Method of replacing mortar in mortar joint for masonry structure reinforcement

A masonry structure and mortar technology, applied in building components, building structure, building maintenance, etc., can solve the problems of seismic performance that cannot meet the requirements of specifications and high costs, reduce personnel and property losses, simple construction operations, and significantly economical. effect of benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

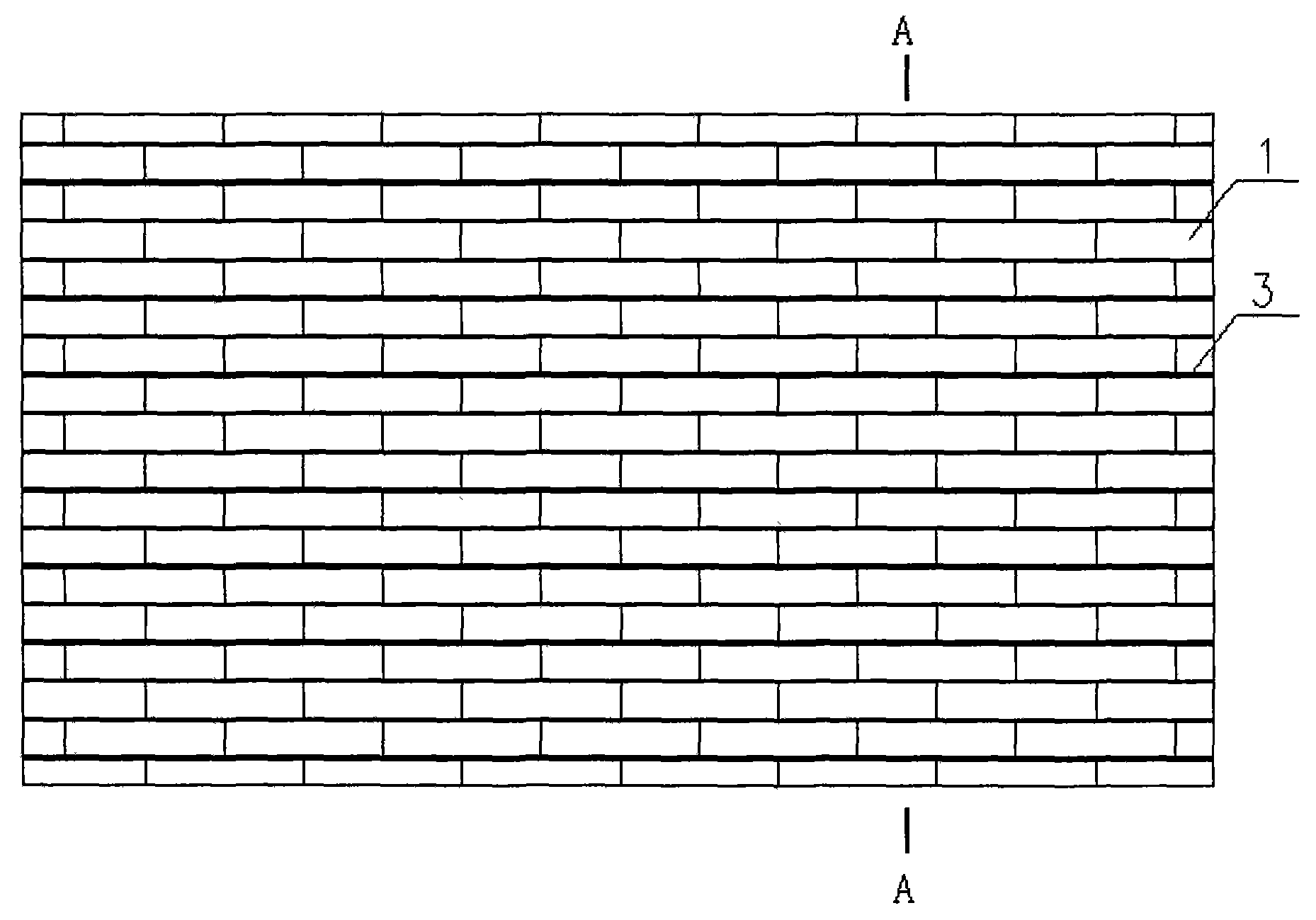

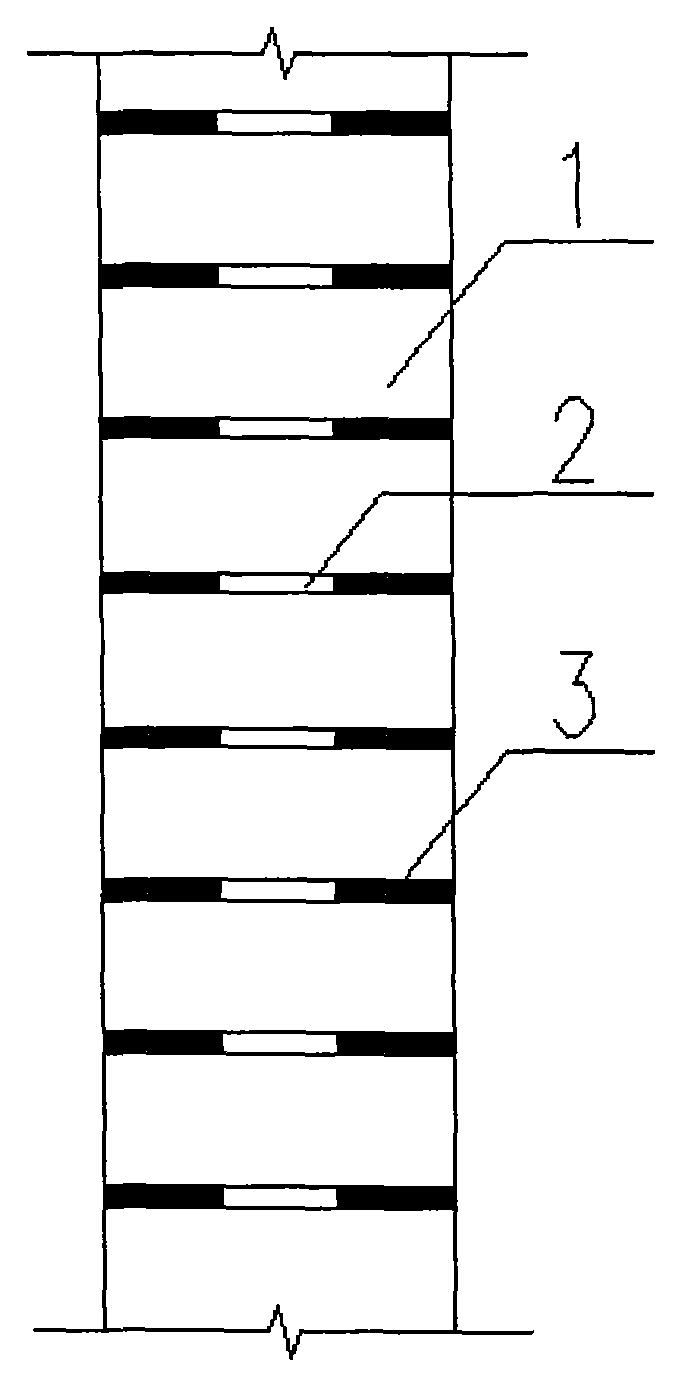

[0024] A method for replacing mortar of a masonry structure for reinforcing mortar joints, comprising the original masonry structure wall body 1, the original low-grade mortar 2 in the original mortar joints and the newly backfilled high-grade mortar 3, the replacement method of the mortar joints adopts The method of replacing the long-length mortar joints on both sides of the wall, that is, the two ends of the original mortar joints in the horizontal direction of the wall thickness are cut horizontally along the longitudinal direction of the original masonry structure wall 1, the original low-grade mortar 2 is removed, and the high-grade mortar is backfilled. Mortar 3 is used to improve the compressive and shear resistance of the masonry structure, while the original low-grade mortar 2 in the middle part of the wall thickness direction remains unchanged. Among them, the wall blocks are solid bricks, the original low-grade mortar 2 has a strength grade of M2.5 or M5.0, and the ...

Embodiment 2

[0033] The wall block in this embodiment is a hollow block, the strength grade of the original low-grade mortar 2 is Mb2.5 or Mb5.0, and the strength grade of the high-grade mortar 3 is Mb7.5, Mb10 or Mb15. Other structures and methods are the same as in Embodiment 1, and will not be described in detail here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com