Ultraviolet light curable high-strength polyurethane acrylate resin and preparation method thereof

A urethane acrylate and hydroxy acrylate technology, applied in the field of materials, can solve the problems of easy warpage and cracking of light-cured thick products, limited thickness of light-cured products, low strength and high brittleness of light-cured products, etc. Activity, optimized synthesis route, outstanding effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

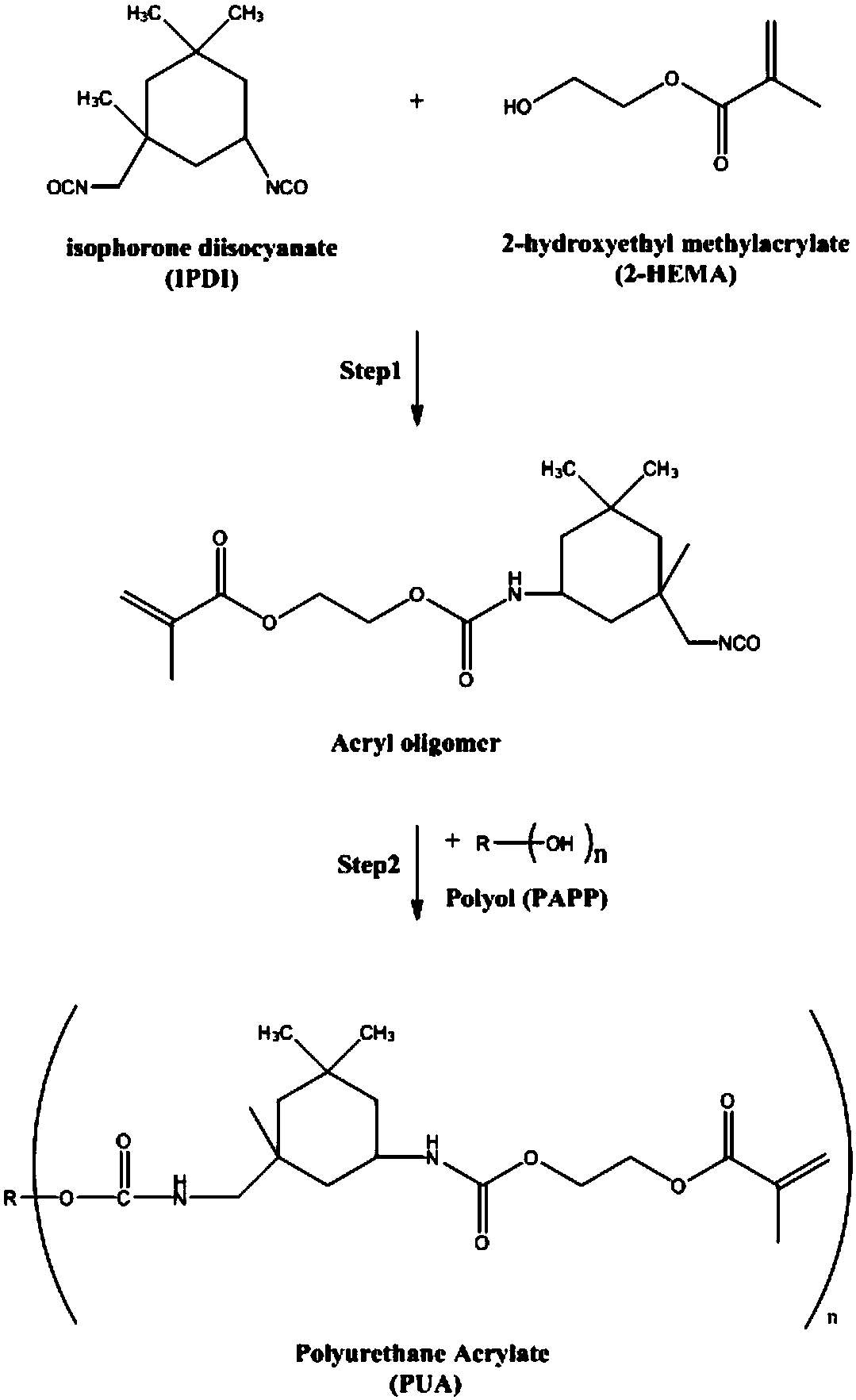

Method used

Image

Examples

Embodiment 1

[0030] The first step, in the there-necked flask that thermometer, mechanical stirrer are equipped with, add metered isophorone diisocyanate 222g (-NCO: 2mol), catalyst dibutyltin dilaurate 0.552g (0.1wt%), polymerization inhibitor Agent 4-hydroxypiperidinol oxygen radical 0.182g (0.033wt%), after stirring evenly, dropwise add 130g (—OH: 1mol) of hydroxyethyl methacrylate in the three-necked flask with the constant pressure dropping funnel, control drop Acceleration, keep the system temperature at about 50°C, and keep the temperature at 60°C for 2 hours after the dropwise addition is completed. In the middle, the change of the NCO group content in the system was determined by the di-n-butylamine method. When the -NCO group content reaches the theoretical value, the intermediate product of the first step is obtained.

