Preparation method of uniform-porous crosslinked polystyrene adsorption resin

A technology for cross-linking polystyrene and adsorption resin, applied in the field of polymer chemistry, can solve the problems of complex components and unclear component structure, and achieve the effects of simple synthesis process, low raw material cost, and convenient industrial production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

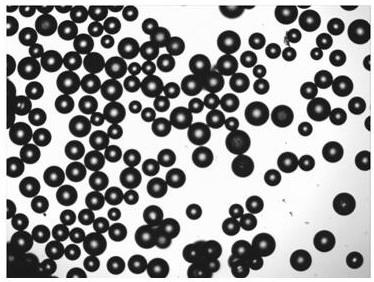

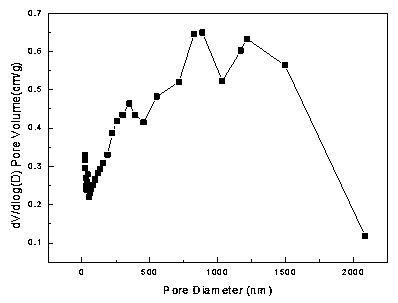

Image

Examples

Embodiment 1

[0026] (1) Oil phase preparation:

[0027] Weigh 100 g of styrene, 5 g of vinyltriethoxysilane, and 10 g of divinylbenzene, 1.05 g of benzoyl peroxide, and 90 g of toluene, 210 g of cyclohexanol in In a beaker, stir evenly to get the oil phase, set aside.

[0028] (2) Preparation of aqueous phase

[0029] Weigh 20 g of PVA, add 2000 g of deionized water, raise the temperature to 90°C and stir for 2-3 hours; after the stabilizer is completely dissolved, cool the system down to 30-50°C to obtain the water phase;

[0030] (3) aggregation

[0031] Add the oil phase in (1) to the water phase in (2), stir at 150 rpm, heat up to 75 °C for 1-5 hours; add 3 g of calcium carbonate aqueous solution, and then heat up to 95 °C to continue React for 6-12 hours; after the reaction, cool down to room temperature to obtain polymer microspheres;

[0032] (4) cleaning

[0033] The polymer microspheres obtained in (3) are drained, washed with a large amount of solvent, and dried to obtain a ...

Embodiment 2

[0036] (1) Oil phase preparation:

[0037] Weigh 100 g of methylstyrene, 1 g of vinyltrimethoxysilane, 150 g of ethylene glycol dimethacrylate, 2.51 g of azobisisobutyl, and 502 g of isobutanol In a beaker, stir evenly to obtain the oil phase, set aside.

[0038] (2) Preparation of aqueous phase

[0039] Weigh 75.3g of PEG, add 3765g of deionized water, raise the temperature to 50°C and stir for 2-3 hours; after the PEG is completely dissolved, cool the system down to 30-50°C to obtain the water phase;

[0040] (3) aggregation

[0041] Add the oil phase in (1) to the water phase in (2), stir at 200rpm, heat up to 75 °C for 1-5 hours; add 3 g of calcium carbonate aqueous solution as an auxiliary material, and then heat up to 80 °C to continue the reaction 6-12h; After the reaction is completed, cool down to room temperature to obtain polymer microspheres;

[0042] (4) cleaning

[0043] The polymer microspheres obtained in (3) are drained, washed with a large amount of solv...

Embodiment 3

[0045] (1) Oil phase preparation:

[0046] Weigh 100 g of ethyl styrene, 1 g of vinyl tris(2-methoxyethoxy) silane, 150 g of glyceryl trimethacrylate, 2.52 g of benzoyl peroxide, and 756 g Put heptane in a beaker, stir evenly to obtain an oil phase, set aside.

[0047] (2) Preparation of aqueous phase

[0048] Weigh 40.3 g of PVP, add 4030 g of deionized water, raise the temperature to 60°C and stir for 2-3 hours; after the PVP is completely dissolved, cool the system down to 30-50°C to obtain the water phase;

[0049] (3) aggregation

[0050] Add the oil phase in (1) to the water phase in (2), stir at 280 rpm, heat up to 70 °C for 1-5 hours; add 4.75 g of aqueous solution of hydroxyapatite as an auxiliary material, and then heat up to 80 °C Continue to react at ℃ for 6-12 hours; after the reaction, cool down to room temperature to obtain polymer microspheres;

[0051] (4) cleaning

[0052] The polymer microspheres obtained in (3) are drained, washed with a large amount o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com