Connecting structure for light steel keel internal parting wall and steel beam

A light steel keel and connecting structure technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of not meeting architectural design and seismic requirements, unable to adapt to the deformation of the main body of the structure, limited application scope, etc., and achieve easy industrialization. The effect of simple production and assembly and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing:

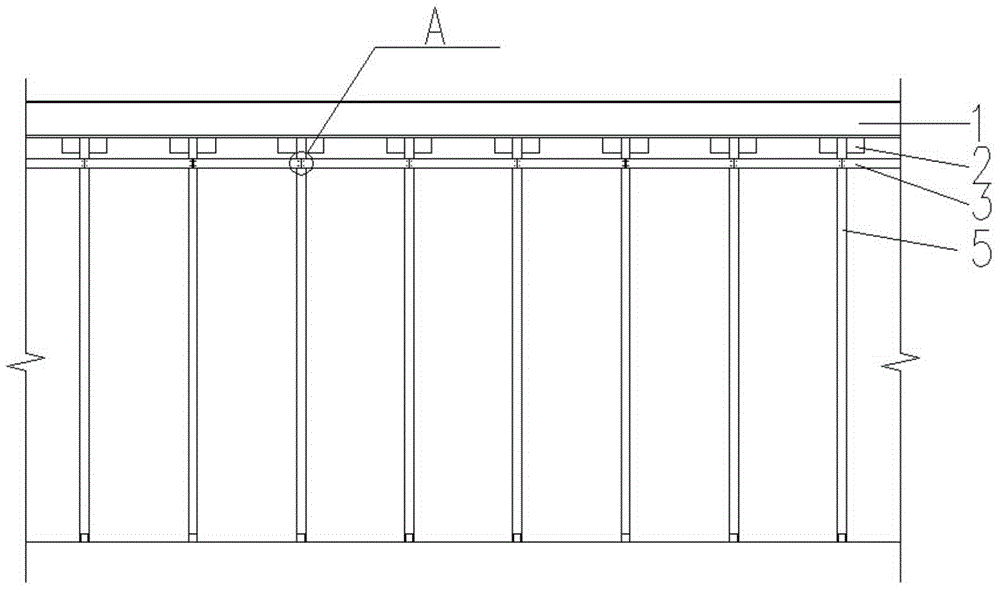

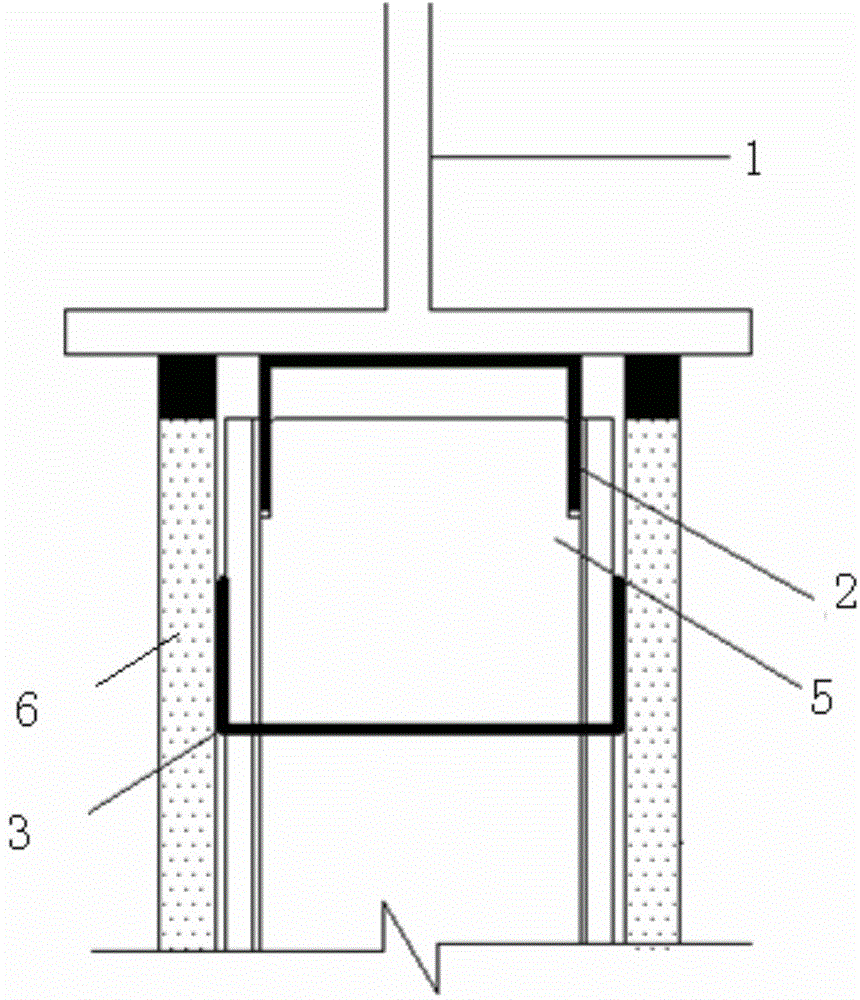

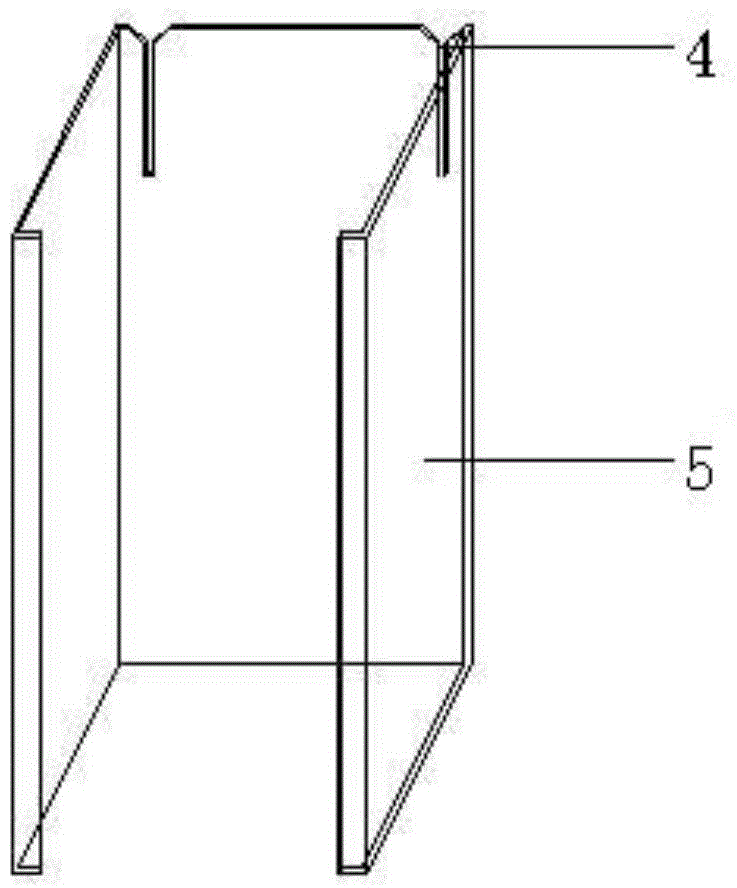

[0021] combine Figure 1 to Figure 6 , The light steel keel internal partition wall and the steel beam connection structure of the present invention include wall panels 6, steel beams 1, horizontal keels 3 and vertical keels 5. In the factory, below the steel beam 1, each vertical keel 5 is welded as Figure 4 The U-shaped steel clip 2 shown; it is made of a channel steel with a right-angled inner flange on the front edge, such as image 3 The vertical keel 5 shown in the vertical keel 5 cuts and processes the card slot 4 corresponding to the two sides of the U-shaped steel card 2 at the upper end of the back side of the vertical keel 5. The slot width of the card slot is consistent with the thickness of the U-shaped steel card. The depth is slightly greater than the height of the U-shaped steel card, and the opening of the card slot is processed into a trumpet shape with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com