Synthetic method for cellulose derivative with large volume liquid crystal unit side group

A technology of liquid crystal unit and cellulose, which is applied in the field of synthesis of cellulose derivatives with side groups of large-volume liquid crystal units, can solve the problems of small substituents, and achieve the effects of easy control, mature synthesis process and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

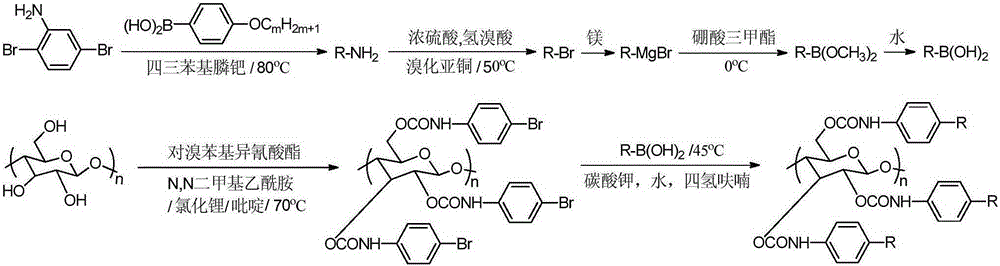

Method used

Image

Examples

specific Embodiment approach 1

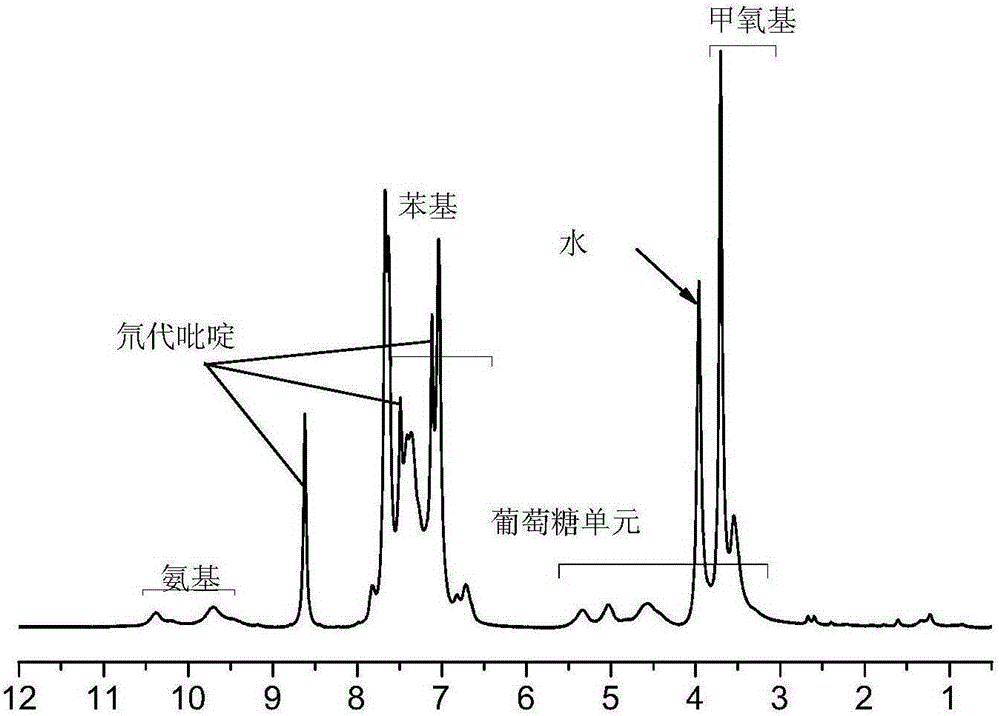

[0029] 1. Take 15mmol 2,5-dibromoaniline, 36mmol p-methoxyphenylboronic acid, 0.09mmol sodium carbonate and 0.6mmol tetrakistriphenylphosphine palladium and vacuum dry for 0.5h, then mix in 75ml dioxane and 37.5ml water Stir and reflux at 80°C for 30 hours to stop the reaction; cool to room temperature, remove the solvent by rotary evaporation, add n-hexane to filter and wash; purify the crude product by column chromatography to obtain pure 2,5-bis(4'-methoxy phenyl) aniline with a yield of 80%.

