Prefabricated profiled steel sheet combined shear wall and construction method thereof

A technology of combining shear walls and profiled steel plates, applied in walls, building components, buildings, etc., can solve the problems of multiple construction steps, lack of integrity, troublesome installation, etc., to improve overall performance and strength, and reduce steel content and weight, the effect of good shear performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

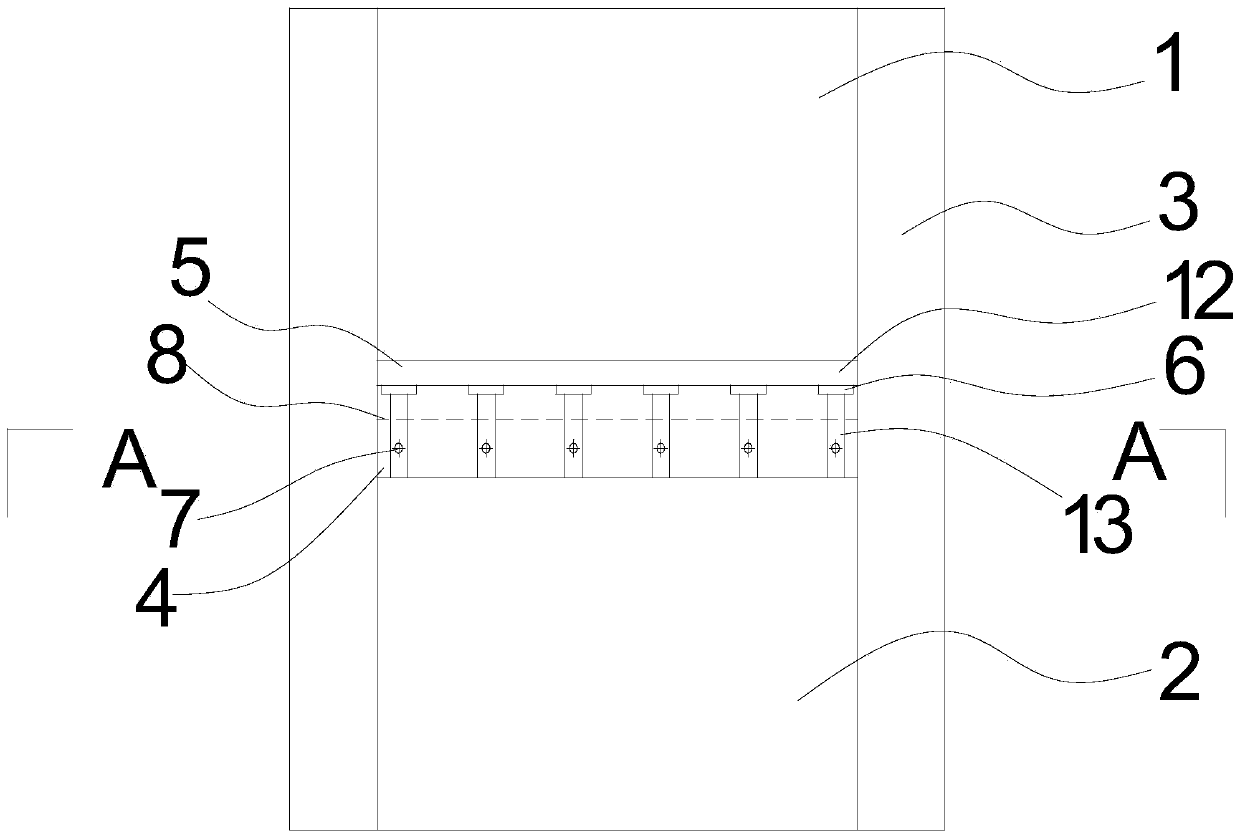

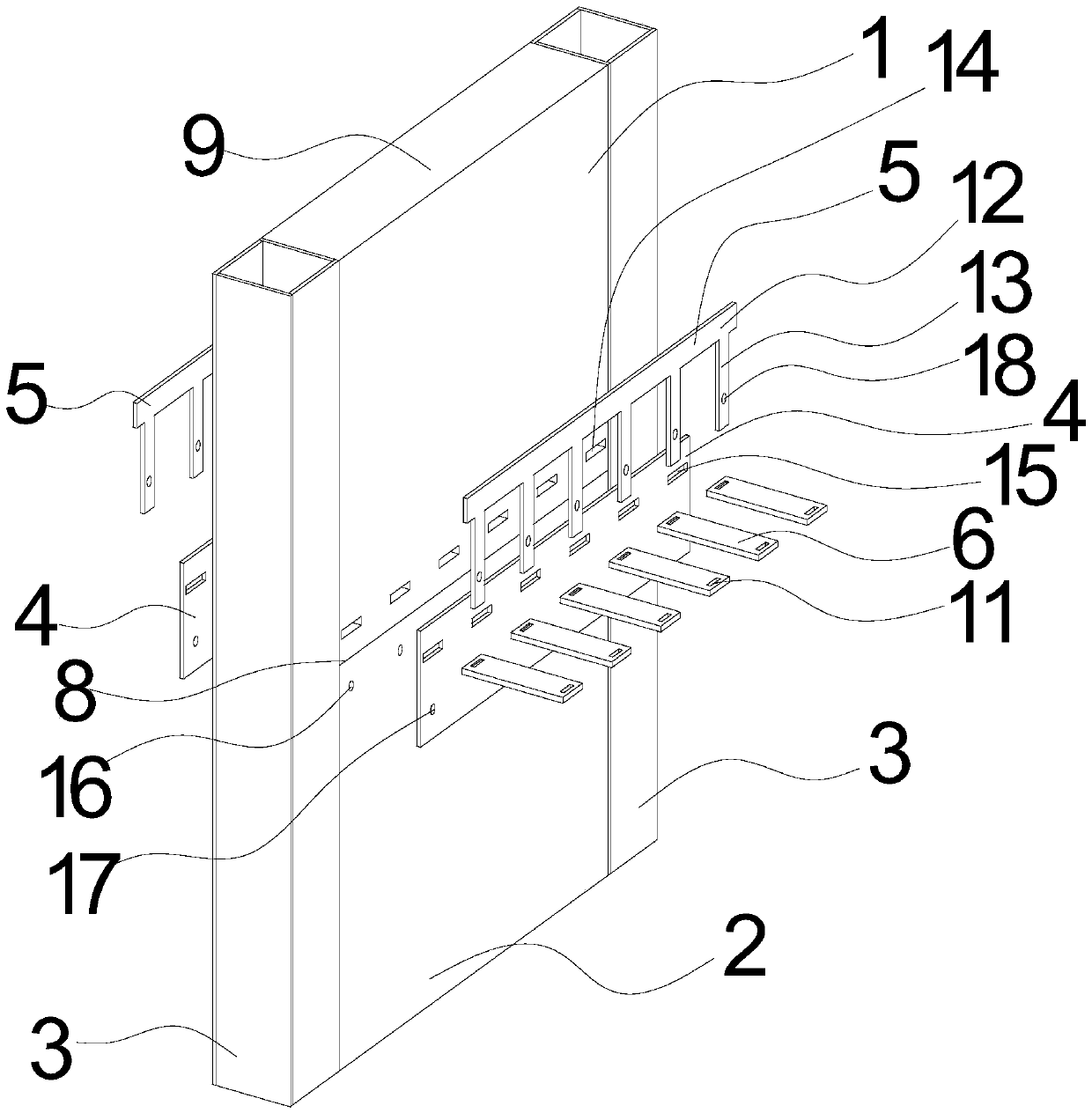

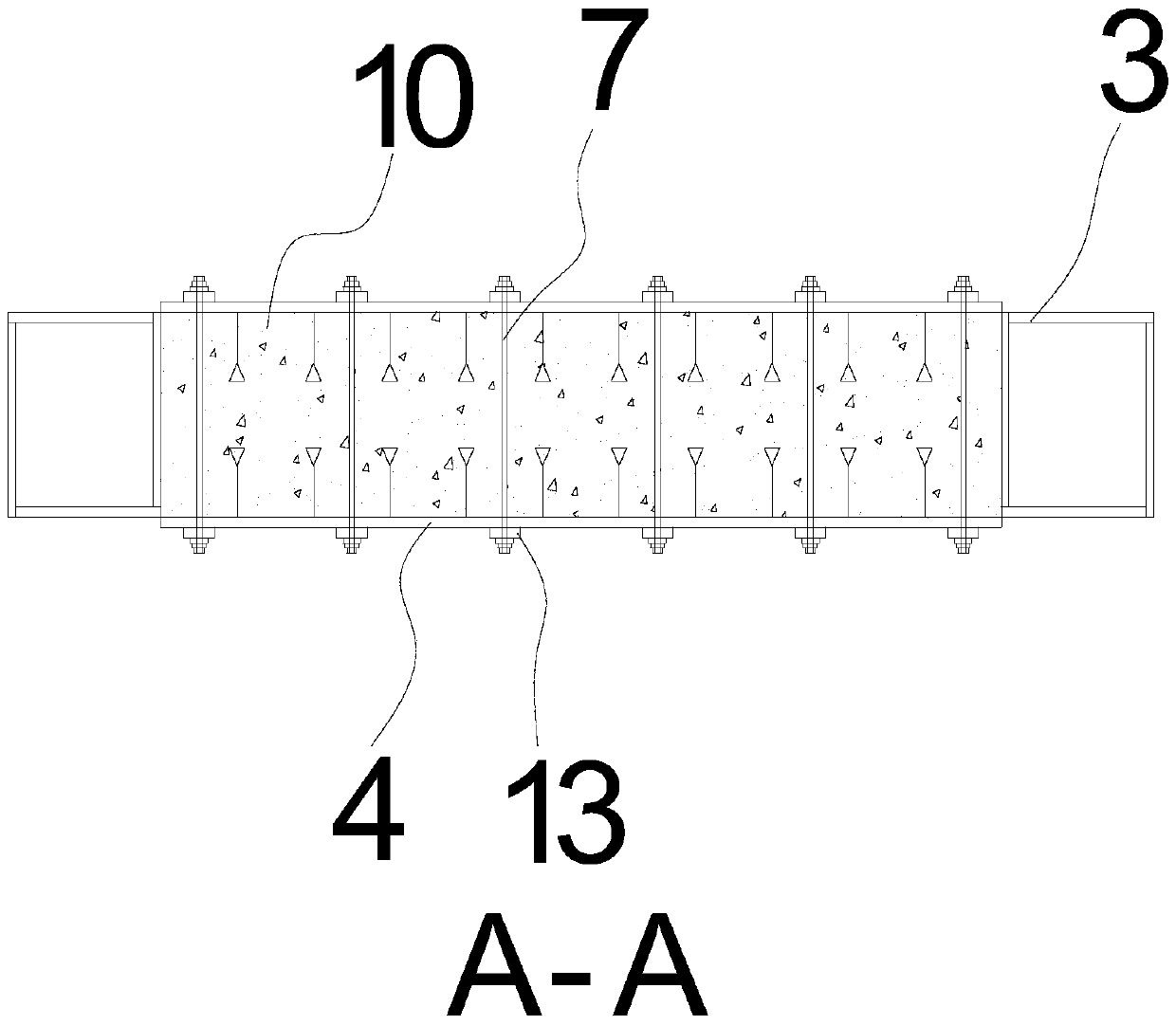

[0032] like figure 1 and figure 2 As shown, this embodiment provides an assembled profiled steel plate composite shear wall, including a first profiled steel plate 1, a second profiled steel plate 2, edge steel columns 3, connecting steel plates 4, and multiple vertical inserts 5. A plurality of transverse inserting plates 6 and a plurality of tension bolts 7 .

[0033] like figure 1 and figure 2 As shown, the first profiled steel plate and the second profiled steel plate are stacked vertically, the first profiled steel plate is located above the second profiled steel plate, and there is a seam at the stack of the first profiled steel plate and the second profiled steel plate 8. The connecting steel plates cover the joints, and the edge steel columns are assembled to both sides of the first profiled steel plate and the second profiled steel plate. Both the first profiled steel plate and the second profiled steel plate are closed profiled steel plates. The first profiled s...

Embodiment 2

[0044] The difference between this embodiment and Embodiment 1 is that the assembled profiled steel plate combined shear wall also includes a braced steel plate 19, such as Figure 4 and Figure 5 As shown, the diagonal bracing steel plate is arranged along the diagonal of the first profiled steel plate and the second profiled steel plate, and the tension bolts penetrate through the diagonal brace steel plate and the first profiled steel plate in order to connect them, and the tension bolts penetrate through the first profiled steel plate in turn. The diagonal bracing steel plate and the second profiled steel plate are used to connect them. By setting the diagonal brace steel plate, the wall has better shear resistance, the tension bolts have a restraining effect on the concrete, and the tension bolts are arranged along the diagonal brace, so that the concrete has a stronger restraint effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com