Patents

Literature

71 results about "Di-n-butyltin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

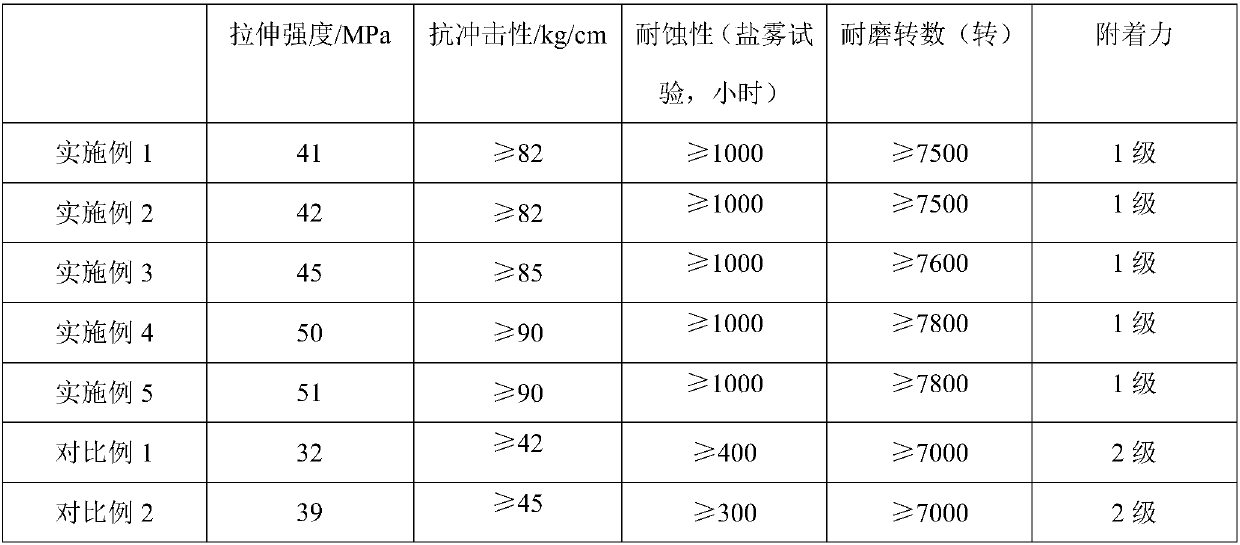

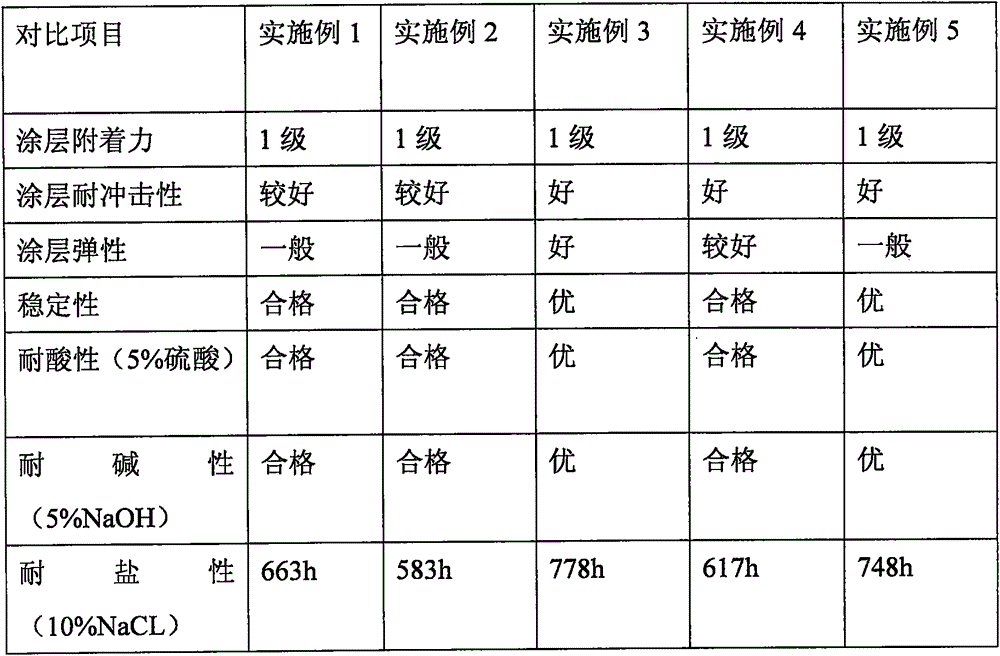

High-temperature-resistant corrosion-resistant coating for aluminum plate

InactiveCN104017466AImprove adhesionImprove high temperature resistanceAnti-corrosive paintsPolyether coatingsEpoxyChlorinated paraffins

The invention discloses a high-temperature-resistant corrosion-resistant coating for an aluminum plate. The coating is prepared from the following raw materials in parts by weight: 30-50 parts of epoxy resin E20, 15-20 parts of furan resin, 8-10 parts of flame retardant polyether polyol, 3-5 parts of nano calcium carbonate, 3-5 parts of tetramethylsilane, 5-8 parts of barium sulfate, 8-10 parts of n-butyl acetate, 10-12 parts of propylene glycol, 10-15 parts of modified zeolite powder, 1-3 parts of di-n-butyltin dilaurate, 5-7 parts of silane coupling agent, 3-5 parts of chlorinated paraffin, 8-12 parts of chlorinated olefins and 5-8 parts of modified straw ash. According to the high-temperature-resistant corrosion-resistant coating for an aluminum plate disclosed by the invention, the modified zeolite powder is added into the formula, so that the adhesive force, the high temperature resistance and resistance to acid and base of the corrosion-resistant coating are greatly improved, and the formula is reasonable. In the aluminum plate preparing process, the aluminum plate is treated, and the corrosion-resistant coating formed on the surface of the aluminum plate is stable in performance, good in adhesive force, high-temperature-resistant, acid-resistant, base-resistant and good in corrosion resistance.

Owner:HEFEI TAITONG REFRIGERATION TECH CO LTD

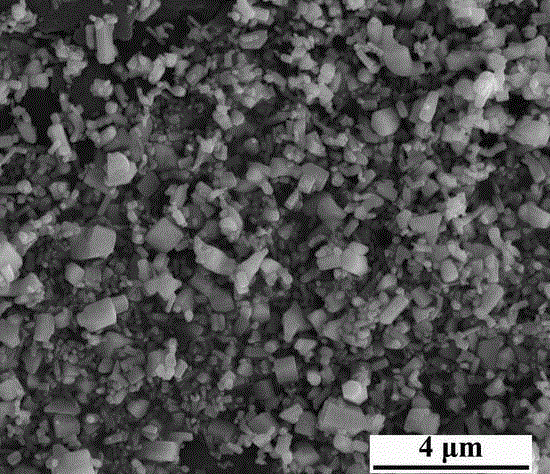

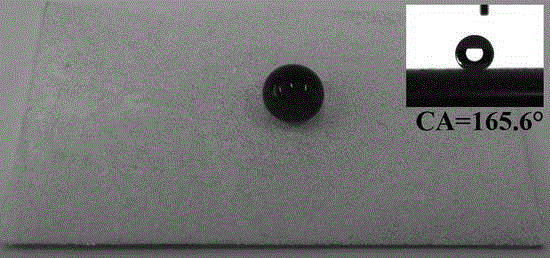

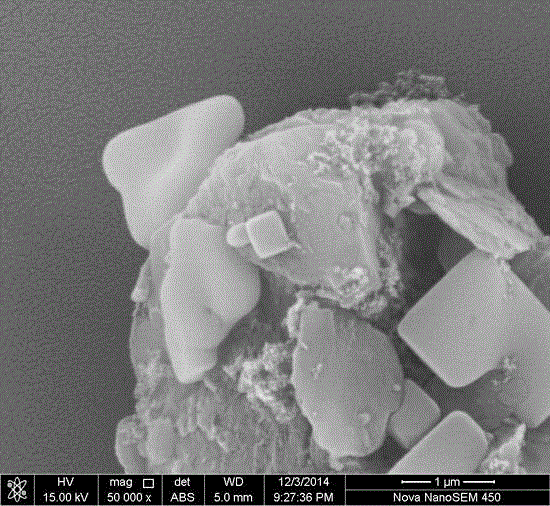

Preparation method of super-hydrophobic surface of room temperature vulcanized silicone rubber

The invention discloses a preparation method of a super-hydrophobic surface of room temperature vulcanized silicone rubber. The preparation method comprises the following steps: (1) preparing 100 parts of alpha, omega-dyhydroxyl polydimethylsiloxane, 4-6 parts of a curing agent tetraethoxysilane, 0.1-0.5 part of a catalyst di-n-butyltin dilaurate and 20-100 parts of a solvent normal hexane into a viscous solution, pouring into a solution film which is 200-500 microns thick on sheet glass and defoaming in vacuum at room temperature; (2) uniformly sieving 5-20 parts of a hydrophobic powder additive on the surface of the viscous solution of room temperature vulcanized silicone rubber which is not cured by virtue of an 80-400-mesh stainless steel sample sieve; and (3) after standing for 24 hours at room temperature, eliminating residual powder on the surface to obtain the super-hydrophobic surface of room temperature vulcanized silicone rubber. The super-hydrophobic surface of room temperature vulcanized silicone rubber disclosed by the invention is simple in preparation method, and the used raw materials are easily available and low in price, so that the super-hydrophobic surface of room temperature vulcanized silicone rubber can be used for surface waterproofness, pollution prevention and self-cleaning of building materials.

