High-resilience self-repair high-polymer aquagel and preparation method thereof

A technology of polymer hydrogel and resilience, which is applied in the field of preparation of polymer hydrogel, can solve problems such as unsatisfactory hydrogel resilience, achieve excellent physical and mechanical properties, good application prospects, and Regulatory effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037]Synthesis of hydrophilic polyurethane macromonomers terminated by hydroxyethyl methacrylate monomers: In terms of mass fraction, first add 75 parts of polyethylene glycol and 1 part of 1,4-butanediol to a 250 ml three-necked flask , stir evenly, heat to 90°C for 3 hours of vacuum defoaming, then let it cool down to below 60°C; then add 20 parts of isophorone diisocyanate drop by drop, after the addition, control the temperature at 70°C for 10 hours, gradually Add 3 parts of hydroxyethyl methacrylate and 1 part of dibutyltin dilaurate dropwise, and react for 64 hours to obtain a hydrophilic polyurethane macromonomer terminated by hydroxyethyl methacrylate, which is sealed and refrigerated for use after vacuum defoaming;

[0038] Preparation of high resilience self-healing polymer hydrogel: by mass fraction, 2.5 parts of sodium dodecylsulfonate and 0.2 parts of sodium chloride were added to 40 parts of deionized water, stirred until a transparent solution was obtained, The...

Embodiment 2

[0045] Preparation of high-resilience self-healing polymer hydrogel: In terms of mass fraction, 3 parts of sodium dodecylsulfonate and 0.1 part of sodium chloride were added to 20 parts of deionized water, and stirred until a transparent solution was obtained. Then 1 part of stearyl acrylate is added to the solution and stirred evenly to obtain an aqueous solution of micelles containing stearyl acrylate; Molecular monomers were added to 30 parts of deionized water, and ultrasonically treated for 60 minutes to obtain a self-assembly aqueous solution of a hydrophilic polyurethane macromer terminated by hydroxyethyl methacrylate; then the micellar aqueous solution and the self-assembly aqueous solution were mixed Evenly, add 10 parts of acrylamide monomer and 0.2 parts of photoinitiator 2-hydroxy-2-methyl-1-phenylacetone, and dissolve it completely with ultrasound; carry out free radical polymerization under photoinitiation for 120 minutes, A polymer hydrogel is obtained.

[004...

Embodiment 3

[0048] Synthesis of polyethylene glycol acrylate-terminated hydrophilic polyurethane macromers: in terms of mass fraction, 40 parts of polyethylene glycol, 0.5 parts of 1,4-butanediol and 0.5 parts of trimethylolpropane were added to the In a 250ml three-neck flask, stir evenly, heat to 130°C for 2 hours and vacuum defoaming, then let it cool down to below 60°C; then add 15 parts of isophorone diisocyanate drop by drop, and control the temperature at 90°C to react For 3 hours, add 3 parts of hydroxyethyl methacrylate and 1 part of dibutyltin dilaurate dropwise, and react for 10 hours to obtain a hydrophilic polyurethane macromer terminated by hydroxyethyl methacrylate, which is sealed after vacuum defoaming Refrigerate for later use;

