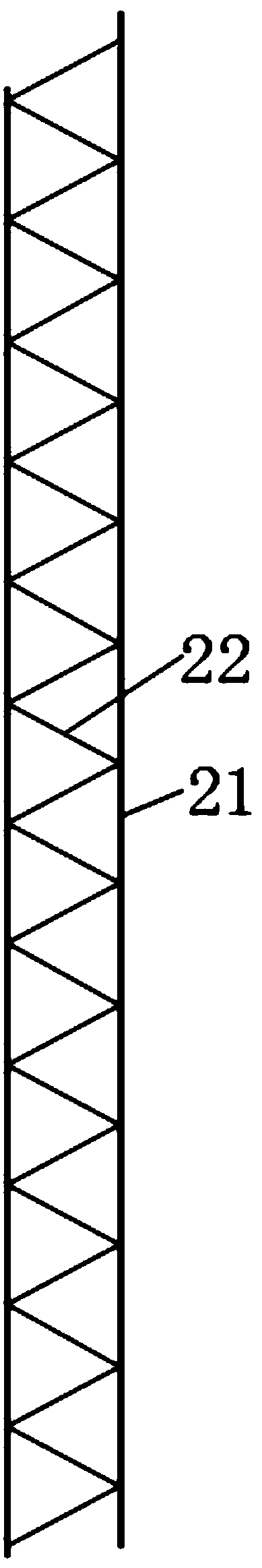

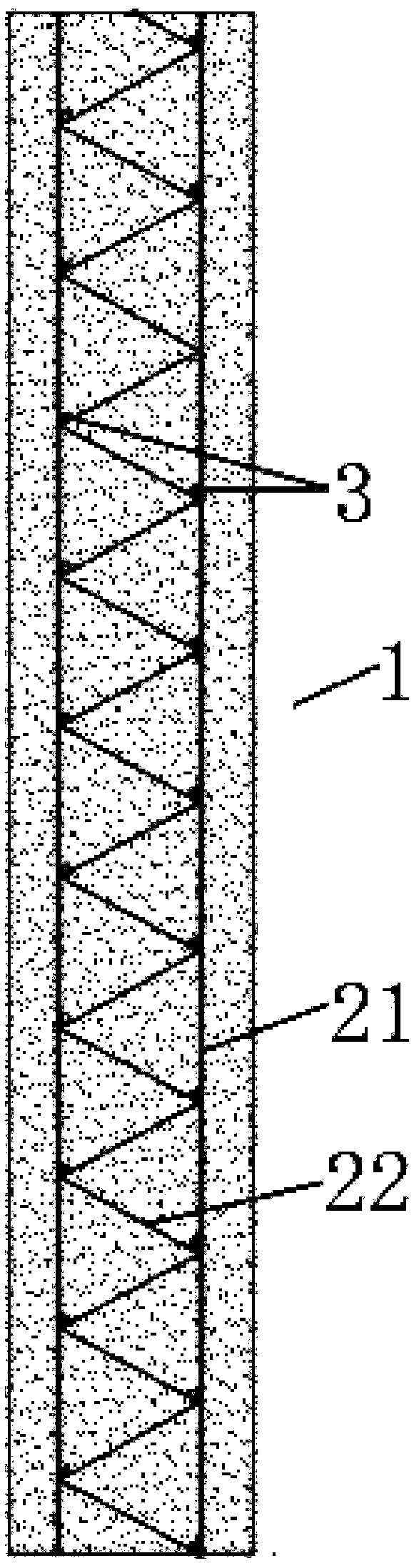

[0054] Embodiment one: if figure 1 , 2 , 3, the high-strength seismic wall of the present embodiment includes a concrete wall 1 and a plurality of truss columns 2 and a plurality of transverse steel bars 3 pre-embedded in the above-mentioned concrete wall 1;

[0055] A plurality of the above-mentioned truss columns 2 have the same specification, are parallel to each other, and are arranged in a row at equal intervals;

[0056] The above-mentioned truss columns 2 each include two vertical steel bars 21 and a first connecting bar 22, and the two above-mentioned truss columns 2 are vertically arranged at intervals, and the above-mentioned first connecting bars 22 are arranged between the two above-mentioned vertical steel bars 21, And be welded and fixed with two above-mentioned vertical reinforcing bars 21 respectively;

[0057] A plurality of the above-mentioned transverse steel bars 3 horizontally penetrate all the above-mentioned truss columns 2 respectively.

[0058] Opti...

Embodiment 2

[0063] Embodiment two: if Figures 3 to 7 As shown, the overall cast-in-place building of this embodiment includes several high-strength seismic walls and truss floors 4 as described above in Embodiment 1;

[0064] The above-mentioned high-strength seismic walls are enclosed together to form a wall;

[0065] Above-mentioned truss floor 4 comprises truss 41, brick 42 and concrete layer 43;

[0066] The above-mentioned trusses 41 are provided with a plurality of pieces, and are arranged horizontally and side by side in the above-mentioned wall at intervals, and the two ends of the above-mentioned trusses 41 are respectively connected to the inner upper ends of the two above-mentioned high-strength seismic walls located on opposite sides;

[0067] The above-mentioned bricks 42 are provided in multiples, and are respectively continuously clamped between two adjacent above-mentioned trusses 41, and the bottom ends of the above-mentioned bricks 42 are flush with the bottom ends of ...

Embodiment 3

[0077] Embodiment three: the construction method of the overall cast-in-place building of the present embodiment comprises the following steps:

[0078] Step 1. Build the wall formwork, specifically,

[0079] S1, connect a plurality of truss columns 2 on the top of the foundation or the substructure, and install a plurality of transverse steel bars 3 on the corresponding plurality of truss columns 2 of each wall (horizontal steel bars 3 are in accordance with the high-strength seismic wall in Embodiment 1 in the position to wear);

[0080] S2. Build building templates 51 parallel to each other on both sides of a plurality of truss columns 2;

[0081] Step 2: Build the floor components, specifically,

[0082] S3. Build a plurality of prefabricated trusses 41 between the upper ends of the building templates 51 located on opposite sides;

[0083] S4. Arrange the above-mentioned bricks 42 sequentially between two adjacent above-mentioned trusses 41 to form a complete above-ment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com