High voltage pool for heating solvent extraction

An extraction cell and high-pressure technology, which is applied in solvent extraction, pressure vessels used in chemical processes, pressure vessels/vacuum vessels, etc., can solve the problems that the extraction cell cannot achieve high-pressure sealing, is difficult to complete the high-pressure sealing function, and the knife edge is easily damaged. , to achieve the effect of simple structure, less quantity and lower processing accuracy requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

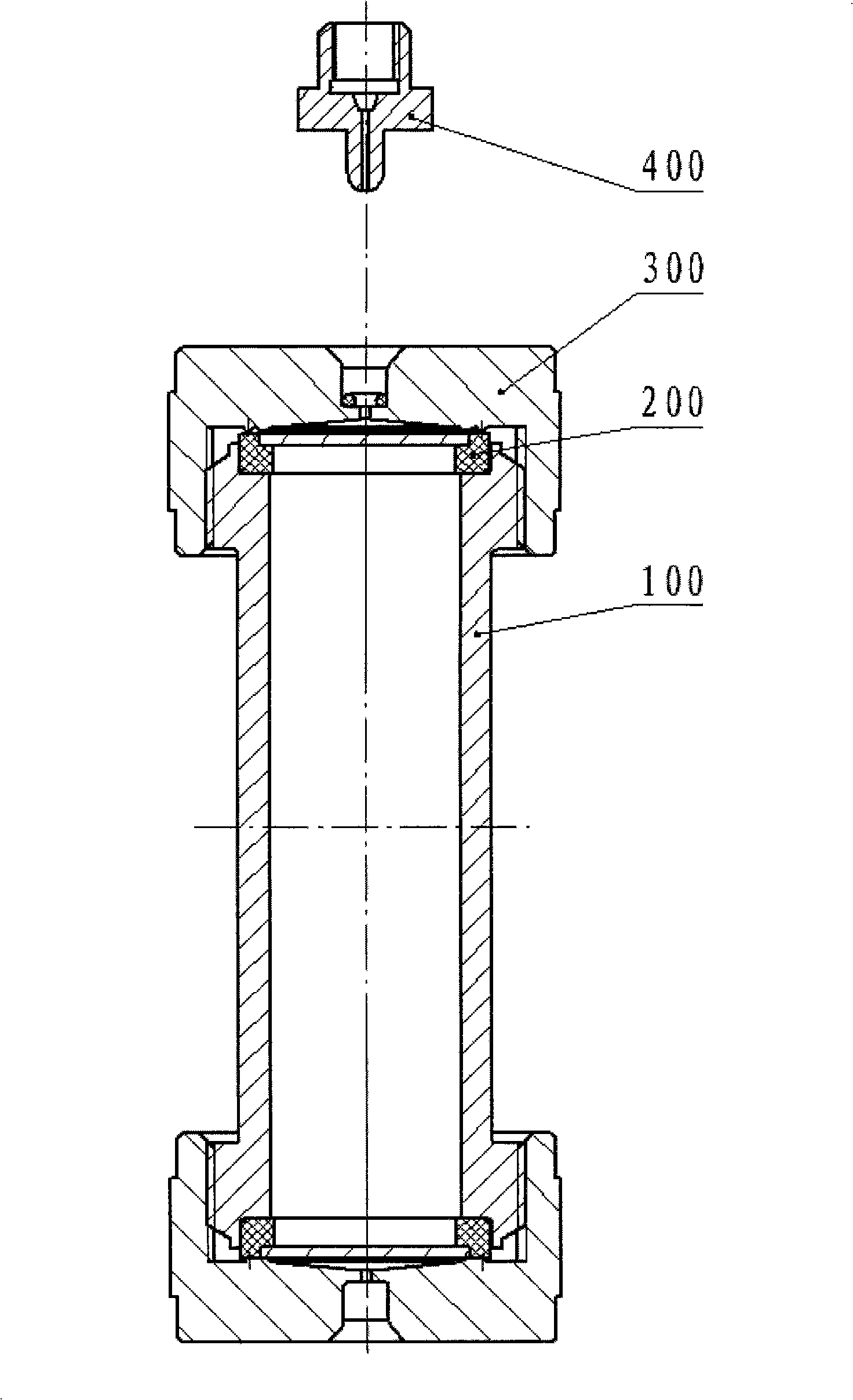

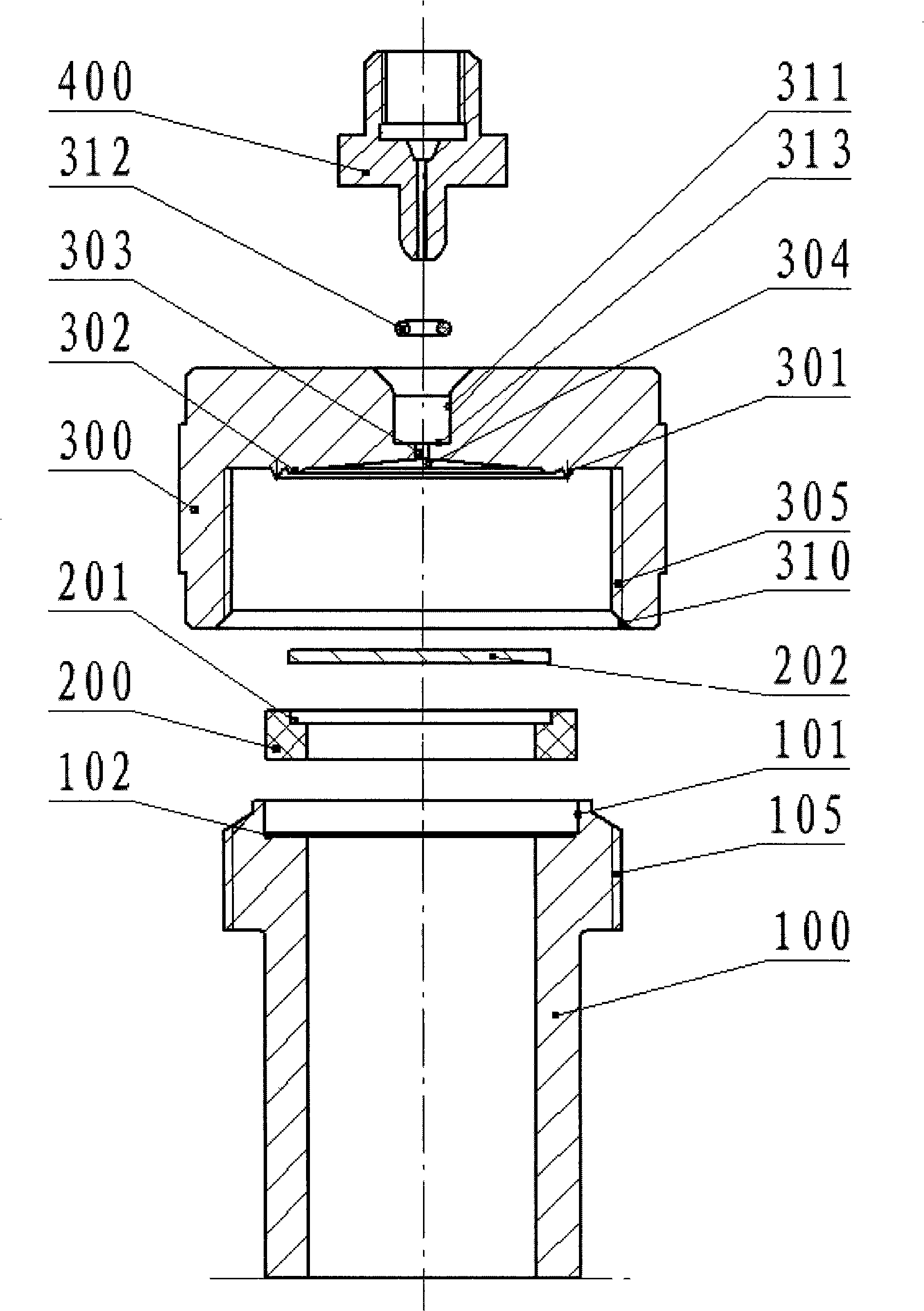

[0028] see figure 1 and figure 2 As shown, an extraction cell that can perform solvent extraction of organic matter in solid or semi-solid samples at a temperature lower than 200 ° C and a pressure lower than 20 MPa, and a high-temperature and high-pressure resistant cell for solvent extraction, mainly consists of a cell body 100 , sealing gasket 200 and sealing cover 300 are composed of three parts.

[0029] The cell body of the extraction cell is made of stainless steel seamless steel pipe material SS316L with good inertness, for example, it can withstand the working pressure above 20MPa, the temperature above 200°C, and the inner diameter of the cavity is 5-40mm.

[0030] A circle of grooves 101 is provided on the end surface of the extraction cell body 100 , and a protruding small step is provided on the inner bottom of the extraction cell groove 101 as a sealing knife edge 102 .

[0031] There are identical sealing covers 300 at both ends of the extraction pool. A prot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com