Nano-alloy and preparation method thereof

A nano-alloy and nano-metal technology, applied in the field of electrochemical catalysis, can solve the problems of insufficient durability of catalytic activity and complex preparation process, and achieve the goal of solving insufficient durability of catalytic activity, simple and controllable synthesis process, and conducive to popularization and application Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

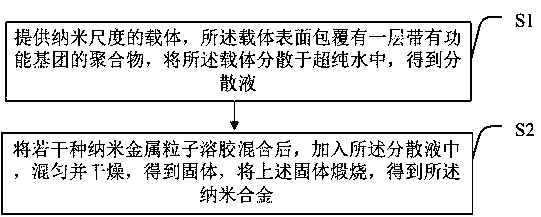

[0027] The preparation method of described nano-alloy, such as figure 1 shown, including steps:

[0028] S1. Provide a nanoscale carrier, the surface of the carrier is coated with a layer of polymer with functional groups, and the carrier is dispersed in ultrapure water to obtain a dispersion;

[0029] S2. After mixing several kinds of nano metal particle sols, adding them to the dispersion liquid, mixing and drying to obtain a solid, and calcining the above solid to obtain the nano alloy.

[0030] In the present invention, a layer of polymer with functional groups is firstly coated on the nano-scale carrier, which can improve the binding strength of nano-metal ions and the carrier, increase the loading capacity, improve the utilization rate of nano-metal particles and the prepared nano-metal ions alloy stability.

[0031] Specifically, in the step S1, nanoscale carrier raw materials are selected, dispersed in a solvent, and stirred evenly to obtain a uniformly dispersed car...

Embodiment 1

[0042] Pt and Au nanoparticles with a particle size of about 3nm were prepared by sodium citrate reduction method:

[0043] 1.0 mL 1% HAuCl 4 ·3H 2 Add O to 90 mL of ultrapure water, stir for 1 min, add 2 mL of 38.8 mM sodium citrate, stir for 1 min, and finally add 1 mL of 0.075% NaBH quickly 4 , and stirred for 5 min to obtain an orange-red Au nanosol;

[0044] Add 47 mL of ultrapure water, 2 mL of 0.1 M sodium citrate, and 1 mL of 0.1 M H2O to a 100 mL round bottom flask 2 PtCl 6 . 6H 2 O. Oil bath 80ºC, mechanical stirring, constant temperature for 1 h. Then add a small amount of NaBH 4 , and stirred for 30 min to obtain a dark brown Pt nanosol;

[0045] Add 32.5 mL of ultrapure water, 1.64 mg of PVP, and 7.5 mL of 4 mM HO to a 100 mL round bottom flask 2 PdCl 4 . 6H 2 O was stirred well, and after a few minutes, 10 mL of absolute ethanol was added. Oil bath at 100°C, mechanical stirring, reflux for 3 hours, and cool to room temperature to obtain Pd nano-sol,...

Embodiment 2

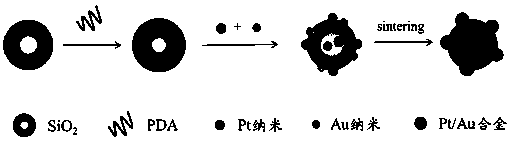

[0049] Weigh 50mg SiO 2 Put the nanoparticles in the flask, add 2mL deionized water, fully dissolve and disperse; after that, weigh 100mg dopamine hydrochloride in the flask, add 50mL Tris-HCl buffer solution, and add the above SiO 2 nanoparticles, stirred mechanically at room temperature for 5 h to obtain SiO 2 @PDA nanoparticle carrier, centrifuge the precipitate, wash it 4 times with ultrapure water, and redisperse it in ultrapure water to obtain a dispersion;

[0050] The metal Pt and Au nano-sols synthesized in Example 1 were added to the above-mentioned dispersion liquid at a molar ratio of 1:1, mechanically stirred overnight, and finally the obtained precipitate was centrifuged, and the precipitate was washed with ultrapure water, and then the sample was placed In a vacuum oven, dry overnight to obtain SiO 2 @PDA@Pt-Au nanoparticles;

[0051] Finally, the dried sample powder was transferred to a porcelain boat, placed in a tube furnace, and carbonized at a high tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com