Owner:NANCHANG HANGKONG UNIVERSITY

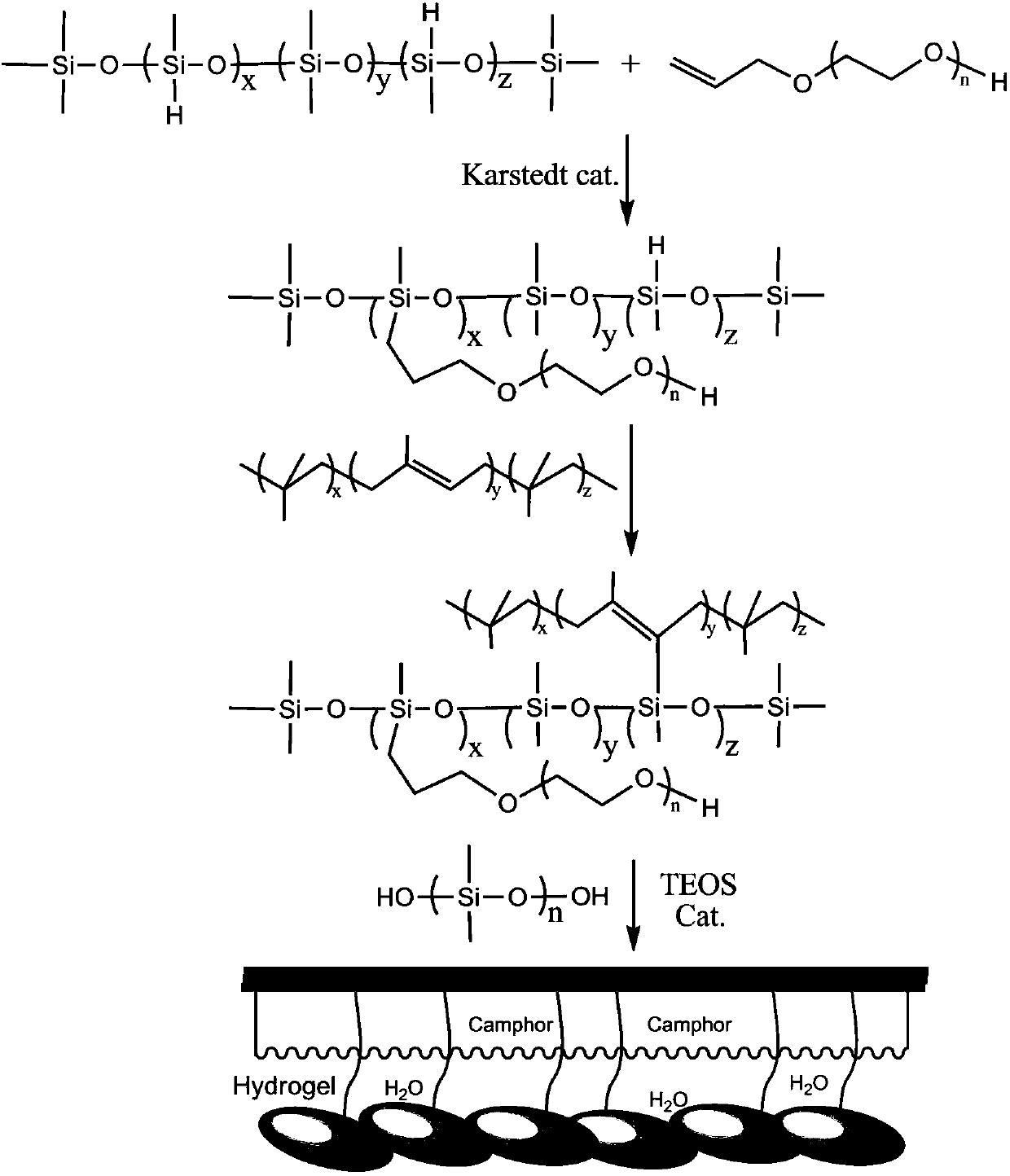

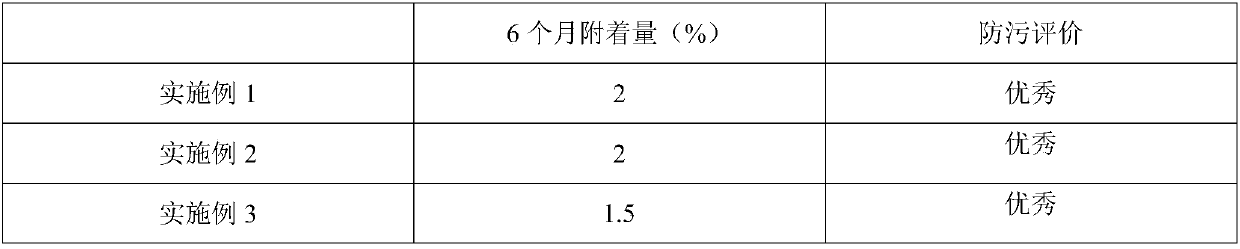

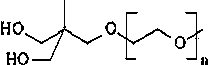

Environment-friendly anti-fouling material based on silicone hydrogel resin and natural anti-fouling agent

ActiveCN107652887AEnvironmentally friendlyImprove adhesionAntifouling/underwater paintsPaints with biocidesCyclohexanonePolyethylene glycol

The invention discloses a preparation method of an environment-friendly anti-fouling material based on silicone hydrogel resin and a natural anti-fouling agent. The preparation method includes: usingallyl polyglycol ether or 2-allyloxyethanol and hydrogen-containing silicone oil as the initial raw materials, heating to perform hydrogen silicification reaction, adding butyl rubber sufficiently swollen and dissolved in xylene, and continuing reaction to prepare silicone hydrogel resin; keeping reaction temperature unchanged, adding a thixotropic agent, hydroxyl silicone oil, diketen, 4, 5-dichloro-2-n-octyl-4-isothiazolin-3-one, synthetic camphor and polyhedral oligomeric silsesquioxane, and performing stirring reaction to obtain a component A for standby; evenly mixing tetraethyl orthosilicate with di-n-butyltin dilaurate, methyl triethoxysilane, cyclohexanone, acetylacetone and xylene to obtain a component B; evenly mixing the component A and the component B according to the mass ratio of (7-9):1, and solidifying for 5-8 hours to obtain the anti-fouling material.

