A kind of integral core material fireproof insulation door and manufacturing method

A fireproof heat preservation and core material technology, which is applied to fireproof doors and other directions, can solve the problems of detachment and poor fireproof performance, and achieve the effects of low manufacturing cost, good overall strength and good fireproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

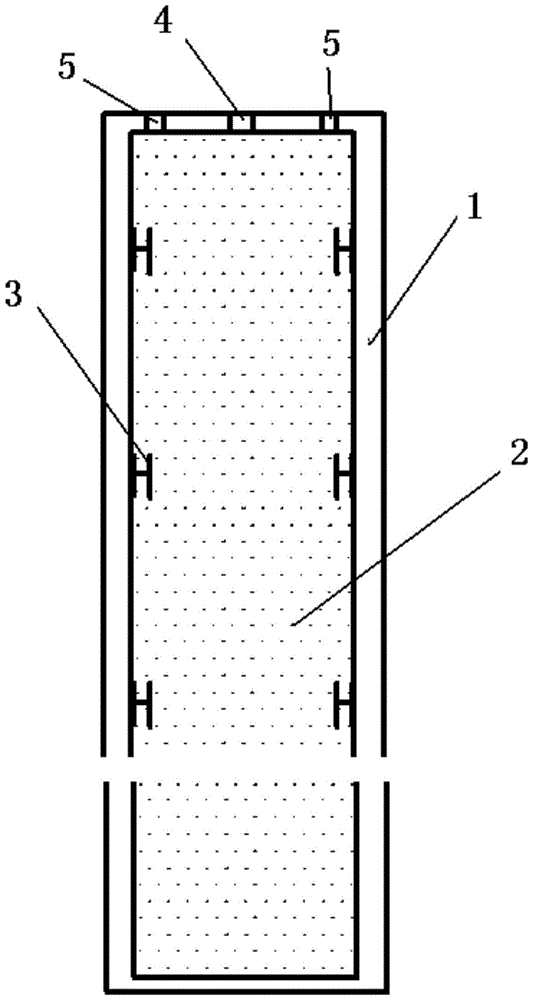

[0009] The present invention is specifically described below in conjunction with accompanying drawing, as figure 1 As shown, the present invention includes a door panel 1, and the door panel 1 is a closed space; a plurality of "I"-shaped anchors 3 are fixedly arranged on the inner side of the door panel 1; an injection hole 4 is arranged above the door panel 1, and the Risers 5 are arranged on both sides of the injection hole 4; the enclosed space formed by the door panel 1 is filled with inorganic fireproof and heat-insulating materials 3.

[0010] The preparation method of the present invention is: first prepare the door panel 1, general technology can be adopted, and then by welding, one surface of the "I"-shaped anchor 3 is welded and fixed on the inner side of the door panel 1, the number of anchors 3 The arrangement and arrangement can be set according to different door specifications and usage requirements, and then the door panel 1 is welded into a closed whole, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com