Profiled angle steel reinforced concrete structure, structure and member combination

A technology for reinforced concrete and reinforced concrete columns, which is applied in the field of special-shaped angle steel reinforced concrete structures and the combination of structures and components, can solve the problems of earthquake resistance, wind pressure resistance, fracture resistance safety factor and durability, etc. Save resources and improve the effect of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

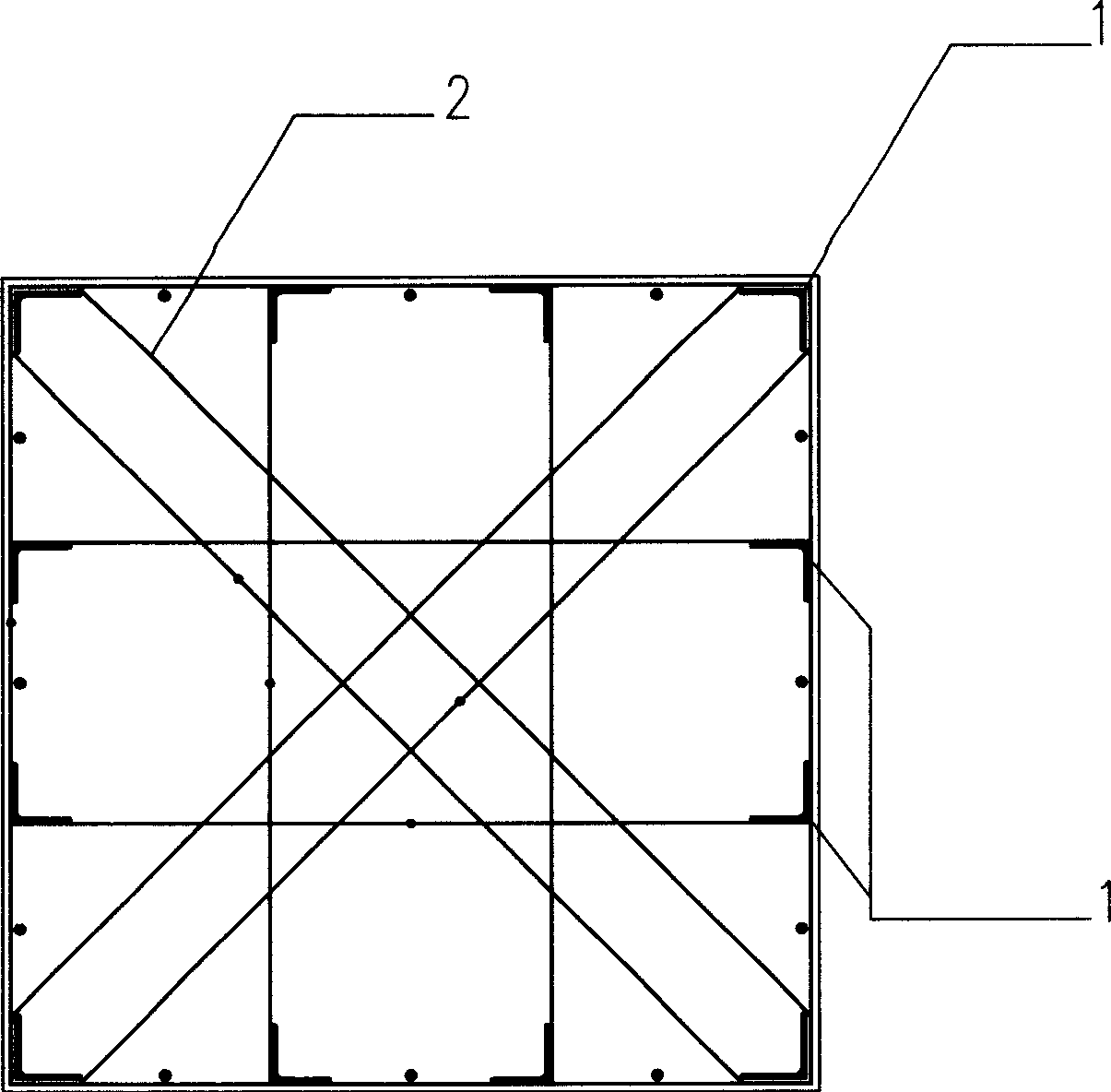

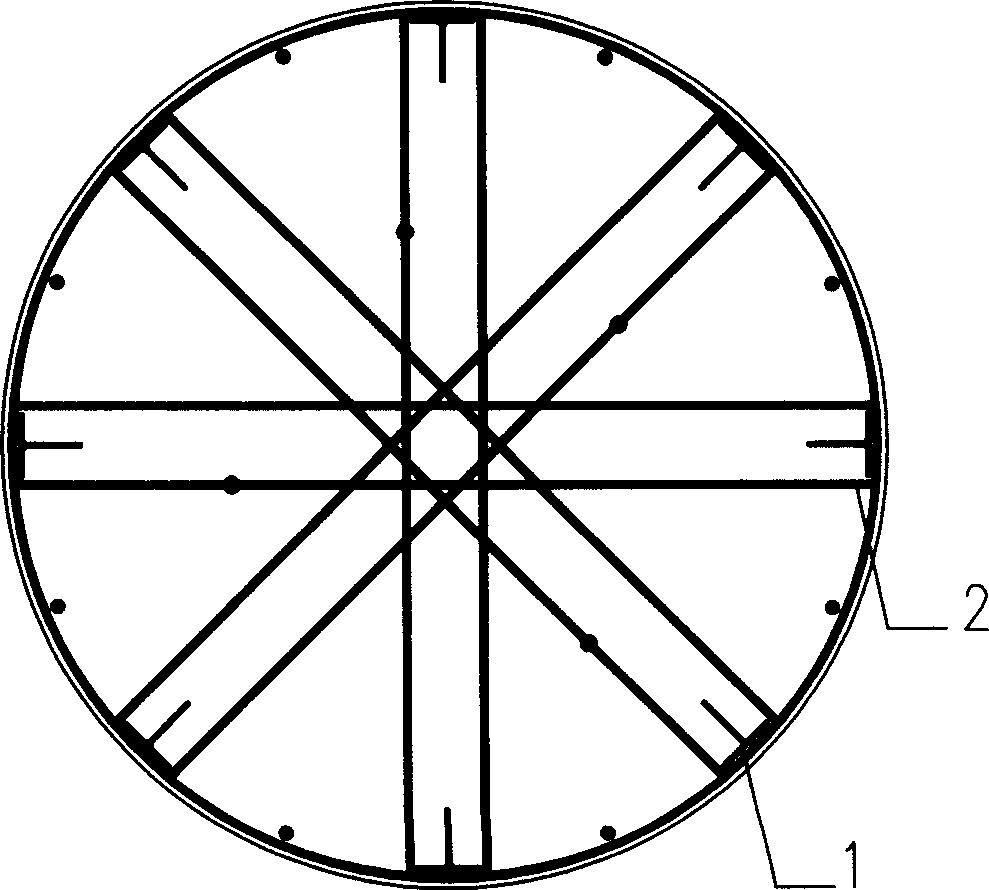

[0031] Example 1 provides a building structure configuration. The embodiment of the component pile foundation of the present invention includes: special-shaped angle steel reinforced concrete square piles, round piles, hollow square piles, hollow round piles, and sheet piles. Such as figure 1 The plane and cross-sectional view of the special-shaped angle steel reinforced concrete square pile is provided. In the picture, the special-shaped angle steel 1 and the stirrup and the frame tie 2 are welded. Such as figure 2 The plane and cross-section diagrams of the special-shaped angle steel reinforced concrete round piles are provided. Special-shaped angle steel combined reinforced concrete pile foundation is adopted, and angle steel 1 is used to protect concrete to increase the bearing capacity. Angle steel 1, vertical reinforcement, stirrup, frame reinforcement 2, and concrete play a strong role in each other to improve the overall rigidity of the pile, resistance to displacement, ...