Owner:ZHEJIANG MARINE DEV RES INST

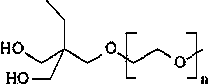

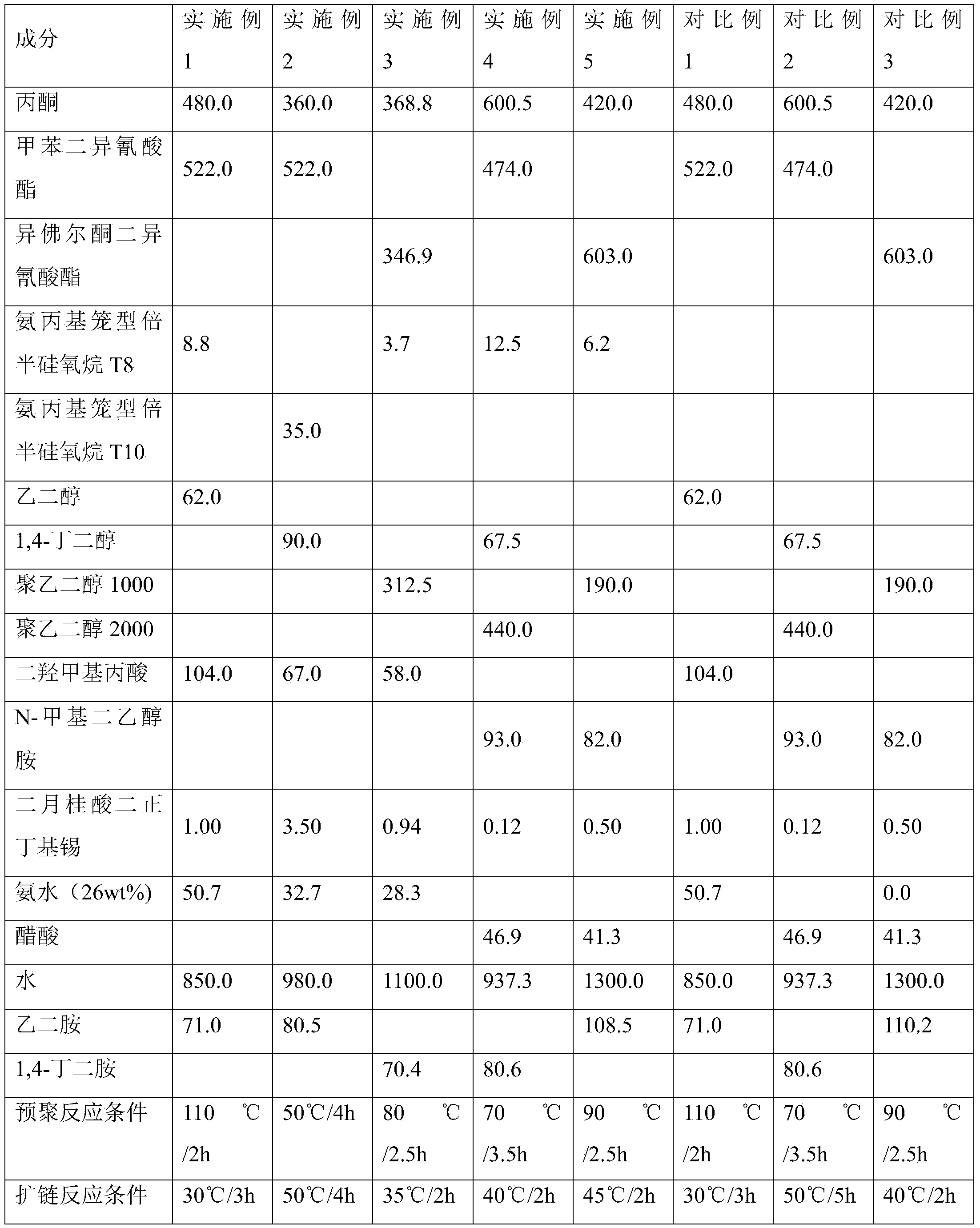

Preparation method of solvent-free waterborne polyurethane resin

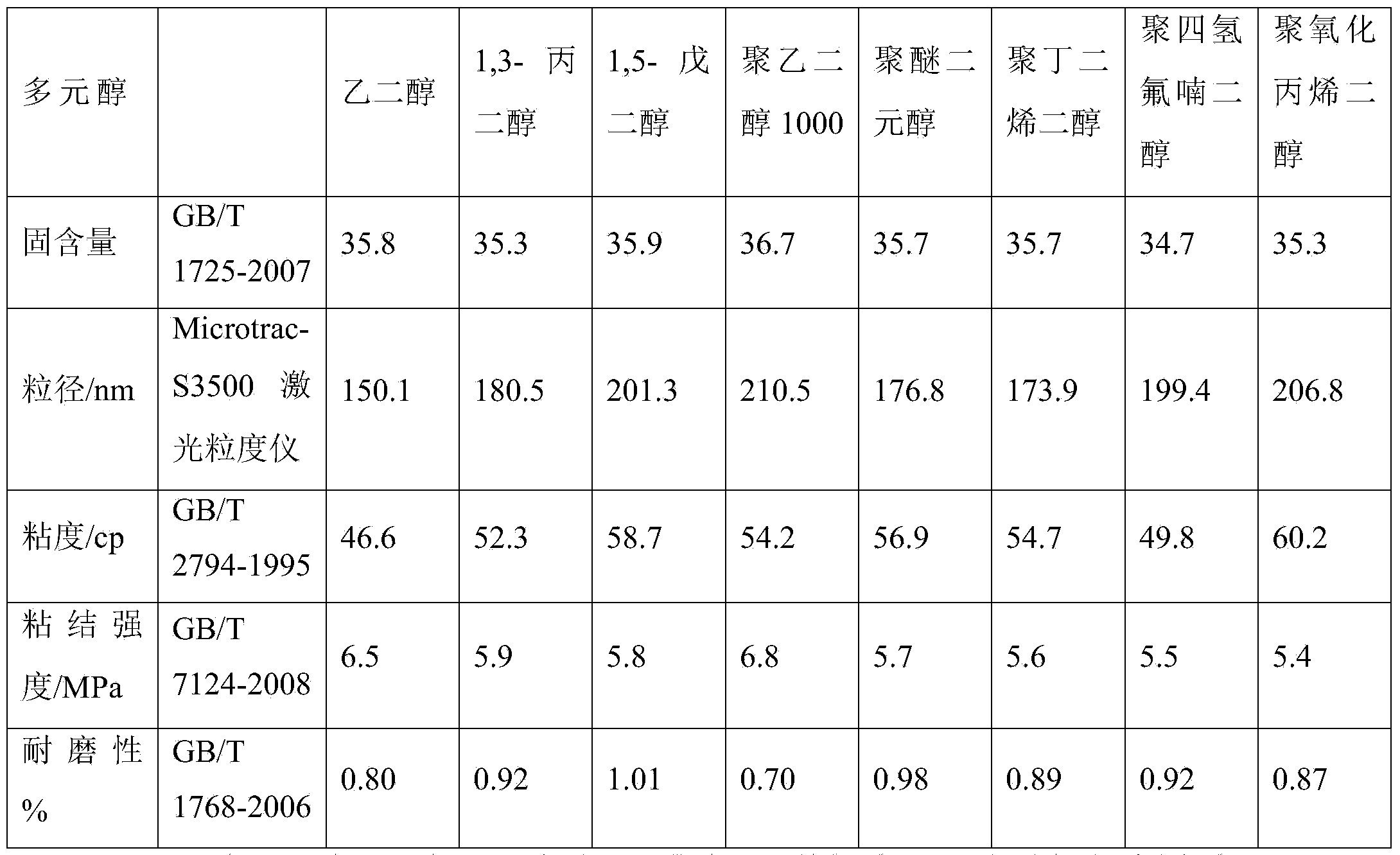

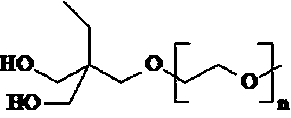

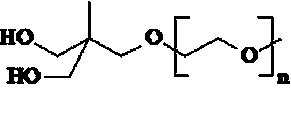

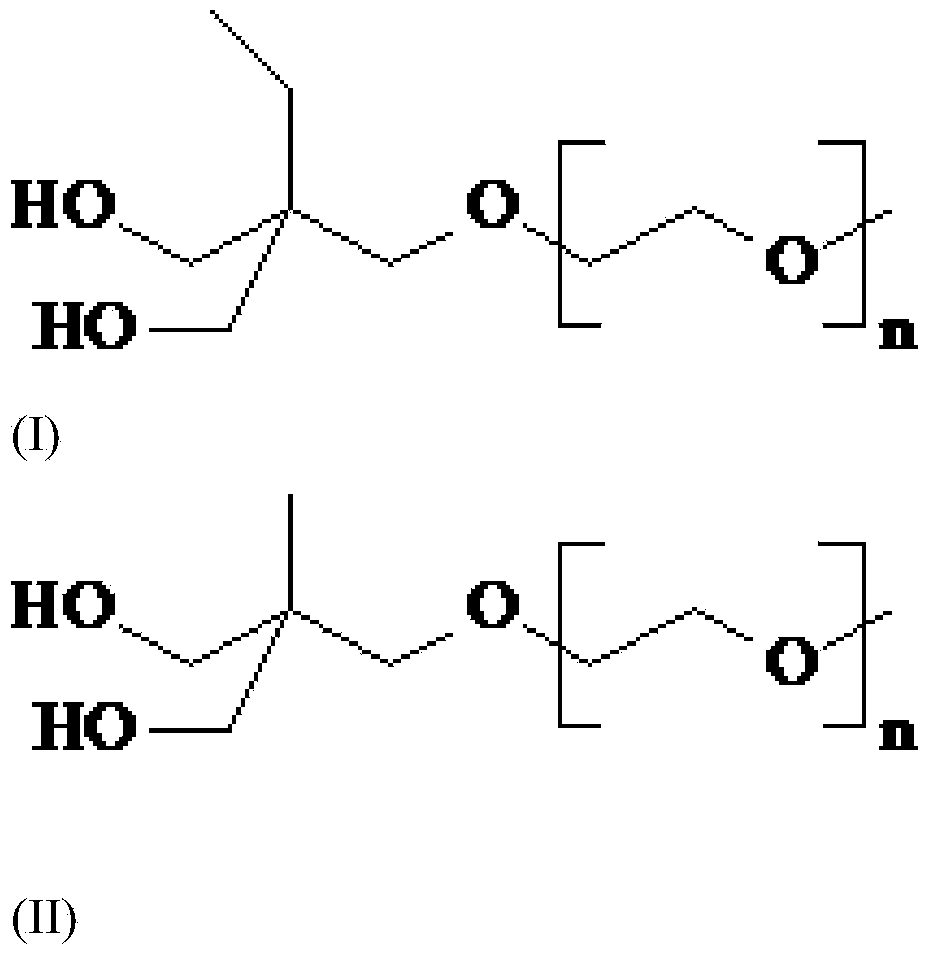

The invention discloses a preparation method of a solvent-free waterborne polyurethane resin. The preparation method specifically comprises: (1), adding amino type cage type silsesquioxane into excessive isocyanate monomers at 20-80 DEG C, reacting until the solution is clear; (2), adding ethyoxyl sealed polymer glycol, hydrophilic functional monomer, dihydric alcohol and catalyst di-n-butyltin dilaurate into the solution obtained in the step (1) (wherein the R value is controlled to be 1.50-3.00 during a pre-polymerization reaction process), reacting for 1-2h at 40-70 DEG C, then heating to 70-90 DEG C, keeping reacting for 1-2h, and then cooling to normal temperature; (3), adding neutralizer and water into the solution obtained in the step (2), and diffusing; and (4), adding a chain extender at 30-50 DEG C, carrying out chain extending reaction for 2-4h, and cooling to normal temperature, so as to obtain the waterborne polyurethane. The solvent-free waterborne polyurethane resin prepared by the method disclosed by the invention has excellent viscosity, adhesive strength and wearing resistance.

