Utility tunnel and construction method thereof

A technology of integrated pipe gallery and combined wall, applied in artificial islands, water conservancy projects, infrastructure projects, etc., can solve the problems of long construction period, large damage to the surrounding environment, large resource consumption, etc., to avoid steel bar binding and formwork. , easy to transport and on-site assembly, improve the effect of construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

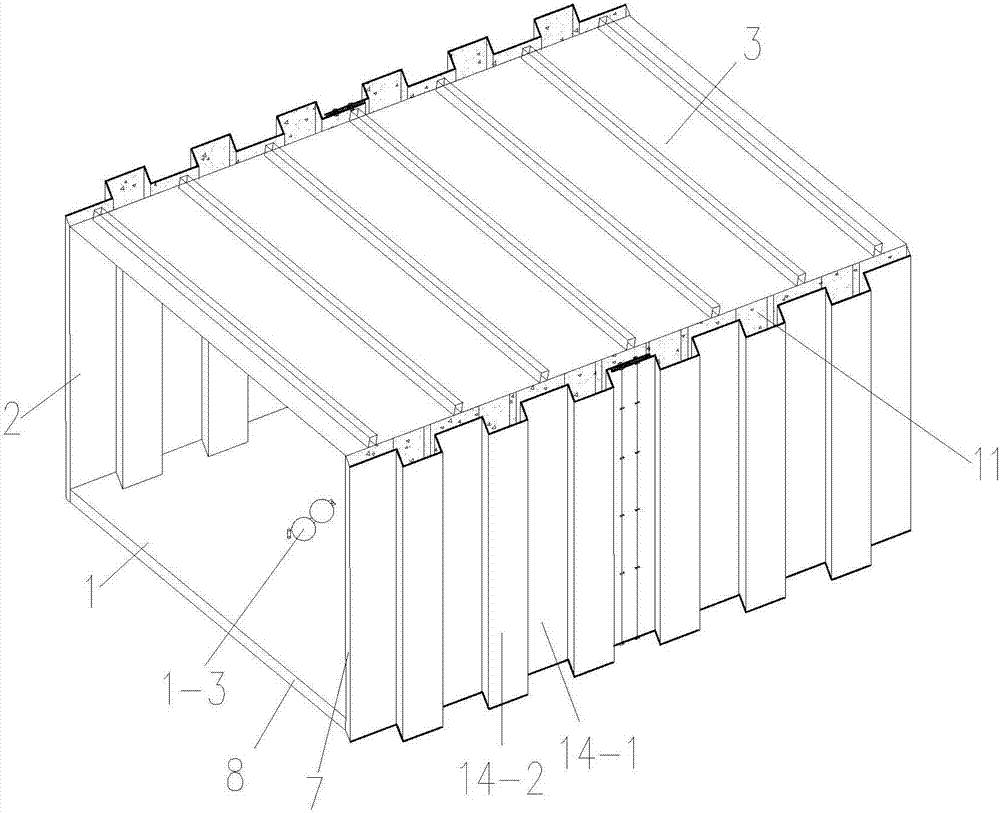

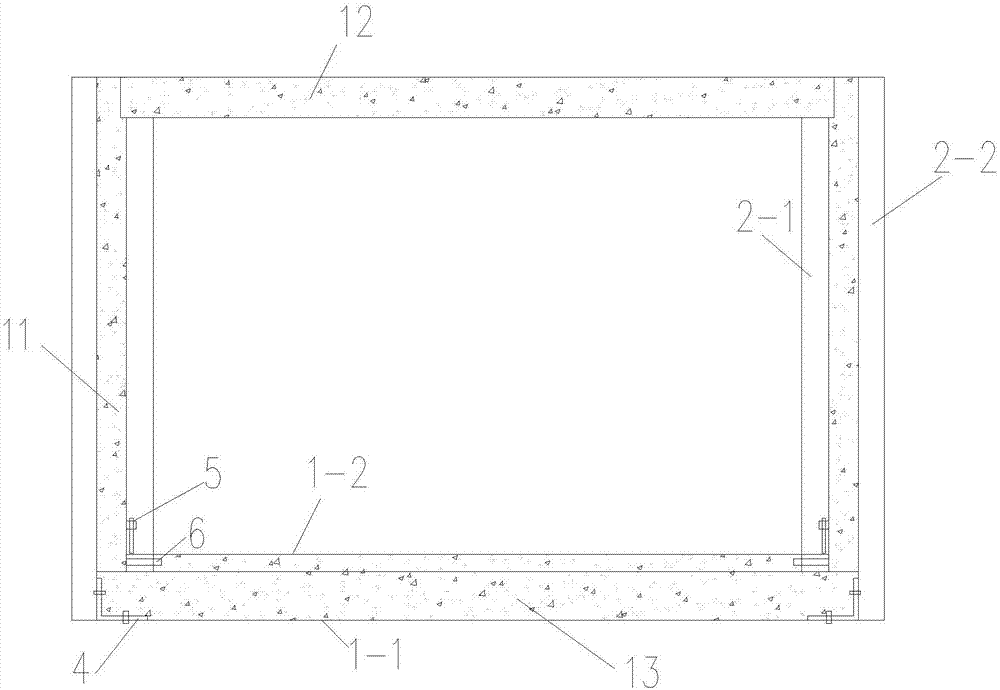

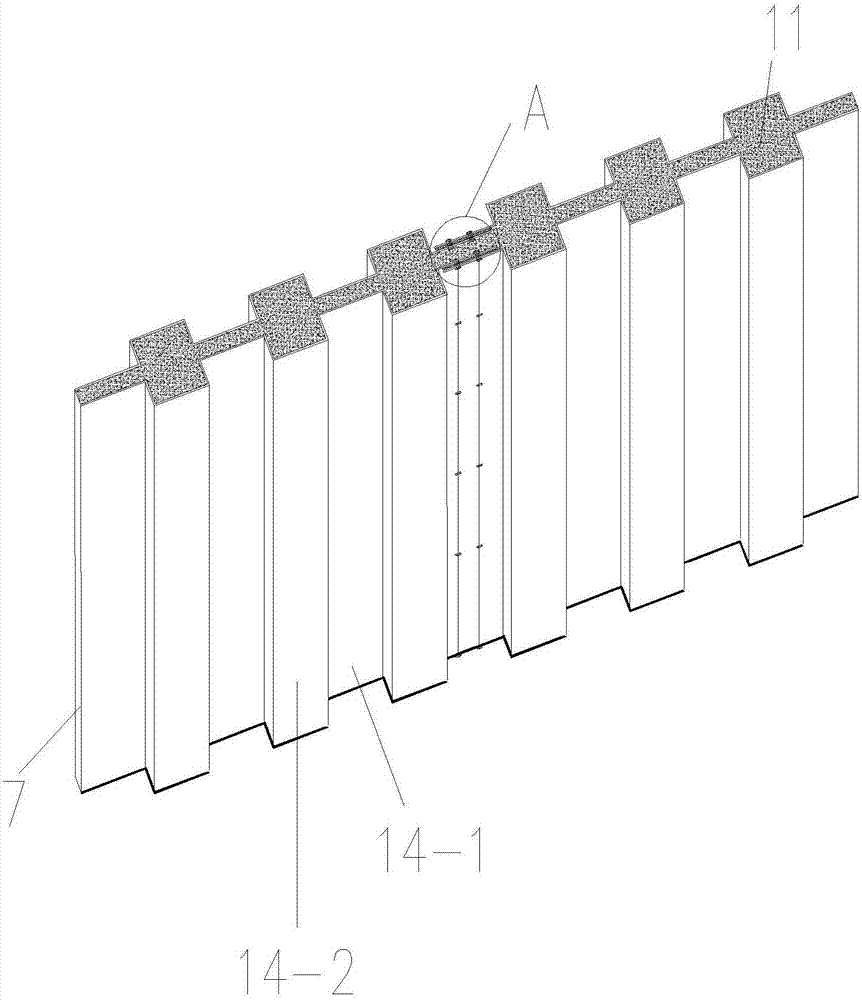

[0042] Such as figure 1 , figure 2 and image 3 A comprehensive pipe gallery shown includes a horizontally arranged rectangular bottom plate 1, a rectangular top plate 3 arranged in parallel above the rectangular bottom plate 1, and two corrugated composite walls 2 vertically arranged between the rectangular bottom plate 1 and the rectangular top plate 3 respectively, The two corrugated composite walls 2 are arranged symmetrically and are respectively arranged on the left and right sides of the rectangular bottom plate 1; the rectangular bottom plate 1, the rectangular top plate 3 and the two corrugated composite walls 2 block out a corridor channel; The cross-section of the corridor passage is a rectangular cross-section;

[0043]Each of the corrugated composite walls 2 includes a corrugated composite board, and the corrugated composite board is composed of a symmetrically arranged inner corrugated board 2-1 and an outer corrugated board 2-2, and the inner corrugated board...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com