Polysiloxane elastomer and preparation method and application thereof

A polysiloxane and elastomer technology, applied in the field of polysiloxane elastomer and its preparation, can solve the problems of low repair temperature, low cost, high reprocessing temperature, etc., and achieve improved mechanical strength, high yield, and synthetic The process is simple and easy to control the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

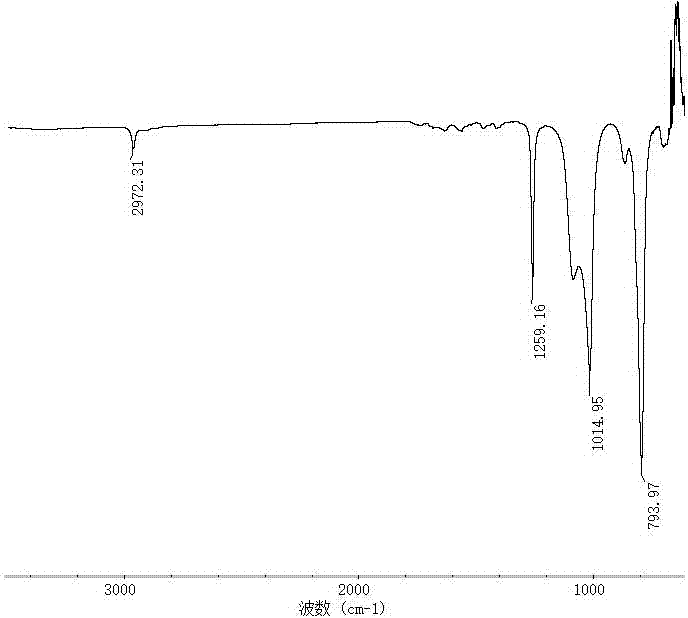

Image

Examples

Embodiment

[0029] A polysiloxane elastomer:

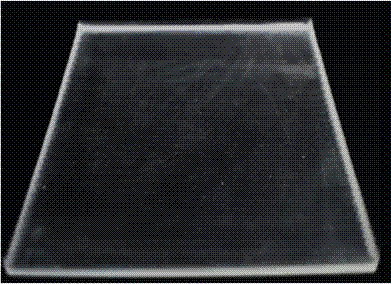

[0030] Dissolving the following raw materials in parts by weight to obtain a reaction liquid: 2-12 parts of crosslinking agent, 18-31 parts of amino- or hydroxyl-terminated polydimethylsiloxane, 10-41 parts of diisocyanate, 5-35 parts 1 part of phenolic compound, 20 to 50 parts of solvent, add 1 drop of N,N-dimethylcyclohexylamine catalyst, stir and react at room temperature for 5 hours; then add 1 drop of dibutyltin dilaurate (DBTDL) catalyst, and continue the reaction at room temperature 5 hours; after the reaction, pour the prepolymer into a polytetrafluoroethylene mold, cure at room temperature for 10-96 hours, then put it in a 60°C oven to remove solvent, continue curing for 10-96 hours, and finally take it out of the mold to obtain Polysiloxane elastomer with phenolic dynamic urethane linkages.

[0031] Preferably, the amino- or hydroxyl-terminated polydimethylsiloxane is at least one of amino- or hydroxyl-terminated polydimethylsiloxa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com