Owner:JIANGSU HUAXIA PAINT MAKING

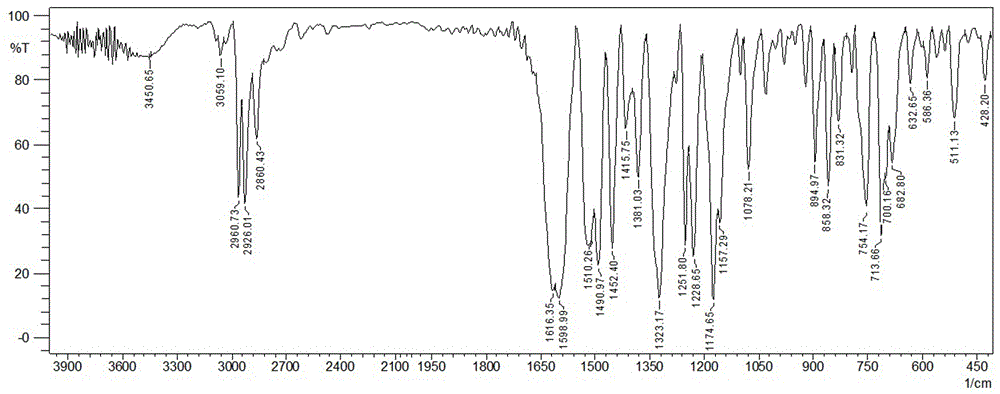

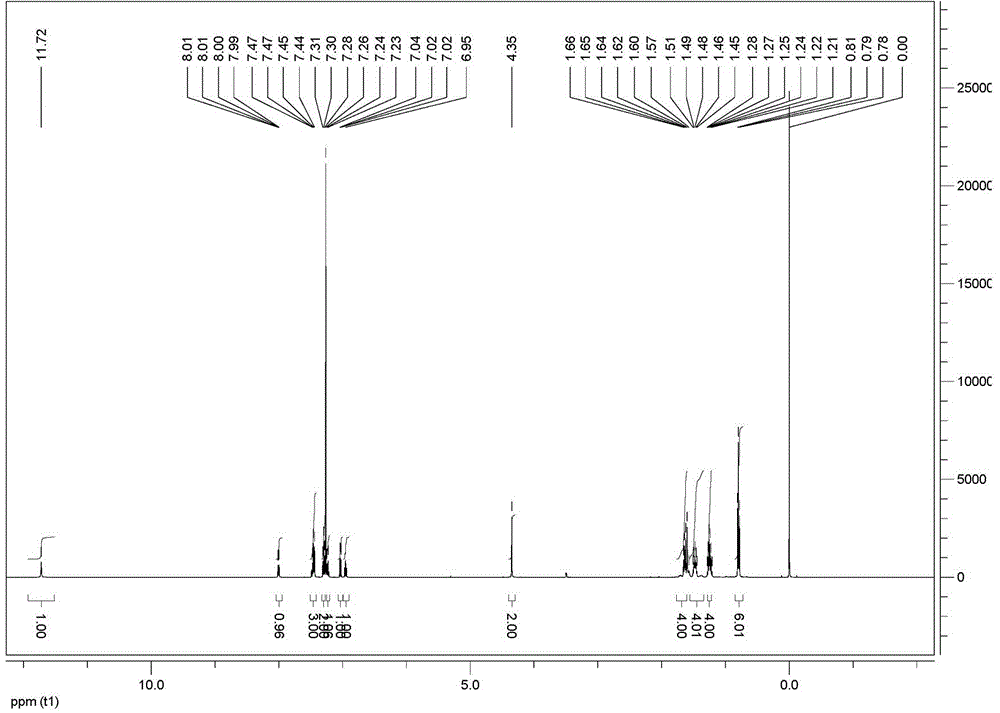

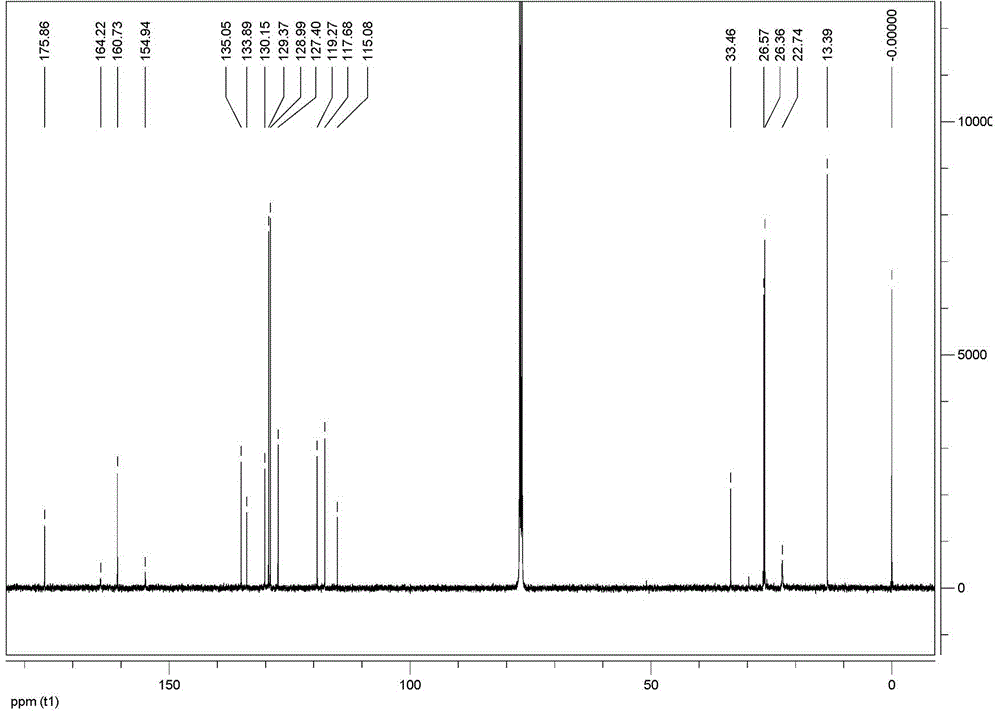

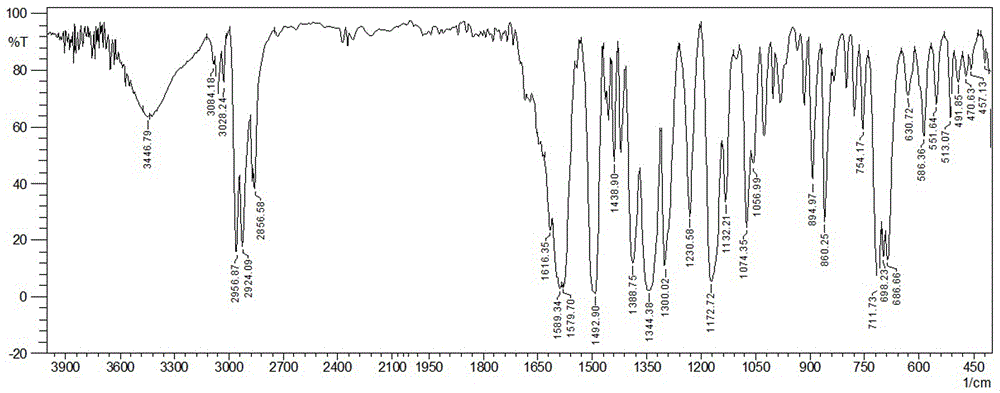

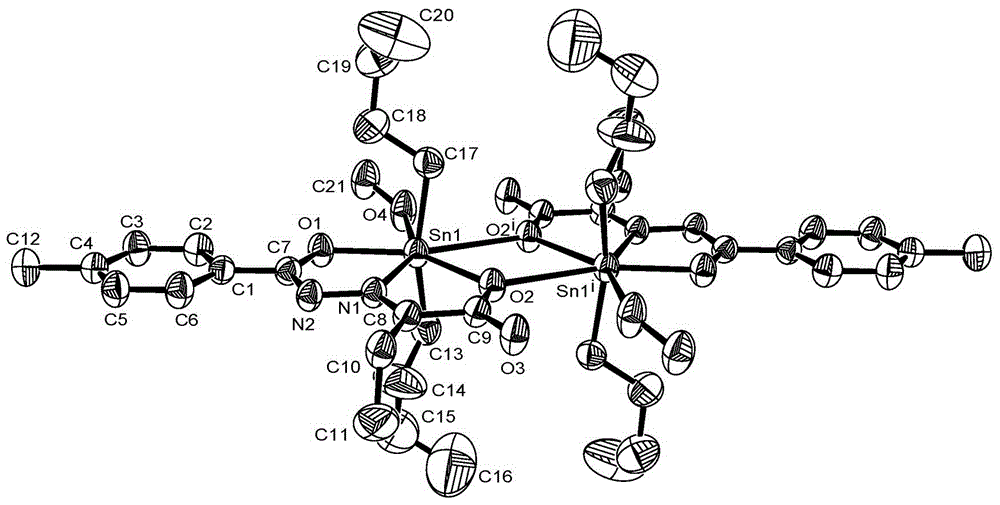

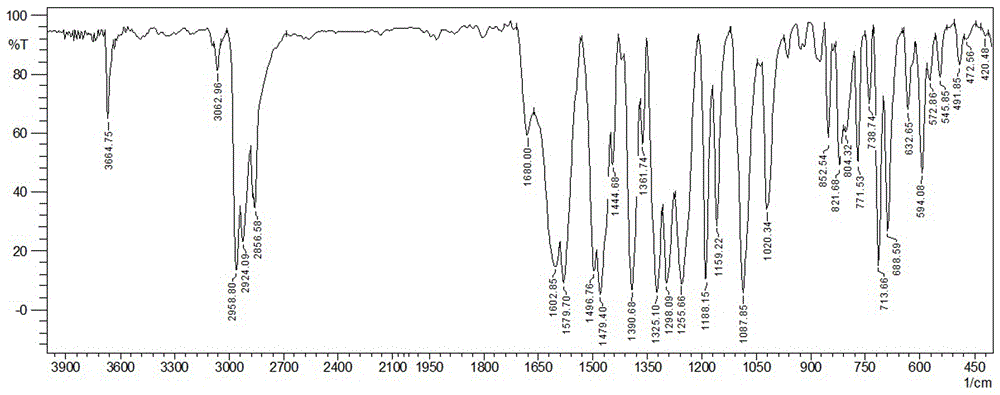

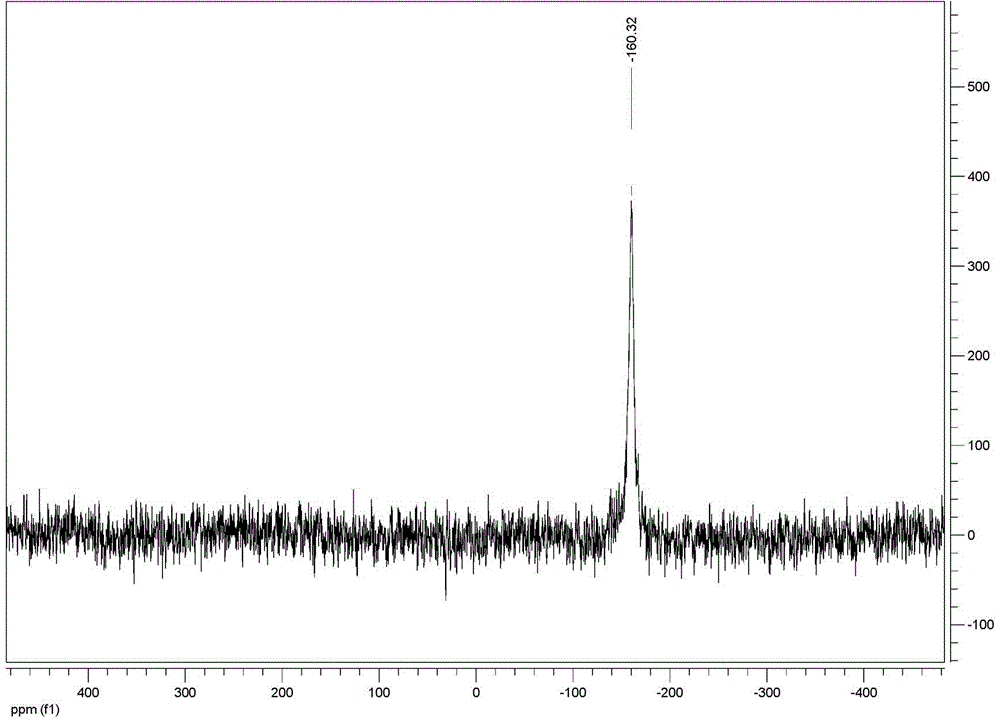

2-carbonyl-3-phenylpropionic acid salicyloyl hydrazone di-n-butyltin complex as well as preparation method and application thereof

ActiveCN106220668AHas a thermally stable rangeFriendly and beneficialTin organic compoundsOrganic chemistry methodsHydrazoneStructural formula

The invention discloses a 2-carbonyl-3-phenylpropionic acid salicyloyl hydrazone di-n-butyltin complex of which the structural formula is as shown in the specification; in the formula, Ph is phenyl, and R is n-butyl. The invention further discloses a preparation method and application of the 2-carbonyl-3-phenylpropionic acid salicyloyl hydrazone di-n-butyltin complex in preparation of anti-cancer medicines.

Owner:HENGYANG NORMAL UNIV

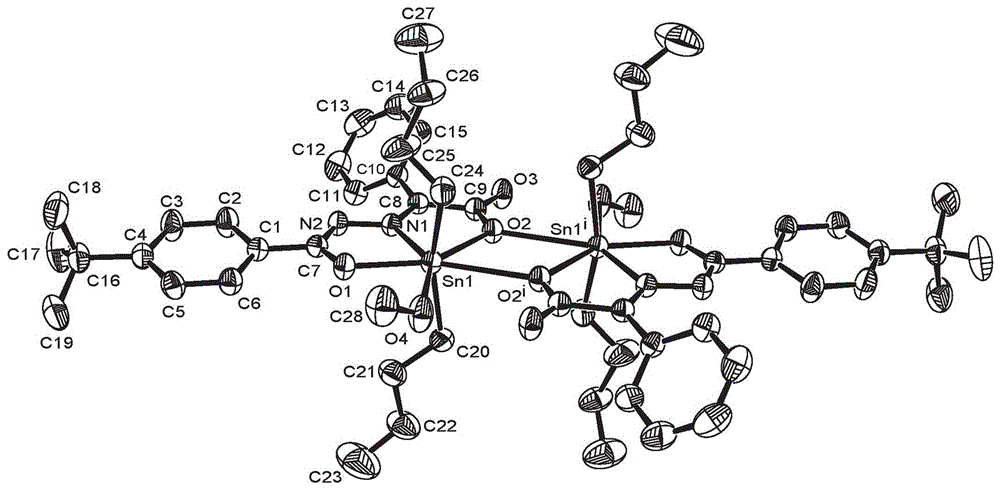

2-carbonyl-3-phenylpropionic acid benzoyl hydrazone di-n-butyltin complex and preparation method and application thereof

ActiveCN106279252AHas a thermally stable rangeFriendly and beneficialTin organic compoundsOrganic chemistry methodsHydrazoneStructural formula

The invention discloses a 2-carbonyl-3-phenylpropionic acid benzoyl hydrazone di-n-butyltin complex. The 2-carbonyl-3-phenylpropionic acid benzoyl hydrazone di-n-butyltin complex is a complex with the structural formula (I) (please see the formula (I) in the description), wherein Ph is phenyl, and R is n-butyl. The invention further discloses a preparation method of the 2-carbonyl-3-phenylpropionic acid benzoyl hydrazone di-n-butyltin complex and application of the 2-carbonyl-3-phenylpropionic acid benzoyl hydrazone di-n-butyltin complex to anti-cancer drug preparation.

