Self-repaired graphene oxide/polyurethane composite material and preparation method thereof

A composite material and graphene technology, which is applied in the field of graphene oxide/polyurethane composite material and its preparation, can solve the problem of low mechanical strength of supramolecular polyurethane, without sacrificing self-healing performance, easy synthesis process, and cheap and easy-to-obtain raw materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

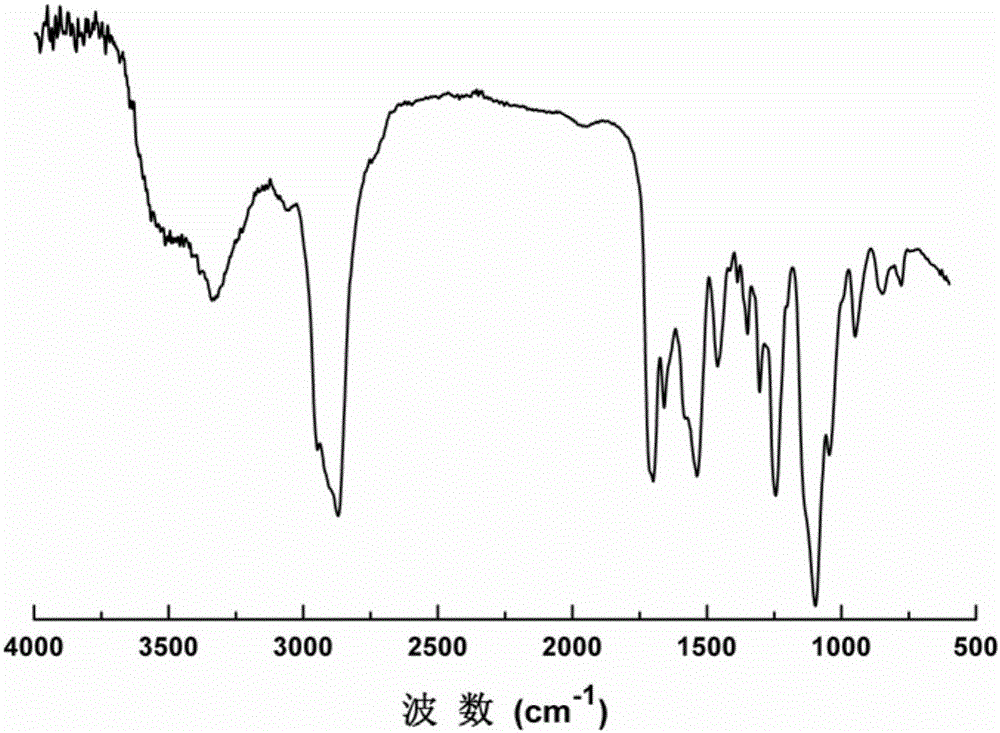

Embodiment 1

[0040] Preparation of polyurethane with quadruple hydrogen bond units: in parts by mass, 40 parts of polyethylene glycol and 3 parts of 1,4-butanediol were mixed and stirred evenly and dehydrated, and 20 parts of Isophorone diisocyanate, after adding, make the reaction system react at a temperature of 85°C for 2 hours to obtain a polyurethane prepolymer; 15 parts of 2-amino-4-carbonyl-6-methylpyrimidine and 50 parts of Mix dimethyl sulfoxide and stir at a temperature of 85°C; after the 2-amino-4-carbonyl-6-methylpyrimidine is completely dissolved, add the polyurethane prepolymer and 0.2 parts of dilauric acid di Butyl tin, reacted at 85°C for 15 hours; after the reaction, precipitated with ether, filtered to obtain a white solid, and dried in vacuum to obtain polyurethane with quadruple hydrogen bond units;

[0041] Preparation of graphene oxide with quadruple hydrogen bond motifs: in parts by mass, 1 part (the amount of 2-amino-4-carbonyl-6-methylpyrimidine accounts for 6.25%...