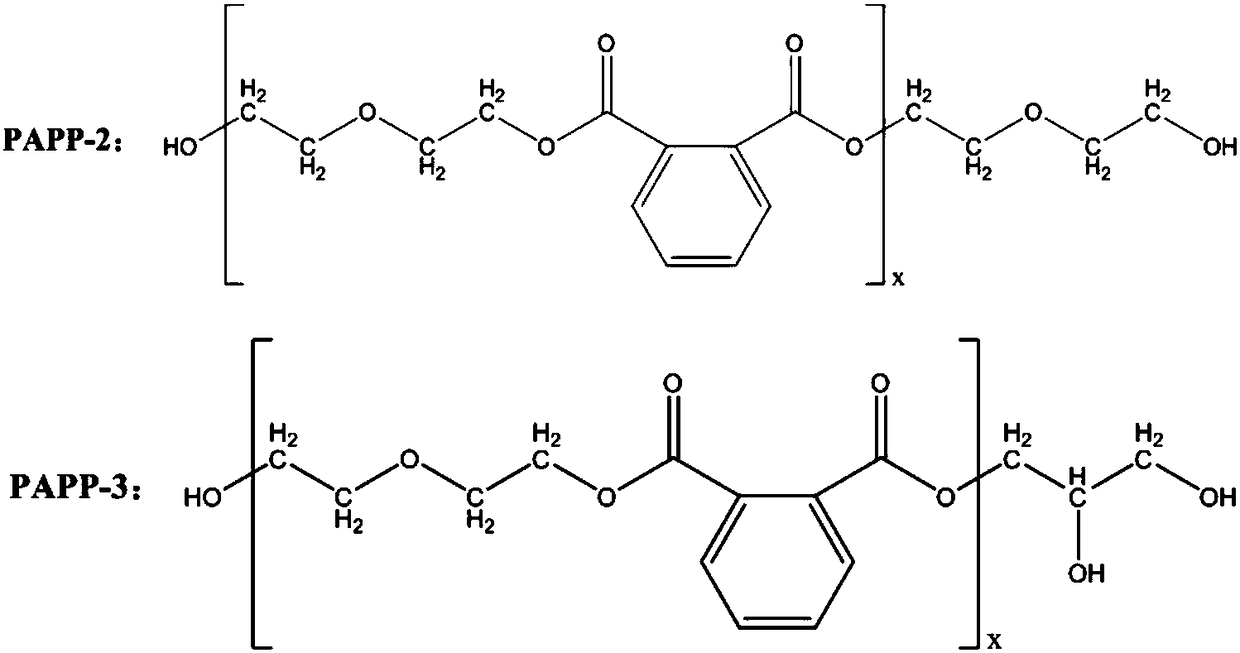

[0031]In the second step, 200 g (PAPP400-2, —OH: 1mol) of phthalic anhydride polyester diol with a molecular weight of 400 is added dropwise to the intermediate...

Embodiment 2

[0034] The first step, in the there-necked flask that thermometer, mechanical stirrer are equipped with, add metered isophorone diisocyanate 222g (-NCO: 2mol), catalyst dibutyltin dilaurate 0.485g (0.1wt%), polymerization inhibitor Agent 4-hydroxypiperidinol oxygen radical 0.160g (0.033wt%), after stirring evenly, dropwise add 130g (-OH: 1mol) of hydroxyethyl methacrylate in the three-necked flask with the constant pressure dropping funnel, control drop Acceleration, keep the system temperature at about 50°C, and keep the temperature at 60°C for 2 hours after the dropwise addition is completed. In the middle, the change of the NCO group content in the system was determined by the di-n-butylamine method. When the -NCO group content reaches the theoretical value, the intermediate product of the first step is obtained.

[0035] In the second step, phthalic anhydride polyester trihydric alcohol 133.3g (PAPP400-3, —OH: 1mol) with a molecular weight of 400 is added dropwise to the ...

Embodiment 3

[0038] The first step, in the there-necked flask that thermometer, mechanical stirrer are equipped with, add metered isophorone diisocyanate 222g (-NCO: 2mol), catalyst dibutyltin dilaurate 0.452g (0.1wt%), polymerization inhibitor Agent 4-hydroxypiperidinol oxygen free radical 0.149g (0.033wt%), after stirring evenly, dropwise add 130g (—OH: 1mol) of hydroxyethyl methacrylate in the three-necked flask with the constant pressure dropping funnel, control dropwise Acceleration, keep the system temperature at about 50°C, and keep the temperature at 60°C for 3h after the dropwise addition is completed. In the middle, the change of the NCO group content in the system was determined by the di-n-butylamine method. When the -NCO group content reaches the theoretical value, the intermediate product of the first step is obtained.

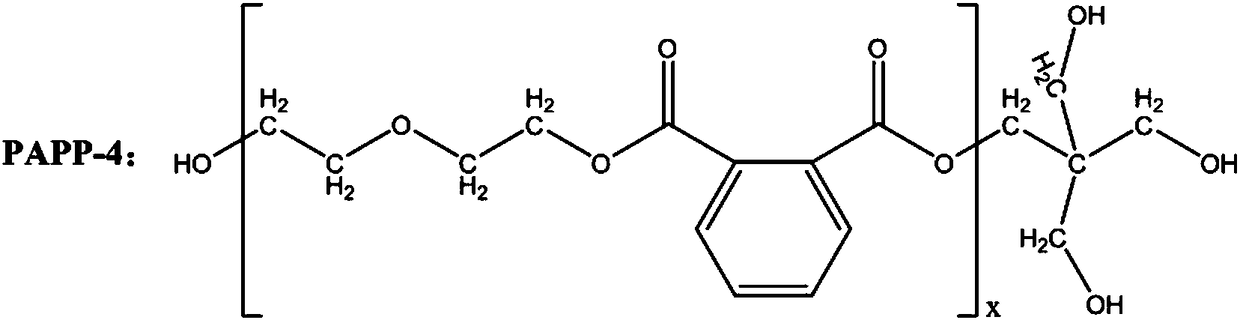

[0039] In the second step, 100 g (PAPP400-4, —OH: 1mol) of phthalic anhydride polyester tetrahydric alcohol (PAPP400-4, —OH: 1mol) with a molecular weight o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com