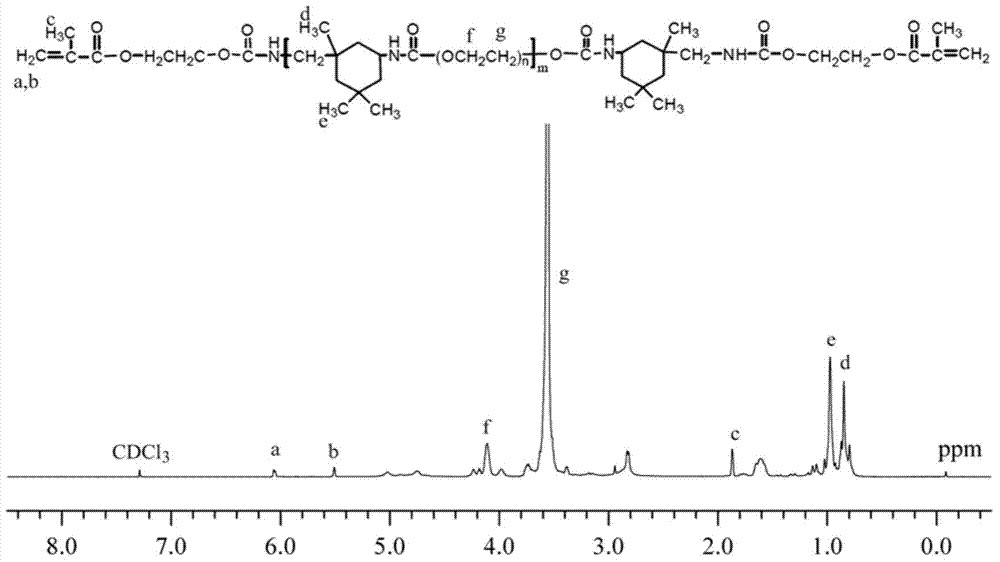

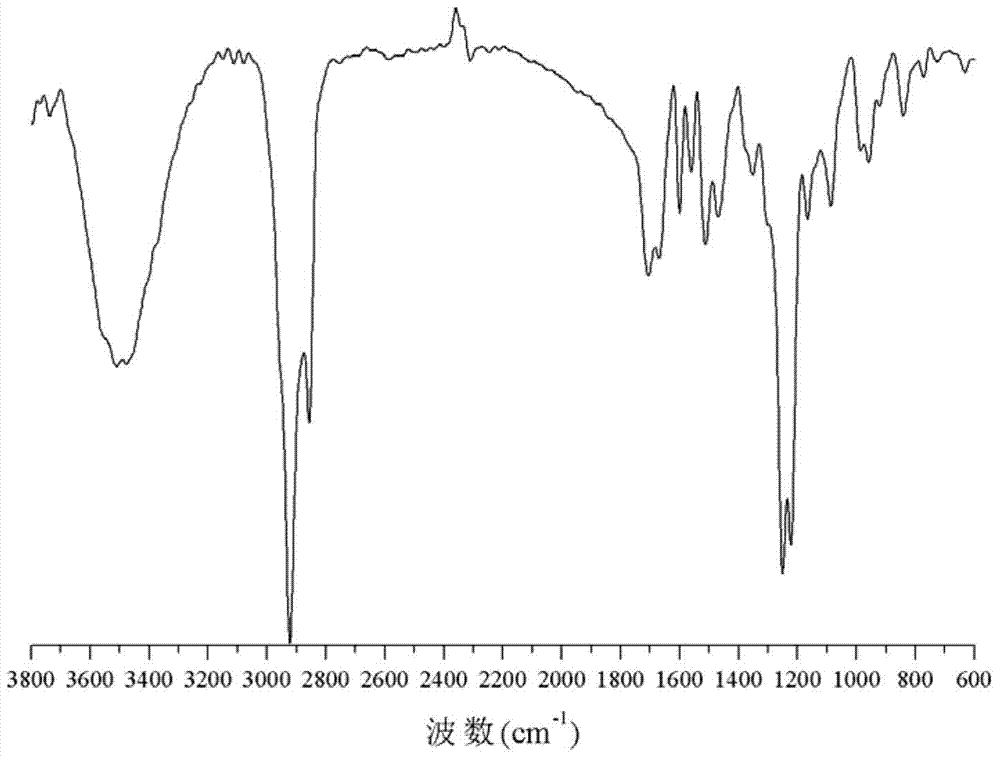

[0049] From the spectrogram ( Image 6 ), it can be seen that the chemical shift of 0.8-1.0ppm is the hydrogen on the methyl group in isophorone diisocyanate, 3.5-3.66ppm is the hydrogen on the methylene group in polyethylene glycol, 5.5 and 6....

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com