Combined self-heat preservation building block and self-heat preservation wall thereof

A self-insulating block and self-insulating technology, applied to walls, building materials, building components, etc., can solve the problems of falling off, cumbersome construction, cracking, etc., and achieve the effect of convenient operation, simple construction, and the same service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

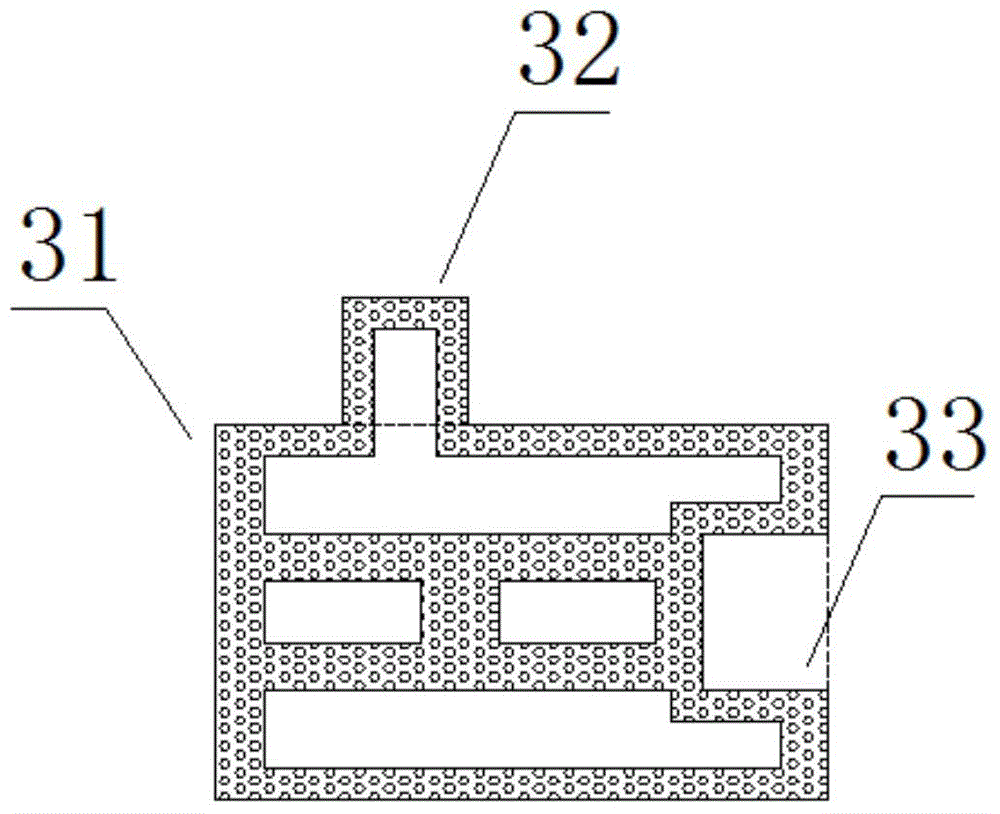

[0027] A combined self-insulating building block, comprising a main block 1, which has a cavity inside, and the cavity is filled with thermal insulation materials, and also includes corner blocks I2 and corner blocks II3, each of which has a cavity inside, and the cavity is filled with thermal insulation materials Material;

