90DEG C cracking-resistant moisture-proof and flame-retardant polyethylene cable material and preparation method thereof

A technology of flame-retardant polyethylene and cable materials, which is applied in the direction of circuits, electrical components, plastic/resin/wax insulators, etc. It can solve the problems of reducing material strength and toughness, potential safety hazards of cable products, and increasing the amount of inorganic flame retardants added, etc. problems, achieve high tensile strength and elongation at break, excellent physical and mechanical strength, and outstanding crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

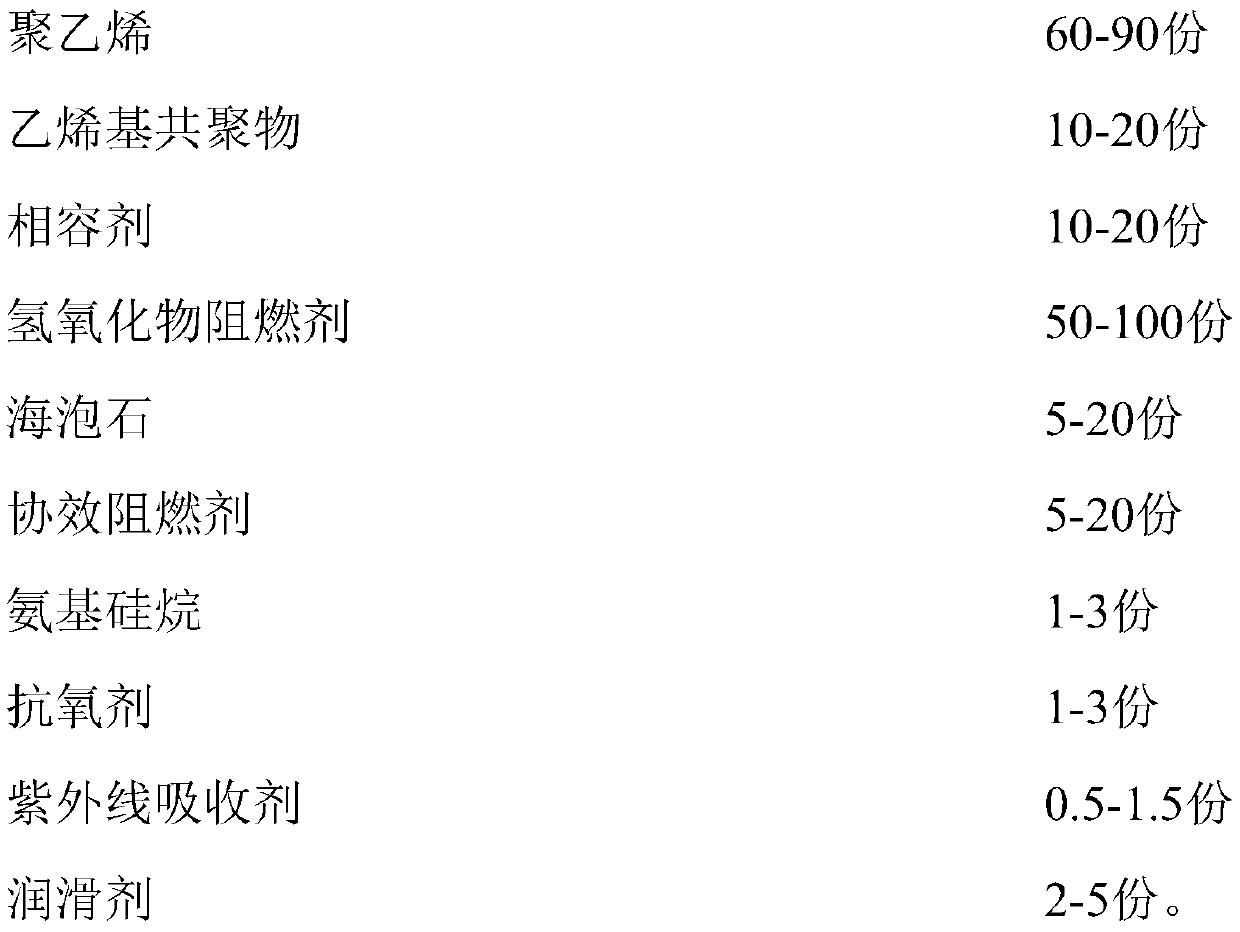

[0033] A 90°C crack-resistant, moisture-resistant, flame-retardant polyethylene cable material is made of the following raw materials by weight:

[0034] 60 parts of polyethylene, the polyethylene is a mixture of metallocene linear low-density polyethylene, bimodal polyethylene and high-density polyethylene, and the melt index of the polyethylene is 0.2g / 10min;

[0035] 10 parts of vinyl copolymer, described vinyl copolymer is the mixture of ethylene-vinyl acetate copolymer, ethylene-octene copolymer and EPDM rubber, and described vinyl copolymer melt index is 0.5g / 10min;

[0036] 10 parts of maleic anhydride grafted ethylene-vinyl acetate copolymers, the grafting rate is 0.6%, and the melt index is 0.1g / 10min;

[0037] 50 parts of hydroxide flame retardant, described hydroxide flame retardant is that aluminum hydroxide and magnesium hydroxide are mixed according to weight ratio 3:1;

[0038] Nano sepiolite 5 parts, its specific surface area is 50m 2 / g;

[0039] 5 parts of...

Embodiment 2

[0046] A 90°C crack-resistant, moisture-resistant, flame-retardant polyethylene cable material is made of the following raw materials by weight:

[0047] 90 parts of polyethylene, described polyethylene is the mixture of metallocene linear low density polyethylene, bimodal polyethylene and high density polyethylene, and the melting index of described polyethylene is 20g / 10min;

[0048] 20 parts of ethylene-based copolymers, the ethylene-based copolymers are a mixture of ethylene-vinyl acetate copolymers, ethylene-octene copolymers and EPDM rubber, and the melt index of the ethylene-based copolymers is 0.5-5g / 10min ;

[0049] 20 parts of maleic anhydride grafted ethylene-vinyl acetate copolymer, its graft rate 1.2%, melt index is 1.0g / 10min;

[0050] 100 parts of hydroxide flame retardant, described hydroxide flame retardant is that aluminum hydroxide and magnesium hydroxide are mixed according to weight ratio 3:1;

[0051] 20 parts of nano sepiolite, its specific surface are...

Embodiment 3

[0059] A 90°C crack-resistant, moisture-resistant, flame-retardant polyethylene cable material is made of the following raw materials by weight:

[0060] 70 parts of polyethylene, described polyethylene is the mixture of metallocene linear low-density polyethylene, bimodal polyethylene and high-density polyethylene, and the melting index of described polyethylene is 5g / 10min;

[0061] 15 parts of vinyl copolymer, described vinyl copolymer is the mixture of ethylene-vinyl acetate copolymer, ethylene-octene copolymer and EPDM rubber, and described vinyl copolymer melt index is 2g / 10min;

[0062] 15 parts of maleic anhydride grafted ethylene-vinyl acetate copolymer, its graft rate 1%, melt index is 5g / 10min;

[0063] 60 parts of hydroxide flame retardant, described hydroxide flame retardant is that aluminum hydroxide and magnesium hydroxide are mixed according to weight ratio 3:1;

[0064] Nano sepiolite 10 parts, its specific surface area is 50m 2 / g;

[0065] 10 parts of syn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com