Owner:HENGYANG NORMAL UNIV

2-oxobutyrate p-toluyl hydrazone di-n-butyltin complex as well as preparation method and application thereof

ActiveCN106220677AHas a thermally stable rangeFriendly and beneficialTin organic compoundsOrganic chemistry methodsHydrazoneStructural formula

The invention discloses a 2-oxobutyrate p-toluyl hydrazone di-n-butyltin complex. The following structural formula (I) of the complex is shown in the description, wherein R is normal-butyl. The invention further discloses a preparation method of the 2-oxobutyrate p-toluyl hydrazone di-n-butyltin complex and application of the 2-oxobutyrate p-toluyl hydrazone di-n-butyltin complex in preparation of an anticancer drug.

Owner:HENGYANG NORMAL UNIV

2-carbonyl-2-phenylacetic acid p-tert-butyl benzoyl hydrazone di-n-butyltin complex and preparation method and application thereof

ActiveCN106220672AFriendly and beneficialHigh anticancer activityTin organic compoundsOrganic chemistry methodsHydrazonePhenylacetic acid

The invention discloses a 2-carbonyl-2-phenylacetic acid p-tert-butyl benzoyl hydrazone di-n-butyltin complex. The 2-carbonyl-2-phenylacetic acid p-tert-butyl benzoyl hydrazone di-n-butyltin complex is the complex with the structural formula (I) shown in the specification, wherein Ph is phenyl, and R is normal-butyl. The invention further discloses a preparation method of the 2-carbonyl-2-phenylacetic acid p-tert-butyl benzoyl hydrazone di-n-butyltin complex and application in preparation of anti-cancer medicine.

Owner:HENGYANG NORMAL UNIV

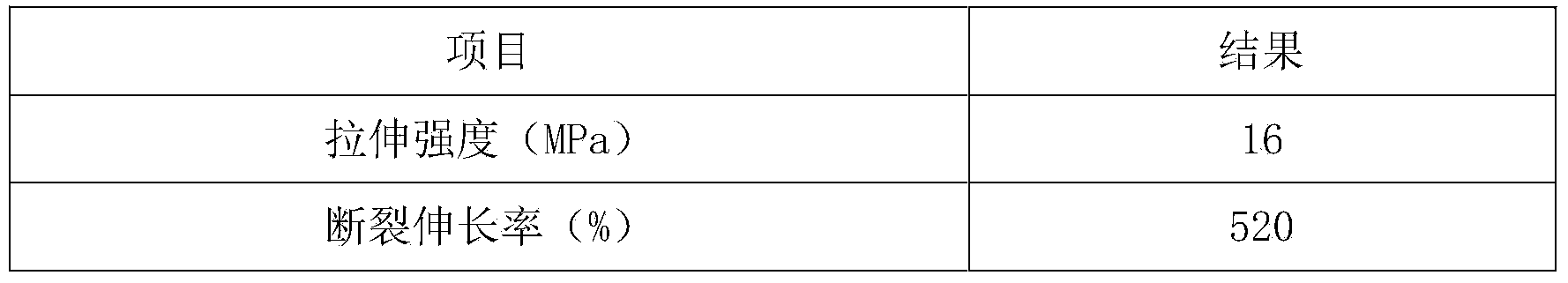

Matte oil-resistant elastomer cable material

The invention provides a matte oil-resistant elastomer cable material which is prepared from the following component raw materials in parts by weight: 20-40 parts of linear low density polyethylene, 10-20 parts of high density polyethylene, 20-40 parts of polyethylene and octylene elastomer, 10-20 parts of ethylene-vinyl acetate copolymer, 10-15 parts of a PVC (Polyvinyl Chloride) paste resin, 2-3 parts of dilauryl thiodipropionate, 1-2 part(s) of di-n-butyltin laurate, 20-25 parts of aluminum hypophosphite, 1-2 part(s) of melamine pyrophosphate, 10-15 parts of magnesium hydroxide, 5-10 parts of zinc borate, 1-3 parts of bi(3,5-tert-butyl-4-hydroxyphenyl) thioether, 2-4 parts of polyethylene wax, 1-2 part(s) of polytetrafluoroethylene, 5-10 parts of modified filler, 3-5 parts of vinyl tri(2-methoxyethoxy) silane, 1-2 part(s) of N-cupric-ion Inhibitor MDA-5 and 1-3 part(s) of dibenzoyl peroxide. Compared with a common low-smoke halogen-free polyolefin cable material, the matte oil-resistant elastomer cable material has the advantages that a temperature resistance grade of the product is improved, the mechanical property is improved, and a problem that the common low-smoke halogen-free polyolefin cable material is easily cracked is solved.

Owner:广东蓝塑实业有限公司

A kind of coating material for electric cable and preparation method thereof

ActiveCN104927454BImprove scratch resistanceImprove surface propertiesCoatingsFiberDimethyl siloxane

The invention discloses a coating material for cables and a preparation method thereof. The coating material for cables is prepared by using the following components in parts by weight: 20-30 parts of dimethacrylate triethylene glycol ester, 18-28 parts of methyl isobutyl ketone, 10-15 parts of polyacrylonitrile fiber, 8-12 parts of bis-(phenyl dimethyl siloxane) methylsiliconate, 3-8 parts of inorganic matter, 3-8 parts of maleic anhydride graft polypropylene, 2-5 parts of propylene oxide butyl ether and 0.5-1 parts of di-n-butyltin dilaurate. The invention further provides a preparation method of the coating material for cables.

