Anti-yellowing polyurethane foam and preparation method thereof

A polyurethane foam and anti-yellowing technology, which is applied in the field of foam, can solve the problems of impact and easy yellowing, and achieve the effects of good toughness, high strength, and improved yellowing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

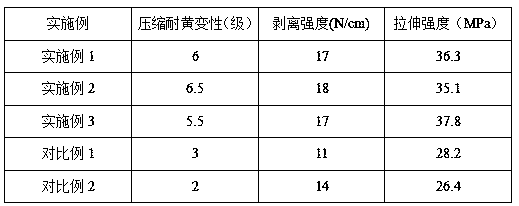

Examples

Embodiment 1

[0022] Yellowing resistant polyurethane foam, including the following components in parts by weight: 60 parts of composite polyol, 15 parts of diphenylmethane diisocyanate, 5 parts of dibutyltin dilaurate, 9 parts of ethylene glycol, and hexamethylene 7 parts of diisocyanate, 6 parts of citric acid, 3 parts of dimethyl silicone oil and 2 parts of water.

[0023] Among them, the composite polyol includes the following components by weight: 22 parts of polyoxypropylene glycol, 16 parts of polyoxytetramethylene glycol, 11 parts of polycarbonate diol and propylene oxide-ethylene oxide copolymer 8 parts of ether triol.

[0024] The preparation method of yellowing-resistant polyurethane foam includes the following preparation steps:

[0025] S1. Add the composite polyol, isocyanate, dibutyltin dilaurate and water into the reaction kettle, stir evenly, heat to 65°C, and react for 1 hour;

[0026] S2. Raise the temperature of the reactor to 80°C, add ethylene glycol and hexamethylene diisocy...

Embodiment 2

[0031] Yellowing resistant polyurethane foam, including the following components in parts by weight: 70 parts of composite polyol, 17 parts of 1,6-hexamethylene diisocyanate, 12 parts of dibutyltin dilaurate, 12 parts of ethylene diamine, hexamethylene 8 parts of diisocyanate, 7 parts of citric acid, 4 parts of dimethicone and 3 parts of water.

[0032] Among them, the composite polyol includes the following components in parts by weight: 25 parts of polyoxypropylene glycol, 18 parts of polyoxytetramethylene glycol, 14 parts of polycarbonate diol, and propylene oxide-ethylene oxide copolymer 11 parts of ether triol.

[0033] The preparation method of yellowing-resistant polyurethane foam includes the following preparation steps:

[0034] S1. Add the composite polyol, isocyanate, dibutyltin dilaurate and water into the reaction kettle, stir evenly, heat to 70°C, and react for 2h;

[0035] S2. Raise the temperature of the reactor to 88°C, add ethylenediamine and hexamethylene diisocyan...

Embodiment 3

[0040] Yellowing resistant polyurethane foam, including the following components in parts by weight: 80 parts of composite polyol, 22 parts of 1,6-hexamethylene diisocyanate, 17 parts of dibutyltin dilaurate, 15 parts of triethylenetetramine, hexamethylene 10 parts of methyl diisocyanate, 9 parts of citric acid, 5 parts of dimethyl silicone oil and 4 parts of water.

[0041] Among them, the composite polyol includes the following components by weight: 28 parts of polyoxypropylene glycol, 21 parts of polyoxytetramethylene glycol, 17 parts of polycarbonate diol and propylene oxide-ethylene oxide copolymer 15 parts of ether triol.

[0042] The preparation method of yellowing-resistant polyurethane foam includes the following preparation steps:

[0043] S1. Add the composite polyol, isocyanate, dibutyltin dilaurate and water to the reaction kettle, stir evenly, heat to 75°C, and react for 3h;

[0044] S2. Raise the temperature of the reactor to 95°C, add triethylenetetramine and hexameth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com