Reinforced gravity type retaining wall antiknock construction

A gravity-type retaining wall technology, applied to underwater structures, infrastructure engineering, water conservancy projects, etc., can solve the problems of increasing the cost of retaining walls, slow construction progress, uneconomical, etc., to improve anti-overturning ability and meet Anti-seismic requirements and the effect of reducing the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

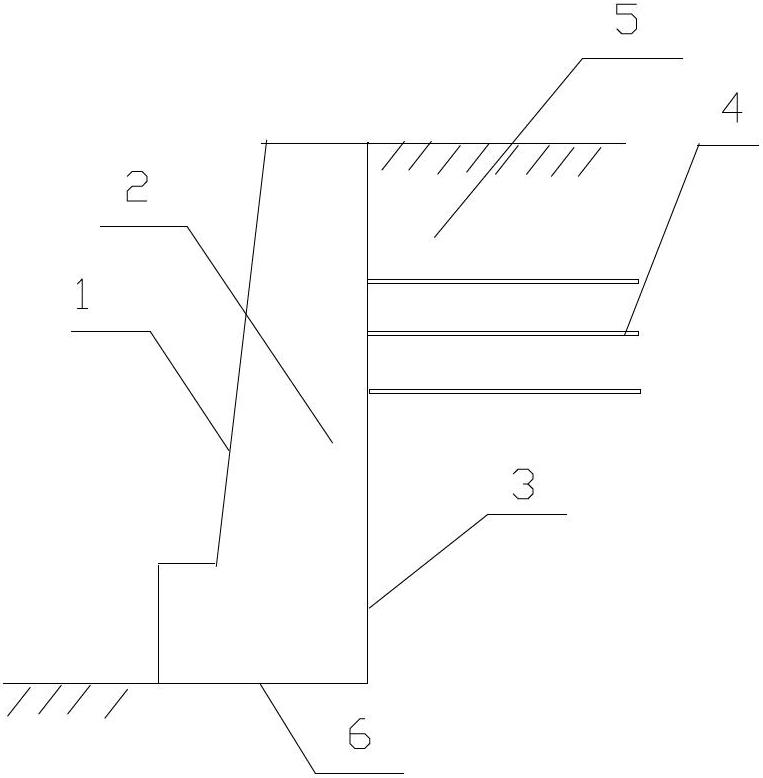

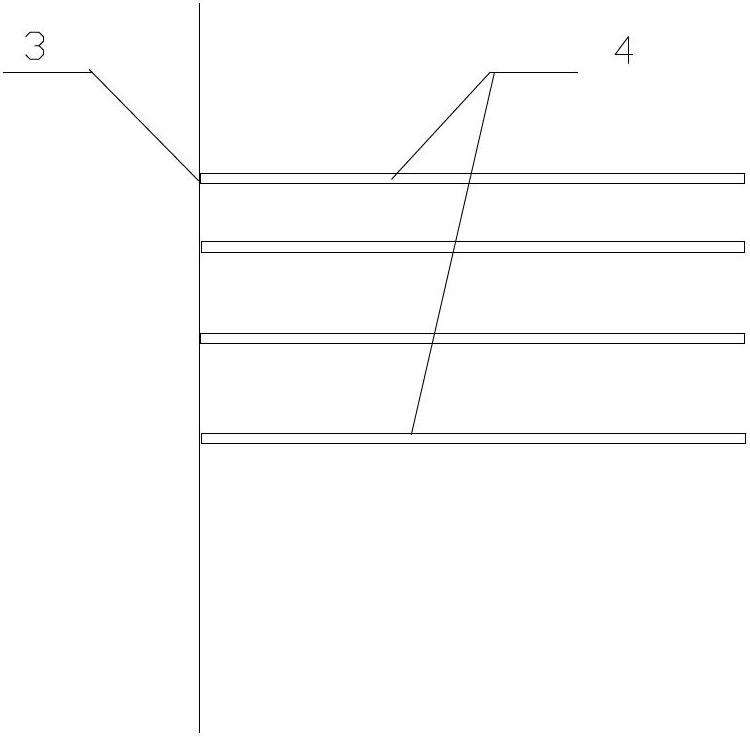

[0017] Such as figure 1 , figure 2 As shown, a reinforced gravity retaining wall includes a wall surface 1, a wall body 2, a wall back 3, and a base 6, and the wall back 3 is internally fixed with steel bars. The tensioning device 4 is composed of a plurality of tensioning bars, one end of which is fixed on the reinforcing bar so as to be connected to the wall back 3, and the rest of the part extends into the supported soil 5 and is connected with the supporting soil 5 as a whole. Two tie bars are parallel to each other, and a plurality of tie bars are installed parallel to the base 6. The tie bars can also be pre-embedded in the retaining wall while pouring the above-mentioned gravity-type reinforced retaining wall, and poured simultaneously with the retaining wall, and the connection method between the tie bars and the supported soil 5 can also be flexible Apply existing technology to connect.