Owner:JIANGSU WANDELI CABLE

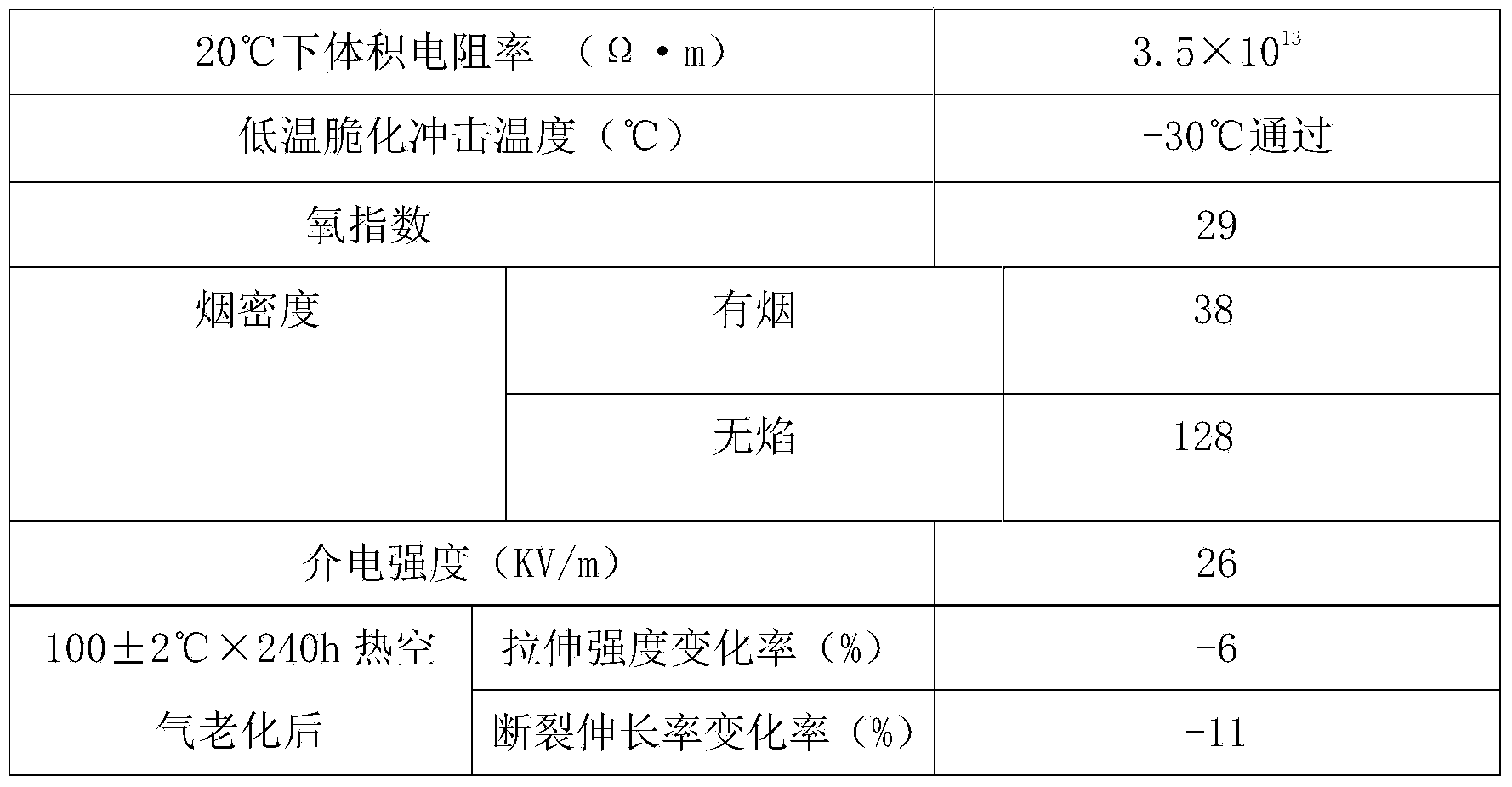

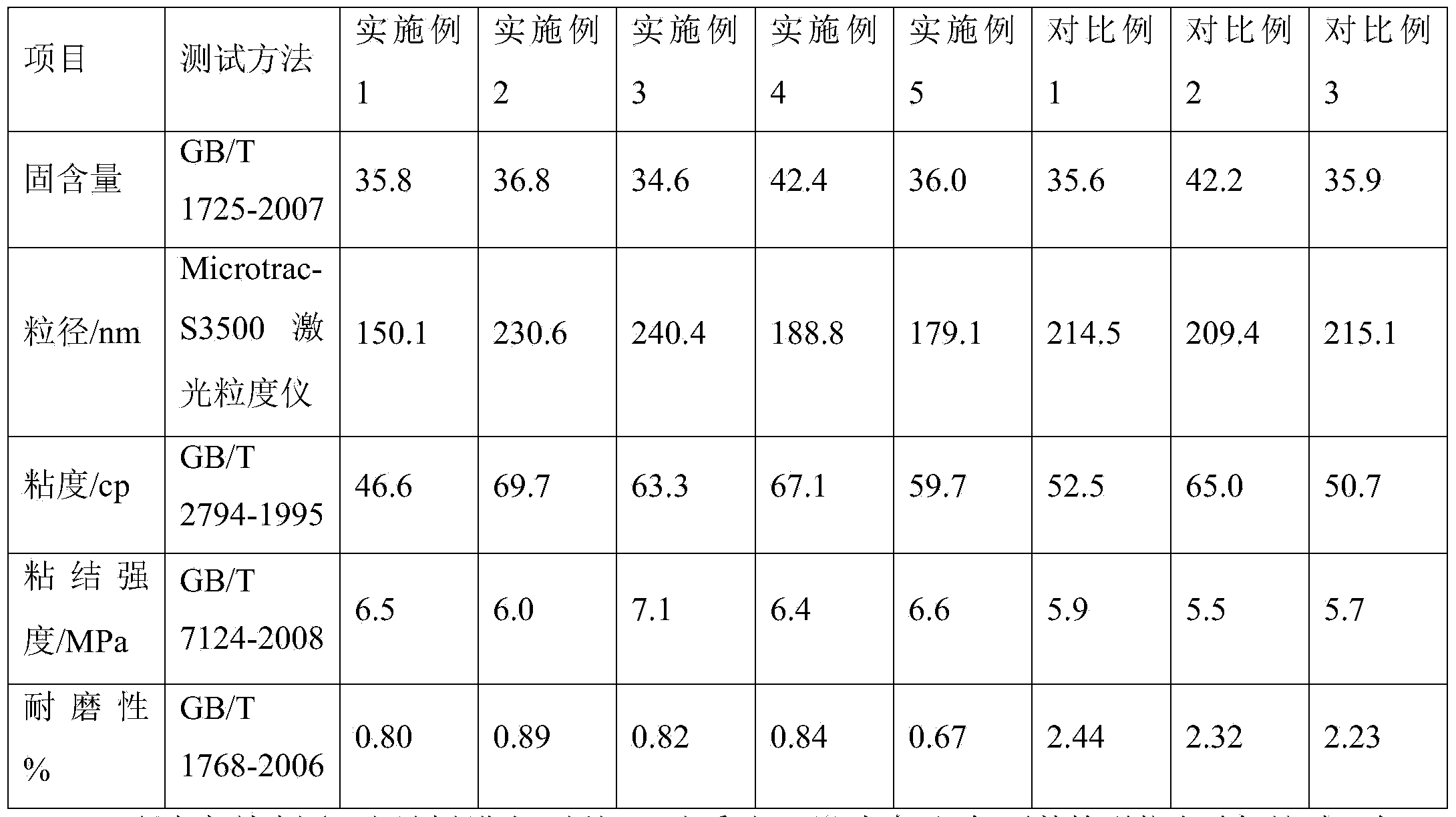

Preparation method of waterborne polyurethane resin

The invention relates to a preparation method of waterborne polyurethane resin, and belongs to the field of preparation of high polymer materials. The method comprises the following steps: mixing acetone, polyisocyanates, amino polyhedral oligomeric silsesquioxane, polyhydric alcohols, a hydrophilic functional monomer and a catalyst di-n-butyltin dilaurate evenly, and then carrying out prepolymerization reaction at 50-110 DEG C for 2-4 hours to obtain a polyurethane prepolymer; adding the polyurethane prepolymer to a neutralizer which is equal to the hydrophilic functional monomer in molar ratio at room temperature, and then adding water to disperse; adding a chain extender at 30-50 DEG C to carry out chain extension for 2-4 hours; and cooling to room temperature to obtain waterborne polyurethane. The polyurethane resin prepared by the method is in an inorganic hybrid structure, and has inorganic nanometer enhancement.

Owner:JIANGSU HUAXIA PAINT MAKING

Method for preparing special material for pipeline by crosslinking modifying of polyethylene

The invention relates to a method for preparing a special material for a pipeline by crosslinking modifying of polyethylene. The method specifically comprises the following steps of mixing polyethylene particles, a polymerization inhibitor 701 and three types of antioxidants 1010, 412S and 697, adding into an extrusion machine, pumping a silane coupler VTMS and an initiator DCP into the extrusion machine in an atomizing and spraying way, extruding a melt, cooling, and cutting particles, so as to obtain a special material A for the pipeline; mixing the dried polyethylene particles and dibutyltin dilaurate, di-n-butyltin dilaurate and three types of antioxidants 1010, 412S and 697, feeding into the extrusion machine, extruding by the extrusion machine, cooling, and granulating, so as to obtain a special material B for the pipeline; mixing the material A and the material B according to a ratio, so as to prepare the special material for the pipeline. The method has the advantages that by adding the polymerization inhibitor, the pre-crosslinking of the polyethylene is avoided; by adding the silane coupler VTMS and the initiator DCP, the crosslinking degree and uniformity are improved, and the generation of gel blocks is avoided; by adding the three types of antioxidants as an anti-aging system, the anti-aging property of a product is improved, and the environment cracking-resistant ability of the pipeline is improved.

Owner:SHAANXI RES DESIGN INST OF PETROLEUM CHEM IND

Preparation method of solvent-free water-based polyurethane resin

The invention belongs to the field of high polymer materials, and particularly relates to a preparation method of a solvent-free water-based polyurethane resin. The method comprises the following steps: uniformly mixing polyisocyanate, amino cage-type silsesquioxane, polyalcohol, ethoxy terminated polymer diol, hydrophilic functional monomer and a catalyst di-n-butyltin dilaurate, and carrying out prepolymerization reaction at 50-110 DEG C for 2-4 hours to obtain a polyurethane prepolymer; adding a neutralizer and water into the polyurethane prepolymer at room temperature, carrying out forced dispersion, adding a chain extender at 30-50 DEG C to carry out chain extension reaction for 2-4 hours, and cooling to room temperature to obtain the water-based polyurethane. The water-based polyurethane resin is solvent-free, and has the characteristic of zero VOC (volatile organic compound) discharge. The performance determination proves that the binding strength is 6.2 MPa above and optimally 6.5 MPa, the wear resistance is 0.87% below and optimally 0.65%, and the number of freezing times can be more than 10.

Owner:JIANGSU HUAXIA PAINT MAKING

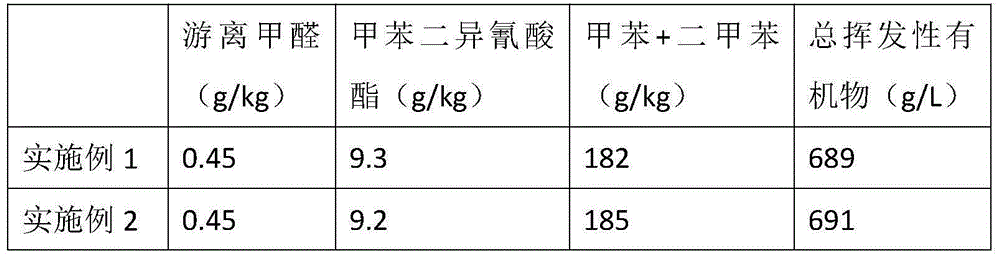

Preparation method for door sheet protective agent

The invention discloses a preparation method for a door sheet protective agent. The preparation method comprises the following steps of completely reacting polyester polyol with poly(hexanediol adipate); uniformly stirring an obtained reaction product and isophorone diisocyanate, and introducing nitrogen to be reacted with the reaction product and the isophorone diisocyanate to generate isocyanate-terminated polyurethane; heating the polyurethane, hydroxyethyl methylacrylate and di-n-butyltin dilaurate to obtain a prepolymer with double bonds at both ends, and adding 2-methyl methacrylate for reaction to make the prepolymer contain both hydrophilic ion groups and unsaturated double bonds; adding 2-methyl methacrylate into the polyurethane prepolymer for viscosity reduction, performing neutralization with triethylamine, and adding an ethylene diamine solution at concentration of 3 percent for emulsion dispersion; performing oscillation dispersion on a polyacrylamide solution at concentration of 1.5 percent, polyoxyethylene ether and nanometer aluminum oxide, performing high-speed grinding with organic siloxane, and adding polyvinylpyrrolidone for oscillation dispersion. Therefore, the acid resistance, the alkali resistance and the stability of the protective agent are improved.

Owner:CHONGQING ZUOEN FURNITURE

Halogen-free flame-retardant insulating material for durable household appliances and preparation method thereof

InactiveCN104893087AImprove mechanical propertiesIncrease elasticityPlastic/resin/waxes insulatorsLow-density polyethyleneSilanes

The invention relates to a halogen-free flame-retardant insulating material for durable household appliances, which is prepared from the following raw materials in parts by weight: 4 to 5 parts of thermoplastic polyurethane elastomer rubber, 1 to 2 parts of alkali lignin, 2 to 3 parts of urea-formaldehyde resin, 1 to 1.5 parts of melamino-formaldehyde resin, 6 to 7 parts of low-density polyethylene resin, 0.3 to 0.4 part of vinyl trimethoxy silane, 0.04 to 0.08 part of dicumyl peroxide, 0.01 to 0.02 part of di-n-butyltin dilaurate, 50 to 60 parts of magnesium hydroxide, 60 to 65 parts of an ethylene vinyl acetate copolymer (EVA), 20 to 23 parts of high-density polyethylene resin and 1 to 1.5 parts of an antioxidant 1010. The insulating material provided by the invention is prepared from the thermoplastic polyurethane elastomer rubber, the alkali lignin and the urea-formaldehyde resin through reaction modification, so that the insulating material has excellent abrasive resistance and ozone resistance, high hardness, high strength, high elasticity, low-temperature resistance, excellent oil resistance, chemical resistance and environment resistance, and has excellent hydrolysis stability in damp environments. The insulating material is applicable to wire harness of household appliances such as refrigerators, air conditioners and the like.

Owner:合肥得润电子器件有限公司

Special flow type silicone sealant for road

InactiveCN105419721AImprove adhesionLow modulusNon-macromolecular adhesive additivesSilanesAging resistance

The invention discloses a special flow type silicone sealant for a road. The special flow type silicone sealant for the road comprise raw materials in parts by weight as follows: 54-58 parts of room temperature vulcanized methyl silicone rubber with the viscosity of 1,200-1,600 mPa*s, 115-125 parts of room temperature vulcanized methyl silicone rubber with the viscosity of 18,000-20,000 mPa*s, 210-220 parts of silica powder, 122-130 parts of nano calcium carbonate, 0.1-1 part of di-n-butyltin dilaurate, 22-30 parts of methyltris(methylethylketoxime)silane, 5-10 parts of vinyltris(methylethylketoxime)silane and 1-2 parts of a coupling agent. The special flow type silicone sealant for the road has excellent high-low-temperature resistance and weather aging resistance, cannot deform in an environment with the too high or too low temperature and has good extensibility, elasticity, convenience in construction and long service life.

