Prefabricated concrete integrated heat preservation wall component and construction method thereof

A technology of prefabricated concrete and thermal insulation walls, applied in thermal insulation, building components, building thermal insulation materials, etc., can solve problems such as high construction quality requirements, water seepage, and cracking of anti-cracking mortar on the surface layer, and achieve optimized construction procedures and good visual effects , the effect of overall improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

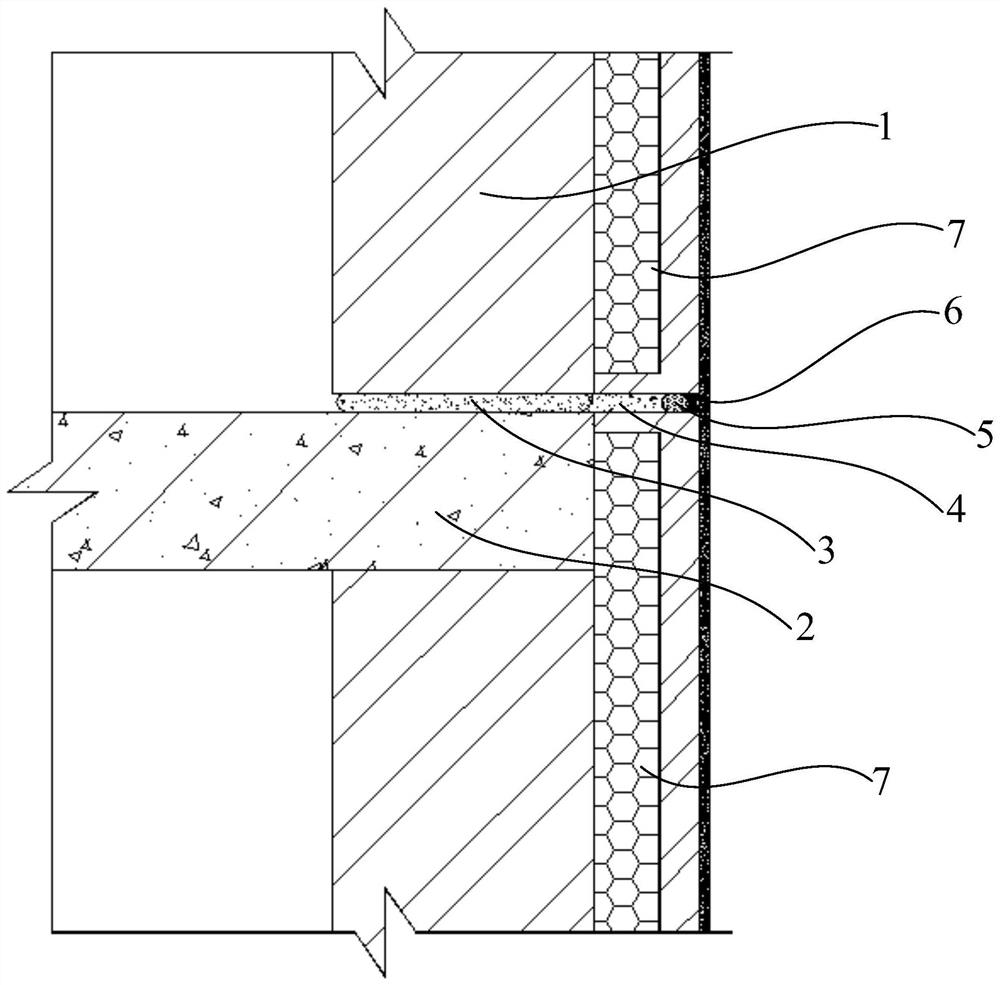

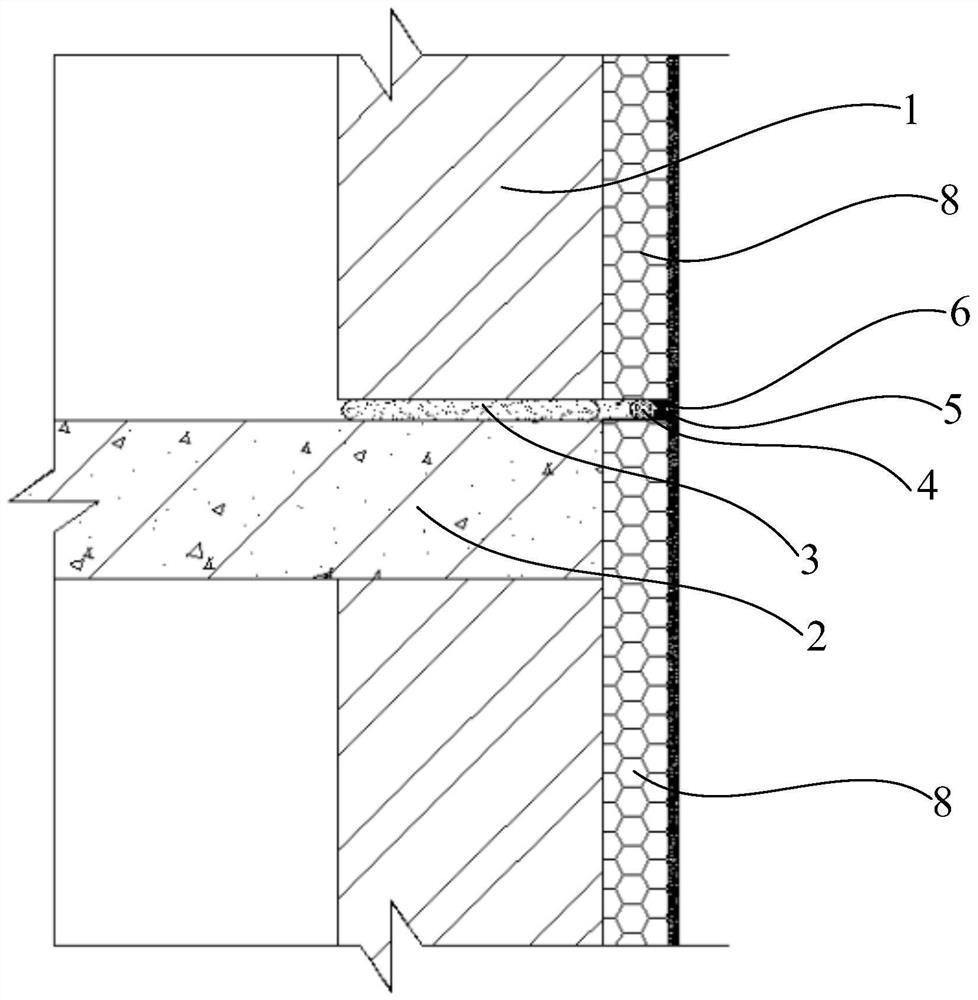

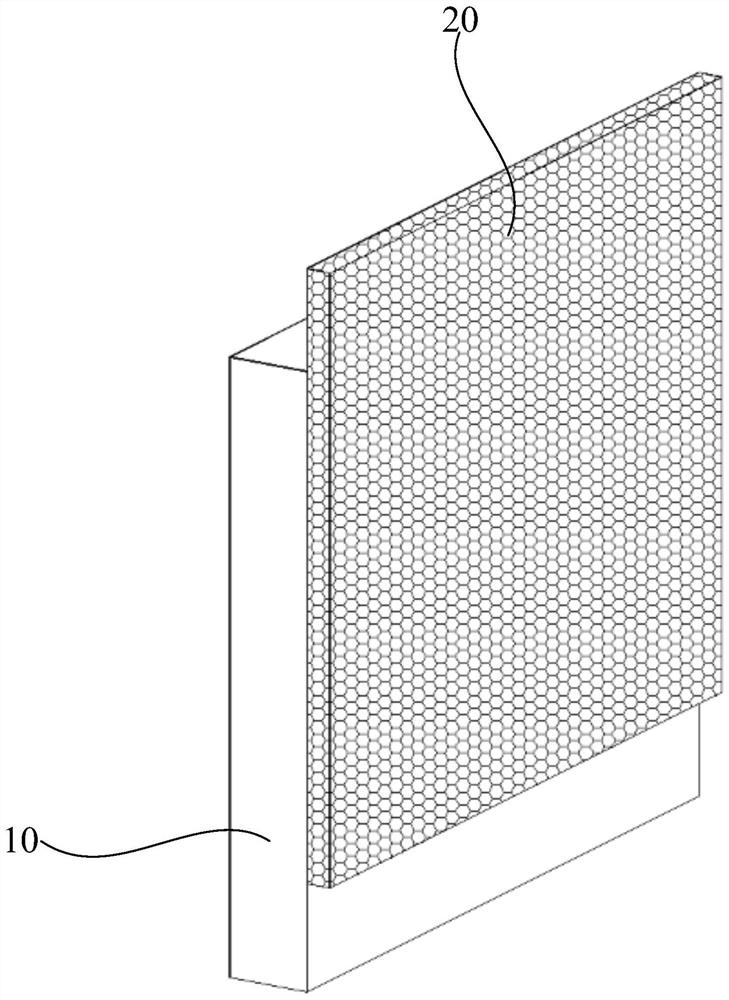

[0078] Such as image 3 , Figure 4 and Figure 5 As shown, this embodiment discloses a prefabricated concrete integrated thermal insulation wall component, the precast concrete integrated thermal insulation wall component includes a thermal insulation layer 10 and a wall layer 20, the thermal insulation layer 10 is on the outside of the wall layer 20, and the thermal insulation layer 10 There is a cantilevered part 201 at the top of the cantilevered part 201. The cantilevered part 201 extends out of the top surface of the wall body layer 20 and forms a connection gap 101 with the wall body layer 20. The bottom end of the insulation layer 10 has a staggered part 202. The bottom end of 20 extends from the misplaced layer portion 202 and an avoidance gap 203 is formed between the misaligned portion 202 .

[0079] When the prefabricated concrete integrated thermal insulation wall component is in use, the top surface of the wall layer 20 will fit against the bottom surface of th...

Embodiment 2

[0100] Such as Figure 6 and Figure 7 As shown, the same parts of the prefabricated concrete integrated thermal insulation wall component of the second embodiment and the first embodiment will not be repeated, and only the different parts will be described. In this embodiment 2, the prefabricated concrete integrated thermal insulation wall member also includes an outer panel 30, and the two sides of the insulation layer 10 are respectively connected to the wall layer 20 and the outer panel 30, and the inner surface of the outer panel 30 is connected to the insulation layer. The outer surfaces of 10 are completely fitted and have the same area.

[0101] In Example 1, the prefabricated concrete integrated thermal insulation wall component adopts the form of anti-beating integrated thermal insulation assembled wall prefabricated component, without outer panel structure. In Embodiment 2, the prefabricated concrete integrated thermal insulation wall component is in the form of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com