[0030] 2. Take 1.6mmol of the above-mentioned intermediate product and put it into reaction bottle 1, add 14.0ml of water and 0.26ml of 98% concentrated sulfuric acid mixture, stir and reflux at 60°C for 1.5h; then add 1ml of 1.76mol / L sodium nitrite at 0°C Solution, stirred and refluxed for 1h; vacuum-dried 2.40mmol cuprous bromide in reaction flask 2 for 0.5h, stirred and refluxed in 4ml of water and 4mL40wt% hydrobromic acid mixture for 2h; reacted in reaction flask 1 at 50°C The...

specific Embodiment approach 2

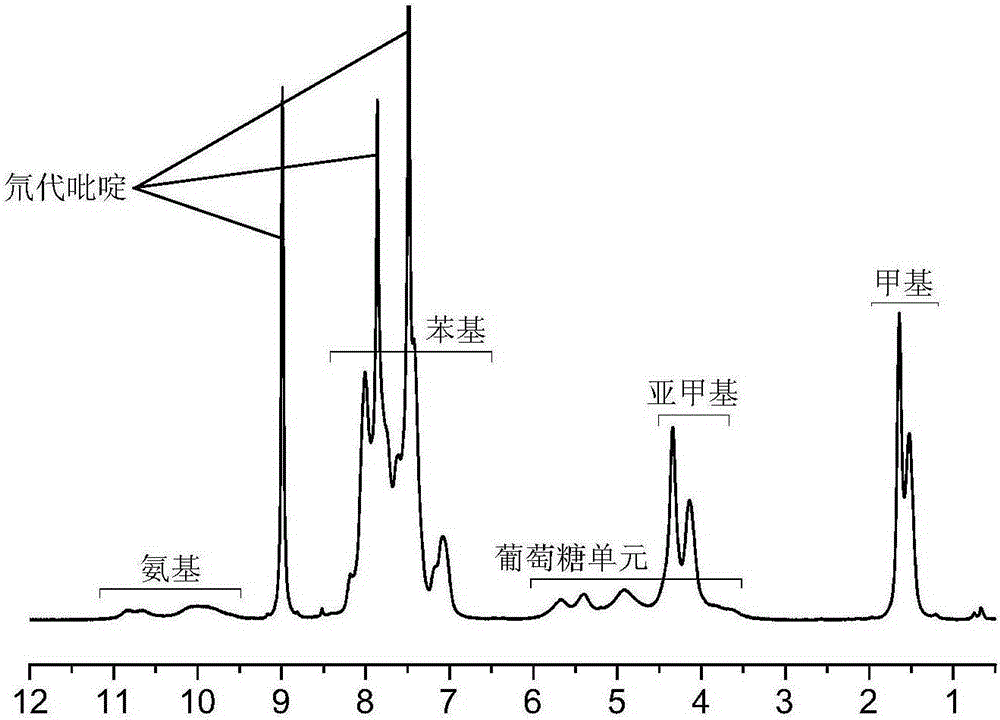

[0035] 1. Take 15mmol 2,5-dibromoaniline, 36mmol p-ethoxyphenylboronic acid, 0.09mmol sodium carbonate and 0.6mmol tetrakistriphenylphosphine palladium and vacuum-dry for 0.5h, then mix in 75ml dioxane and 37.5ml water Stir and reflux at 80°C for 30 hours to stop the reaction; cool to room temperature, remove the solvent by rotary evaporation, add n-hexane to filter and wash; purify the crude product by column chromatography to obtain pure 2,5-bis(4'-ethoxy phenyl) aniline with a yield of 80%.

[0036] 2. Take 1.6mmol of the above-mentioned intermediate product and put it into reaction bottle 1, add 14.0ml of water and 0.26ml of 98% concentrated sulfuric acid mixture, stir and reflux at 60°C for 1.5h; then add 1ml of 1.76mol / L sodium nitrite at 0°C Solution, stirred and refluxed for 1h; vacuum-dried 2.40mmol cuprous bromide in reaction flask 2 for 0.5h, stirred and refluxed in 4ml of water and 4mL40wt% hydrobromic acid mixture for 2h; reacted in reaction flask 1 at 50°C The m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com