Flexible fire-resistant branch cable with anti-vibration and anti-spraying performances

A branch cable and flexible technology, applied in the field of flexible fire-resistant branch cables, can solve problems such as the inability to meet the requirements of rigid fire-resistant cables for electrification, the inability to guarantee the fire resistance and waterproof test, and the inability to withstand the spray vibration test, etc., to avoid melting and dripping. The effect of crusting is good and the effect of improving connection stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

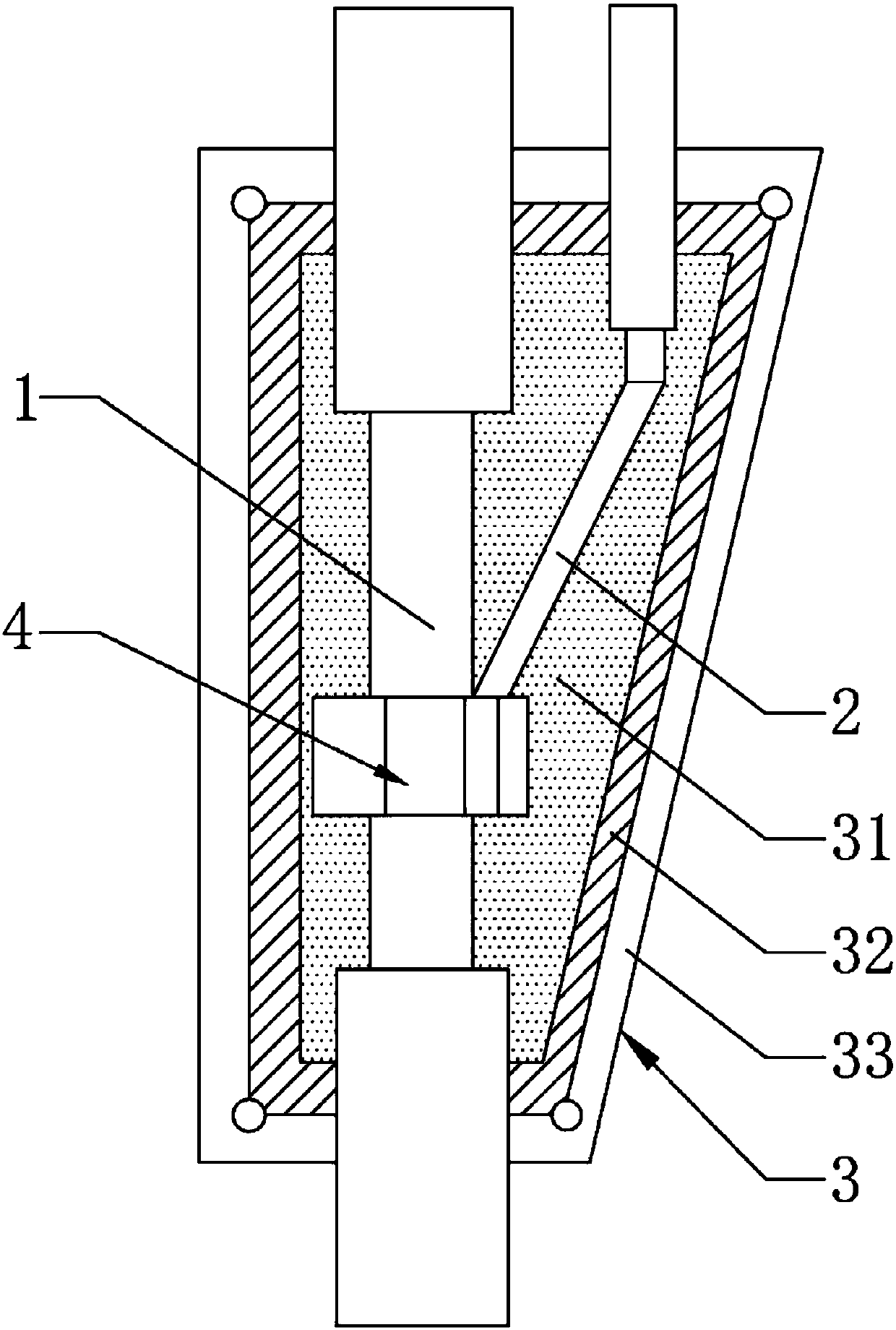

[0040] See figure 1 , an anti-seismic and spray-resistant flexible fireproof branch cable, the flexible fireproof branch cable includes a main cable 1 and a branch cable 2 connected to the middle of the main cable, the outer wall of the main cable 1 and the branch cable 2 A branch connector 3 is provided, and the branch connector 3 includes an inner layer 31, a middle layer 32 and an outer layer 33 sequentially connected from the inside to the outside, the inner layer 31 is ceramic oxygen barrier mud, and the middle layer 32 is a stainless steel armor. The outer layer 33 is ceramicized silicone rubber, and the ceramicized oxygen barrier clay is filled between the main cable 1 , branch cables 2 and the middle layer 32 .