Embodiment 2

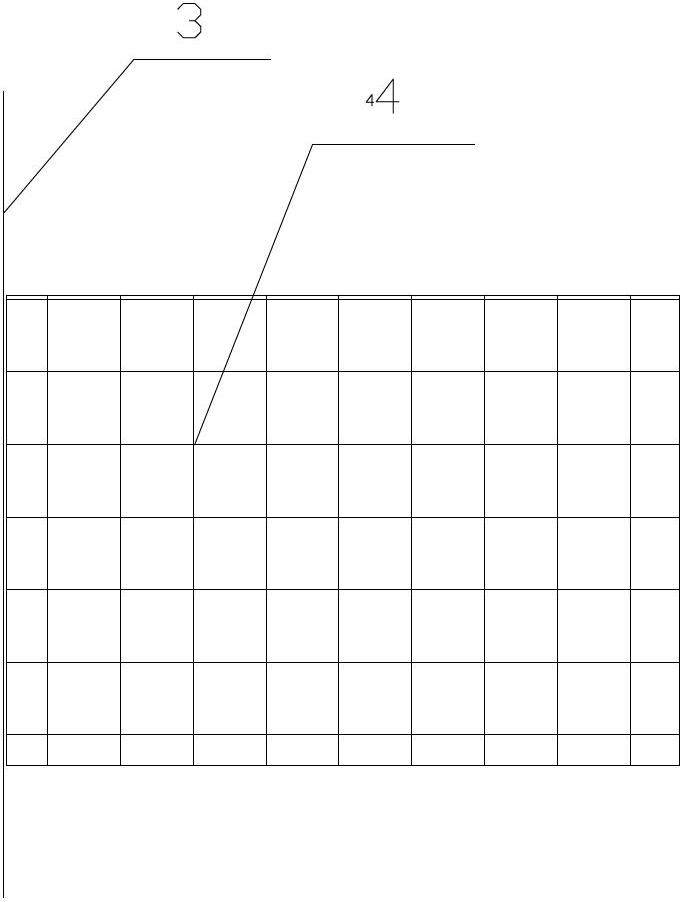

[0019] Such as figure 1 , image 3 As shown, a reinforced gravity retaining wall includes a wall surface 1, a wall body 2, a wall back 3, and a base 6, and the wall back 3 is internally fixed with steel bars. Tensioning device 4 is made up of reticular geogrid, and one end is fixed on the reinforcing bar so as to be connected with wall back 3, and the rest part extends into supported soil 5, and is connected with supporting soil 5 as a whole, above-mentioned net The reticulated geogrids are parallel to each other, and a plurality of reticulated geogrids are installed parallel to the base 6. The mesh geogrid can also be pre-embedded in the retaining wall while pouring the above-mentioned gravity-type reinforced retaining wall, and poured at the same time as the retaining wall, and the connection between the mesh geogrid and the supported soil body 5 The method can also flexibly apply existing technologies for connection. At the same time, since the geogrid is a light-weight,...

Embodiment 3

[0021] A reinforced gravity retaining wall comprises a wall surface 1, a wall body 2, a wall back 3 and a base 6, and the wall back 3 is internally fixed with steel bars. The tensioning device 4 is composed of one or more geotextiles, one end is fixed on the steel bar so as to be connected with the wall back 3, and the rest of the part extends into the supported soil 5 and is connected with the supporting soil 5 as a whole. The plurality of geotextiles are parallel to each other, and the plurality of geotextiles are installed parallel to the base 6 . The geotextile can also be pre-embedded in the retaining wall while pouring the above-mentioned gravity-type reinforced retaining wall, and poured simultaneously with the retaining wall, and the connection method between the geotextile and the supported soil 5 can also be flexibly applied on-site. There are technologies to connect.

[0022] The manufacturing process of geotextiles is to first process polymer raw materials into si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com