Weather-resistant conductive silicone sealant and preparation method thereof

A silicone sealant, weather resistance technology, applied in the direction of adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the general weather resistance of silicone sealants, can not meet special needs, does not have electrical conductivity, etc. problems, to achieve the effect of improving thermal stability and chemical stability, good electrical conductivity, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

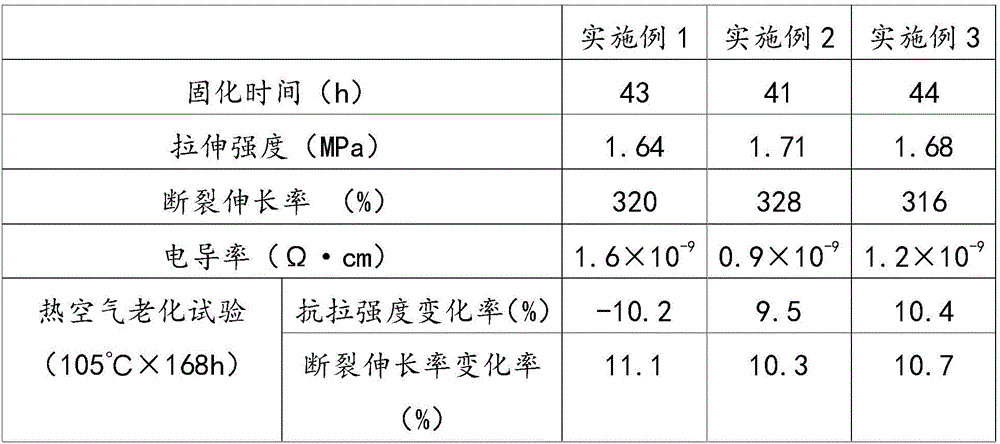

Embodiment 1

[0015] Example 1, a weather-resistant and conductive silicone sealant, made of the following raw materials in parts by weight (kg): α, ω-dihydroxypolydimethylsiloxane 98, titanium oxide 4, 200 low-molecular polysiloxane Amide 6, methyl tributylketoxime silane 7, rosin modified maleic acid resin 8, isobutyltriethoxysilane 2, acetylene carbon black 3, dimethyl silicone oil 6, nano-bentonite 5, aluminum phosphite 3. Dimethicone 2. Di-n-butyltin dilaurate 4. Nano zinc powder 2. Antimony tin oxide 3. Conductive mica powder 4.

[0016] A preparation method of a weather-resistant and conductive silicone sealant, comprising the following steps:

[0017] (1) Weigh each raw material by weight;

[0018] (2) 100 parts of α, ω-dihydroxy polydimethylsiloxane, titanium oxide, 200 low molecular weight polyamide, rosin modified maleic acid resin, acetylene carbon black, dimethyl silicone oil, nano-bentonite, Add aluminum phosphite, dimethyl ketone, antimony tin oxide, and conductive mica pow...

Embodiment 2

[0022] Example 2, a weather-resistant and conductive silicone sealant, made of the following raw materials in parts by weight (kg): α, ω-dihydroxypolydimethylsiloxane 100, titanium oxide 5, 200 low-molecular polysiloxane Amide 7, methyl tributylketoxime silane 8, rosin modified maleic acid resin 9, isobutyltriethoxysilane 3, acetylene carbon black 4, dimethyl silicone oil 7, nano-bentonite 6, aluminum phosphite 4. Dimethicone 3. Di-n-butyltin dilaurate 5. Nano zinc powder 2. Antimony tin oxide 4. Conductive mica powder 5.

[0023] A preparation method of a weather-resistant and conductive silicone sealant, comprising the following steps:

[0024] (1) Weigh each raw material by weight;

[0025] (2) α, ω-dihydroxy polydimethylsiloxane, titanium oxide, 200 low molecular weight polyamide, rosin modified maleic acid resin, acetylene carbon black, dimethyl silicone oil, nano-bentonite, phosphorous acid Add aluminum, dimethyl ketone, tin antimony oxide, and conductive mica powder i...

Embodiment 3

[0029] Example 3, a weather-resistant and conductive silicone sealant, made of the following raw materials in parts by weight (kg): α, ω-dihydroxypolydimethylsiloxane 102, titanium oxide 6, 200 low-molecular polysiloxane Amide 8, methyl tributylketoxime silane 9, rosin modified maleic acid resin 10, isobutyltriethoxysilane 4, acetylene carbon black 5, dimethyl silicone oil 8, nano-bentonite 7, aluminum phosphite 5. Dimethicone 4. Di-n-butyltin dilaurate 6. Nano zinc powder 3. Antimony tin oxide 5. Conductive mica powder 6.

[0030] A preparation method of a weather-resistant and conductive silicone sealant, comprising the following steps:

[0031] (1) Weigh each raw material by weight;

[0032] (2) α, ω-dihydroxy polydimethylsiloxane, titanium oxide, 200 low molecular weight polyamide, rosin modified maleic acid resin, acetylene carbon black, dimethyl silicone oil, nano-bentonite, phosphorous acid Add aluminum, dimethyl ketone, tin antimony oxide, and conductive mica powder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com