Embodiment 2

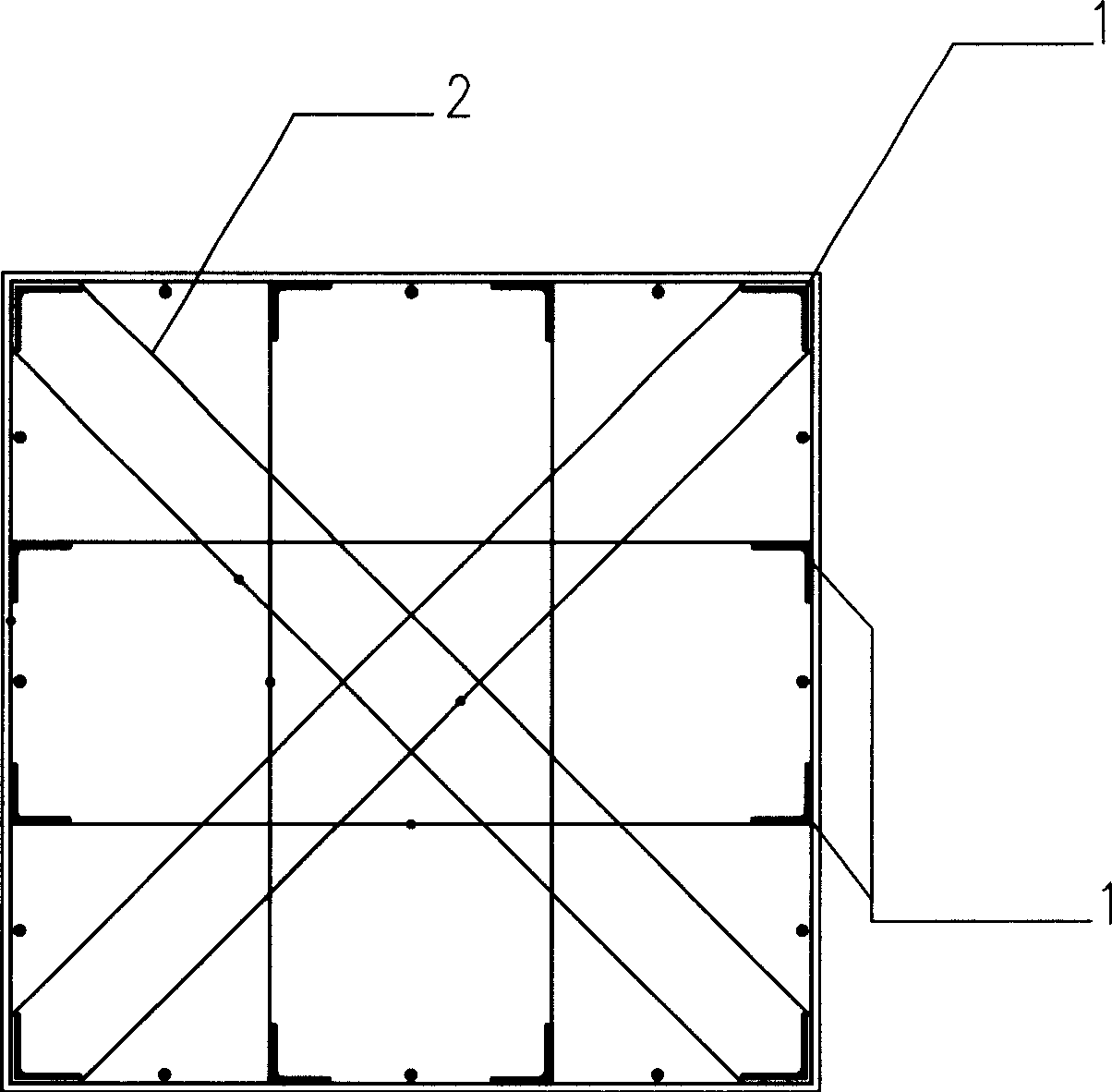

[0033] Example 2 provides the building structure configuration, the embodiment of the component column of the present invention, the column includes: frame square column, frame column and so on. Such as image 3 The plane and cross-sectional view of the square column of the special-shaped angle steel reinforced concrete frame provided, the special-shaped angle steel 1 and the vertical reinforcement, stirrup, and frame tie 2 are welded. Such as Figure 4 The plane and cross-section diagrams of the profiled angle steel reinforced concrete frame column are provided. In the picture, the profiled angle steel 1 and the steel bar 2 are welded. The special-shaped angle steel is used to combine the reinforced concrete column, and the angle steel 1 is used to enclose the concrete to increase the bearing capacity. The angle steel, the steel bar, and the concrete play a strong role in each other to improve the overall rigidity, displacement resistance, fracture resistance and durability of the...

Embodiment 3

[0035] Example 3 provides the building structure matching, the implementation of the component shear wall of the present invention, the shear wall includes: equilateral short-supported shear wall, unequal-sided short-supported shear wall, T-shaped short-supported shear wall Shear walls, cross-shaped short-supported shear walls, special-shaped short-supported shear walls, elevator shaft shear walls, and shear walls. Such as Figure 5 Provide the plan and cross-section diagrams of the special-shaped angle steel reinforced concrete cross-shaped short-supported shear wall. In the picture, the special-shaped angle steel 1 and the vertical reinforcement, stirrup, and frame tie 2 are welded, and the beam angle steel is connected at the end of each type of shear wall. Block 3. Special-shaped angle steel is used to combine various types of reinforced concrete shear walls, and angle steel 1 is used to enclose concrete to improve the bearing capacity. Angle steel 1, vertical reinforcement, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com