Composite heat-insulation truss, wall comprising composite heat-insulation truss and construction method of wall

A composite thermal insulation and truss technology, applied in the field of composite thermal insulation trusses, can solve the problems of slow construction speed of composite thermal insulation wall pavement, unreasonable connection between thermal insulation layer and structural layer, unreasonable wall structure design, etc. The effect of variable, excellent fire resistance and simple construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

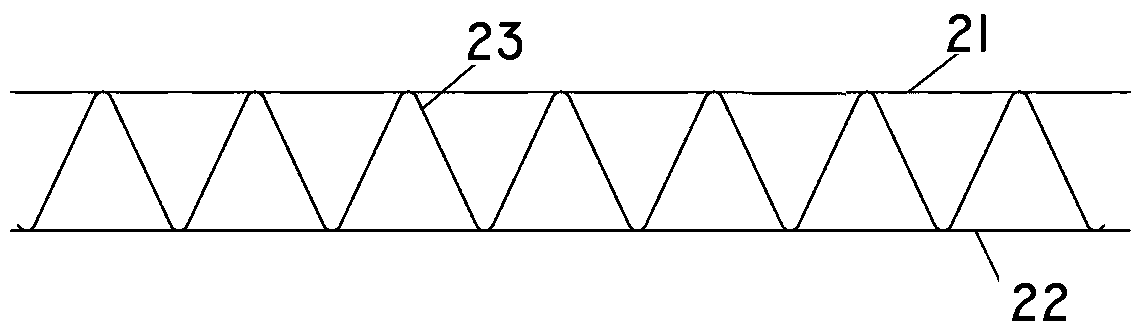

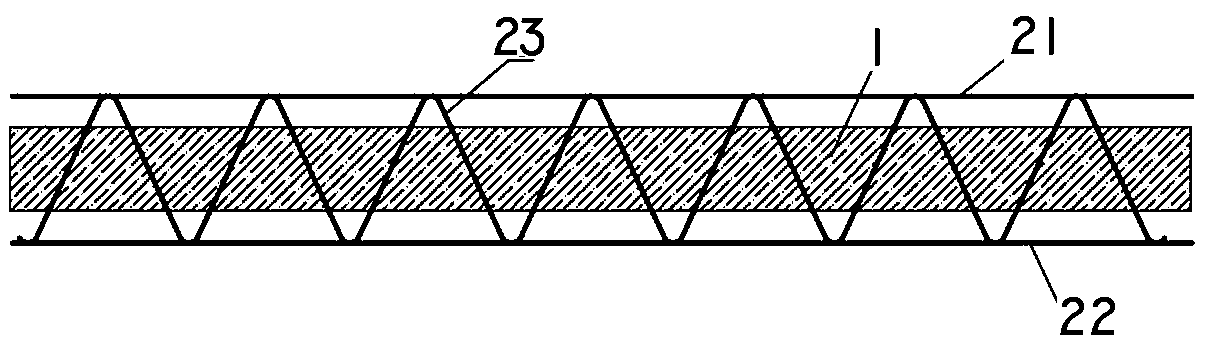

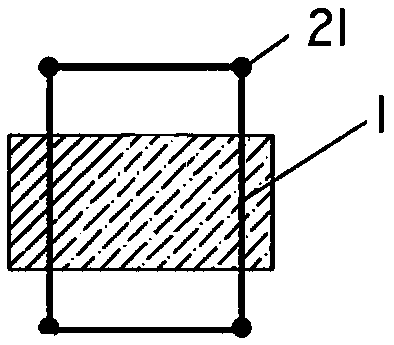

[0059] Such as figure 1 As shown, the present invention provides a composite thermal insulation truss, comprising a strip-shaped thermal insulation material 1 and a truss skeleton sheathed outside the thermal insulation material 1, the cross section of the truss skeleton is rectangular, and the truss skeleton includes an upper chord steel bar 21, a lower chord steel bar 22 and a steel bar arranged on the upper chord 21 and the web reinforcement 23 between the lower chord reinforcement 22; the bonding between the thermal insulation material 1 and the truss skeleton.

[0060] Wherein, the thermal insulation material 1 is a cuttable thermal insulation block material; the cuttable thermal insulation block material is an airgel felt or an extruded board or rock wool treated with waterproofing. The truss skeleton adopts steel fiber reinforced plastic bars; the fiber reinforced plastic bars are glass fiber bars or basalt fiber bars. The top surface of the truss frame exceeds or is at ...

Embodiment 2

[0075] Such as Figure 4 As shown, the wall body comprising the above thermal insulation truss, the wall body includes the outer leaf plate 3, the inner leaf plate 4 and the middle layer heat preservation structure arranged between the outer leaf plate 3 and the inner leaf plate 4, the cross section of the middle layer heat preservation structure Rectangular, the middle thermal insulation structure includes reinforced concrete concealed column 5, the first composite thermal insulation truss arranged on one short side of the rectangle, the second composite thermal insulation truss arranged on the other short side of the rectangle, and the first composite thermal insulation truss and the second composite thermal insulation truss The wall insulation layer 6 between the composite insulation trusses.

[0076] Wherein, the thickness of the outer leaf plate 3 is 100mm, the thickness of the middle insulation structure is 150mm, and the thickness of the inner leaf plate 4 is 120mm. Th...

Embodiment 3

[0088] Such as Figure 5 As shown, the wall body of the composite thermal insulation truss includes an external bearing layer 7 with a thickness of 80 mm and an internal thermal insulation layer with a thickness of 320 mm. The internal thermal insulation layer includes a microporous concrete thermal insulation layer, a composite thermal insulation truss arranged at one end of the internal thermal insulation layer and a hanging embedded part 8,

[0089] The microporous concrete composite thermal insulation wall adopts a composite thermal insulation truss with a built-in 120mm and two wings exceeding the thermal insulation truss 150mm rock wool insulation layer, that is, the composite thermal insulation truss includes a third thermal insulation material 13 The third truss frame 26 outside the material 13, the section width of the third thermal insulation material 13 is greater than the section width of the third truss frame 26; the width of the third truss frame 26 is 120mm, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com