Owner:HENAN GUIBAO ENERGY TECH

Silicone weather-proofing sealant

InactiveCN107805480AGood adhesionHigh tensile strengthNon-macromolecular adhesive additivesMacromolecular adhesive additivesSilanesFumed silica

The invention discloses a silicone weather-resistant sealant, which comprises the following raw materials in parts by weight: 50-60 parts of vulcanized methyl silicone rubber with a viscosity of 15000-25000 Pa·S, and 130 parts of vulcanized methyl silicone rubber with a viscosity of 70000-90000 Pa·S ~160 parts, 8~15 parts of methyl silicone oil with a viscosity of 400~500Pa·S, 22~45 parts of methyl silicone oil with a viscosity of 200~300Pa·S, 180~210 parts of nano-active calcium carbonate, 70 parts of fumed silica ~90 parts, silicon dioxide 20~30 parts, methyl tributylketoxime silane 20~40 parts, di-n-butyltin dilaurate 5~10 parts, aminopropyl triethoxysilane 1~2 parts, propane 1-3 parts of trimethoxysilane, 1-3 parts of anti-mold agent, and 10-20 parts of pigment; the silicone weather-resistant sealant has good anti-mold effect and good weather resistance.

Owner:SICHUAN KELIXIN NEW MATERIALS CO LTD

Alcohol-soluble letterpress ink

The invention relates to an alcohol-soluble letterpress ink which is prepared from the following raw materials in parts by weight: 15-25 parts of pigment, 35-40 parts of binder, 15-18 parts of barium sulfate, 20-30 parts of anhydrous ethanol, 1-2 parts of TX-9, 1-3 parts of tridecanol, 1-2 parts of di-n-butyltin dilaurate and 0.5-1 part of vaseline. The binder is prepared from the following raw materials in parts by weight: 25-28 parts of polyvinyl butyral resin, 7-13 parts of acrylic acid monomer, 3-7 parts of phenol aldehyde resin, 4-7 parts of tung oil, 40-45 parts of anhydrous ethanol, 5-7 parts of nitrocellulose solution and 0.5-1.5 parts of paraffin. The ink can be degrade in an alcohol solvent, has the advantages of environmental protection, no pollution, high adhesive force, favorable wear resistance and high glossiness, and is suitable for large-scale industrial production.

Owner:SUZHOU YIHENG PRINTING

Environment-friendly stabilizer

The invention relates to an environment-friendly stabilizer which is applied to the machining process of PVC resin. The environment-friendly stabilizer is prepared from calcium stearate, zinc stearate, di-n-butyltin dilaurate, epoxidized soybean oil and pentaerythritol in parts by weight. The various components of the stabilizer of the invention can be fully mixed in the production process of the stabilizer, thereby greatly improving the uniformity of mixed dispersion with resin. The stabilizer of the invention has the advantages of excellent heat stability, prolonged stable phase, excellent electrical insulation property, good weather resistance, low price, good transparency, no toxicity and improved lubricating property.

Owner:INT TECH INCUBATION CENT HEPING DISTRICT SHENYANG CITY

Water-base sealant for automobiles and manufacturing process of water-base sealant

InactiveCN103525339ALow priceNon-macromolecular adhesive additivesOther chemical processesWater basedEmulsion

The embodiment of the invention discloses a water-base sealant for automobiles. The water-base sealant comprises the following components in mass ratio: pure crylic acid copolymer emulsion, a water soluble resin, di-n-butyltin dilaurate, carboxymethylcellulose, polyvinyl chloride, talcum powder, heavy calcium carbonate, phenethyl alcohol and clay. The water-base sealant is prepared by taking the crylic acid copolymer emulsion as a base material together with a plasticizer, a thickening agent, assistants and the like, and has the characteristics of being non-poisonous, tasteless, non-combustible, nonexplosible, free of environment pollution, low in price and the like.

Owner:林贤文

Anti-ageing flame retardant safe insulated conductor

InactiveCN108841133ALow costGood weather resistancePlastic/resin/waxes insulatorsAntistatic agentWeather resistance

The invention provides an anti-ageing flame retardant safe insulated conductor. The conductor comprises polyformaldehyde resin, a weather resistance agent, a flame retardant, a heat stabilizer, an antistatic agent, a dispersing agent and a filling agent, wherein the weather resistance agent adopts dilauryl thiodipropionate; the flame retardant adopts antimony trioxide; the heat stabilizer adopts dodecyl mercaptan di-n butyltin; the antistatic agent adopts dodecyl dimethyl betaine, and the dispersing agent adopts polyethylene wax; the filling agent adopts talcum powder. The conductor has the characteristics of low cost, good weather resistance, good flame resistance, good antistatic property, high strength and long service life.

Owner:苏州天鸿电子有限公司

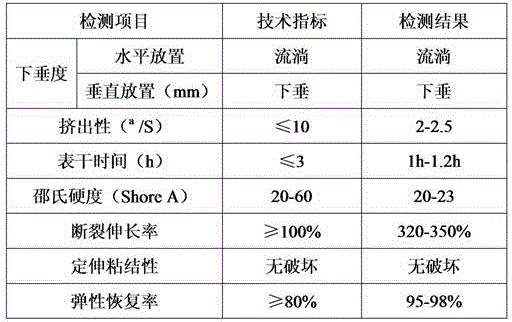

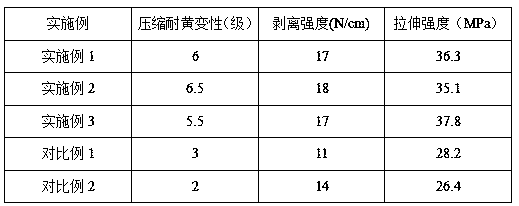

Anti-yellowing polyurethane foam and preparation method thereof

The invention discloses an anti-yellowing polyurethane foam, which is prepared from the following components in parts by weight: 60 parts of pluronic polyols, 15 parts of diphenylmethane diisocyanate,5 parts of di-n-butyltin dilaurate, 9 parts of ethylene glycol, 7 parts of hexamethylene diisocyanate, 6 parts of citric acid, 3 parts of dimethicone, and 2 parts of water. A preparation method of the anti-yellowing polyurethane foam comprises the steps of adding the citric acid and the hexamethylene diisocyanate during a preparation process, and soaking in a buffer solution after finishing foaming, so that the yellowing resistance of the foam can be well improved; meanwhile, the prepared anti-yellowing polyurethane foam is high in strength and good in toughness.

Owner:JIANGSU SIRUIDA NEW MATERIAL TECH

Nanometer transparent scratch-resistant glass and preparation method thereof

InactiveCN105776856AImprove scratch resistanceImprove machinabilityGlass shaping apparatusSilicon dioxideZirconium dioxide

The invention discloses nanometer transparent scratch-resistant glass and a preparation method thereof.The nanometer transparent scratch-resistant glass is prepared from, by weight, 60-70 parts of silicon dioxide, 20-30 parts of zirconium dioxide, 3-5 parts of glass beads, 1-2 parts of sodium hexafluorozirconate, 1-2 parts of sodium fluosilicate, 1-2 parts of barium oxide, 1-1.5 parts of methyltriacetoxysilane, 1-1.5 parts of sodium hydroxide, 0.5-1 part of nickel foam, 0.5-0.8 part of di-n-butyltin dilaurate and 0.4-0.8 part of polydithiazole.The invention further provides a preparation method of the nanometer transparent scratch-resistant glass.

Owner:SUZHOU YUNSHU NEW MATERIAL TECH

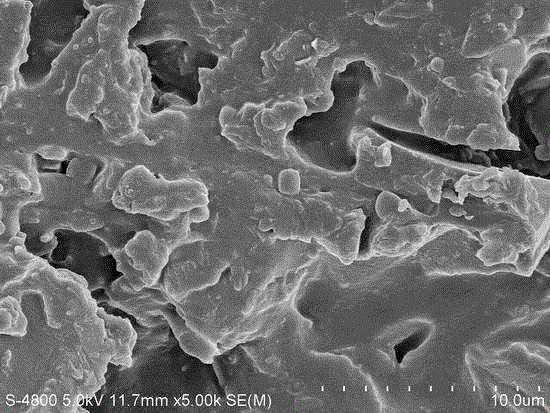

Preparation method for anti-icing silicone rubber composite material surface

The invention discloses a preparation method for an anti-icing silicone rubber composite material surface. The preparation method comprises the following steps of firstly, mixing potassium chloride, silicon dioxide and diatomite particles in acetone to obtain modified potassium chloride powder filler; secondly, performing ball milling and uniformly mixing on the modified potassium chloride powder filler and alpha, omega-dihydroxyl polydimethylsiloxane, tetraethoxysilane as a curing agent and normal hexane as solvent, adding di-n-butyltin dilaurate as a catalyst and then continuously performing ball milling; casting uniformly-mixed suspension on a glass sheet to form a film; curing at room temperature to obtain a silicone rubber composite material. The silicone rubber composite material surface is simply polished to obtain the anti-icing performance, and further the surface ice-coating amount under the icing condition can be remarkably reduced by at most over 91 percent; after the cycle for 10 times, the ice-coating amount can still be at most reduced by over 83 percent. The preparation method for the anti-icing silicone rubber composite material surface, disclosed by the invention, is simple; used raw materials are wide in source and low in price; the anti-icing silicone rubber composite material surface is remarkable in anti-icing performance, can be recycled and can be used for preventing the icing on the surfaces of building materials or the surfaces of important facilities.

Owner:NANCHANG HANGKONG UNIVERSITY

High-flame-retardance cable coating layer and preparation method thereof

InactiveCN108148322AImprove flame retardant performanceImprove wear resistancePlastic/resin/waxes insulatorsPolyvinyl chlorideGlycerol

The invention discloses a high-flame-retardance cable coating layer and a preparation method thereof. The high-flame-retardance cable coating layer is prepared from the following raw materials: propylene homopolymer, polyvinylvinyl chloride resin, chlorinated polyethylene, (Z)-but-2-enedioic acid,chloroethene,ethenyl acetatechlorinated vinegar resin, polyurethane, vinisol, vinyl trimethoxy silane,calcium stearate, glass fiber, boron nitride nNano-powder, mineral cotton, antimony trioxide, zinc borate, aluminum triphosphate, magnesium powder, nano-silica, isopropyl phenyl diphenyl phosphate, N,N'-di-furfurylidene-acetone, diphenyl isooctyl phosphate, diphenyl phosphate isopropyl benzene ester, diphenylamine, sulfur, triphenyl phosphate, glycerol triacetate, dimethyl phthalatedimethyl esterphthalate, di-n-butyltin di(monobutyl maleate)mono-n-butyl dimaleate dibutyltin, vulcanizing agent VA-7 and promoting agent BZ. The high-flame-retardance cable coating layer is an intermediate product prepared by the following steps: primary banburying, secondary banburying, mixing and discharging glue are performed to obtain an intermediate product, and vulcanizing the intermediate is vulcanized. The cable coating layer has superior flame resistance and superior abrasion resistance.

