Anti-cracking high density polyethylene cable material and preparation method thereof

A high-density polyethylene, cable material technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problem of easy cracking of the cable sheath, and achieve the effect of good high and low temperature resistance, good bending performance, and excellent anti-cracking performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

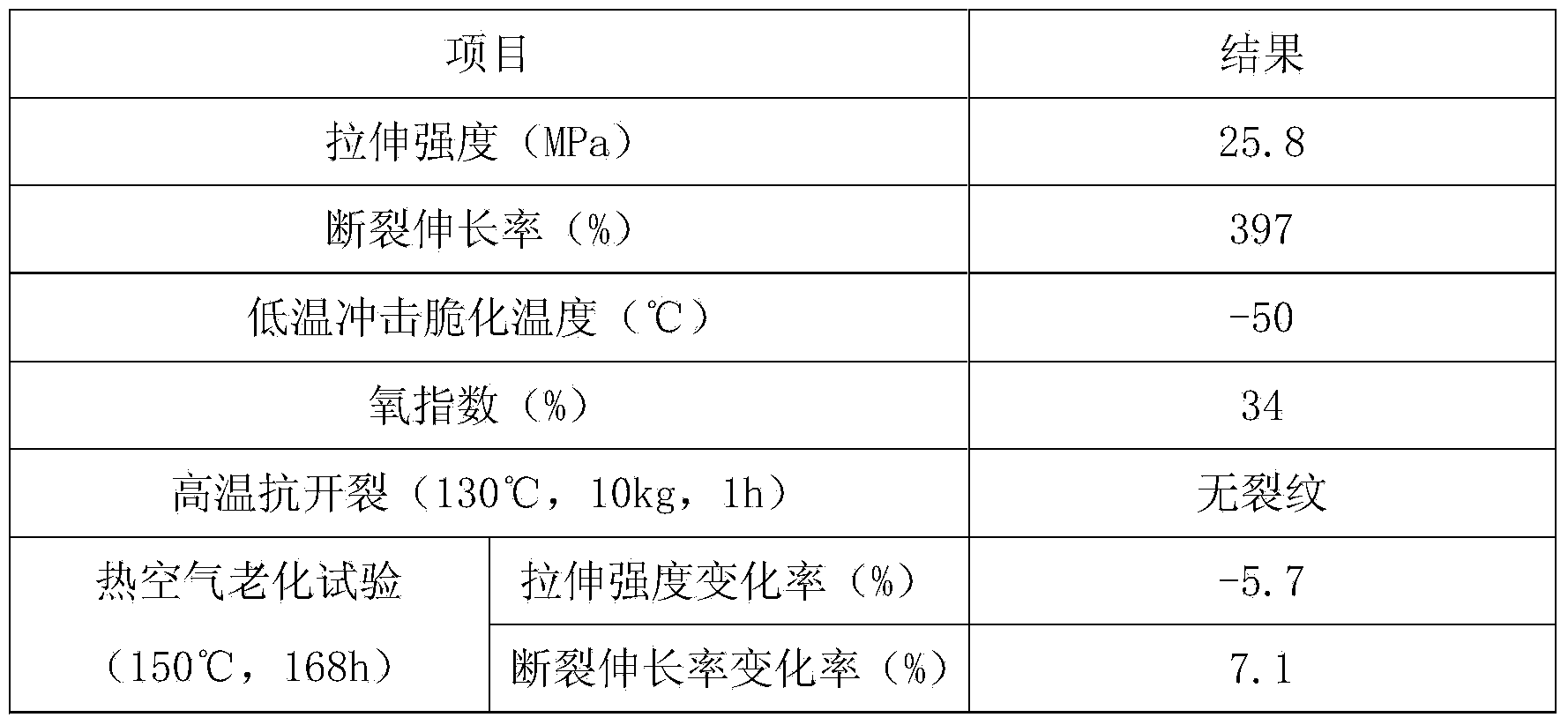

[0013] A crack-resistant high-density polyethylene cable material, made of the following raw materials by weight (kg): high-density polyethylene 60, ethylene-vinyl acetate copolymer 25, ethylene-tetrafluoroethylene copolymer 15, methyl methacrylate - Acrylonitrile-butadiene-styrene copolymer 10, ethylene-vinyl acetate copolymer grafted maleic anhydride 8, magnesium hydroxide 12, red phosphorus 7, zinc borate 5, ethylene bisstearamide 4, stearin Calcium acid 2, activated alumina 15, dicumyl peroxide 3, di-n-butyltin dilaurate 1.5, epoxy soybean oil 15, nano wollastonite 15, heavy calcium powder 8, basic magnesium sulfate whisker 6, Antioxidant 10351, antioxidant DSTP2, composite filler 5;

[0014] The preparation method of the composite filler is as follows: a. Weigh olivine, kyanite, and bauxite in a weight ratio of 5:3:1 and mix them uniformly, calcinate at 940°C for 1 hour, cool to room temperature, and then add to a concentration of 20 % hydrochloric acid solution, keep wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com