Special-shaped combined block and method for constructing wall body by adopting same

A block and masonry technology, applied in the direction of walls, buildings, building materials, etc., to achieve the effect of consistent structure, less block forms, and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

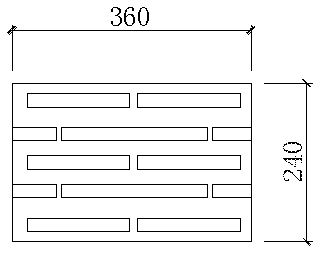

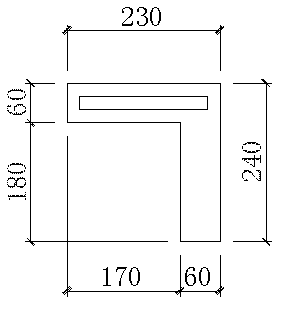

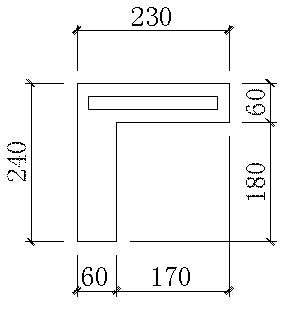

[0033] As shown in Figure 1, No. 0 building block of the present invention is a main building block, and its section is rectangular. Blocks No. 1 to No. 6 are all L-shaped in cross-section, and Block No. 0 is a rectangular block with a length of 360mm×width 240mm×thickness of 60mm. The filling groove for filling the thermal insulation material; the shapes of the No. 1 block and the No. 2 block are symmetrical, and both are L-shaped blocks with a length of 230 mm × width 240 mm × thickness 60 mm × arm width 60 mm, and each of the surfaces has a symmetrical position It is used to fill the filling groove of thermal insulation material; No. 3 block and No. 4 block are symmetrical in shape, both are L-shaped blocks with length 350 mm × width 240 mm × thickness 60 mm × width of narrow arm 60 mm × width of wide arm 180 mm. There are more than one filling grooves on the surface for filling thermal insulation materials, among which there is one filling groove on the narrow arm, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com