Owner:CHANGSHA WUDAO IND DESIGN CO LTD

Modified polyurethane resin coating and preparation method thereof

InactiveCN105419620APH-responsiveFunction increaseAnti-corrosive paintsPolyurea/polyurethane coatingsEpoxyPhosphoric acid

The invention discloses a modified polyurethane resin coating, which is made from raw materials with parts by weight: toluene diisocynate 60-80 parts, dicyclohexylmethane diisocyanate 5-10 parts, hexamethylene diisocyanate 5-10 parts, hexanedioic acids 4-8 parts, alkyd resins 1-5 parts, epoxy resins 2-4 parts, propylene glycol 1-3 parts, methyldiethanolamine 1-3 parts, di-n-butyltin diester 1-4 parts, acetic ethers 5-10 parts, phosphoric acids 0.5-1 part, deionized water 10-30 parts and polymer nanoparticles 8-16 parts. The modified polyurethane resin coating combines the polymer nanoparticles and a coating, disperses in modified polyurethane resins, forms an effective corrosion resistant composite coating, and has the excellent performance of oil resistivity, seawater resistant, wear resistance and impact resistance and the like.

Owner:中山新隆昌化工有限公司

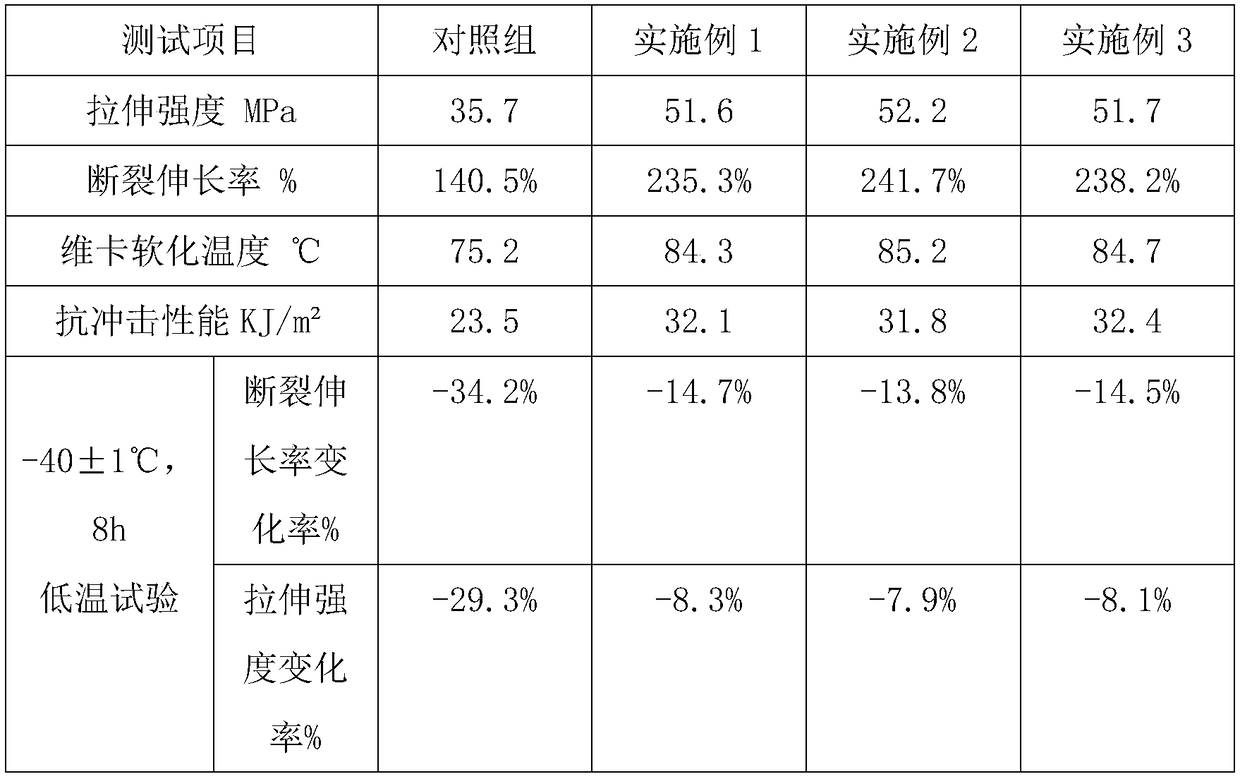

Cold-resistant and crack-resistant PVC resin for door and window plastic steel profiles

The invention relates to the technical field of polymer materials, in particular to a cold-resistant and crack-resistant PVC resin for door and window plastic steel profiles. The PVC resin includes PVC, ACR processing aid, filler, cold-resistant toughening agent, polyethylene wax, composite stabilizer, ultraviolet absorber and antioxidant. The cold-resistant toughening agent is a novel material prepared by compounding a plurality of elastomer materials and high-hardness fillers; the filler is a mixture of titanium dioxide and light calcium carbonate; the composite stabilizer contains calcium-zinc stabilizer and di-n-butyltin dilaurate; the ultraviolet absorber is ultraviolet absorber RMB, ultraviolet absorber UV-9 or ultraviolet absorber UVP-327; and the antioxidant is antioxidant 164, antioxidant 1076 or antioxidant TNP. The PVC resin material has good toughness and outstanding low temperature resistance, and is not easily embrittled under low temperature conditions. The cold-resistant and crack-resistant PVC resin is good in impact resistance and does not crack easily.

Owner:HEFEI LONGYANG AGRI TECH CO LTD

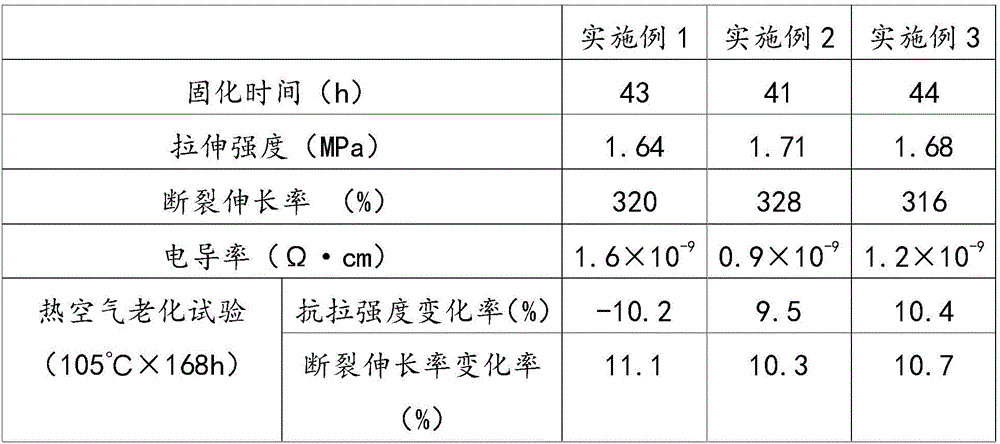

Weather-resistant conductive silicone sealant and preparation method thereof

InactiveCN106190014AImprove thermal stabilityGood chemical stabilityNon-macromolecular adhesive additivesMacromolecular adhesive additivesSilanesPolyamide

The invention discloses a weather-resistant conductive silicone sealant and a preparation method thereof. The weather-resistant conductive silicone sealant is mainly prepared from alpha,ometa- dihydroxyl polydimethylsiloxane, titanium black, low molecular polyamide 200, methyl-tri-(butanone-oxime) silane, rosin-modified maleic resin, isobutyltriethoxysilane, acetylene black, dimethyl silicone oil, nanometer bentonite, aluminophosphite, dimethyl ketone, di-n-butyltin dilaurate, nano-zinc powder, tin antimony oxide and the like. According to the silicone sealant, the nano-zinc powder, tin antimony oxide, conductive mica powder and acetylene black are compounded to serve as a conductor, the conductor is good in conductive effect and beneficial for improving the thermal stability and the chemical stability of the silicone sealant by being applied to cooperate with aluminophosphite and titanium black, and the weather resistance and the aging resistance of the silicone sealant are enhanced through the rosin-modified maleic resin, low molecular polyamide 200, isobutyltriethoxysilane and the like. The produced silicone sealant is good in conductivity, excellent in weather resistance and long in service life.

Owner:覃树强

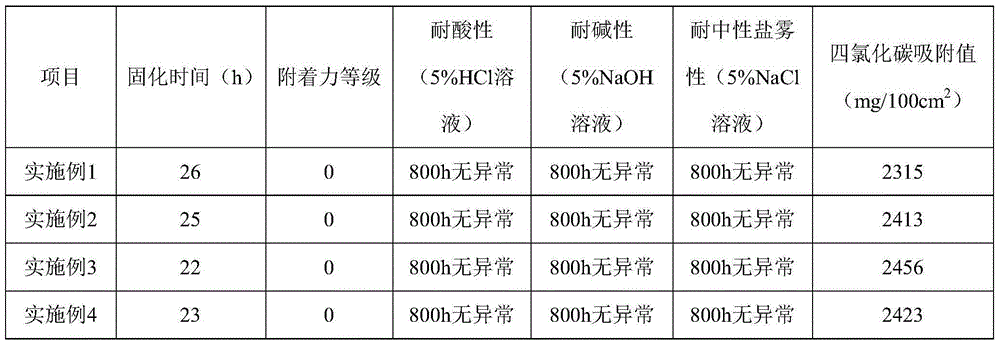

Preparation method for corrosion resistance water-based paint with activated carbon as raw material

The invention discloses a preparation method for corrosion resistance water-based paint with activated carbon as a raw material. The method comprises the steps that firstly, the activated carbon is soaked into a hydrochloric acid solution for a certain period of time and then is filtered and dried to obtain a first material; then, the first material is added into a reaction kettle, an ammonium carbonate solution is added, heating and stirring are performed, filtering is performed, and a solid substance obtained after filtering is dried to obtain a second material; then, the second material, tetrabutyl titanate, di-n-butyltin dilaurate, polyester fiber and tetraethoxysilane are added into the reaction kettle, heating and stirring are performed on the vacuum condition, then, crylic acid, barium stearate, benzyldimethylstearyl ammonium chloride, deionized water and absolute ethyl alcohol are added, continuous stirring is performed and then the temperature is decreased to reach the room temperature to obtain the corrosion resistance water-based paint with the activated carbon as the raw material. The water-based paint obtained through the preparation method has the good corrosion resistance and absorption performance, and the application range is further enlarged.

Owner:江苏通瑞环保科技发展股份有限公司

Hose and preparation method thereof

The invention discloses a hose and a preparation method thereof. The preparation method comprises a step of weighing PVC, N-butylphthalimide, zinc stearate, calcium stearate, epoxidized soybean oil, DOP, DBP, DOA, barium stearate, cadmium stearate, di-n-octyl phthalate, stainless steel metal powder, di-n-butyltin dilaurate and ACR. The hose has a bending strength of 80-100MPa and an impact strength of 30-50 kJ / m<3>; the hose is resistant to high temperature of 120-160 DEG C, and has a tensile strength of 55-95MPa; the hose is self-extinguishing in the case of being away from fire, non-toxic and sanitary, and has an elongation at break of 420-480%; and the hose is resistant to drop-hammer impact, has an elasticity modulus of 1.9-2.3GPa, and can be widely produced and continuously replace the existing material.

Owner:WUXI YONGXING METAL HOSE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com