Matte oil-resistant elastomer cable material

A technology for elastomers and cable materials, which is applied in the field of matte oil-resistant elastomer cable materials, can solve the problems of poor compatibility, lower mechanical properties and processing properties of materials, and achieve good oil resistance and mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

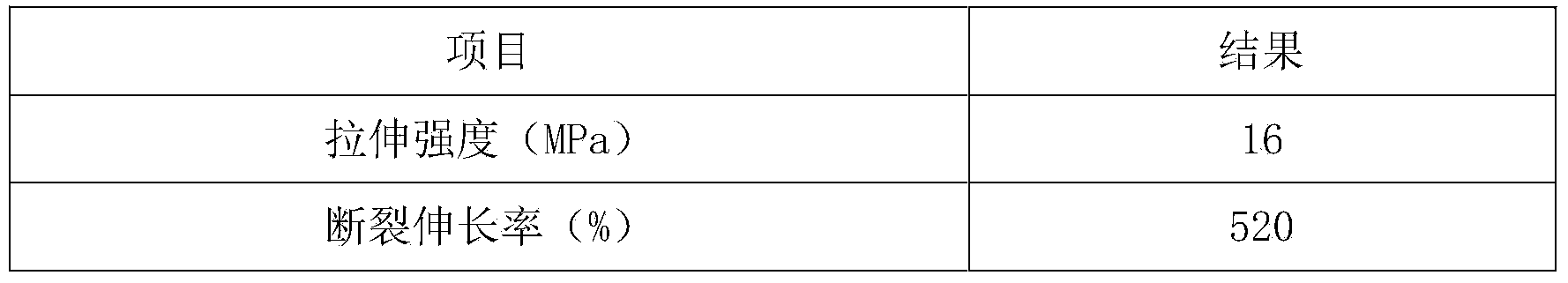

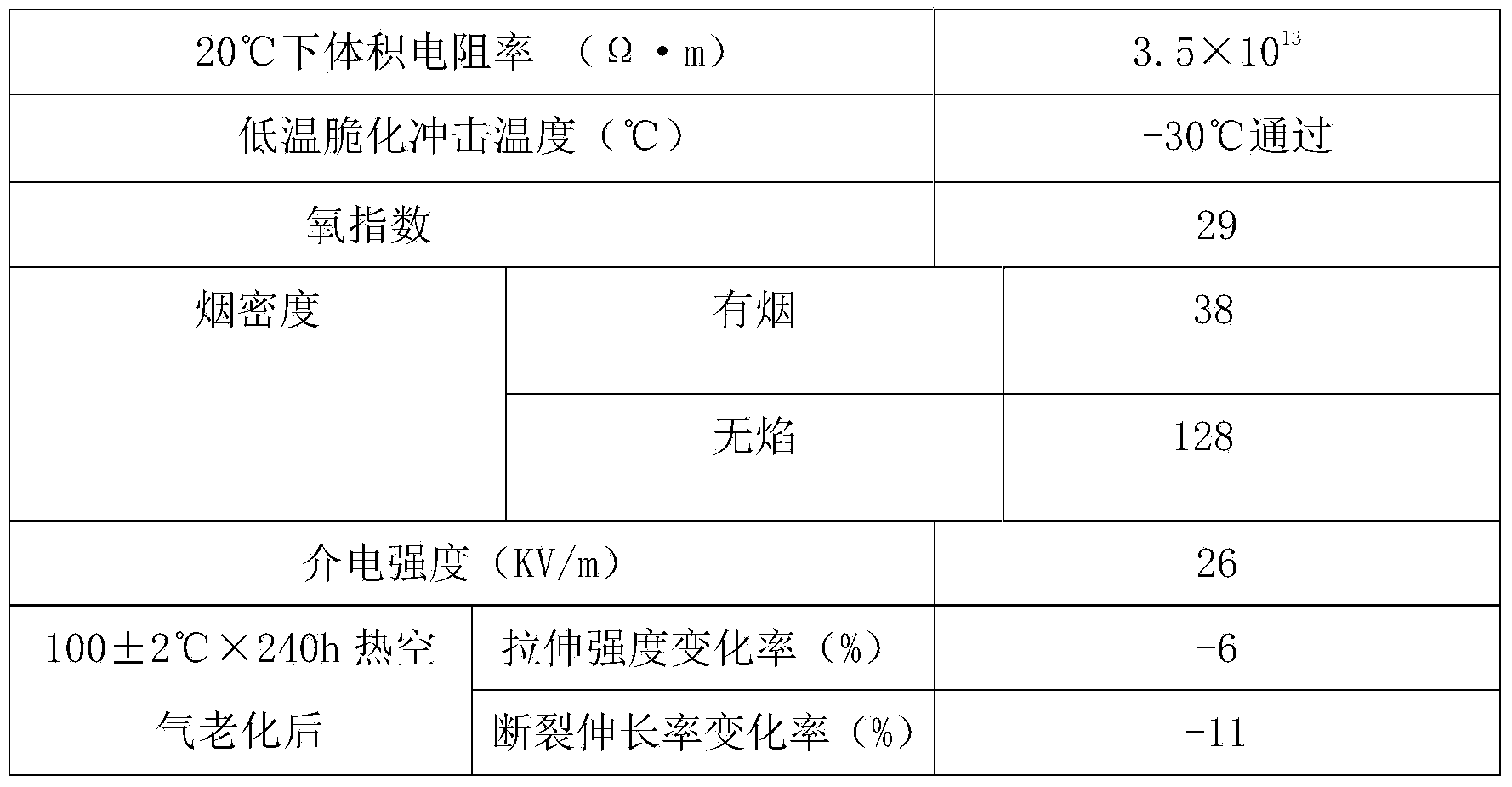

[0017] A matte oil-resistant elastomer cable material, prepared from the following component raw materials in weight (kg):

[0018] Hydrogenated styrene butadiene styrene 30, polypropylene 20, nitrile rubber 9, polyacrylamide resin 8, triethylene glycol diisocaprylate 12, triethyl citrate 6, methyl silicone oil 3, ethylene propylene Rubber 6, light calcium carbonate 8, stearic acid 1, zinc oxide 2, wollastonite powder 8, magnesium oxide 2, lapis lazuli 4, fluorite 5, clay 6, zirconia 2, antioxidant 1010 0.4, antioxidant Agent DLTP 0.3, triphenyl phosphite 0.4, zinc borate 7, ammonium molybdate 9, copper oxide 1, dicumyl peroxide DCP 1, modified filler 14,

[0019] The modified filler is prepared by the following method: a. Get the raw materials of the following weight (kg): kaolin 190, medical stone 33, nano carbon 2, ascorbic acid 1, barley oil 2, aluminum nitride powder 1, glucose Zinc acid 3, jade powder 2, polyisobutylene 2, aluminate coupling agent DL-411 1, stearic acid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com