[0041] The connection between the main cable 1 and the branch cable 2 is provided with a C-shaped clamp 4 for clamping the connection; the outer walls of the main cable 1 and the branch cable 2 are provided with a ceramic silicone rubber insulating layer .

...

Embodiment 2

[0055] The difference between this embodiment and above-mentioned embodiment 1 is:

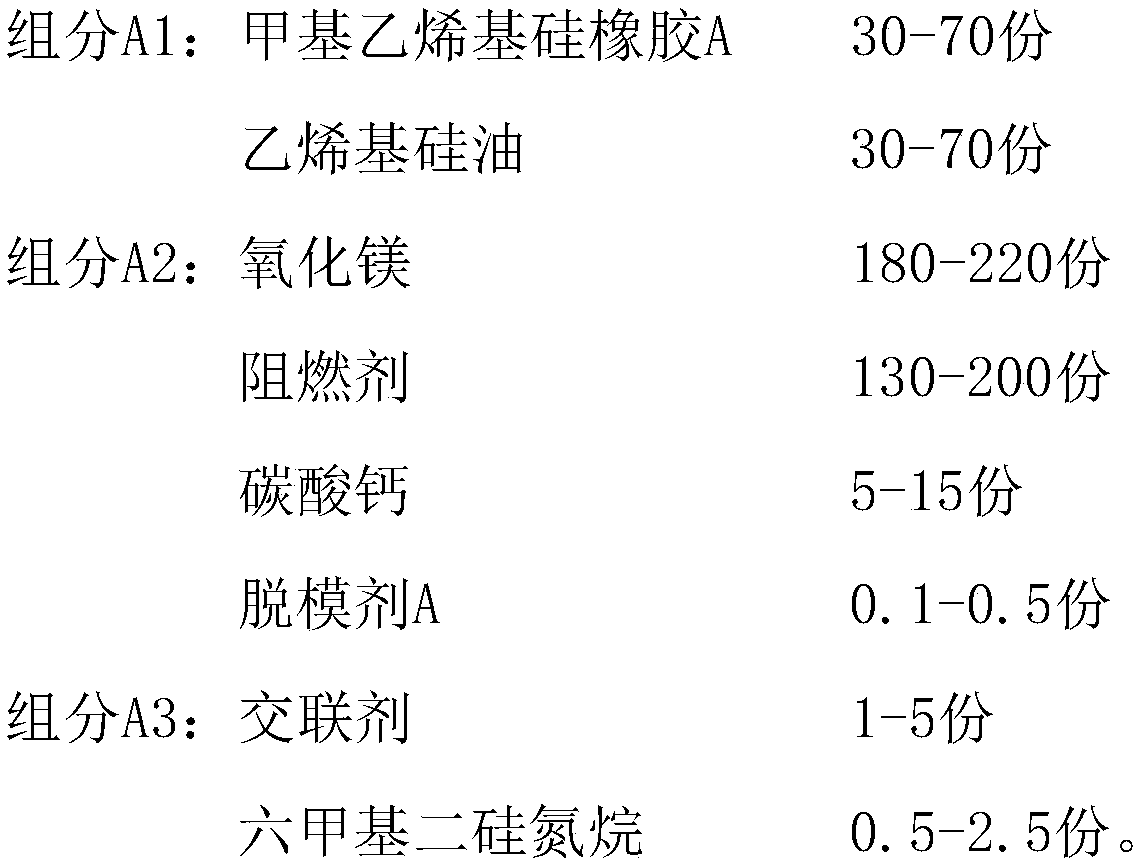

[0056] The vitrified oxygen barrier clay includes the following raw materials in parts by weight:

[0057]

[0058] The weight content of the vinyl monomer of the methyl vinyl silicone rubber A is 0.03%, and the molecular weight is 620,000; the weight content of the vinyl monomer of the vinyl silicone oil is 0.16%, and the viscosity is 900CS; The combustion agent is a mixture of aluminum hydroxide fine powder and zinc borate in a weight ratio of 110:35, the crosslinking agent is vinyltrimethoxysilane, and the release agent A is zinc stearate.

