L-shaped and T-shaped concrete shear wall structure combined type prefabricated edge component

A technology of concrete shear walls, edge elements, applied in the direction of building elements, walls, manufacturing tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

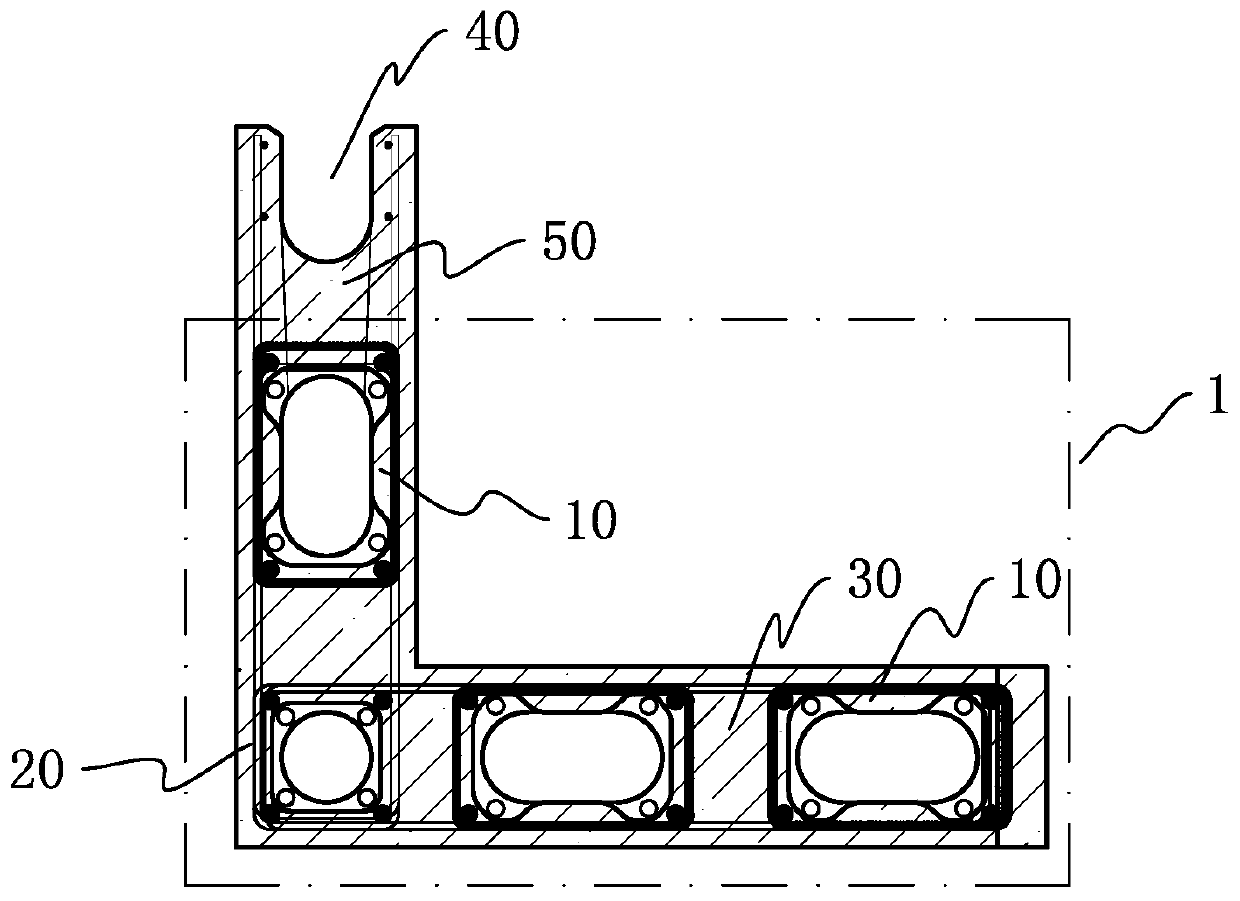

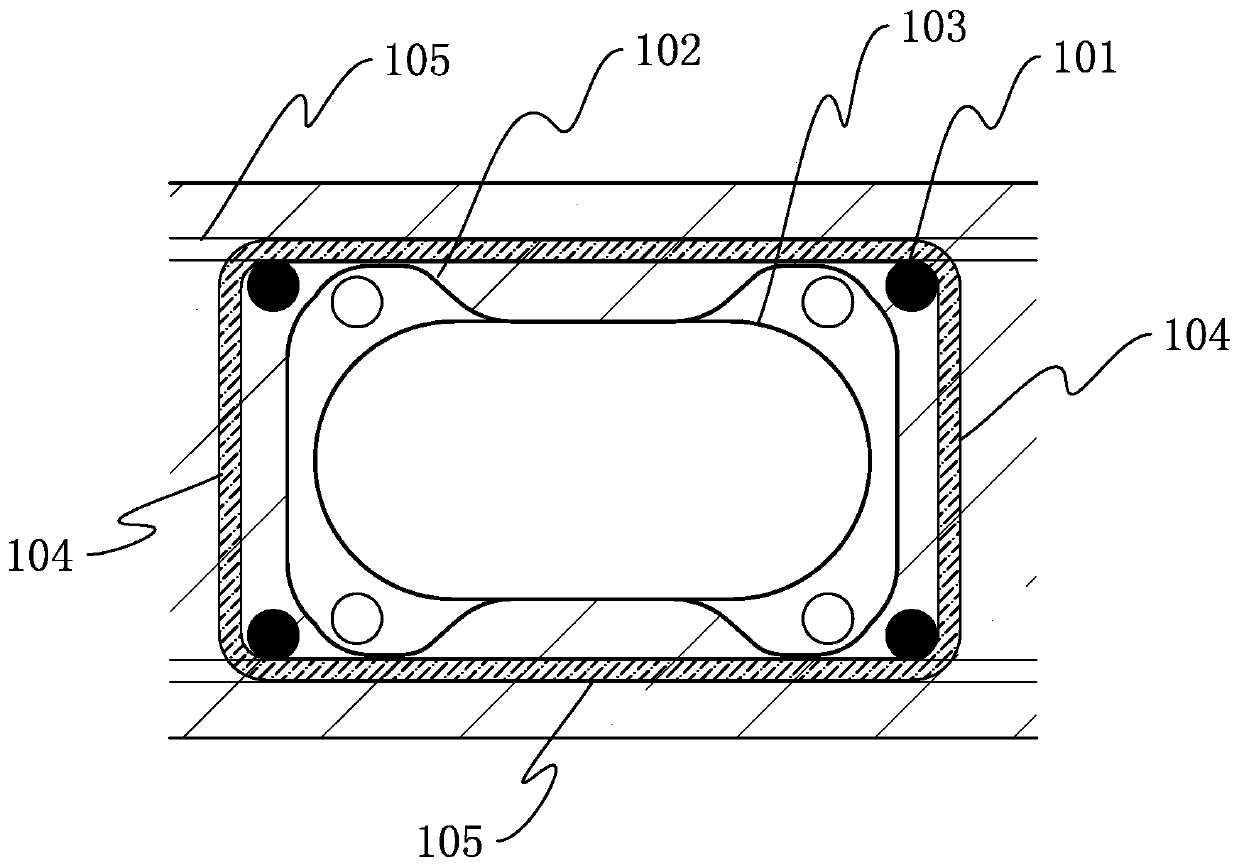

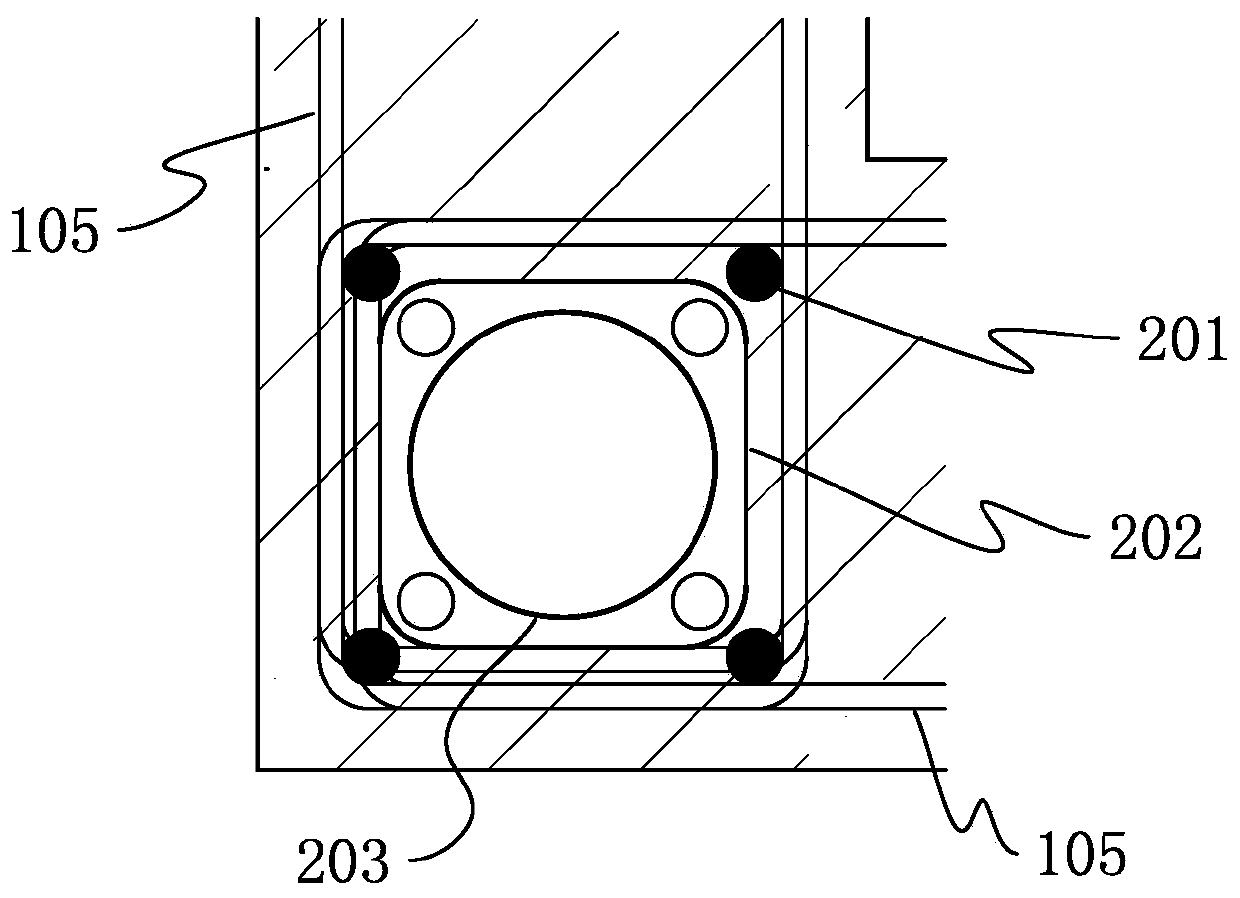

[0043] Such as Figure 1-3As shown, a combined prefabricated edge member of an L-shaped concrete shear wall structure is composed of concrete 30 and a steel skeleton, including an edge member area 1 with an L-shaped cross section, and the edge member area 1 is composed of three extended edge members Unit 10 and a corner edge member unit 20; all extended edge member units 10 are distributed on both sides of the edge member area 1 (two on one side and one on the other side), with a corner edge member unit 20 in the middle; The extended edge member unit 10 and the corner edge member unit 20 are all provided with through holes extending along the height direction; the cross-sectional shapes and cross-sectional areas of the upper and lower parts of the through holes are not equal; the four corners of the through holes of the extended edge member unit 10 One edge member reinforcing bar 101 extending along the height direction is respectively provided; the edge member reinforcing bar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com