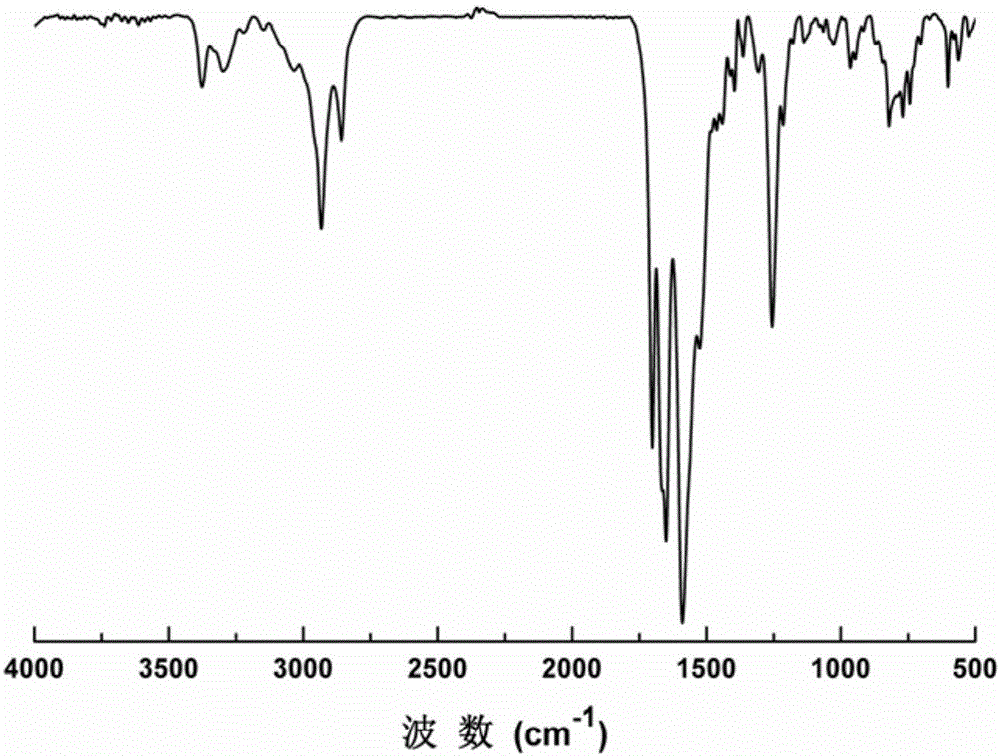

Embodiment 2

[0049] Preparation of polyurethane with quadruple hydrogen bond units: in parts by mass, 60 parts of polyethylene glycol and 2 parts of 1,4-butanediol were mixed and stirred evenly and dehydrated, and 20 parts of Diphenylmethane-4,4'-diisocyanate, after the addition, the reaction system was reacted at a temperature of 70°C for 4 hours to obtain a polyurethane prepolymer; 13 parts of 2-amino-4-carbonyl-6-methyl The base pyrimidine is mixed with 50 parts of dimethyl sulfoxide, and stirred at a temperature of 85°C; after the 2‐amino‐4‐carbonyl‐6‐methylpyrimidine is completely dissolved, the polyurethane prepolymer and 0.2 Parts of dibutyltin dilaurate were reacted at 85°C for 16 hours; after the reaction, precipitated with ether, filtered to obtain a white solid, and vacuum-dried to obtain a polyurethane with a quadruple hydrogen bond;

[0050] Preparation of graphene oxide with quadruple hydrogen bond motifs: in parts by mass, 1 part (the amount of 2-amino-4-carbonyl-6-methylpyr...

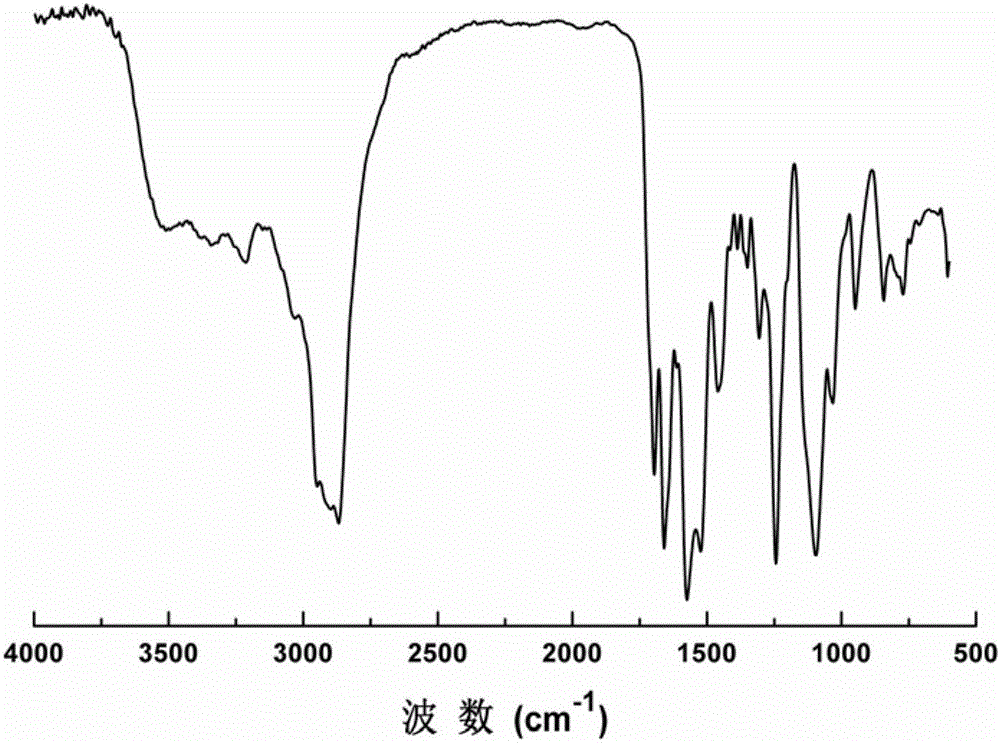

Embodiment 3

[0054] Preparation of polyurethane with quadruple hydrogen bond units: in parts by mass, 30 parts of polytetrahydrofuran diol and 2 parts of 1,4-butanediol were mixed and stirred evenly and dehydrated, and 16 parts of Isophorone diisocyanate, after adding, make the reaction system react at a temperature of 80°C for 3.5 hours to obtain a polyurethane prepolymer; 15 parts of 2-amino-4-carbonyl-6-methylpyrimidine and 50 parts of Mix dimethyl sulfoxide and stir at a temperature of 70°C; after the 2-amino-4-carbonyl-6-methylpyrimidine is completely dissolved, add the polyurethane prepolymer and 0.2 parts of dilauric acid di Butyltin, reacted at 70°C for 24 hours; after the reaction, precipitated with ether, filtered to obtain a white solid, and vacuum-dried to obtain polyurethane with quadruple hydrogen bond units;

[0055] Preparation of graphene oxide with quadruple hydrogen bond motifs: in parts by mass, 1 part (the amount of 2-amino-4-carbonyl-6-methylpyrimidine accounts for 6....

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com