Assembly type prefabricated beam and column connecting joint and construction method

A beam-column connection and prefabricated technology, which is applied in the direction of architecture and building construction, can solve problems such as the difficulty of beam-column joint connection, and achieve the effects of clear and reasonable force transmission mechanism, accelerated construction speed, and good cohesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

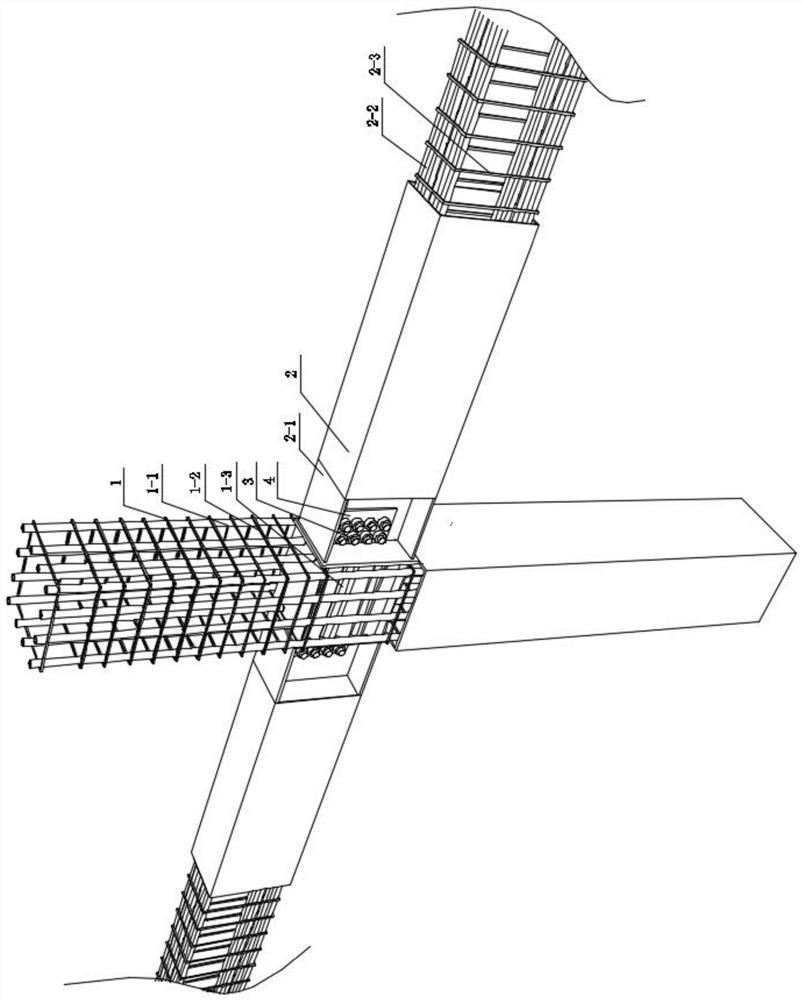

[0049] An assembled prefabricated beam-column connection node includes a prefabricated column 1 and two prefabricated beams 2, and the prefabricated beam and the prefabricated column are fixedly connected by a pre-embedded H-shaped steel 2-1 at one end of the prefabricated beam. In this embodiment, both sides of the prefabricated column are connected to a prefabricated beam respectively; The specific structure of the connection node is as follows:

