Two-dimensional sheet MoS<2>@ graphene composite nano-material and preparation method thereof

A technology of graphene composite and graphene nanosheets, which is applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of cumbersome preparation process, unsatisfactory performance, single shape, etc. The effect of good repeatability, unique shape and uniform loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] a. Weigh 30 mg of dried reduced graphene oxide, dissolve it in 40 ml of deionized water, and ultrasonicate for 2 hours to make it evenly dispersed;

[0023] b. Weigh 344mg of polyethyleneimine, dissolve it in 20ml of deionized water, stir for 2h to make it evenly dispersed; mix the above solutions, stir for 1h to make it evenly mixed;

[0024] c. Add 0.3g of sodium molybdate to the above mixed solution and continue to stir for 1h; then add 0.4g of thiourea and stir for 1h;

[0025] d. Pour the reacted mixed solution into a polytetrafluoroethylene-lined autoclave and react at 200°C for 24 hours;

[0026] e. After the reaction is completed, the product is centrifuged and washed repeatedly with deionized water and ethanol, dried at 60°C and calcined at 600°C for 2 hours in a nitrogen atmosphere to obtain the two-dimensional sheet-like MoS prepared by the present invention 2 @graphene nanomaterials.

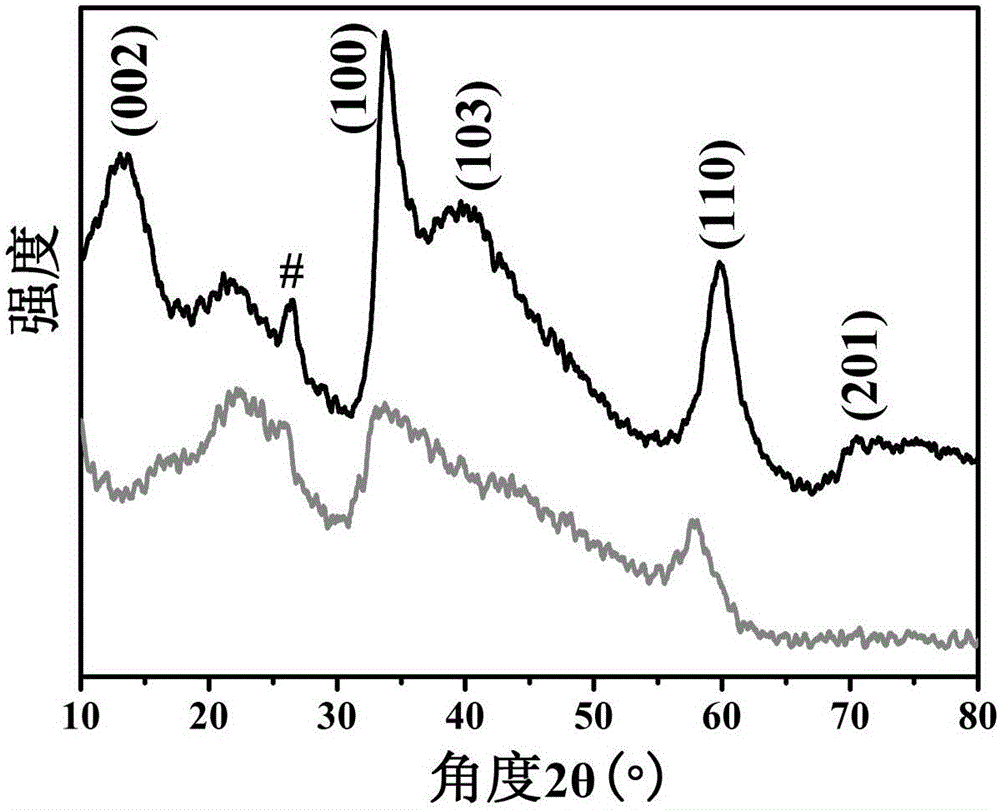

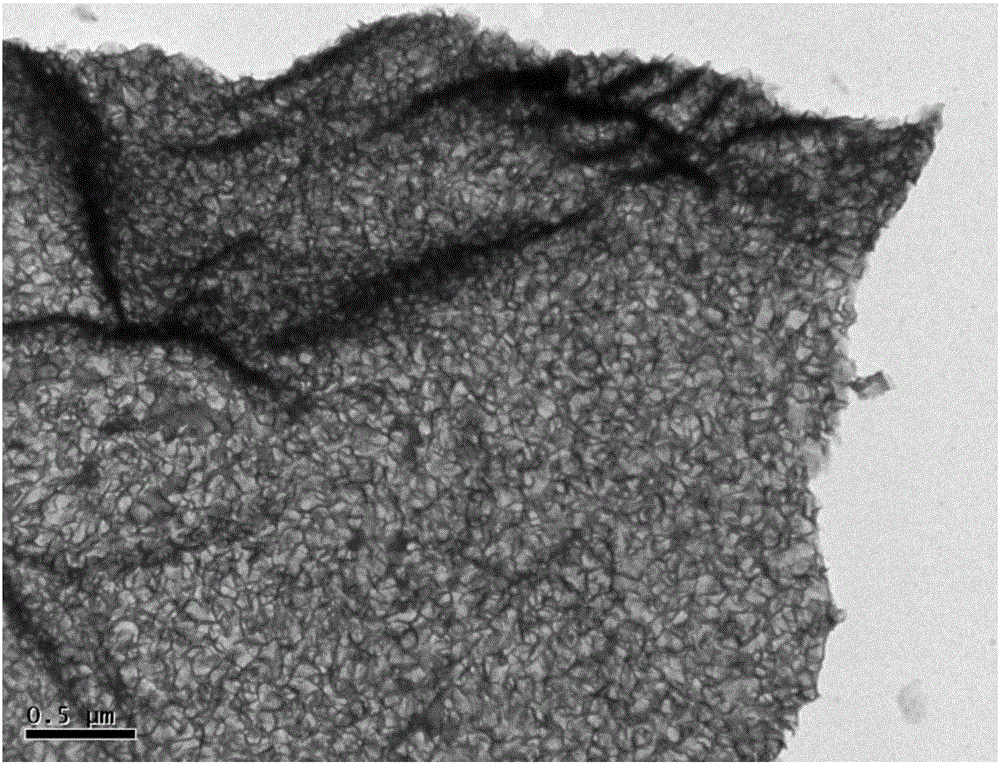

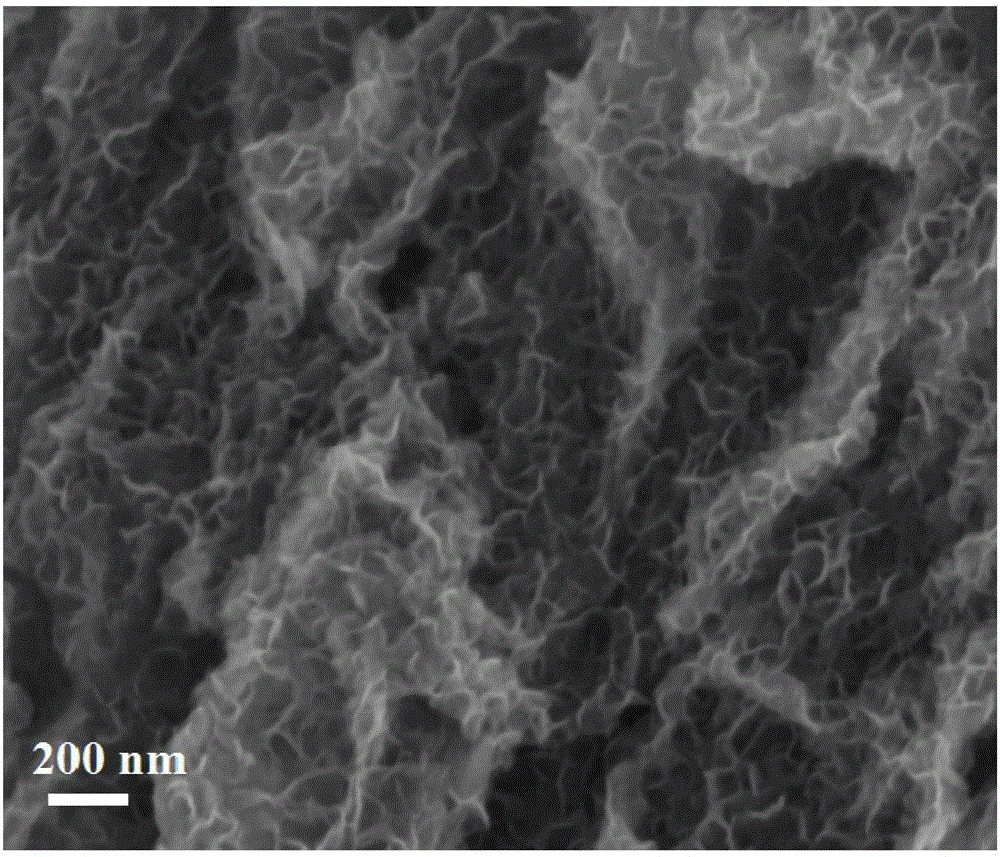

[0027] The prepared samples were characterized for their physical prope...

Embodiment 2

[0029] The preparation process and steps of this embodiment are basically the same as in Example 1, except that the d step:

[0030] Add 0.1g of sodium molybdate to the above solution, and continue to stir for 1h; then add 0.4g of thiourea, and stir for 1h;

[0031] The obtained results are similar to the results of Example 1, all of which are flaky MoS 2 loaded on graphene, but loaded MoS 2 The flakes are sparse and their appearance has changed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com