Manufacturing method of assembled polygonal Mongolian yurt

A production method and technology for yurts, which are applied in residential construction, construction material processing, construction components and other directions, can solve problems such as inconvenience in production and transportation, and achieve the effects of being less prone to collision and damage, beautifying the living environment, and having high construction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The embodiment of the present application discloses a manufacturing method of an assembled polygonal yurt. A method for fabricating an assembled polygonal yurt, comprising the following steps:

[0047] S1. Making or installing the base: the base includes two types, one type of base 2 is a concrete cast-in-place platform or a concrete cast-in-place regular hexagonal ground beam;

[0048] Another form of the base 2 is a regular hexagonal ground beam composed of H-shaped steel connections, and adjacent H-shaped steels are connected by bolts.

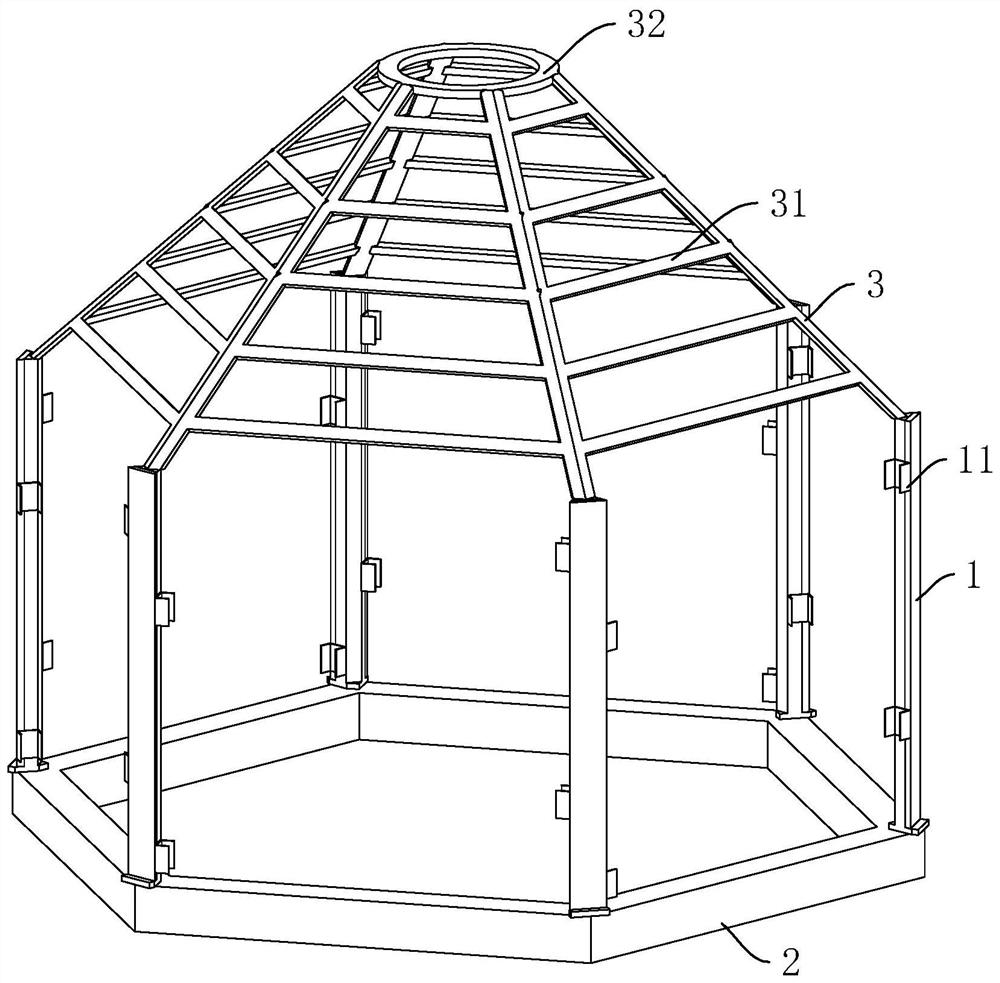

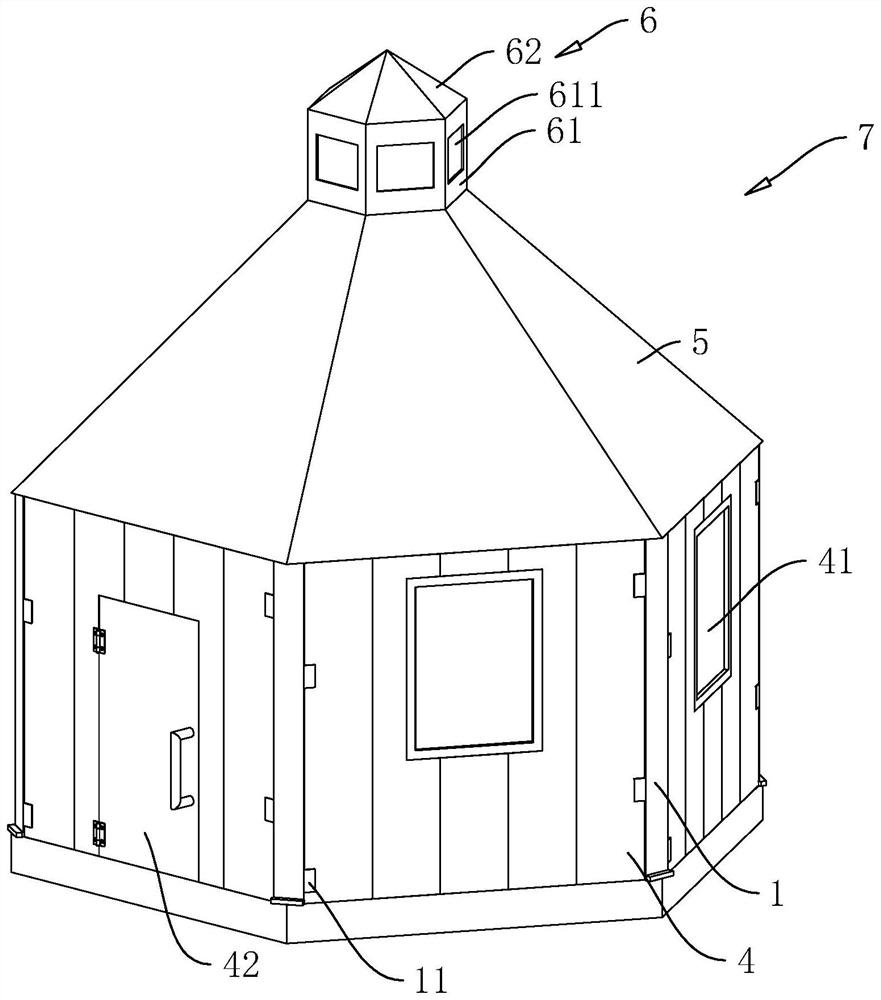

[0049] S2. Install steel columns: refer to figure 1 , the steel column 1 is installed on the base 2, the bottom of the steel column 1 is welded with a mounting plate, the four corners of the mounting plate are provided with mounting holes, and bolts are pierced in the mounting holes to fix the steel column 1 on the ground, six A steel column 1 is surrounded by a regular hexagon; U-shaped clips 11 for installing prefabricated therma...

