Preparation method for door sheet protective agent

A protective agent, door panel technology, applied in coatings, anti-corrosion coatings, etc., can solve the problems of high brittleness, resistance to sunlight, poor waterproof and anti-corrosion effect, and high requirements for construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

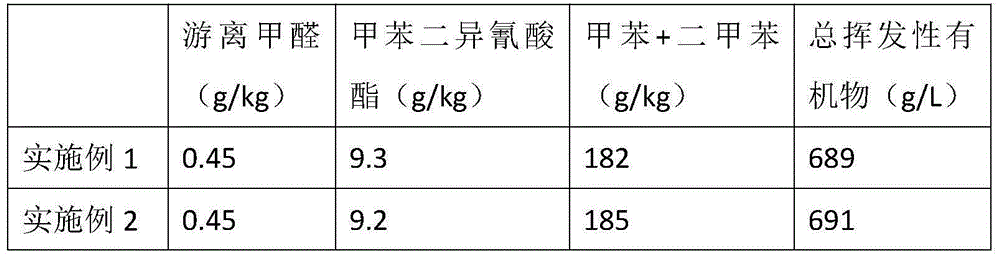

Examples

Embodiment 1

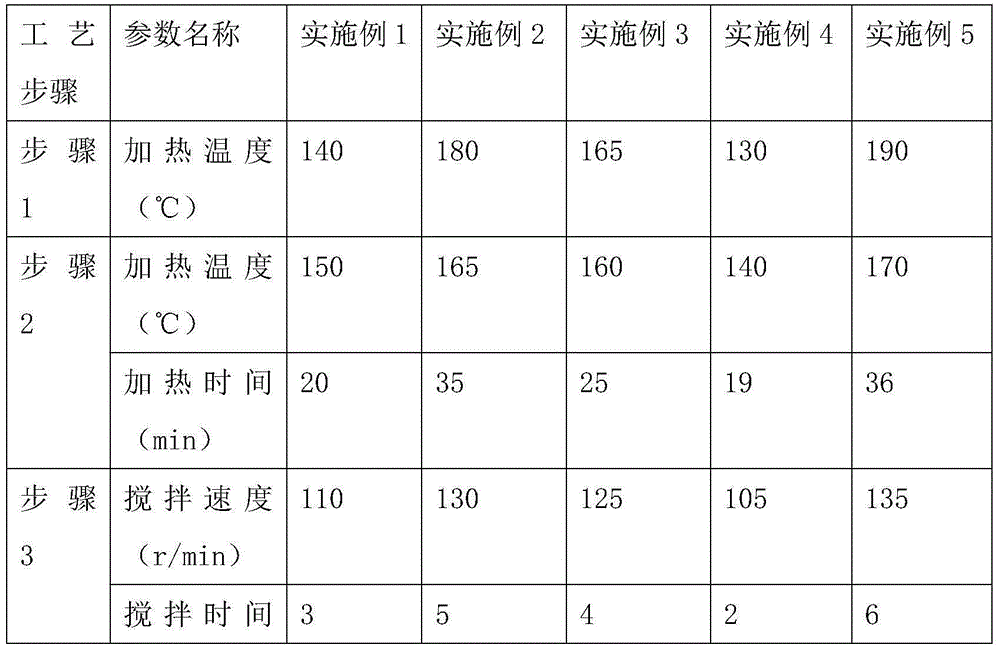

[0022] Step 1: react 2 parts of diethylene glycol and 1 part of dicarboxylic acid at 140°C to obtain polyester polyol;

[0023] Step 2: The polyester polyol obtained in step 1 and 5 parts of polyhexylene adipate are heated and dehydrated in a vacuum environment, the heating temperature is 150° C., and the composition A is obtained by heating for 20 minutes.

[0024] Step 3: The composition A in step 2 and 9 parts of isophorone diisocyanate are put into a mixer with a rotating speed of 110r / min and stirred for 3min, and the mixture is placed in a condenser tube for heating, and the heating temperature is 90 ℃. ℃, during the heating process, nitrogen gas was slowly introduced, and the nitrogen flow rate was 0.3 ml / s, and the composition B was obtained after 1.5 hours of reaction.

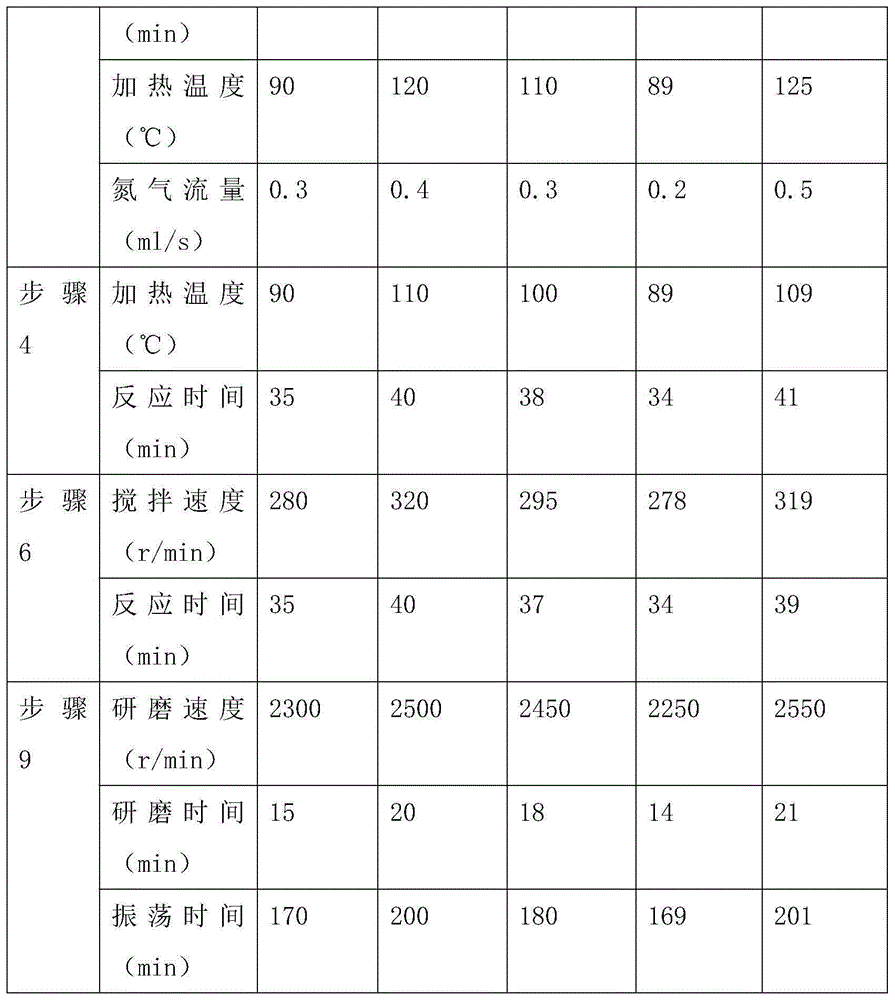

[0025] Step 4: Add 5 parts of polyhexylene adipate and 0.05 part of di-n-butyltin dilaurate to composition B, and heat at 90°C until the content of isocyanate groups drops to 2 %, after adding 1 part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com