Finite element-based mining XLPE cable current leakage dynamic analysis method

A leakage current and analysis method technology, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve problems such as gaps, and achieve accurate calculation, convenient solution, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] specific implementation plan

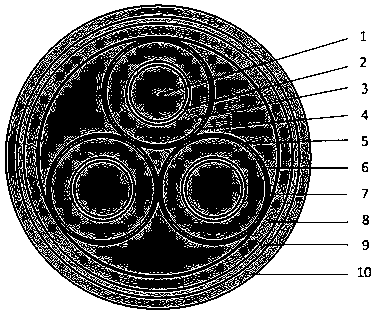

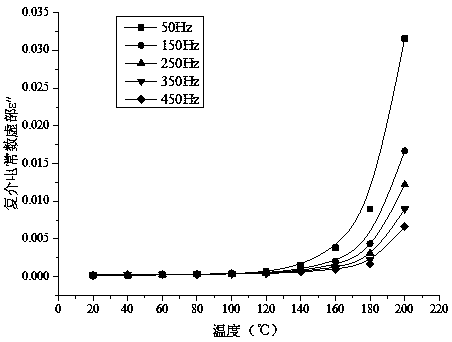

[0031] Because the temperature and electric field of the cable during operation are different at different insulations, and the parameters of the cable insulation such as DC conductance and complex dielectric constant change with temperature, electric field, frequency and other factors. Therefore, the equivalent resistance and capacitance of the cable insulation to the ground will be affected by the operating state. In order to analyze the cable leakage current response under different operating conditions, it is necessary to build a cable model under the action of electrothermal coupling.

[0032] The method for dynamic analysis of leakage current of mining XLPE cables involved in the present invention will be described in detail below in conjunction with the accompanying drawings and implementation cases.

[0033] Implement the mine XLPE cable leakage current dynamic analysis method based on finite element provided by the present invent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com