Carbon nitride-polyaniline nano composite material and preparation method thereof, and carbon nitride-polyaniline intumescent fire retardant coating and preparation method thereof

A technology of nano-composite materials and fire-retardant coatings, which is applied in the fields of carbon nitride-polyaniline intumescent fire-retardant coatings and their preparation, carbon nitride-polyaniline nano-composite materials and their preparation fields, and can solve problems such as research and application gaps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048]Put 30g of melamine into the crucible, put the lid on and put it into the muffle furnace, raise the temperature at a rate of 18°C / min, heat it up to 550°C, keep it for 3 hours, cool it down to room temperature, and take it out to get a light yellow graphite phase Lumpy carbon nitride. Then put it into an uncovered crucible, put it into a muffle furnace under the condition of flowing nitrogen (nitrogen input pressure is 0.15MPa), and raise the temperature at a heating rate of 18°C / min. After cooling down to room temperature, it was taken out to obtain a dark yellow carbon nitride solid after thermal stripping. Afterwards, the obtained yellow solid is put into a ball mill for ball milling to obtain carbon nitride nanosheets with a particle size of 0.2-2 microns.

[0049] Take 0.1 g of the obtained carbon nitride nanosheets in 50 ml of 1 mol / L phosphoric acid solution, stir evenly, ultrasonically disperse for 30 min, and then add 3 g of aniline to obtain solution A.

[00...

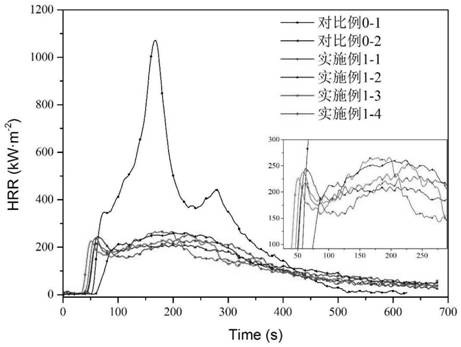

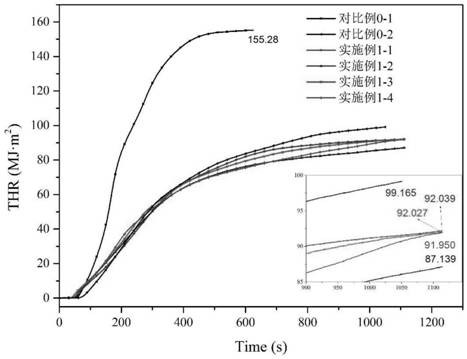

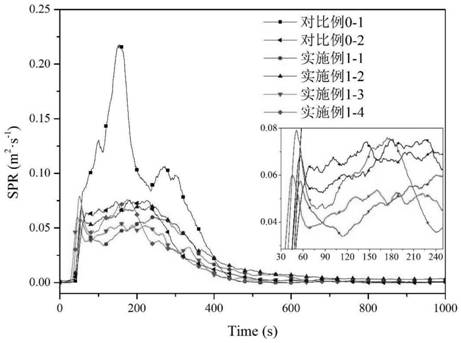

Embodiment 1-1

[0055] Example 1-1: Add 52.5% of the E-44 ring epoxy resin into the container of the high-speed stirring frosted disperser according to the mass percentage, add 0.125% of the carbon nitride-polyaniline nanocomposite material and stir at 800r / min for 30min, Add 29.875% intumescent flame retardant system and continue to stir at 800r / min for 30min, then add 17.5% solvent-free cardanol modified curing agent, stir at 800r / min for 6min, take 50g and pour it into a 10cm*10cm*1cm aluminum box mold , cured at room temperature for 3 days, and tested with a cone calorimeter after 7 days of curing.

Embodiment 1-2

[0056] Example 1-2: Add 52.5% of the E-44 type ring epoxy resin into the container of the high-speed stirring frosted disperser according to the mass percentage, add 0.188% of the carbon nitride-polyaniline nanocomposite material 800r / min and stir for 30min, Add 29.812% intumescent flame retardant system and continue stirring at 800r / min for 30min, then add 17.5% solvent-free cardanol modified curing agent, stir at 800r / min for 6min, take 50g and pour it into a 10cm*10cm*1cm aluminum box mold , cured at room temperature for 3 days, and tested with a cone calorimeter after 7 days of curing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com