[0059] The preparation method of the vitrified oxygen barrier clay comprises the following steps:

[0060] (1) Mixing: mix component A1 evenly to obtain mixed material A; then add component A2, which accounts for 18% of the total weight of component A2, into the mixed material A, stir evenly, then add component A3, mix Evenly, add the remaining com...

Embodiment 3

[0069] The difference between this embodiment and above-mentioned embodiment 1 is:

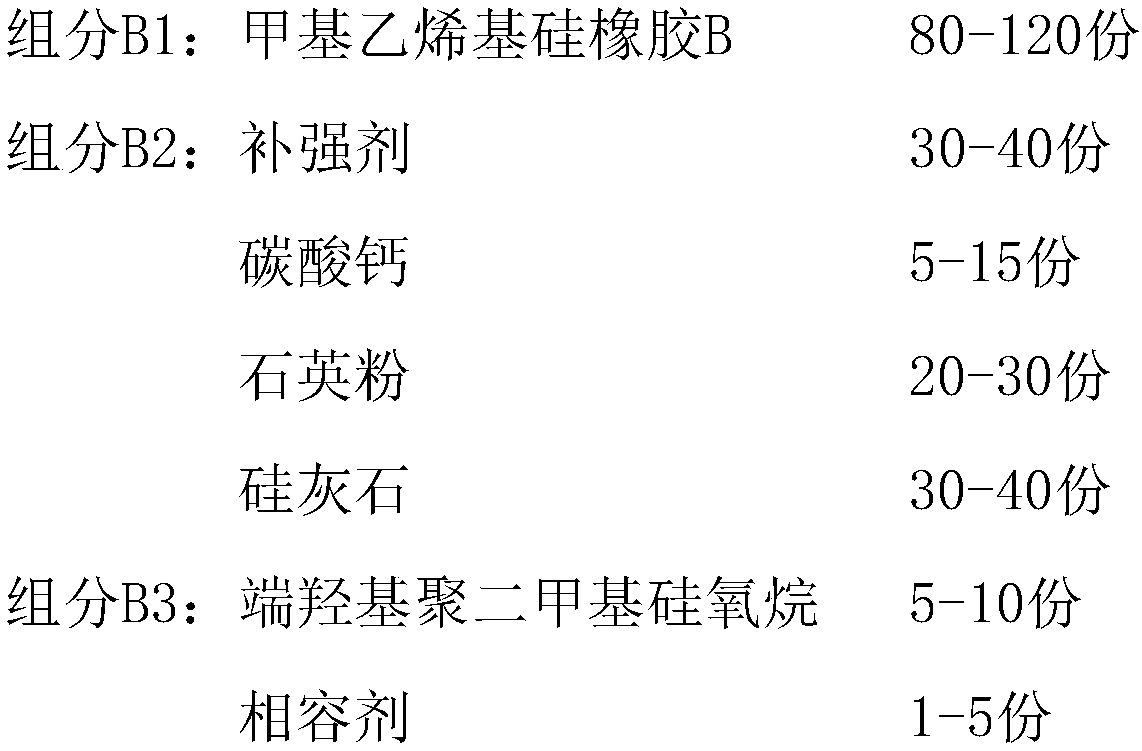

[0070] The vitrified oxygen barrier clay includes the following raw materials in parts by weight:

[0071]

[0072] The weight content of the vinyl monomer of the methyl vinyl silicone rubber A is 0.04%, and the molecular weight is 650,000; the weight content of the vinyl monomer of the vinyl silicone oil is 0.17%, and the viscosity is 100CS; The combustion agent is a mixture of aluminum hydroxide fine powder and zinc borate in a weight ratio of 125:40, the crosslinking agent is vinyltrimethoxysilane, and the release agent A is zinc stearate.

[0073] The preparation method of the vitrified oxygen barrier clay comprises the following steps:

[0074] (1) Mixing: mix component A1 evenly to obtain mixed material A; then add component A2, which accounts for 20% of the total weight of component A2, into the mixed material A, stir evenly, then add component A3, mix Evenly, add the remaining com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com