Prefabricated hybrid structure frame-shear wall building system and construction method

A technology of mixed structure and construction method, which is applied in the direction of construction, building structure, and construction material processing, etc. It can solve the problems that affect the development of prefabricated buildings, long maintenance time, long operation time, etc., and achieve less pollution and construction waste, and the overall The effect of high earthquake resistance and low fire prevention cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] This embodiment discloses a construction method of a prefabricated hybrid structure frame-shear wall building system, which includes the following steps:

[0049] 1) Carry out foundation construction in accordance with construction design drawings. Transport the various prefabricated components from the factory to the construction site.

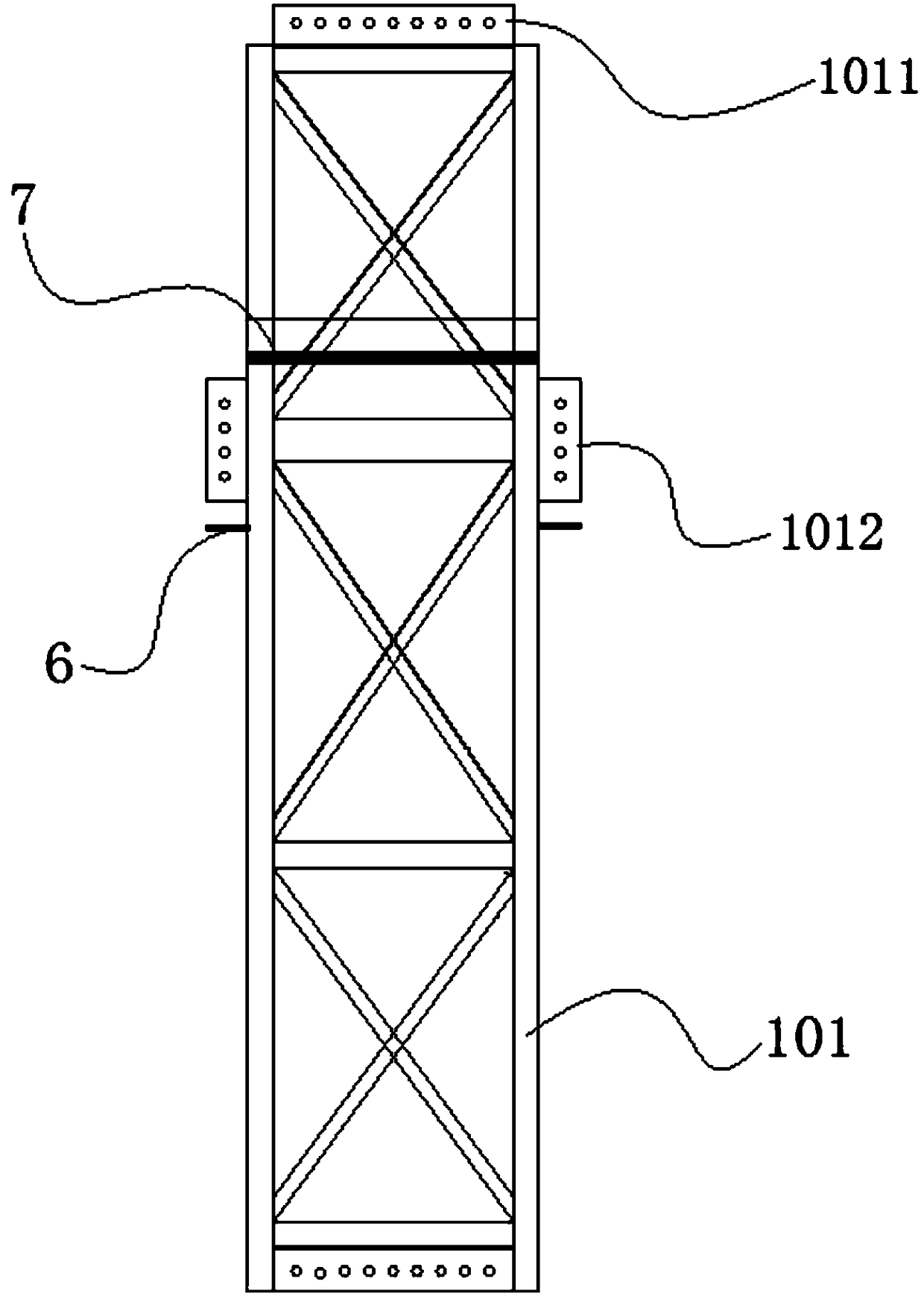

[0050] 2) Install the prefabricated steel concrete shear wall 1 on the first floor. The prefabricated steel concrete shear wall 1 is hoisted by a crane or a tower crane, and the embedded slab is connected with the foundation through bolts. The prefabricated steel concrete shear wall 1 can be installed with a temporary oblique support at an elevation of 2m from the ground to achieve temporary stability. Then correct the verticality and horizontal elevation of the wall. Among them, see figure 2 The prefabricated steel concrete shear wall 1 is a composite panel structure as a whole, including a steel frame 101 and a composite concrete laye...