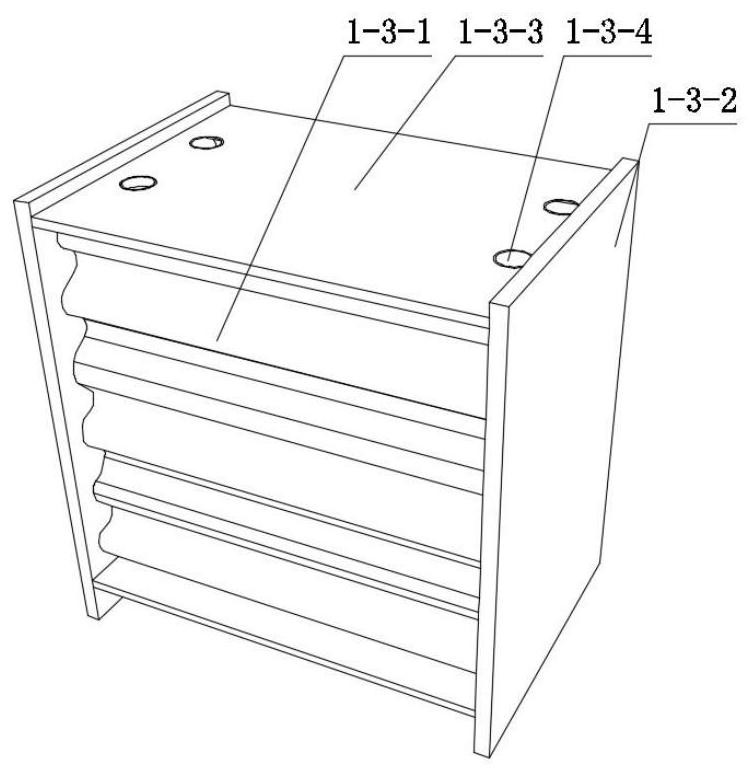

[0050] The prefabricated column includes a column internal longitudinal reinforcement 1-1, a column internal stirrup 1-2 and a column internal embedded part 1-3, the column internal stirrup is located outside the column internal longitudinal reinforcement, and the column internal The parts are fixed in position by interspersing and bundling the stirrups in the column and the longitudinal bars in the column. The embedded parts in the column include corrugated steel 1-3-1 and steel plate 1-3-2 on the side of the column. The two ends ...

Embodiment 2

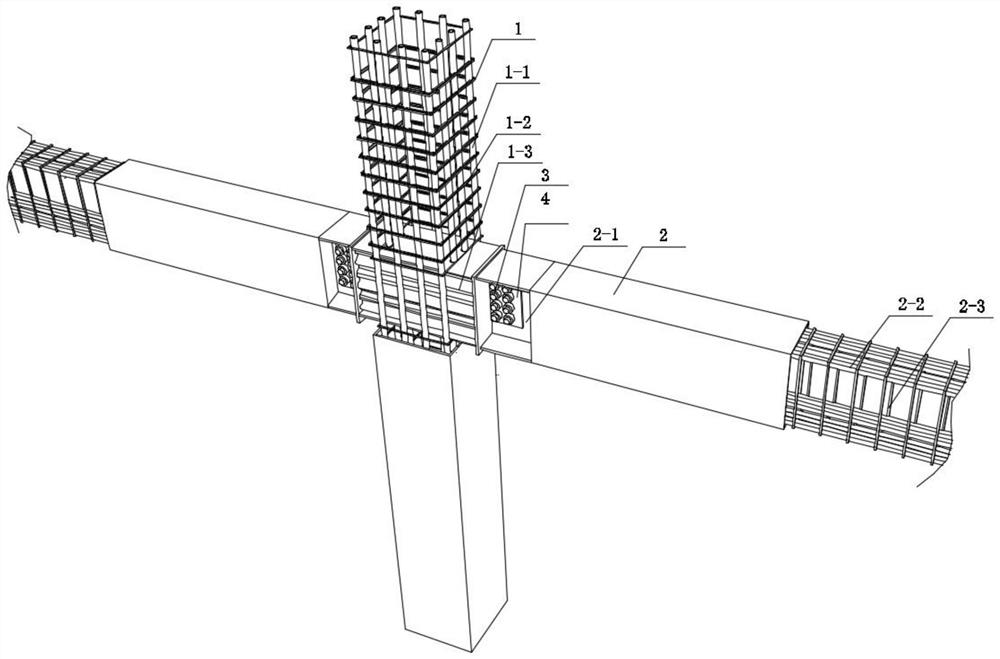

[0065] An assembled prefabricated beam-column connection node, including a prefabricated column and four prefabricated beams, the four sides of the prefabricated column are respectively connected to a prefabricated beam at the same time, the specific details of the connection node between the end of the prefabricated beam and the side of the prefabricated column The structure is as follows:

[0066] The prefabricated column includes the longitudinal reinforcement in the column, the stirrup in the column and the embedded part in the column. The stirrup in the column is located outside the longitudinal reinforcement in the column. The interspersed binding of the longitudinal reinforcement realizes the limit fixation. The embedded parts in the column are the embedded parts 1-4 in the well-shaped column or the embedded parts 1-5 in the cross-shaped column. The embedded parts include well-shaped corrugated steel and four column-side steel plates 1-4-2, and the well-shaped corrugate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com