Web perforated box-type combined steel beam

A web and steel girder technology, applied in the field of web opening box-type composite steel girders and building components, can solve the problems of increasing the indoor net height of the house and affecting the indoor use space, so as to reduce the steel content and make the building space flexible variable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical solutions, innovative features, objectives and effects of the present invention easy to understand, the present invention will be further elaborated and described below in conjunction with specific illustrations and through the following specific embodiments.

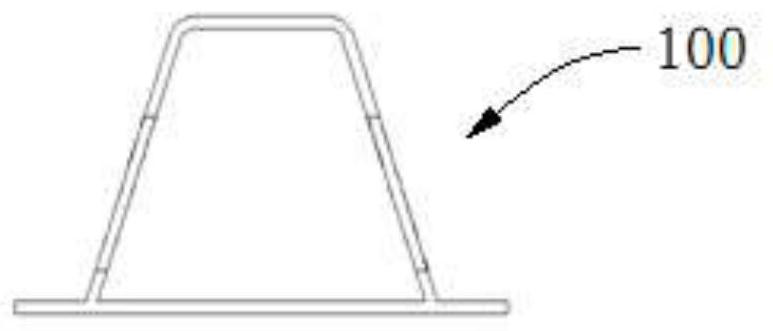

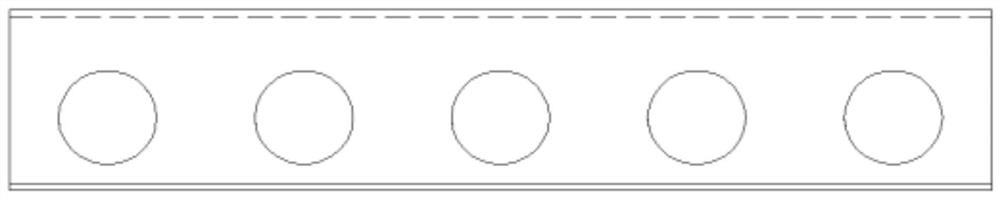

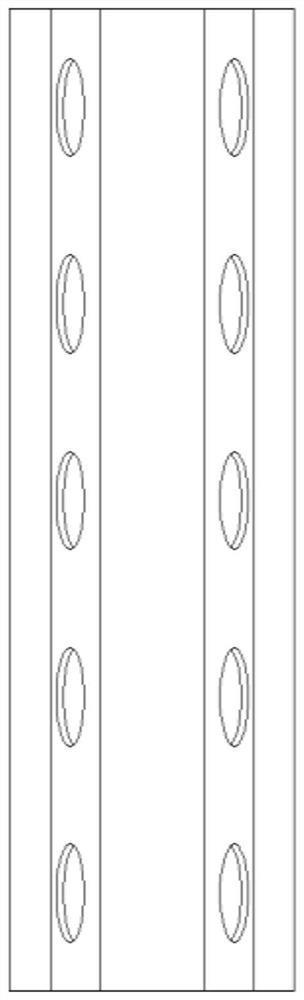

[0025] One embodiment of the present invention provides a box-type composite steel girder with web openings, which includes an upper flange, webs on both sides, and a bottom plate, wherein the webs can be arranged obliquely, and the cross-section The two ends of the bottom plate protrude from the junction of the web, the cavity formed between the upper flange, the web and the bottom plate has a trapezoidal or rectangular cross-section, and the web is provided with a certain interval along its longitudinal direction. Multiple holes.

[0026] In a specific embodiment, such as Figures 1A-1D As shown, when the cavity section of the box-shaped composite steel girder 100 with openings in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com