Embodiment 2

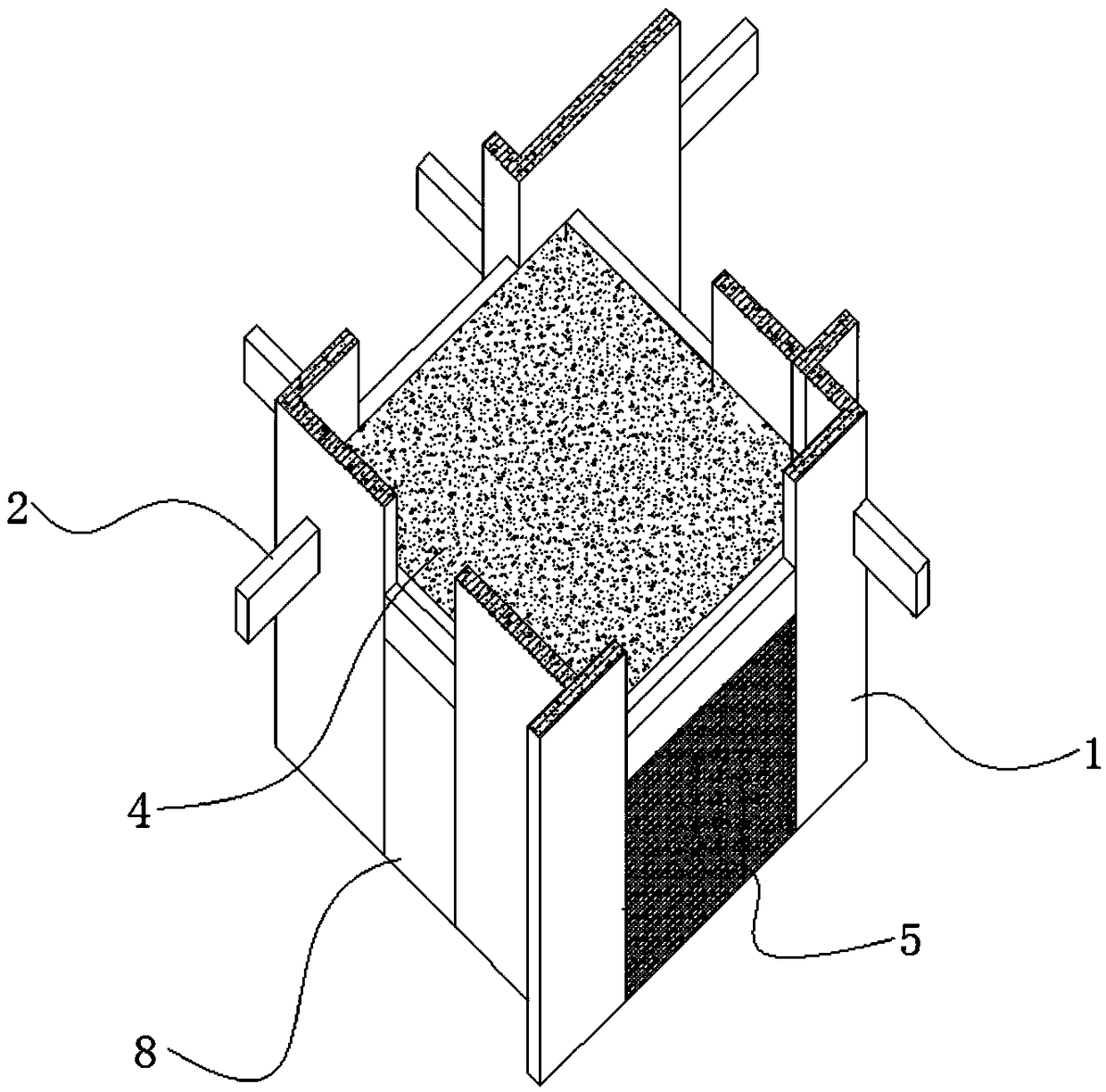

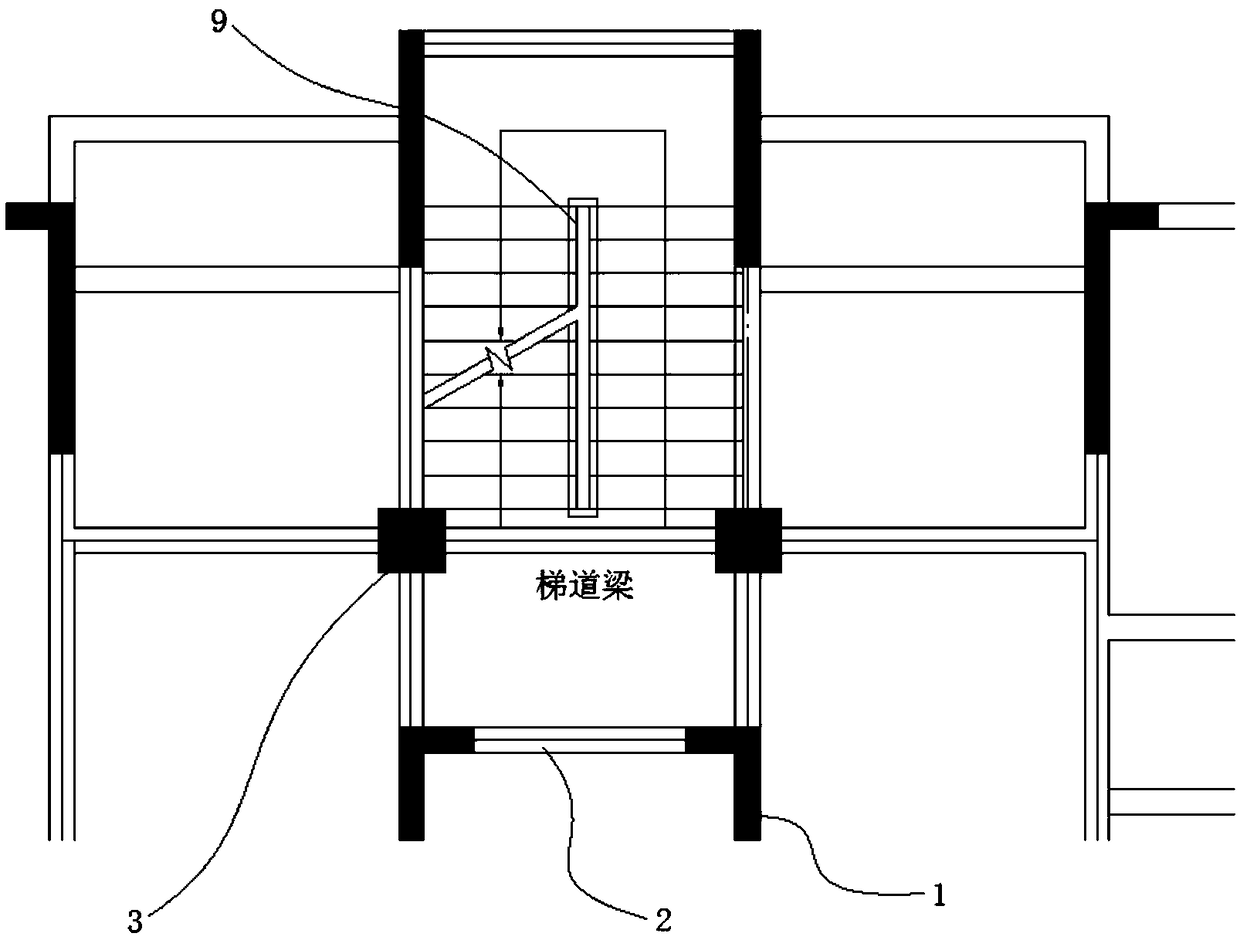

[0063] See figure 1 with Figure 5 This embodiment discloses a prefabricated hybrid structural frame-shear wall building system obtained by the above construction method, which includes a prefabricated steel concrete shear wall 1 and a prefabricated steel concrete composite beam 2 that are hoisted and spliced on the foundation.

[0064] The prefabricated steel concrete shear wall 1 is connected with the prefabricated steel concrete composite beam 2 to form a frame structure. The reinforced truss concrete floor 3, the prefabricated reinforced concrete stairs 4 and the lightweight masonry partition wall 5 are fixed on the frame structure to form a house construction system.

[0065] This embodiment uses both the steel structure assembly type installation and the practicality and durability of the concrete assembly type building, improves the overall structural strength and the overall building's seismic resistance, reduces pollution and construction period, and provides a green buil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com