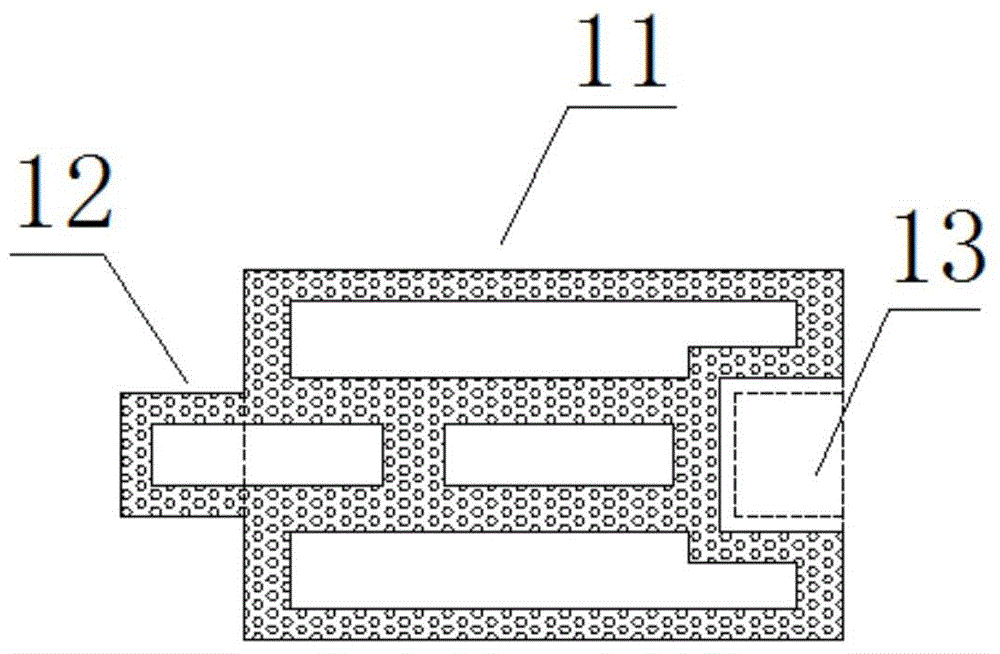

[0028] Main block 1 comprises main block rectangular main body 11, main block protruding part 12 and main block concave part 13, as figure 1 As shown, the main block protruding part 12 is located in the middle part of the left side of the main block rectangular body 11, and the main block concave part 13 is located in the right middle part of the main block rectangular body 11. The main block protruding part 12 and the main block concave part 13 The depth is consistent, and the concave part 13 of the main block is 20mm wider than the convex part 12 of the main block;

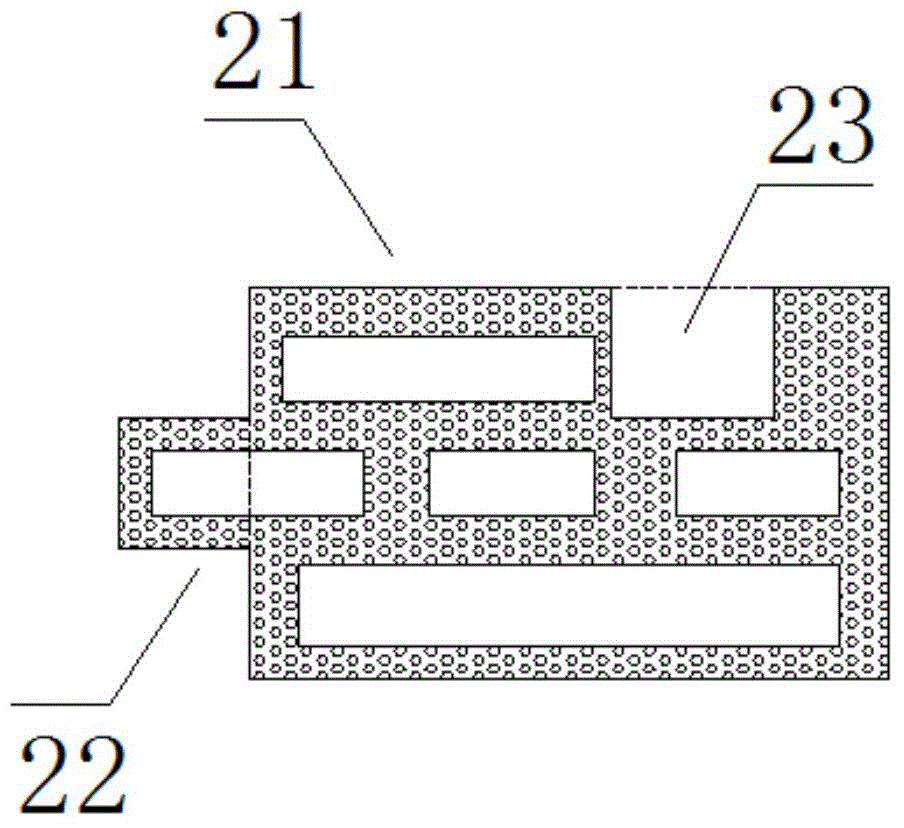

[0029] The corner block I2 includes a corner block I rectangular main body 21, a corne...

Embodiment 2

[0033] The present invention may also include T-shaped wall edge block I4 and T-shaped wall edge block II5, both of which have cavities inside, and the cavities are filled with thermal insulation materials;

[0034] The T-shaped wall edge block I4 includes the T-shaped wall edge block I rectangular main body 41, the T-shaped wall edge block I first protruding part 42, the T-shaped wall edge block I second protruding part 43 and the T-shaped wall edge block I concave part 44, the T-shaped wall edge block I The first protruding part 42 of the wall side block I is located in the middle part of the left side of the rectangular body 41 of the T-shaped wall side block I, and the second protruding part 43 of the T-shaped wall side block I is located on the right side of the upper side of the rectangular body 41 of the T-shaped wall side block I. The recessed part 44 of the wall edge block I is located in the middle part of the right side of the rectangular main body 41 of the T-shaped...

Embodiment 3

[0038] The present invention can also include a dislocation auxiliary block 6, whose structure is consistent with the main block 1, the width is consistent with the main block 1, and the length is half of the main block 1 and less than 10 mm. There are cavities inside, and the cavity is filled with heat-insulating materials. Such as Figure 9 As shown, the misalignment auxiliary block 6 plays the purpose of staggering the gray joints, Figure 9 It is only a schematic diagram of the front view of a part of the wall.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com