Concrete bridge protection structure layer with heat insulation and cooling functions and construction method of structure layer

A technology of heat insulation and cooling, heat insulation layer, applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems of undisclosed painting pre-treatment and post-maintenance methods, narrow application range, unfavorable promotion, etc., to achieve bonding Good performance, excellent crack resistance, simple construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

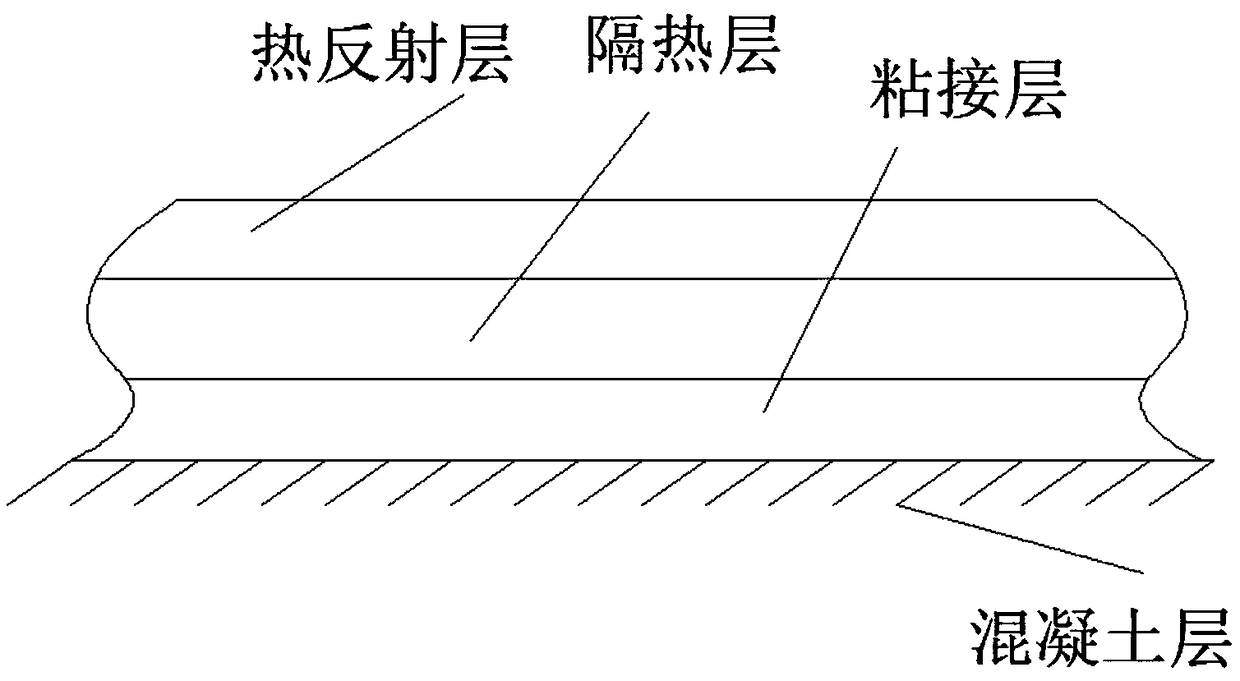

[0026] A concrete bridge protection structure layer with heat insulation and cooling function, which includes a bonding layer, a heat insulating layer and a heat reflecting layer; the thickness of the bonding layer is 0.2mm, the thickness of the heat insulating layer is 0.8mm, and the thickness of the heat reflecting layer is 0.6mm mm.

[0027] The bonding layer is sprayed on the bridge concrete surface, and the material of the bonding layer is a modified epoxy resin and a curing agent; the mass ratio of the modified epoxy resin to the curing agent is 10:1, and the curing agent It is a modified polyamide, the amine value of the modified polyamide is 650mg KOH / g, and the viscosity is 11cP at 25°C;

[0028] The heat insulation layer is arranged between the adhesive layer and the heat reflection layer, and the material of the heat insulation layer is modified epoxy resin, putty powder, heat insulation material, and the modified epoxy resin, putty powder, insulation material The ...

specific Embodiment 2

[0031] A concrete bridge protective structure layer with heat insulation and cooling function, which includes a bonding layer, a heat insulating layer and a heat reflecting layer; the thickness of the bonding layer is 0.5mm, the thickness of the heat insulating layer is 1.2mm, and the thickness of the heat reflecting layer is 1mm .

[0032] The bonding layer is spray-coated on the bridge concrete surface, and the material of the bonding layer is a modified epoxy resin and a curing agent; the mass ratio of the modified epoxy resin to the curing agent is 5:1, and the curing agent It is a modified polyamide, the amine value of the modified polyamide is 650mg KOH / g, and the viscosity is 9cP at 25°C;

[0033] The heat insulation layer is arranged between the adhesive layer and the heat reflection layer, and the material of the heat insulation layer is modified epoxy resin, putty powder, heat insulation material, and the modified epoxy resin, putty powder, insulation material The m...

specific Embodiment 3

[0036] A concrete bridge protective structure layer with heat insulation and cooling function, which includes a bonding layer, a heat insulating layer and a heat reflecting layer; the thickness of the bonding layer is 0.3mm, the thickness of the heat insulating layer is 1mm, and the thickness of the heat reflecting layer is 0.8mm .

[0037] The bonding layer is sprayed on the bridge concrete surface, and the material of the bonding layer is a modified epoxy resin and a curing agent; the mass ratio of the modified epoxy resin to the curing agent is 8:1, and the curing agent It is a modified polyamide, the amine value of the modified polyamide is 650mg KOH / g, and the viscosity is 10cP at 25°C;

[0038] The heat insulation layer is arranged between the adhesive layer and the heat reflection layer, and the material of the heat insulation layer is modified epoxy resin, putty powder, heat insulation material, and the modified epoxy resin, putty powder, insulation material The mass ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com