Aromatic polyesterimide and preparation method thereof

A polyester imide and aromatic technology, applied in the field of high-performance polymers, can solve the problems of easy warping and cracking of parts, difficult material processing and molding, and large residual stress of parts, etc., to achieve structural symmetry reduction, Effects of reduced crystallinity and high Tg

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

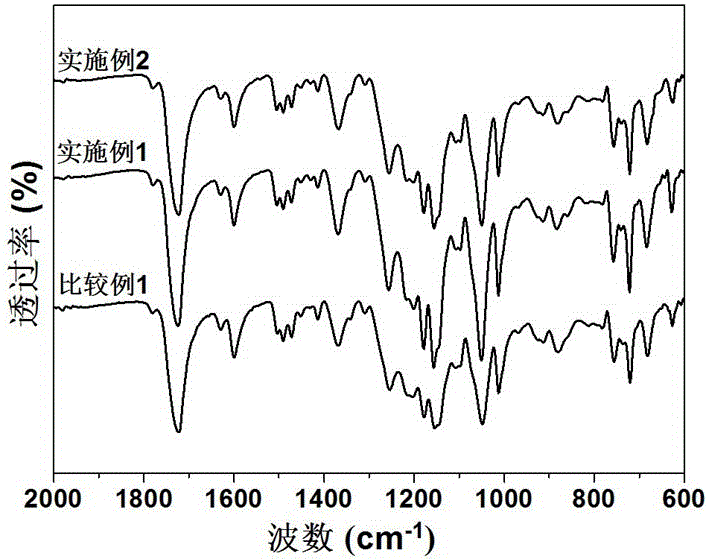

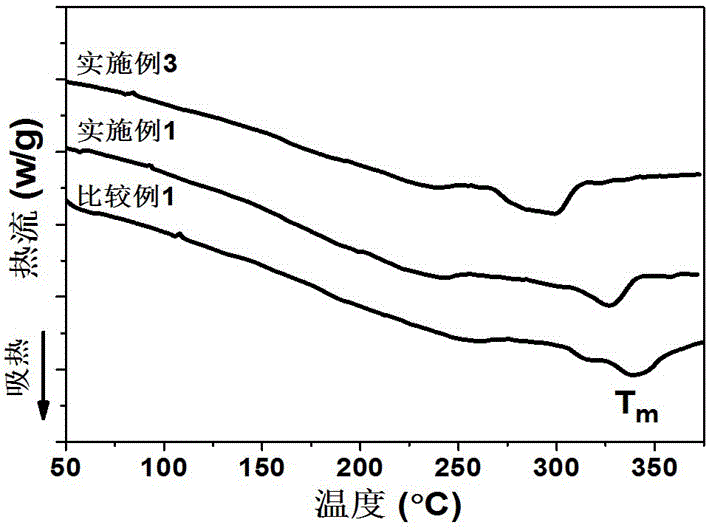

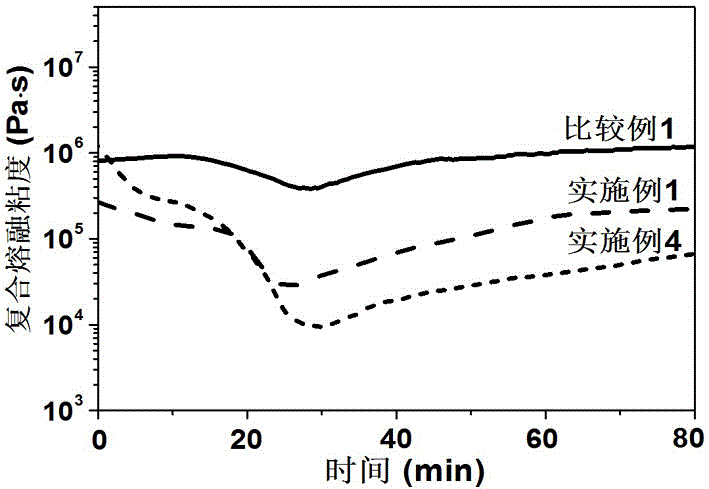

Embodiment 1

[0028] 1. Preparation of aromatic diphenol monomers containing imide bonds: 294.22g of 2,2',3,3'-biphenyltetracarboxylic dianhydride, 218.26g of 3-aminophenol and 200mL of acetic acid were added for reaction React in a container at a temperature of 130°C for 6 hours under nitrogen protection; after the reaction, filter, wash, and dry to obtain a light yellow powder, which is an aromatic diphenol monomer containing an imide bond, which is designated as IM1.

[0029] 2. Preparation of polyester imide from aromatic diphenol monomers containing imide bonds and meta-aromatic diacid monomers: add 238.22g IM1, 82.06g 1,3-meta Phthalic acid, 69.06 g 4-hydroxybenzoic acid, 142 mL acetic anhydride, and 49.07 mg potassium acetate. The flask was fitted with a sealed glass paddle stirrer, a nitrogen inlet tube and an insulated distillation head. A moderate nitrogen flow was introduced, and the acetylation reaction was carried out at a temperature of 140° C. for 60 minutes. The reaction m...

Embodiment 2

[0036] According to the preparation method of Example 1, the aromatic diphenol monomer IM1 containing imide bonds is obtained, and it is reacted with the meta-position aromatic diacid monomer to prepare polyester imide. The specific steps are: in a 2000mL three-hole round bottom The flask was charged with 476.44 g of IM1, 242.23 g of 1,1'-biphenyl-3,3'-dicarboxylic acid, 428.44 g of 4'-hydroxybiphenyl-4-carboxylic acid, 500 mL of acetic anhydride and 82 mg of sodium acetate. The flask was fitted with a sealed glass paddle stirrer, a nitrogen inlet tube and an insulated distillation head. A moderate nitrogen flow was introduced, and the acetylation reaction was carried out at a temperature of 120° C. for 60 minutes. The reaction mixture was heated (0.8°C / min) in a quicksand bath, and the reaction temperature rose from 120°C to 300°C. At this point, the reaction system was slowly evacuated (vacuum degree: 1 mbar), and kept at 300° C. for 30 min. The opaque melt was cooled to r...

Embodiment 3

[0045] The aromatic diphenol monomer IM1 containing imide bonds prepared in Example 1 and the meta-position aromatic diacid monomer are used to prepare polyester imide: add 238.22g IM1, 108.10 in a 500mL three-necked round bottom flask g 1,7-naphthalene dicarboxylic acid, 94.09 g 6-hydroxy-2-naphthoic acid, 80 mL acetic anhydride, and 8.20 mg stannous octoate. The flask was fitted with a sealed glass paddle stirrer, a nitrogen inlet tube and an insulated distillation head. A moderate nitrogen flow was introduced, and the acetylation reaction was carried out at a temperature of 140° C. for 60 minutes. The reaction mixture was heated (1.0°C / min) in a quicksand bath, and the reaction temperature rose from 140°C to 320°C. At this point, the reaction system was slowly evacuated (vacuum degree: 5 mbar), and kept at 320° C. for 15 min. The opaque melt was cooled to room temperature and the product was removed from the flask and ground to a fine powder. Finish polycondensation reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com