Embodiment 2

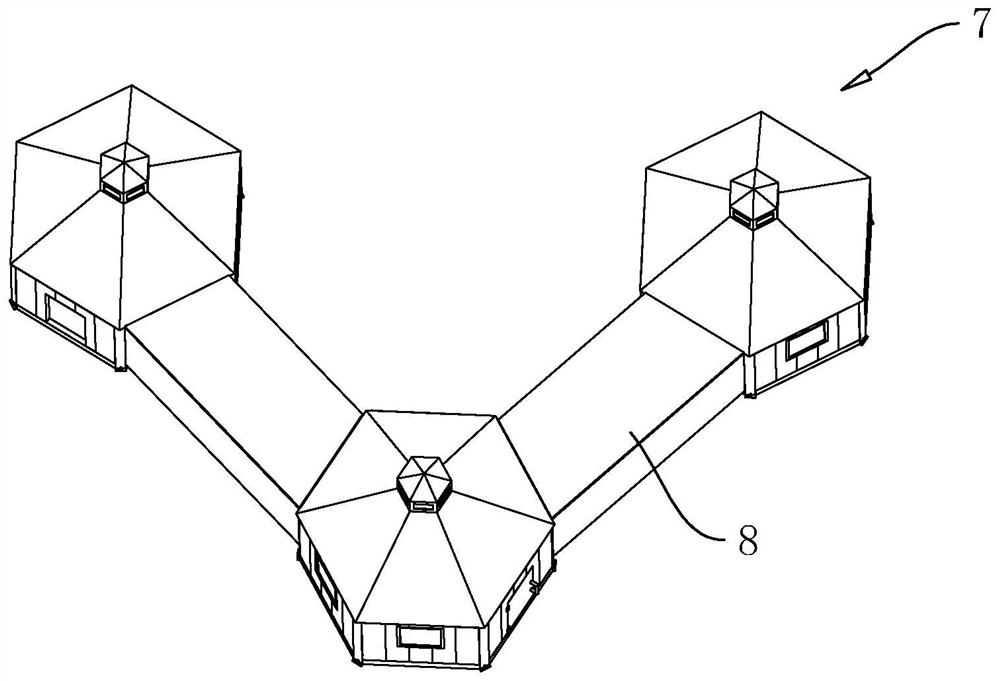

[0062] refer to image 3 The difference between this embodiment and Embodiment 1 is that: this embodiment is provided with three yurts 7, and the three yurts 7 are distributed in a triangle, and one of the yurts 7 communicates with the yurts 7 on both sides thereof;

[0063] A corridor 8 is set between the two connected yurts 7, and the corridor 8 includes two rows of steel columns 1 oppositely arranged, and prefabricated thermal insulation wall panels 4 are assembled between the steel columns 1, and prefabricated thermal insulation walls assembled in the two rows Top plate is installed on the board 4, thereby forms corridor 8, two yurts 7 are communicated, wash room can be set in corridor 8, also can be provided with toilet.

Embodiment 3

[0065] refer to Figure 4 , The difference between this embodiment and Embodiment 1 is that: this embodiment is provided with four yurts 7, and the four yurts 7 are arranged in a square shape, and adjacent yurts 7 are connected through corridors 8.

[0066] Green plants can be planted on the courtyard 9 enclosed between the four yurts 7, thereby forming a garden and beautifying the living environment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com